Inverted conical shell water tower construction process

A construction process and technology of inverted cone shell, applied in the field of inverted cone shell water tower construction technology, can solve the problems of affecting the construction progress, long construction period, many construction personnel, etc., and achieve the effect of saving time, simple construction and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the examples; it should be understood that these examples are only used to clearly illustrate what the present invention does, rather than limiting the scope of the present invention. All changes are within the protection scope of the present invention.

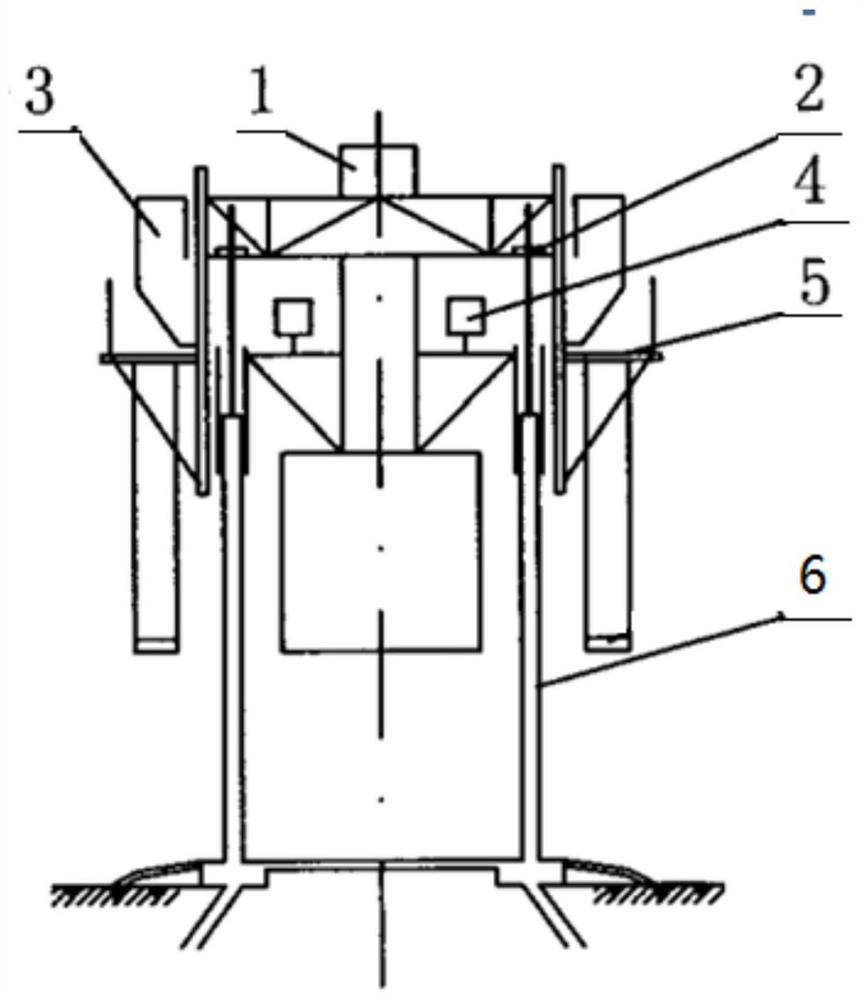

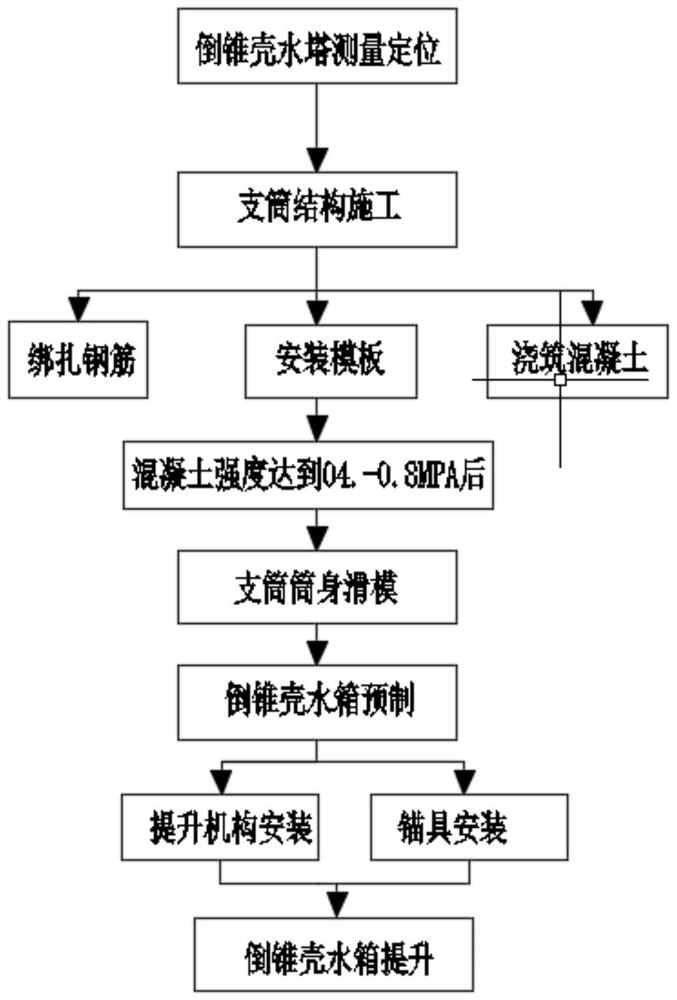

[0032] Such as figure 2 Shown, a kind of inverted conical shell water tower construction technique is characterized in that, comprises the following steps:

[0033] Step 1. Measurement and positioning of the inverted conical shell water tower;

[0034] Step 2, the structural construction of the support tube 6 includes the following steps:

[0035] Steel bar binding, formwork installation, and concrete pouring; when the concrete reaches the strength of the sliding form, the sliding form construction is carried out. During the sliding form, multiple through-hole jacks 2 assembled in pairs and climbing poles cooperate with each other to achieve l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com