A tightening device for a cylindrical material cutting machine

A material cutting machine and cylindrical technology, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of unreliable fixing of cylindrical materials, inconvenience for continuous operation, and large safety hazards, and achieves improved strength and The effect of gripping contact area, avoiding mechanical damage, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

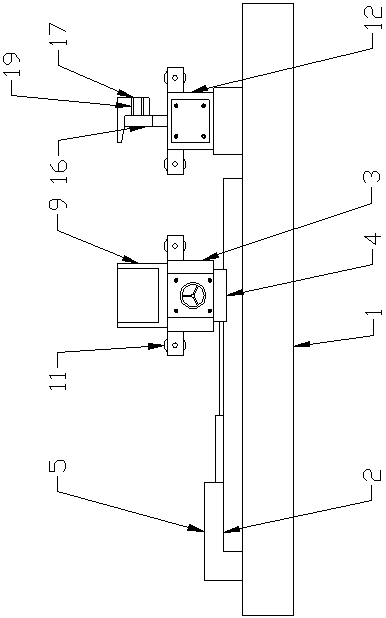

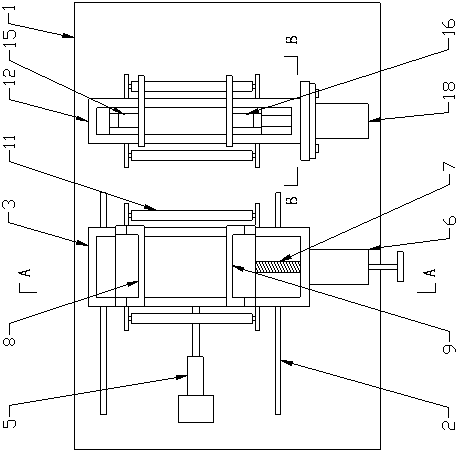

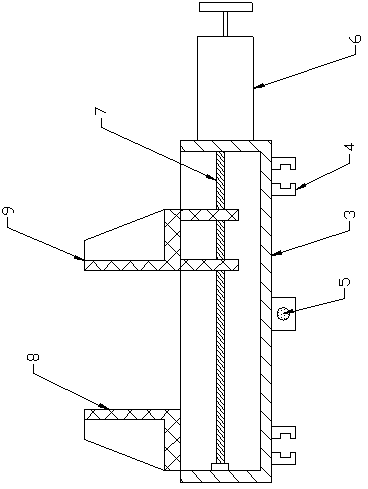

[0018] Such as Figure 1-4 As shown, a tightening device for a cylindrical material cutting machine includes a base 1, a track 2 is provided along the length direction on the left side of the base 1, and a moving tightening device is mounted on the track 2, and the moving tightening device The mobile frame 3 is provided with a rectangular parallelepiped groove with an upper opening inside, the two ends of the lower surface of the mobile frame 3 are provided with rail clips 4, and the middle of the lower surface of the mobile frame 3 is connected with electric Adjusting rod 5, the end surface of one end of the moving frame 3 is connected with a rotating motor 6, said rotating motor 6 is connected with an adjusting screw 7, one end of the upper surface of the moving frame 3 is fixedly provided with a positioning seat A8, and the other on the upper surface of the moving frame 3 One end is provided with a positioning seat B9. The lower surface of the positioning seat B9 is provided...

Embodiment 2

[0021] Such as Figure 1-4 As shown, a tightening device for a cylindrical material cutting machine includes a base 1, a track 2 is provided along the length direction on the left side of the base 1, and a moving tightening device is mounted on the track 2, and the moving tightening device The mobile frame 3 is provided with a rectangular parallelepiped groove with an upper opening inside, the two ends of the lower surface of the mobile frame 3 are provided with rail clips 4, and the middle of the lower surface of the mobile frame 3 is connected with electric Adjusting rod 5, the end surface of one end of the moving frame 3 is connected with a rotating motor 6, said rotating motor 6 is connected with an adjusting screw 7, one end of the upper surface of the moving frame 3 is fixedly provided with a positioning seat A8, and the other on the upper surface of the moving frame 3 One end is provided with a positioning seat B9. The lower surface of the positioning seat B9 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com