A Stirring Guide Positioning Mechanism for Diamond Cutting Wire Production Equipment

A diamond cutting line and production equipment technology, which is applied to stone processing equipment, fine working devices, manufacturing tools, etc., can solve problems such as fouling of the plating solution, decline in product qualification rate, and increase in motor load, so as to prevent the plating solution from Deterioration, good lubricating effect, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

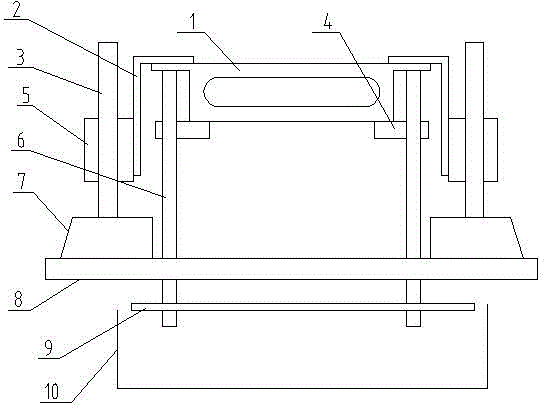

[0011] Such as figure 1 The agitation guide positioning mechanism of the diamond cutting wire production equipment shown includes a slideway 1, a stirring rod 6 at both ends of the slideway 1, and an agitator 9 at the lower end of the agitation rod 6. The agitator 9 is a strip-shaped square plate. A plating solution tank 10 is provided below the agitator 9 for storing the plating solution. Above the bath 10 is provided with a fixed frame 8, the two ends of the fixed frame 8 are provided with an oil receiving box 7, and the oil receiving box 7 is provided with a guide rod 3 upwards, and the guide rod 3 is fixed on the fixed frame 8. A slider 5 is sheathed on the guide rod 3, the slider 5 can move up and down on the guide rod 3, and simultaneously drives the stirring rod 6 to reciprocate up and down to stir the plating solution in the plating solution tank 10. The slide block 5 is connected with the slideway 1 through the connecting plate 2, so that the slide block 5 and the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com