Patents

Literature

55results about How to "Avoid wiggle phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for measuring coefficient of secondary cooling area for continuous casting

ActiveCN101349663AAvoid wiggle phenomenonReliable measurement dataMaterial thermal conductivityMaterial heat developmentDiffusionMeasurement point

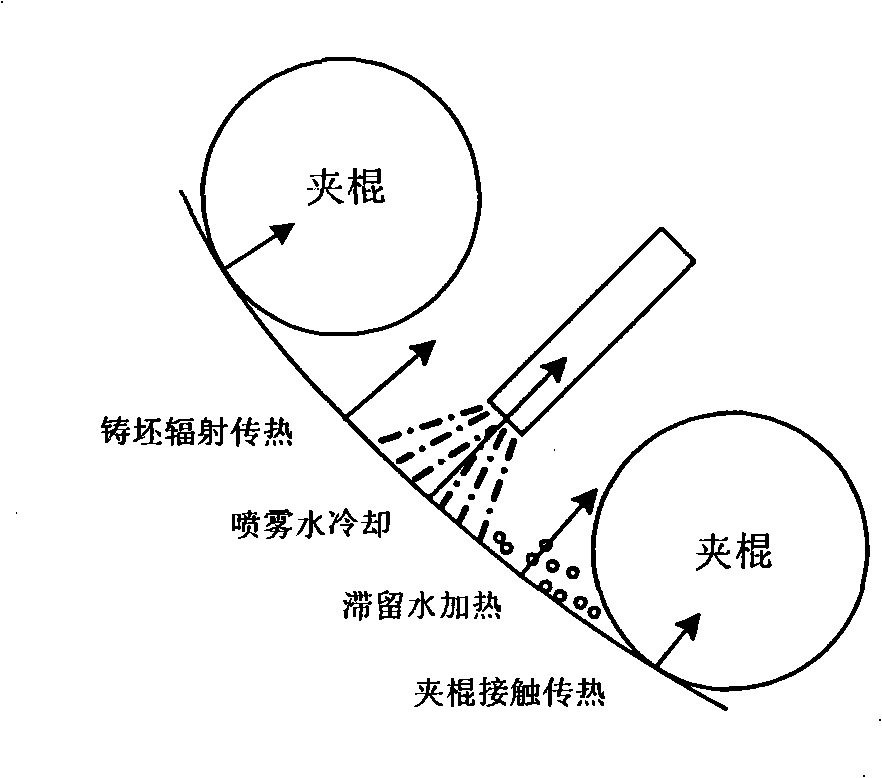

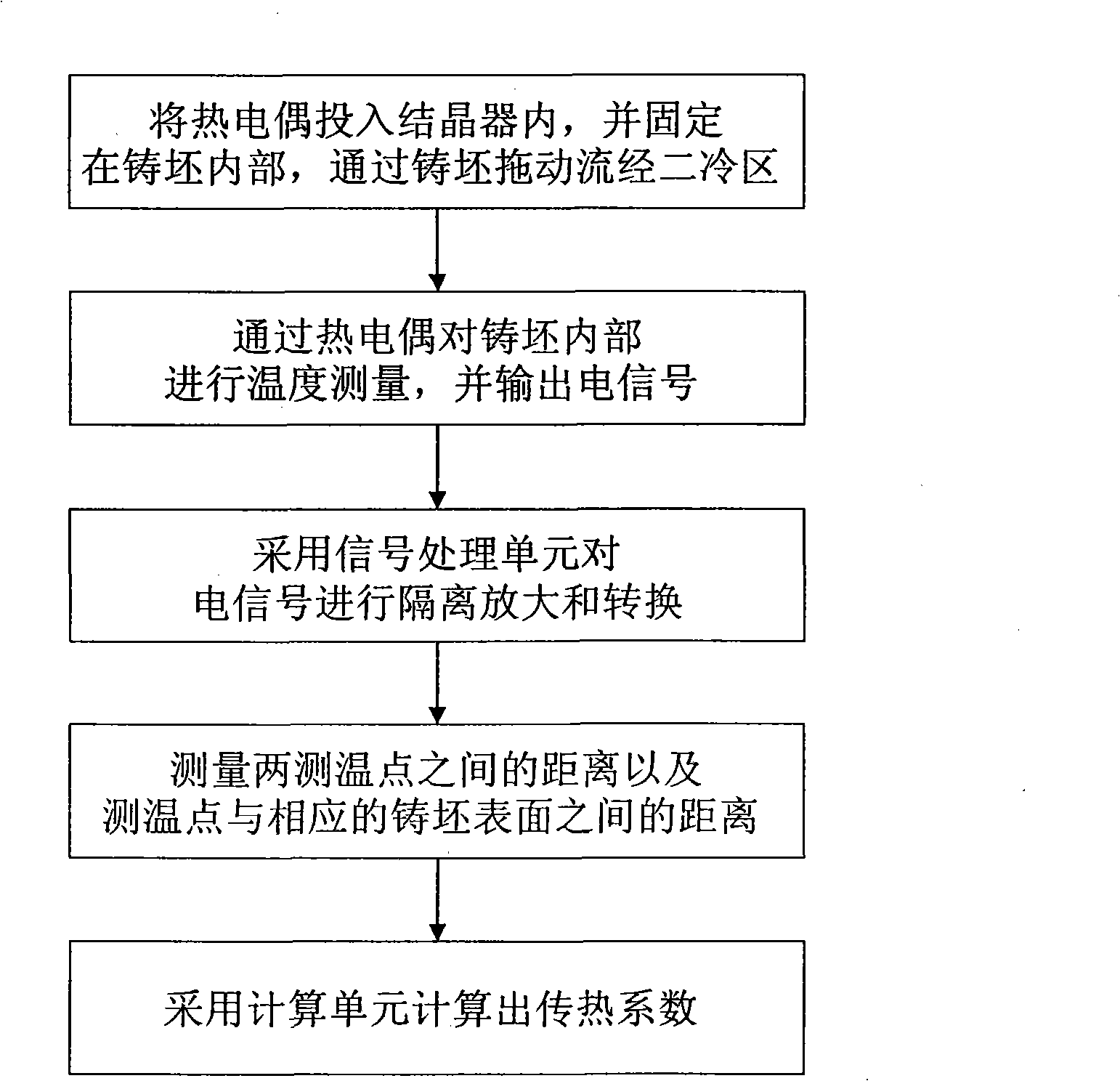

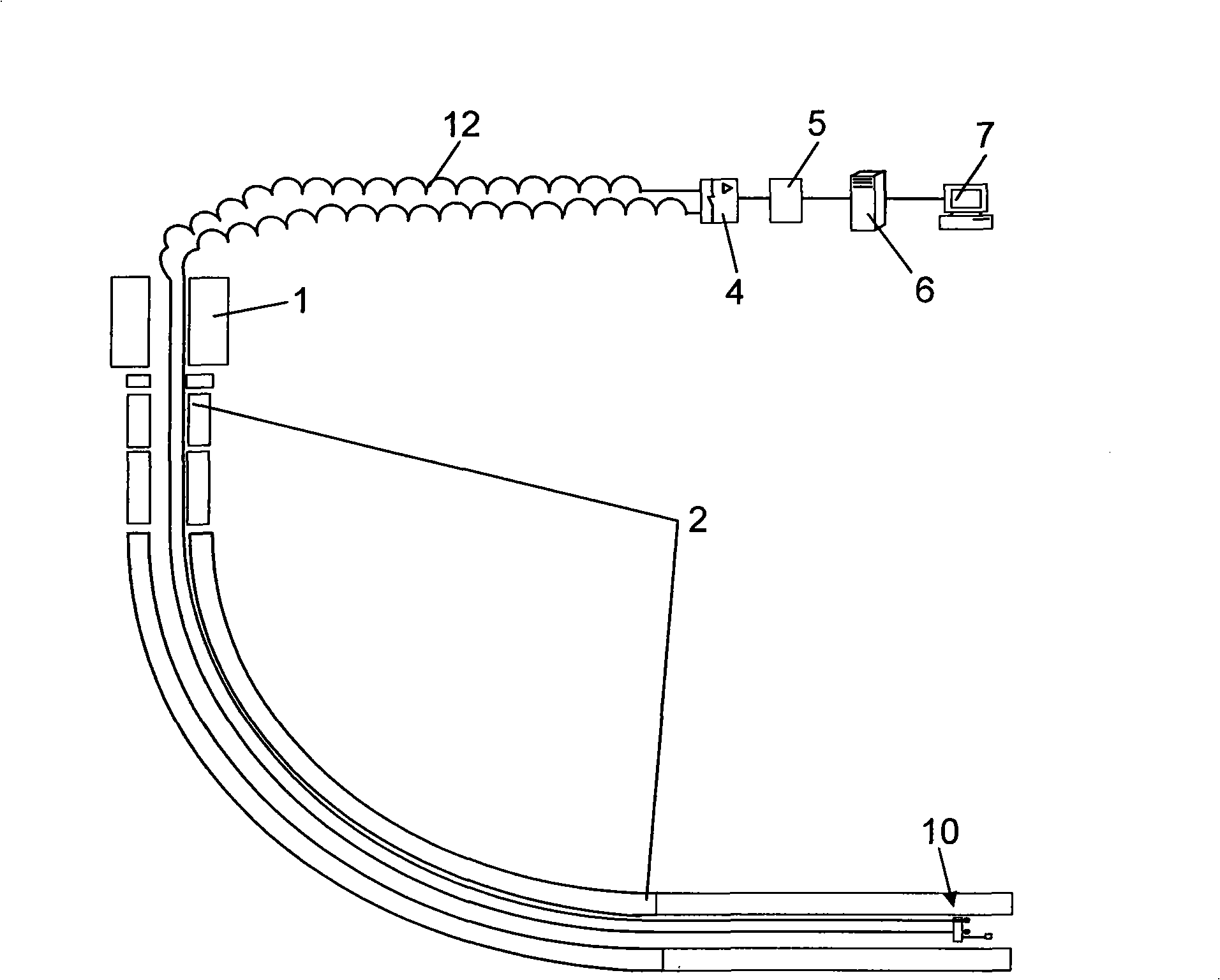

The invention discloses a method for testing the heat transfer coefficient in a continuous-casting secondary cooling area, which comprises casting a flame couple into a crystallizer, and fixing in a casting blank, dragging the flame couple through the casting blank to pass through the secondary cooling area, measuring the temperatures of two temperature measurement points in the casting blank through the flame couple, outputting electrical signals, adopting a signal processing unit to separate and magnify the electrical signals, and conversing into digital signals to be output, splitting the casting blank, measuring the distance between two temperature measurement points in the casting blank, adopting a calculation unit to record each measurement data, calculating and processing, and calculating the heat transfer coefficient. The testing method adopts a couple pulling method to directly measure temperatures in the casting blank of the secondary cooling area, and actually reflects the integral influences of various heat diffusion in the secondary cooling area through calculating to get the heat transfer coefficient, the measurement data are more accurate and reliable, and the actual production applicability is improved. The phenomenon that the flame couple is swung is avoided through adopting a supporting stand to fix the flame couple, and the accuracy of measurement is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

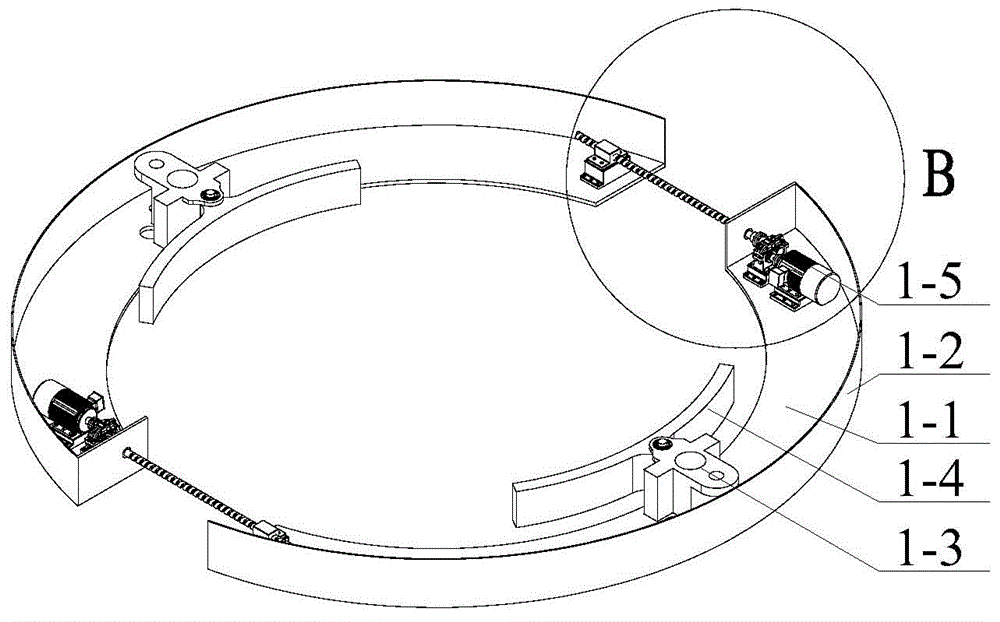

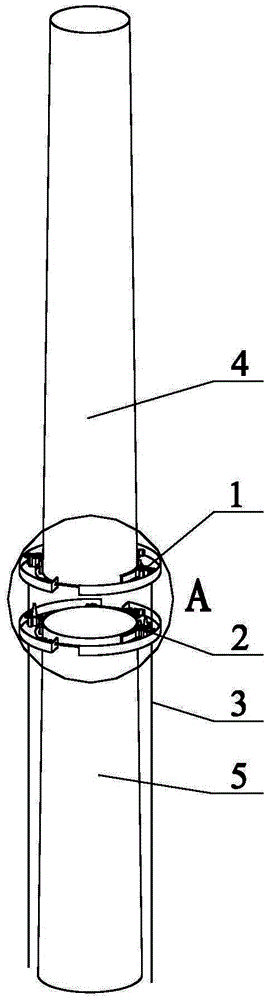

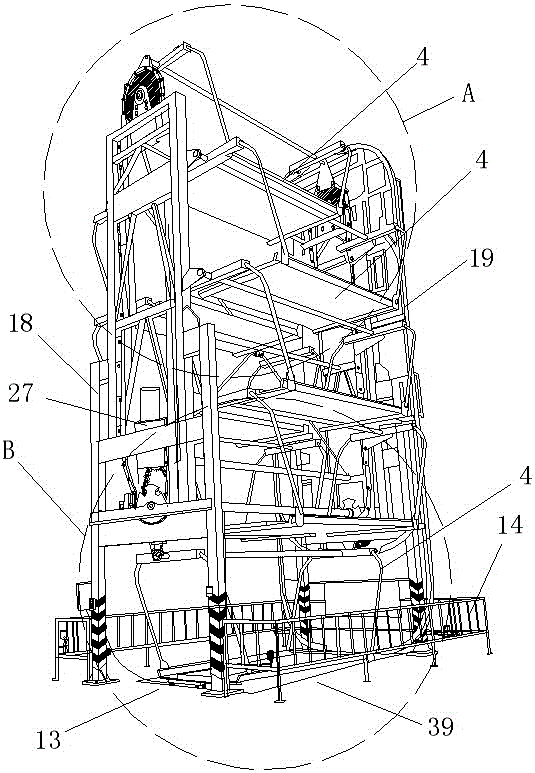

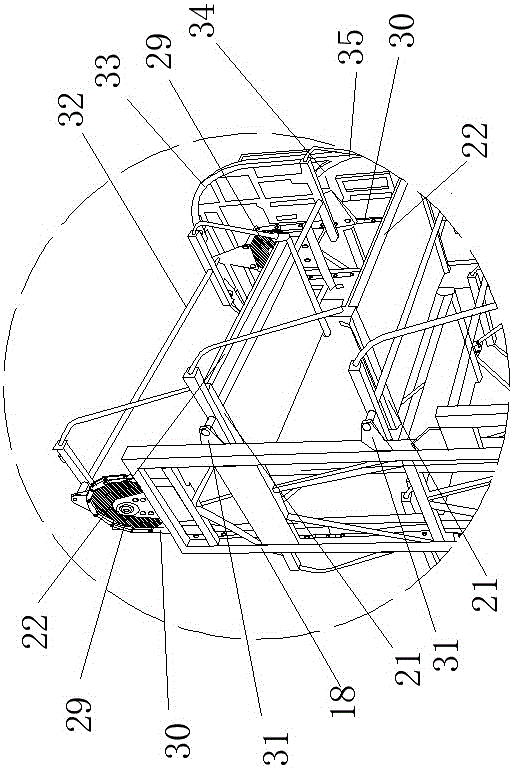

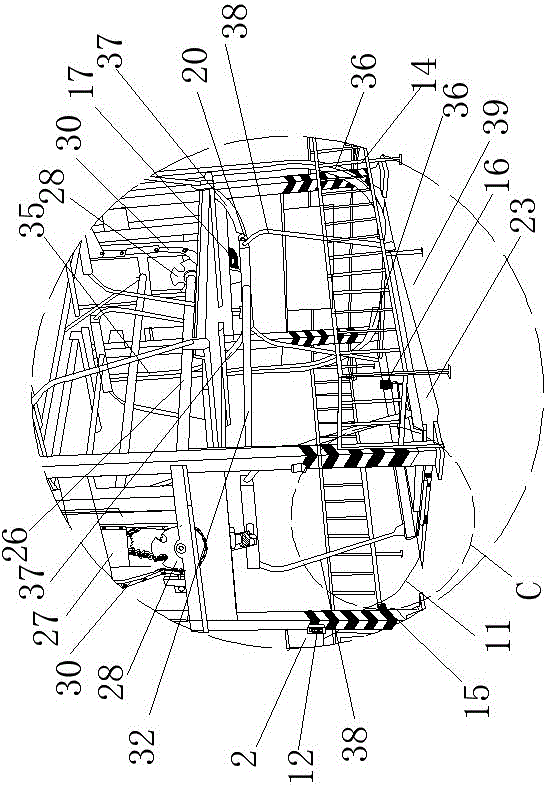

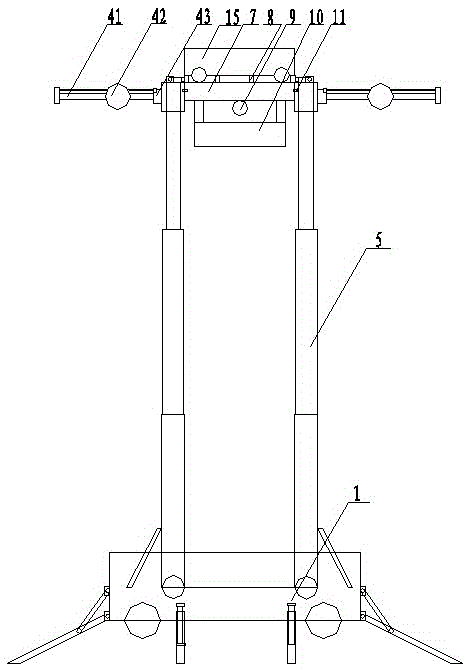

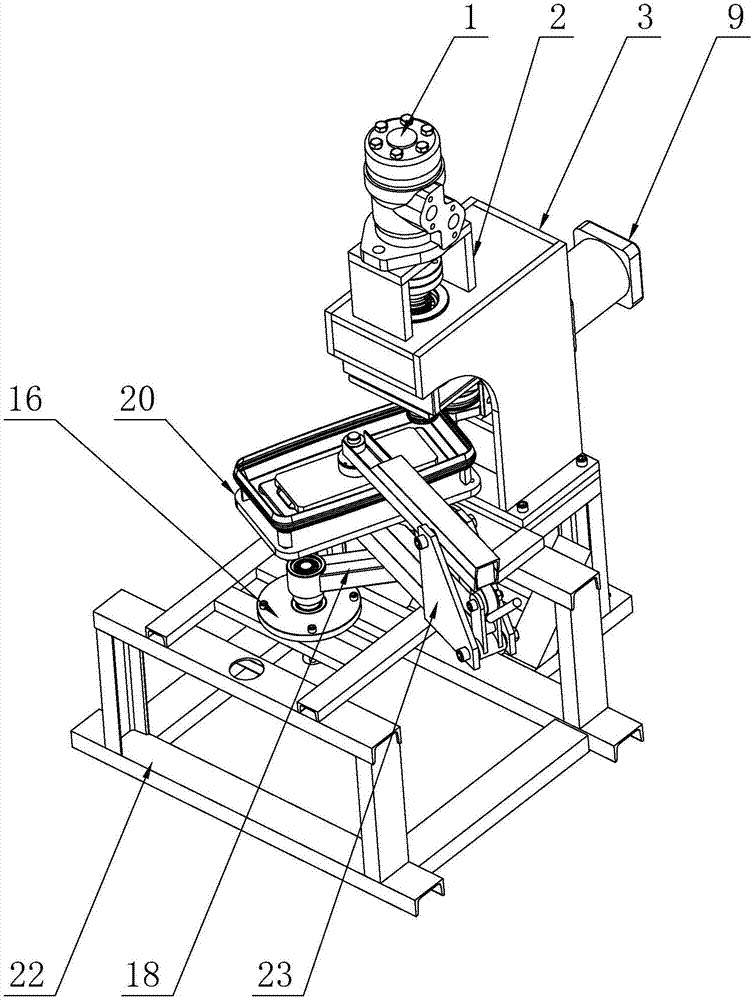

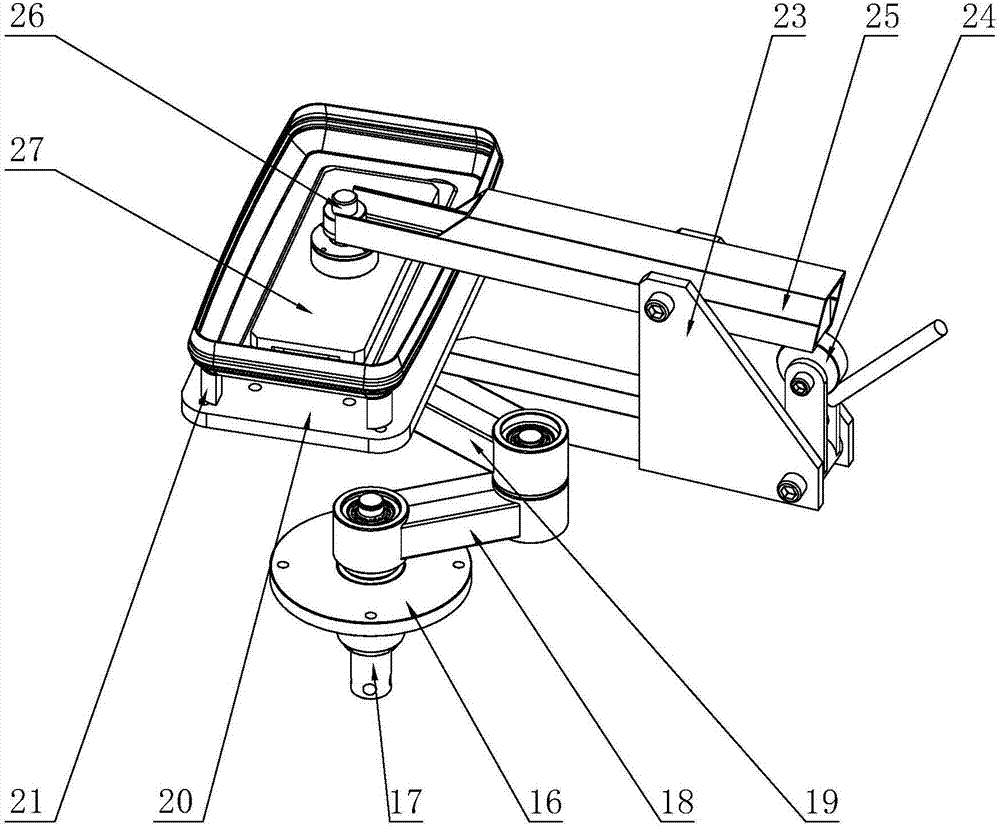

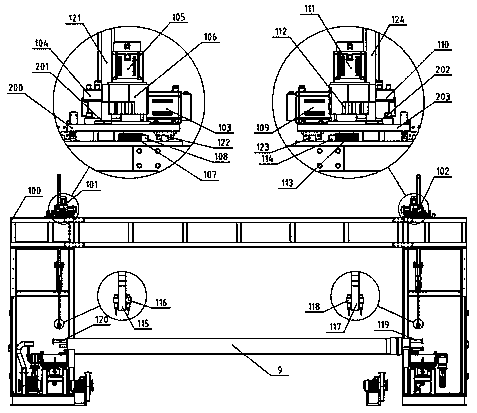

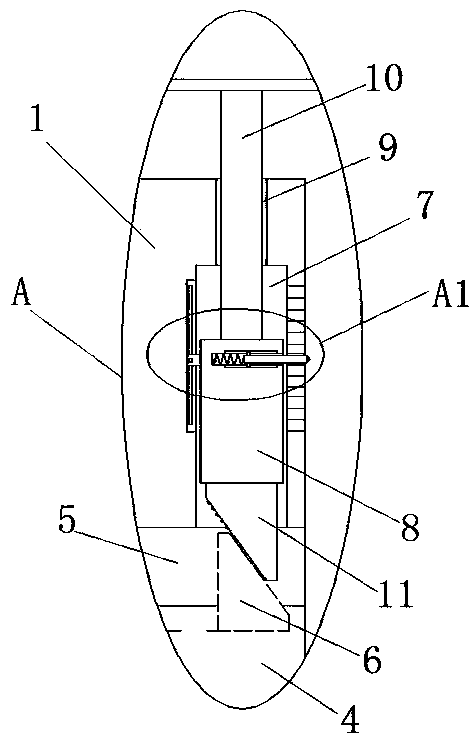

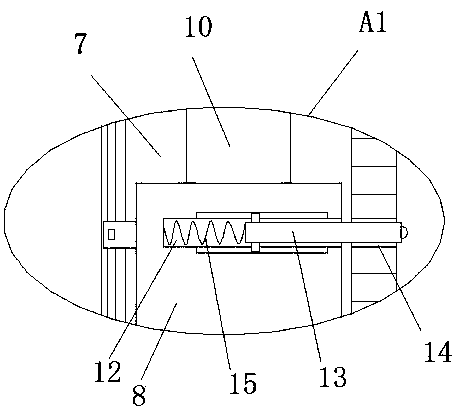

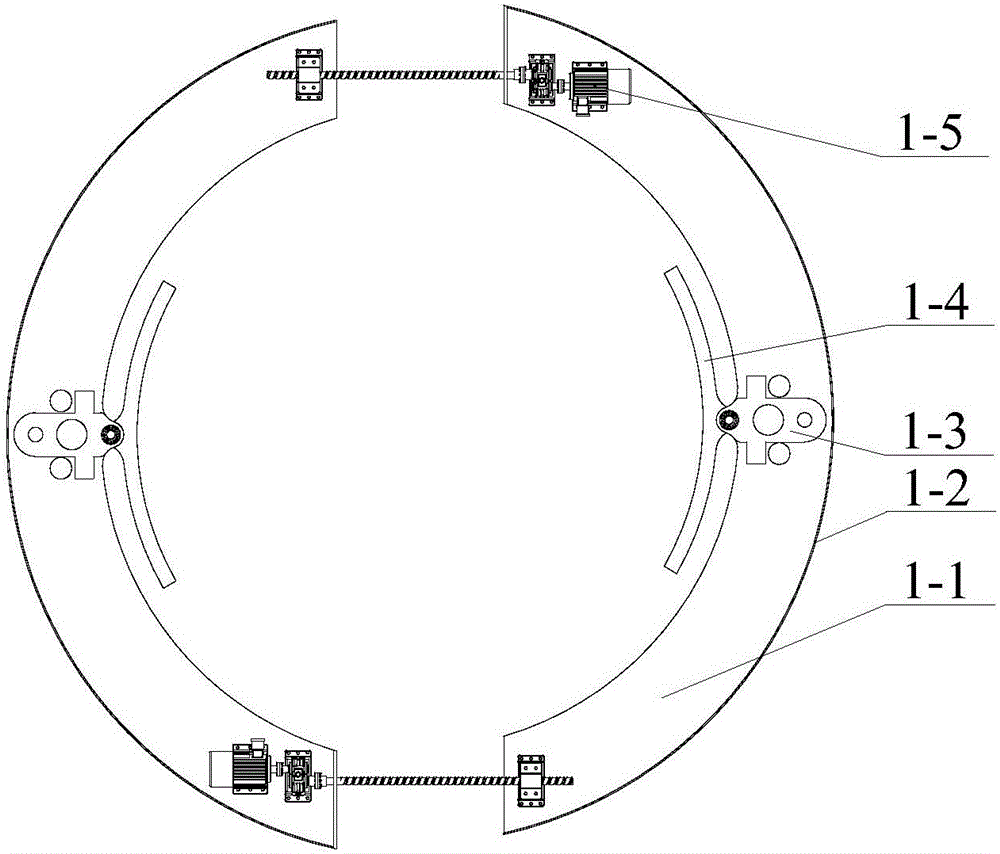

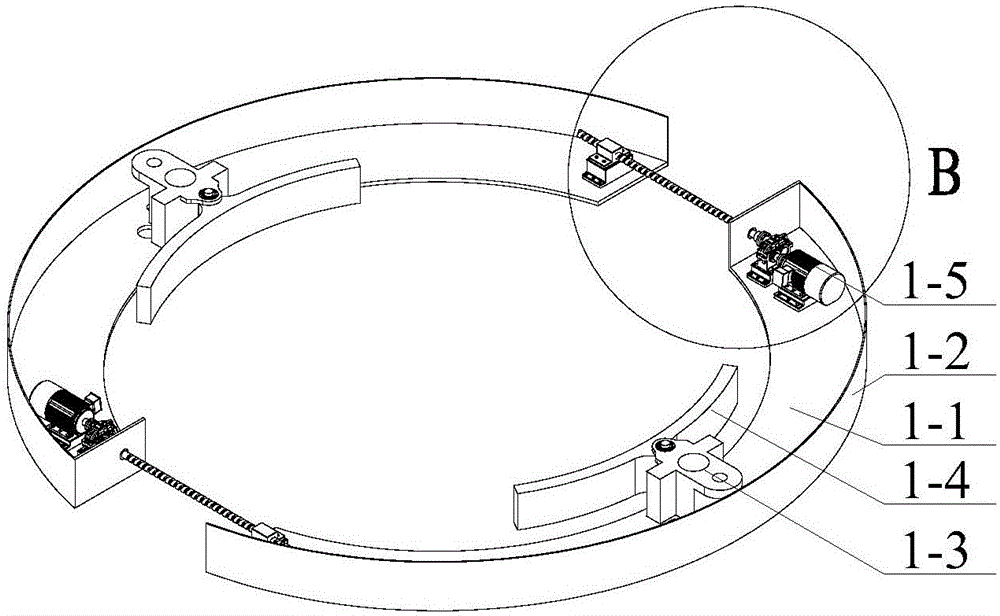

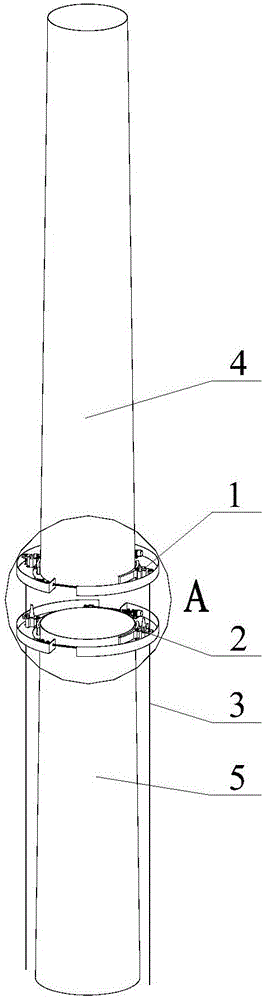

Guiding and positioning device for tower barrel hoisting and abutting joint of large wind driven generator set

InactiveCN103603772AAvoid wiggle phenomenonAchieve precise positioningWind energy generationWind motor componentsWind drivenEngineering

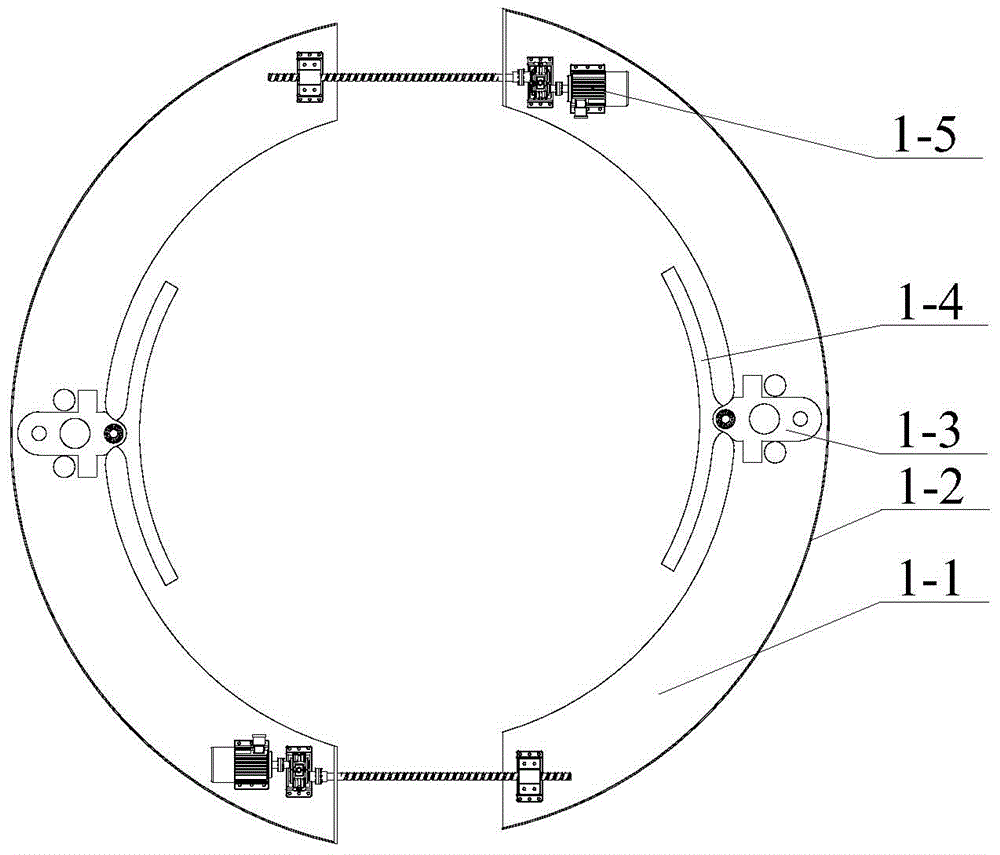

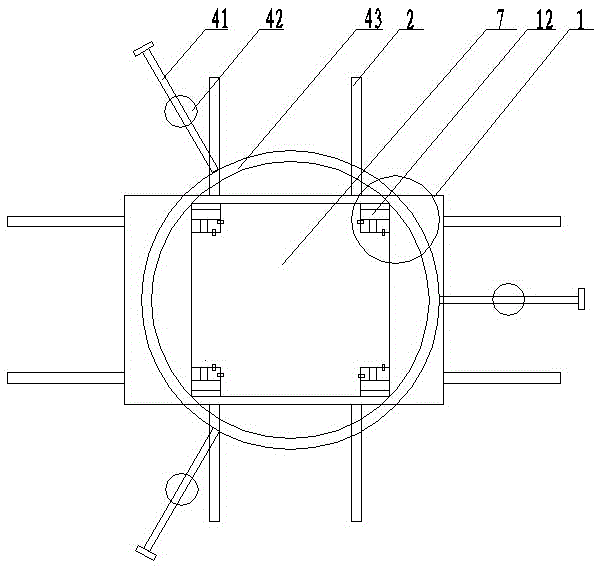

A guiding and positioning device for tower barrel hoisting and abutting joint of a large wind driven generator set comprises an upper hoop device, a lower hoop device and a traction steel wire rope, wherein the upper hoop device and the lower hoop device are circular-arc-shaped and respectively comprise two half hoops symmetrical relative to a central shaft. The upper hoop device comprises an upper positioning and guiding module for positioning an upper tower barrel section and an upper tightening module for adjusting a distance between the two half hoops, wherein the upper positioning and guiding module is respectively installed in the middles of the half hoops, and the upper tightening module is connected between the two half hoops. The lower hoop device comprises a lower positioning and guiding module for positioning a lower tower barrel section and a lower tightening module for adjusting a distance between the two half hoops. One end of the traction steel wire rope penetrates a round hole in an upper hoop device chassis to be fixed in a rope feeding hole, and the other end of the traction steel wire rope penetrates a rope discharging hole and a round hole in a lower hoop device chassis to be connected with a motor on the ground. The guiding and positioning device can guide a flange bolt welded on a tower barrel to achieve quick positioning and is high in hoisting efficiency.

Owner:ZHEJIANG UNIV

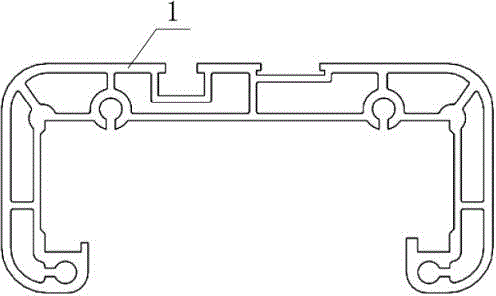

Full-automatic anti-swing control system of stereo garage

The invention discloses a full-automatic anti-swing control system of a stereo garage. The stereo garage comprises a frame body, wherein the frame body is provided with a plurality of vehicle carrying mechanisms which can do cyclic motion and of which the bottom parts are made of iron. The full-automatic anti-swing control system of the vehicle carrying mechanisms comprises an electromagnet, wherein the electromagnet is connected with a power supply through a control circuit; a plurality of plug holes are vertically formed in the electromagnet; one upright post is inserted in each plug hole; all upright posts are arranged on the ground under the lowest position where the bottom part of each vehicle carrying mechanism on the frame body can move to; gaps are reserved between the top surface of the electromagnet and the lowest position where the bottom part of each vehicle carrying mechanism on the frame body can move to. The full-automatic anti-swing control system of the stereo garage, disclosed by the invention, has the advantages that the vehicle carrying mechanisms are accurately located, and parking is convenient; shaking and collision cannot be caused during parking, and no abnormal sound is generated; the problems of switch failure, deformation of the vehicle carrying mechanisms and the like caused by frequent swinging of the vehicle carrying mechanisms can be effectively prevented, and the service life of the stereo garage is prolonged.

Owner:SHANDONG JIU ROAD PARKING EQUIP CO LTD

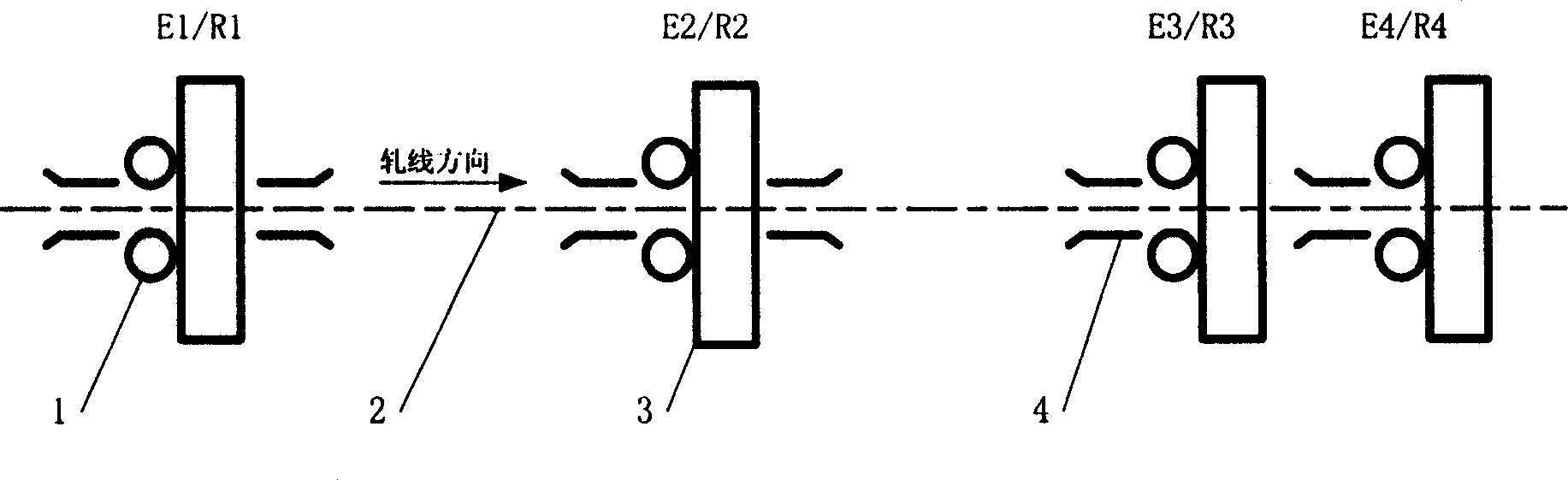

Three-point type position control method based on slide distance

This invention relates to a three-point type position control method based on slide distance. Wherein, setting the value variation to divide the control process into two stages: first, comparing the new set value Wo with real width, modifying it as Wo+2So or Wo-2So (or more large for real condition); second, when the error more than 2So, taking position control by original value. By This invention, the probability that the number of rotation and counter-rotation is within 3 can be more than 80%.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

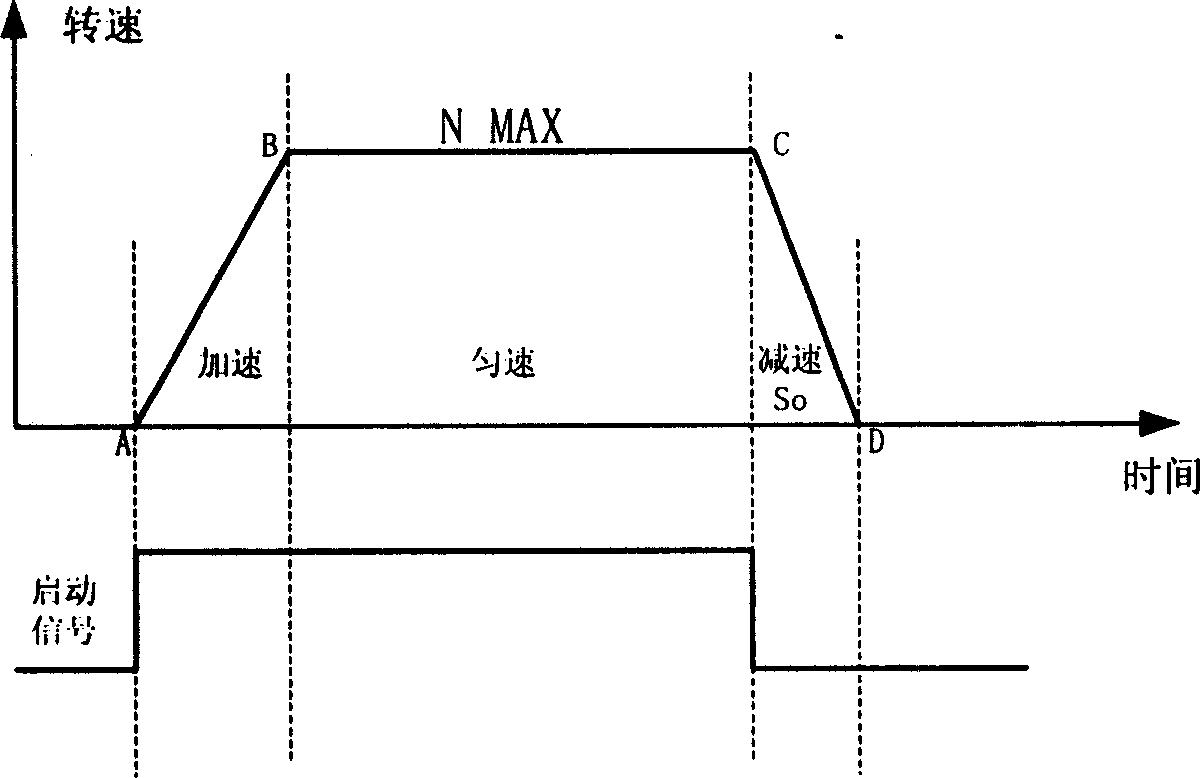

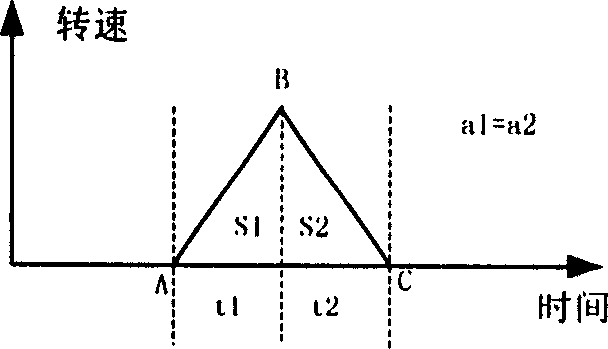

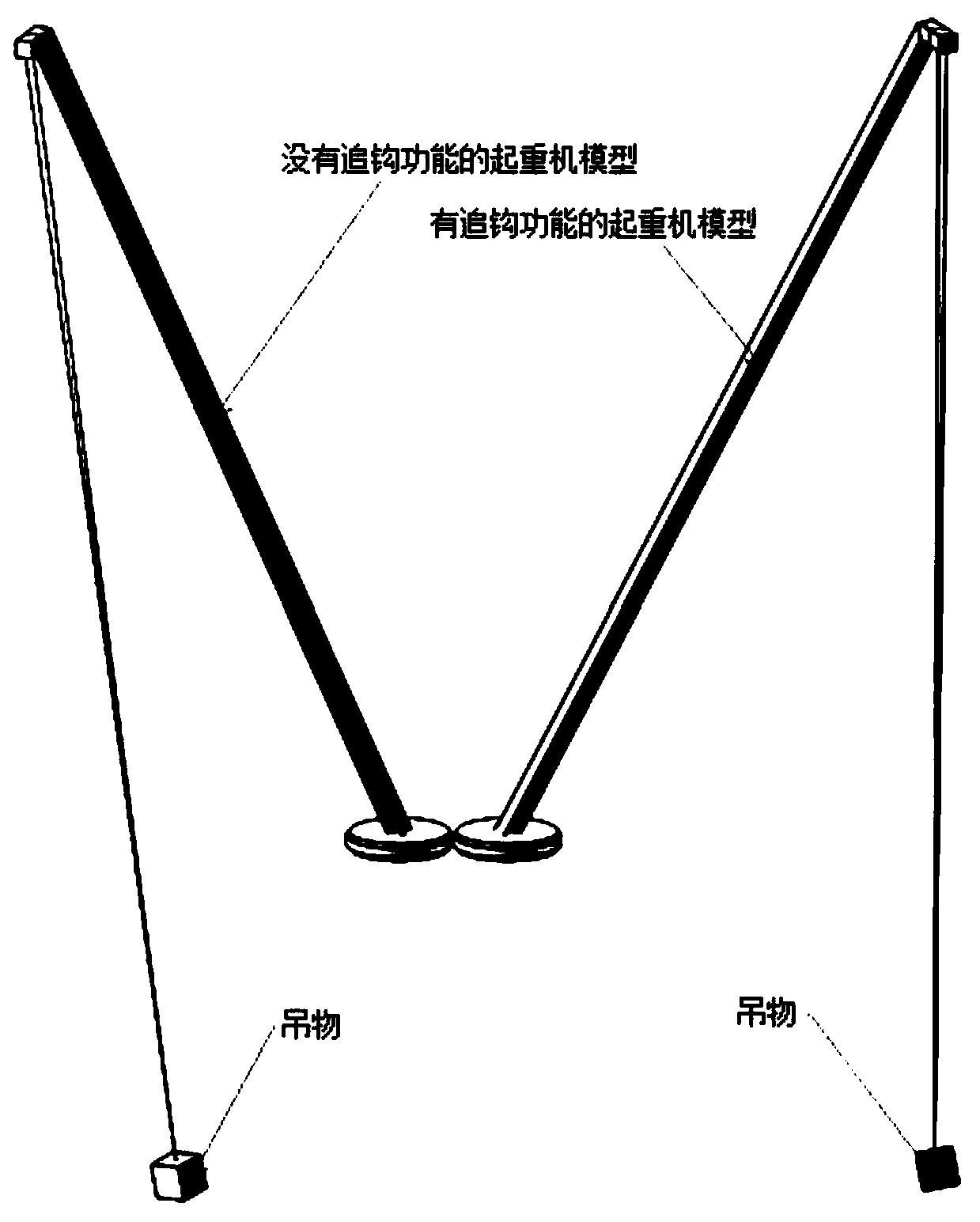

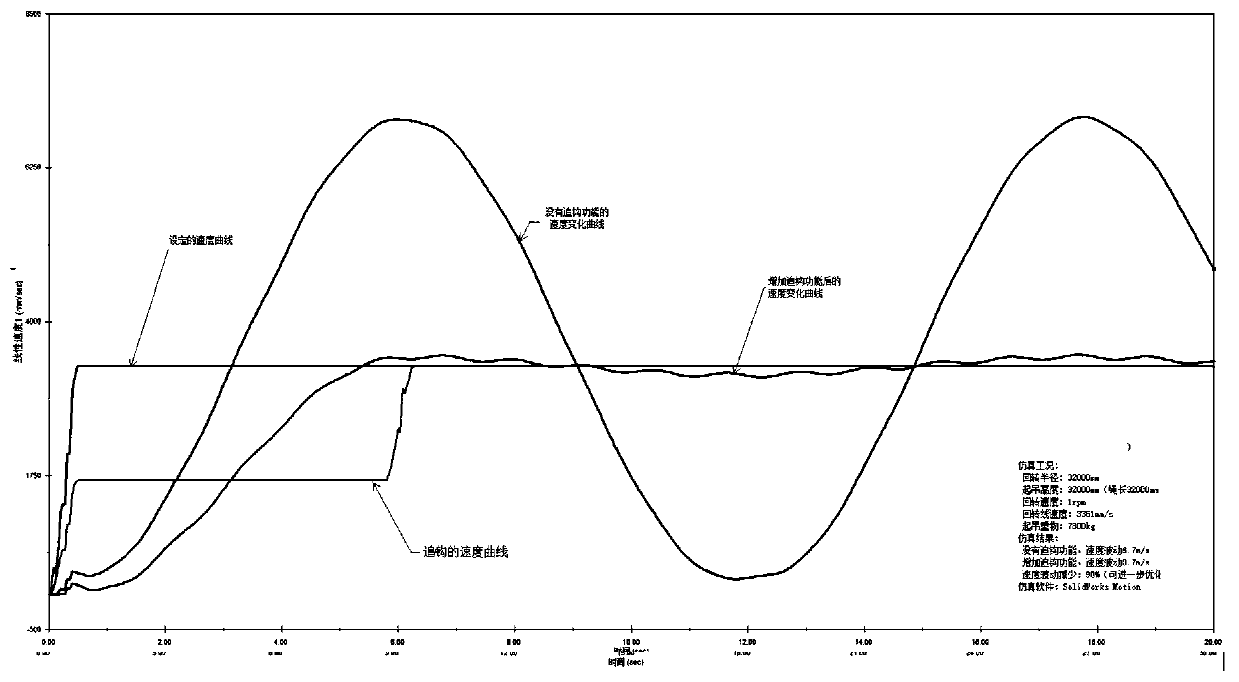

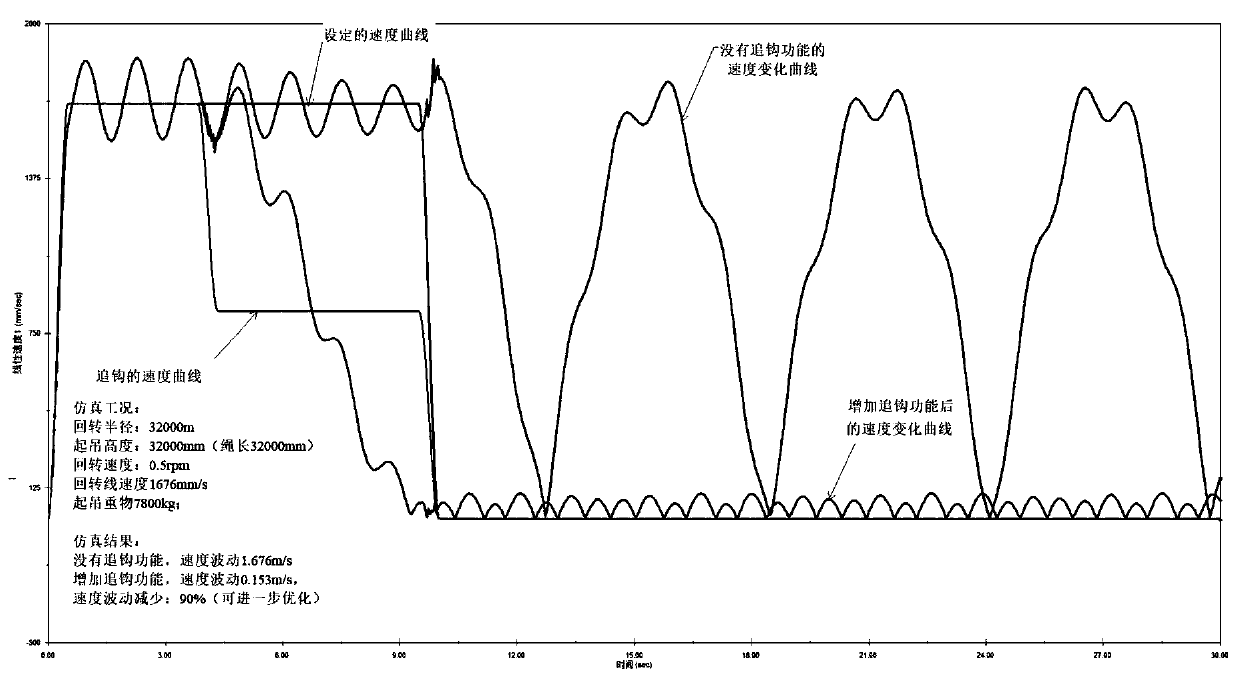

Computer control method for hook stabilizing of crane and crane

The invention relates to a computer control method for hook stabilizing of a crane and the crane. The computer control method includes the steps that during the starting stage and the braking stage ofhorizontal carrying of the crane, the carrying distance, and the carrying speed and acceleration are controlled through a computer, and thus hook stabilizing is realized. According to the computer control method for hook stabilizing of the crane and the crane, the speed and time of horizontal carrying of the crane are controlled through the computer, thus the crane keeps the stable state during starting and braking of horizontal carrying of the crane, and the phenomenon of swinging of a lifting hook and objects is effectively avoided; the safety is improved, the working efficiency is improved, the operation difficulty is lowered, and the labor intensity is reduced; and speed-downstarting and braking also reduce the impact on the crane.

Owner:长沙亿美博智能科技有限公司 +2

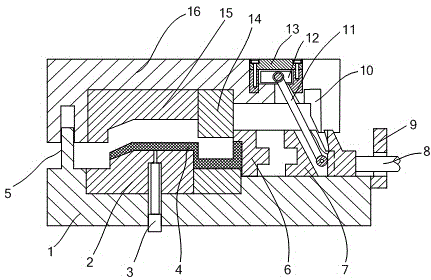

Forced demoulding device for injection molds

The invention relates to the field of injection mold manufacturing, and particularly relates to a forced demoulding device for injection molds. The forced demoulding device comprises an upper die, a lower die, a demoulding block and a demoulding swing-rod, wherein an upper die insert and a lower die insert which are matched to form an injection part cavity are respectively fixedly arranged in the upper die and the lower die, the lower die is provided with an injection gun extending to the cavity, the demoulding block comprises a positioning block and a slide block, the upper die is provided with a stop dog which is pressed against the horizontal direction of the lower die, one end of the demoulding swing-rod is hinged with the upper die, the other end of the demoulding swing-rod is hinged on the slide block, a swing travel slot is arranged on the upper die and the slide block, the positioning block and the lower die are fastened, the lower die is provided with a vertical sliding pin, the upper die is provided with a pin slot matched with the sliding pin, and the slide block is fixedly connected with a power shaft. The forced demoulding device disclosed by the invention has the beneficial effect that in the process of demoulding, the upper die does not produce an extrusion force on injection parts of injection molds so as to ensure the completeness of the injection parts.

Owner:DINGSHENG CORP

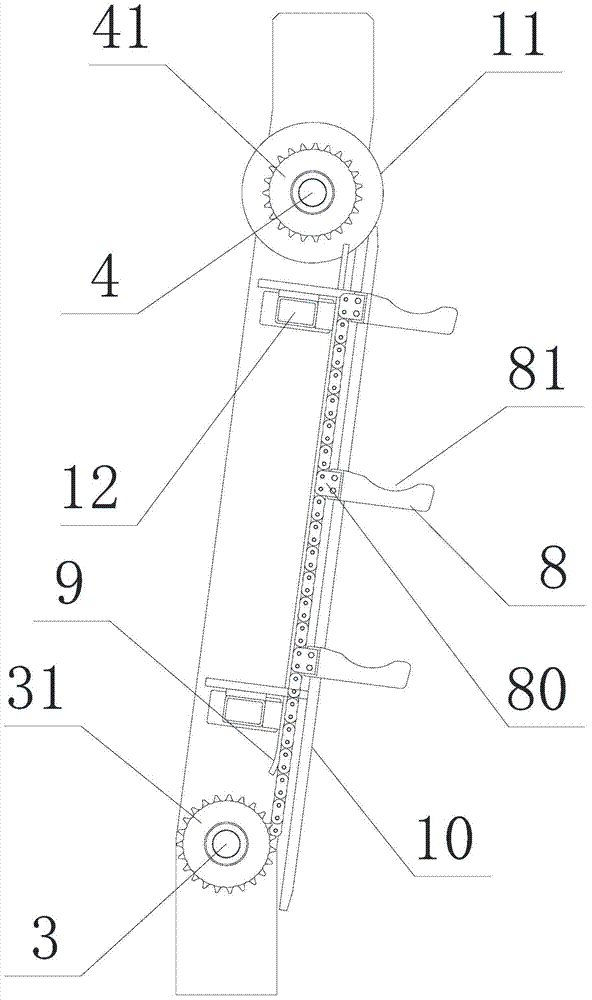

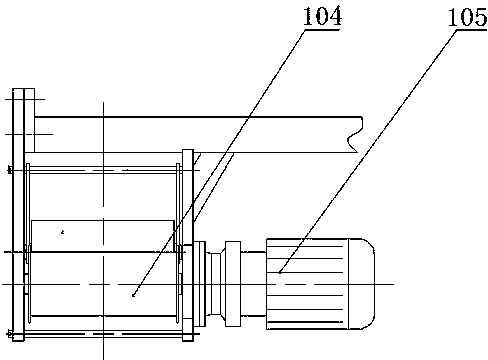

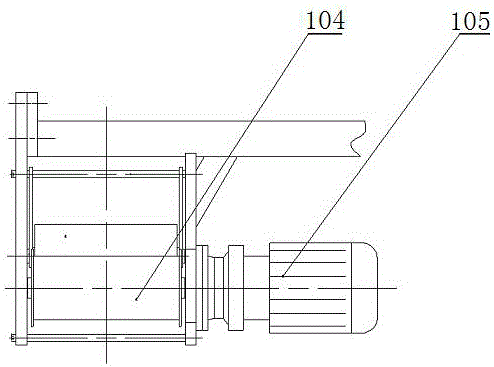

Automatic feeder of paper tubes

The invention relates to an automatic feeder of paper tubes, comprising a left support plate, a right support plate, a transmission shaft, transmission chains and a drive unit. The transmission chains are provided with positioning plates. Guide rails and retaining plates are arranged between the left support plate and the right support plate. Limiting devices are arranged on a driven shaft. The drive unit comprises a drive motor, a reducer and a torsion limiter which is connected with the transmission shaft. The automatic feeder has the advantages that the drive unit drives the transmission shaft to rotate so that the transmission chains are driven to control paper tubes placed on the positioning plates to be fed in a chain transmission direction, torque in normal running is set in a reasonable range through the torsion limiter, an alarm unit sends out an alarm to automatically stop the automatic feeder in case that the torsion limiter slips after production abnormalities such as tube jamming occur, no damage is caused to the motor, the reducer, the transmission chain, the shafts and the like, the torsion limiter automatically returns after the abnormalities such as tube jamming occur, and the automatic feeder can be normally started for use.

Owner:浙江三信智能机械股份有限公司

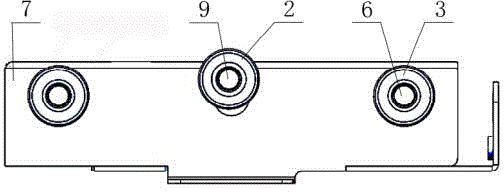

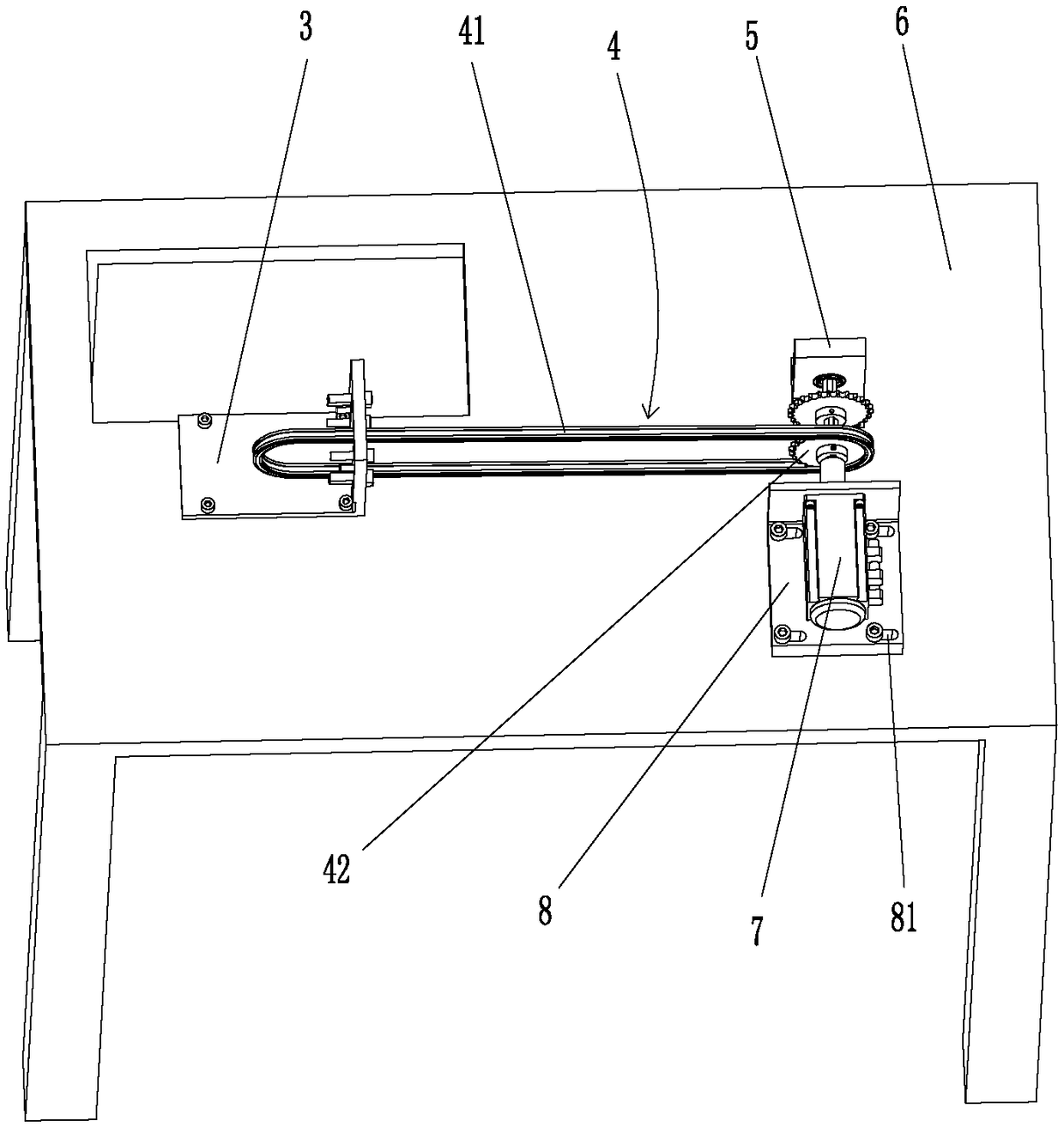

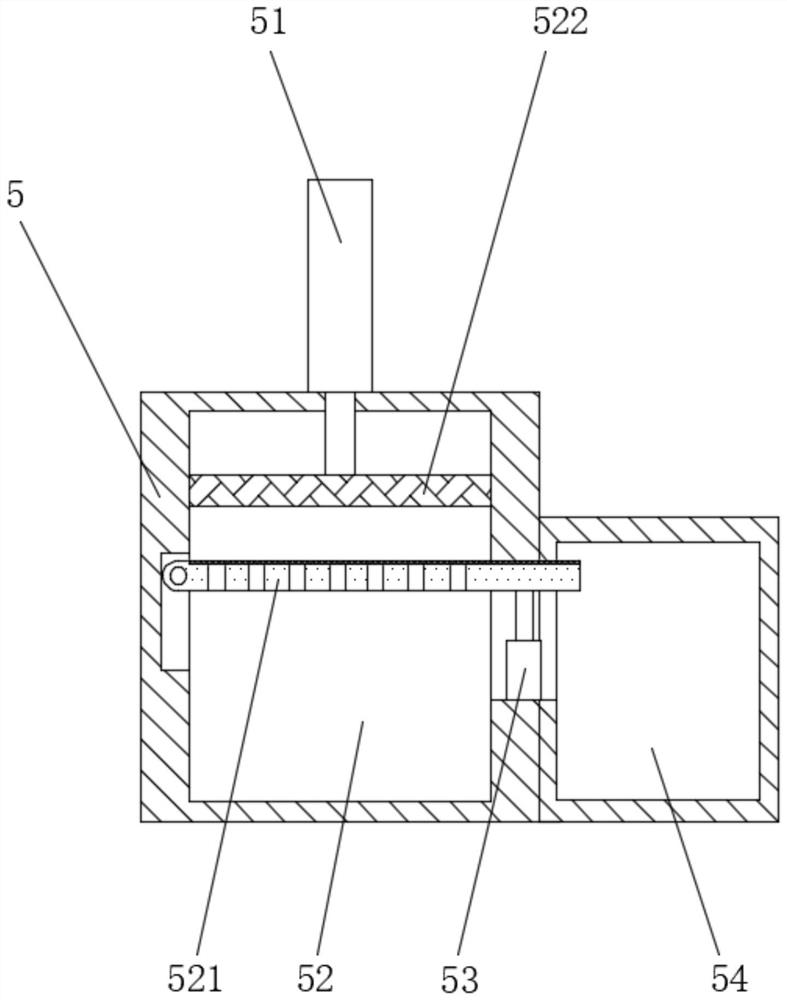

Cutting and moving system for stone cutting machine

InactiveCN104552620AEnsure cutting qualityAvoid wiggle phenomenonWorking accessoriesStone-like material working toolsInterference fitSTONE CUTTER

The invention relates to a cutting and moving system for a stone cutting machine. The cutting and moving system comprises a guide rail and a motor holder; two sides of the motor holder are respectively provided with a bearing fixing shaft and a tension shaft; the bearing fixing shaft and the tension shaft which are arranged on one side of the motor holder are in interference fit with inner rings of bearings; and the bearing fixing shaft and the tension shaft which are arranged on the other side of the motor holder are in clearance fit with the inner rings of the bearings; the bearing fixing shaft arranged on the other side of the motor holder is provided with a shaft shoulder; and a spring is arranged between the shaft shoulder and the bearing arranged on the shaft. The cutting and moving system for the stone cutting machine can not only ensure the cutting quality, but also reduce the production cost.

Owner:YANCHENG BAODING POWER TOOLS

Ultra-large combined fire-fighting equipment special for super high-rise building

The invention discloses ultra-large combined fire-fighting equipment special for a super high-rise building. The ultra-large combined fire-fighting equipment special for the super high-rise building comprises a moving carrier and a control mechanism which is in signal interconnection with a lifting mechanism and a supporting mechanism which are arranged on the moving carrier. The lifting mechanism is disposed on the upper portion of the moving carrier, the supporting mechanism is mounted on the circumferential side of the moving carrier, and a balance module is disposed on the upper portion of the lifting mechanism. The ultra-large combined fire-fighting equipment is combined with a fire fighting apparatus, the range of a fire fighting truck or other fire fighting apparatuses can be broadened, and moreover the influence of a base plane on the fire fighting truck or the other fire fighting apparatuses can be reduced by means of the ultra-large combined fire-fighting equipment, so that the ultra-large combined fire-fighting equipment special for the super high-rise building is more suitable for fire-fighting work of the super high-rise building.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

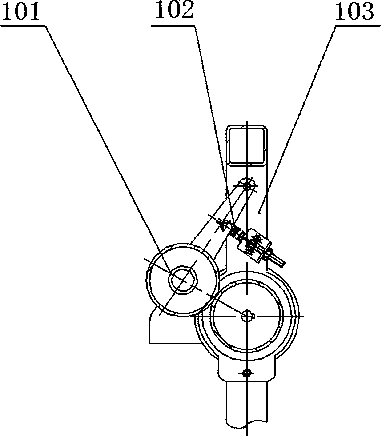

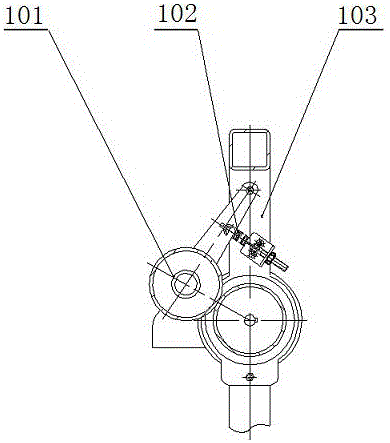

Stirring guide and location mechanism for diamond cutting line production equipment

InactiveCN102862241ACause deteriorationSimple structureFine working devicesDiamond cuttingFixed frame

The invention discloses a stirring guide and location mechanism for diamond cutting line production equipment, comprising a slide way, a stirring rod on the slide way, and a stirrer at the lower end of the stirring rod, wherein a plating solution groove is arranged below the stirrer; a fixed frame is arranged above the plating solution groove; oil receiving boxes are arranged at the both ends of the fixed frame; guide rods are arranged in the inner directions of the oil receiving boxes; slide blocks are sleeved on the guide rods; and the slide blocks are connected with the slide way via connection plates. During the use of the stirring guide and location mechanism, a lubricating grease is added between the slide blocks and the guide rods, a friction force between the guide rods and the slide blocks achieves the minimum under the action of the lubricating grease, and the redundant lubricating grease flows downwards into the oil receiving boxes and can be recycled; the lubricating effect is good, and the deterioration of plating solution caused by the falling-off of the lubricating grease in a plating solution box can be effectively prevented, thus keeping clean and being environment-friendly; the long-time stable and continuous working, and the high production efficiency of the equipment can be ensured; and a guarantee is provided for the stable and continuous production for qualified diamond cutting lines, of the diamond cutting line production equipment.

Owner:SINO CRYSTAL PRECISION MFG

Crane anti-swing device and working method thereof

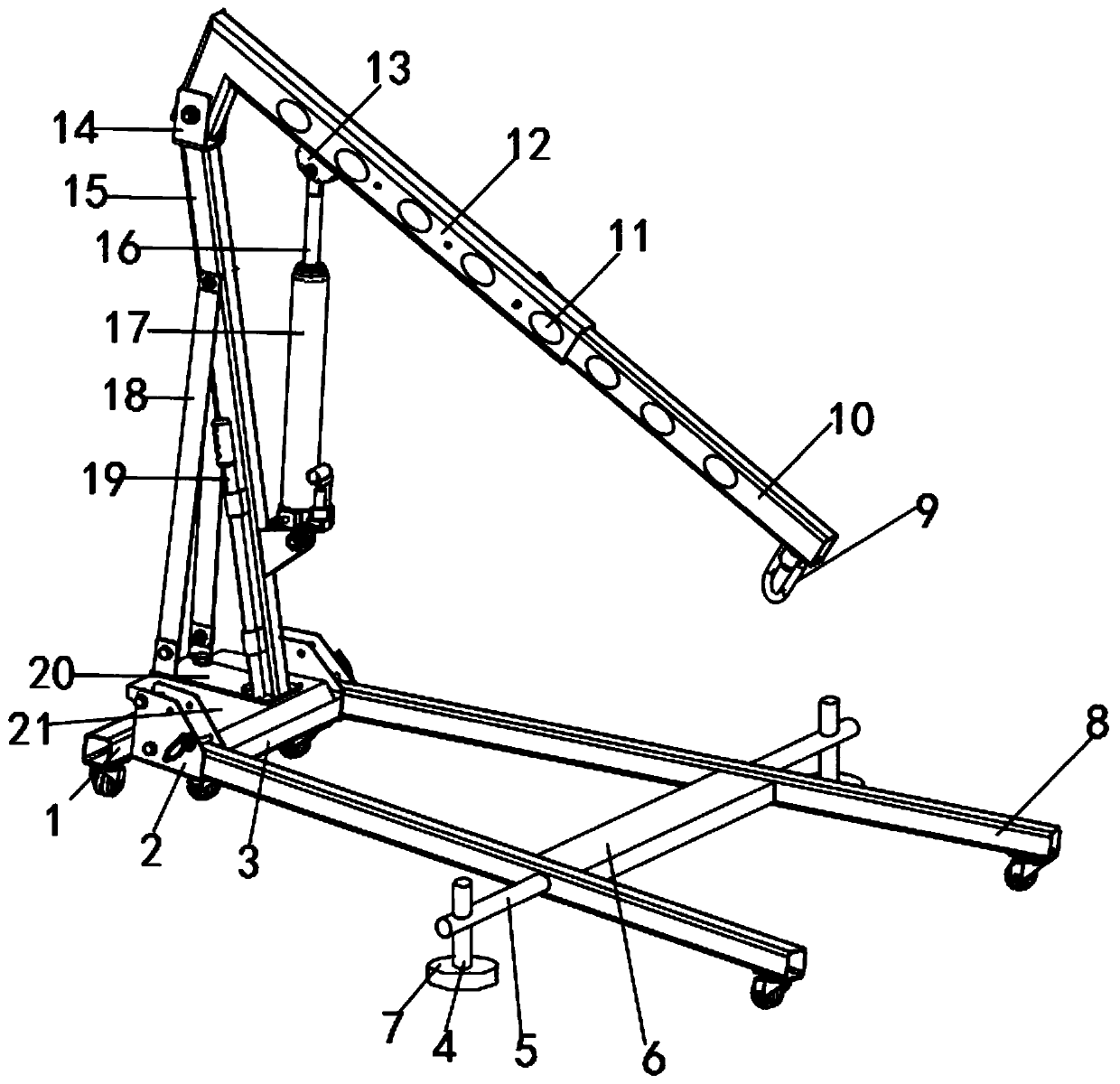

InactiveCN111056438AAvoid wobblingMaintain balanceLoad-engaging elementsCranesButt jointControl theory

The invention discloses an anti-swing device of a crane. The device comprises a supporting foot stand, a fixed bottom plate, a balance bottom plate, a fixed supporting arm, a telescopic arm and a siderotating foot rod. Butt joint clamping seats are fixedly mounted on the outer surfaces of the two sides of the fixed bottom plate. The supporting foot stand is fixedly mounted at the front part of the fixed bottom plate. The side rotating foot rod is movably installed on one side of the supporting foot stand. The outer surface of the side rotating foot rod is movably sleeved by a side rotating clamping rod. Inclined supporting feet are movably installed at the bottom of the side rotating foot rod. Spherical clamping grooves are formed in the middles of the inner sides of the inclined supporting feet. A ball clamping pin is fixedly installed on the outer surface of the lower end of the side rotating foot rod. The upper portion, fixedly close to the ball clamping pin, of the outer surface of the side rotating foot rod is movably sleeved by a fixing clamping sleeve. According to the crane anti-swing device, the crane anti-swing device is provided with an inclination angle adjusting structure, so that the stability of the crane anti-swing device is improved; meanwhile, the crane anti-swing device is provided with an inclination auxiliary fixing structure, so that the fixing operationis firmer, and the anti-swing effect of the crane anti-swing device is improved.

Owner:安徽江河智能装备集团有限公司

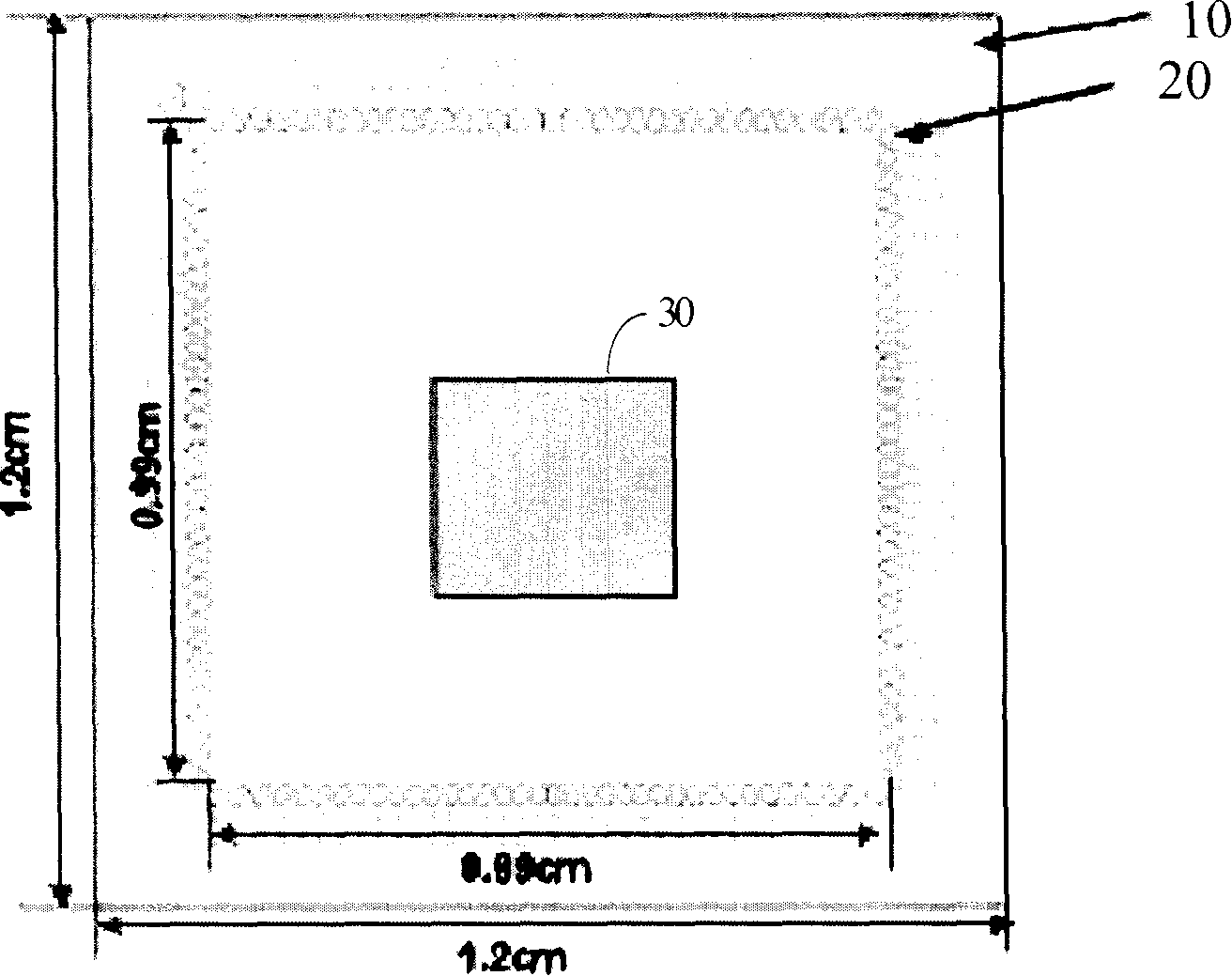

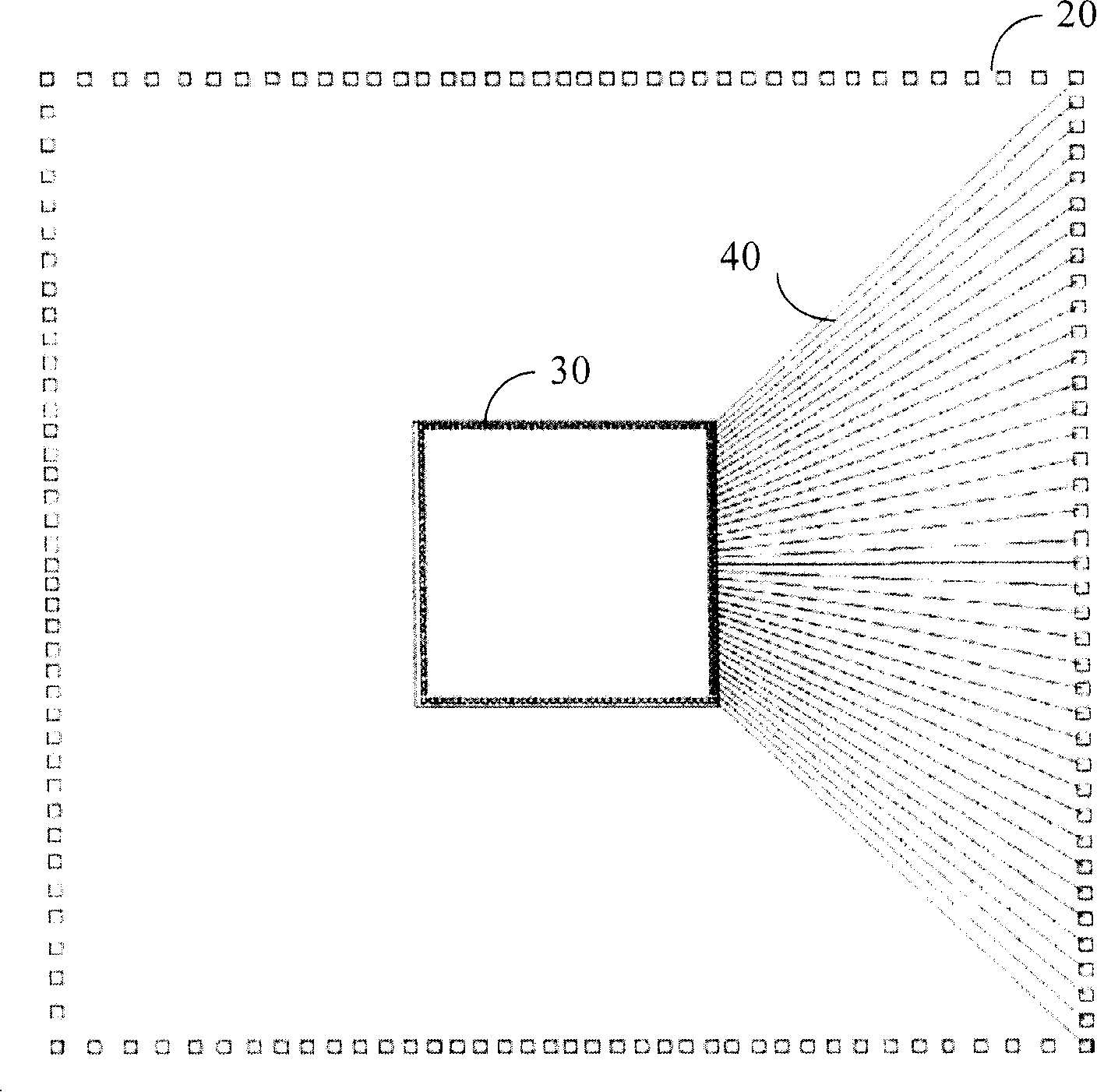

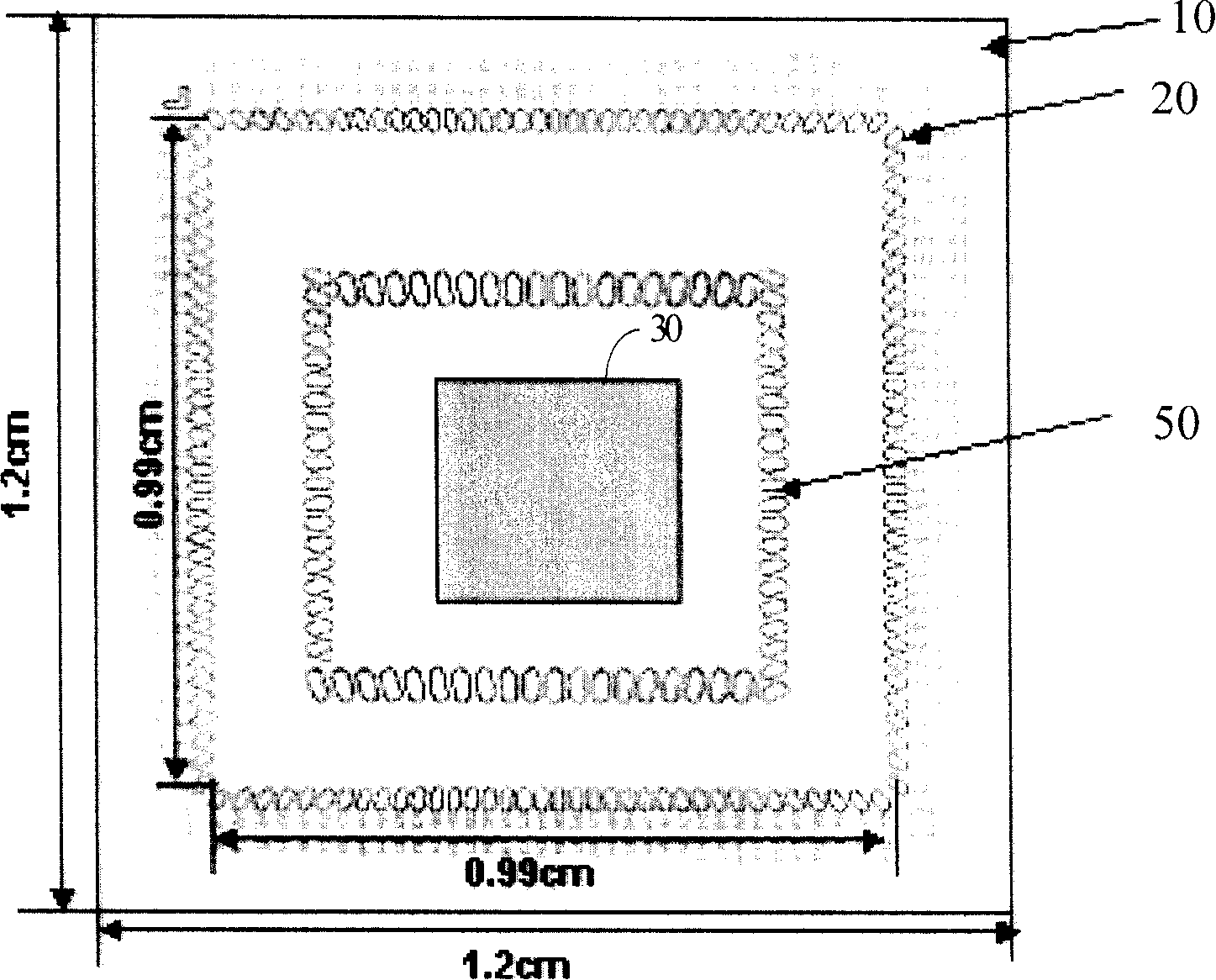

Connection device between packaging substrate and chip thereon

InactiveCN101211880AShorten the lengthIncrease productivityPrinted circuit detailsSemiconductor/solid-state device detailsEngineeringPrinted circuit board

The invention provides a device for connecting a packaging substrate with a chip on the packaging substrate, which comprises a plurality of figure-like solder sheet rings on the packaging substrate which enclose the chip; each figure-like solder sheet ring comprises a plurality of figure-like solder sheets; and a plurality of connection lead wires which are used for connecting the chip and the figure-like solder sheet of the innermost ring of the figure-like solder sheet ring and for connecting the figure-like solder sheet of the neighboring figure-like solder sheet ring. The invention also provides a printed circuit board with the connection device, By adopting the technical proposal of the invention, length of the connection lead wire can be effectively reduced under a condition of small-sized chip, thereby effectively avoiding generation of excessive droop and swing as well as increasing yield of the connection lead wire and reducing cost. In particular to non-amount-production application like engineering verification and reliability test, the invention has practical value. Under a condition of limited available substrate, product function and reliability can be verified and evaluated rapidly with low cost, which wins the time for the follow-up market operation and mass production.

Owner:SEMICON MFG INT (SHANGHAI) CORP

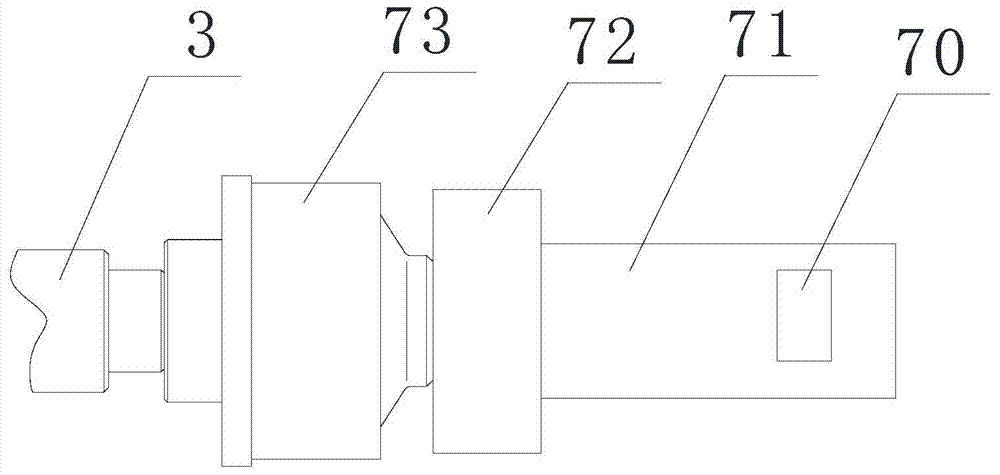

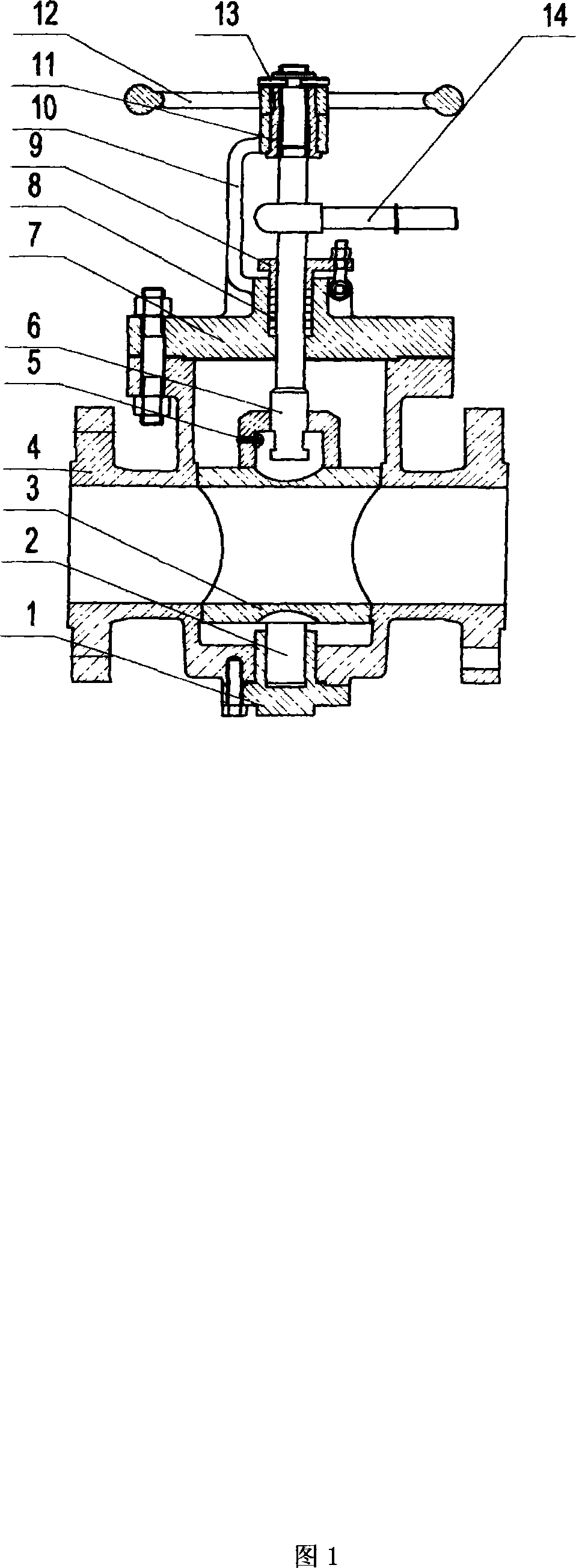

Directly lifting type plug valve

InactiveCN101220870AAvoid wiggle phenomenonCock stablePlug valvesOperating means/releasing devices for valvesHigh pressureScrew thread

The invention relates to a plug valve, in particular to a straight lifting typed plug valve. The invention is characterized in that the internal chamber of a valve body is provided with a space which can lead the plug valve to move up and down; the plug valve is arranged in the valve body; a valve cover is fixedly connected with the upper part of the valve body by a fastener; the valve cover is provided with a valve cover bracket; the lower end of the valve rod is provided with two horizontal straight troughs; the top thread of the plug valve is acted on the straight troughs; a valve rod nut is sheathed in a fixed ring on the valve cover bracket; the internal thread of the valve rod nut is engaged with an external thread which is arranged on the upper part of the valve rod; a handwheel is arranged above the fixed ring of the valve cover bracket, sheathed on the valve nut and provided with a fastener; the handwheel is fixedly connected with the middle part of the valve rod. The invention has the advantages that, as the straight lifting structure is adopted, the friction of the matching surface is greatly reduced, the operation is convenient, the work is safe and reliable, and the invention can be applied to high pressure sites with the pressure more than 2500LB, when the plug valve is started and closed.

Owner:SHANGHAI FUDI VALVE CO LTD

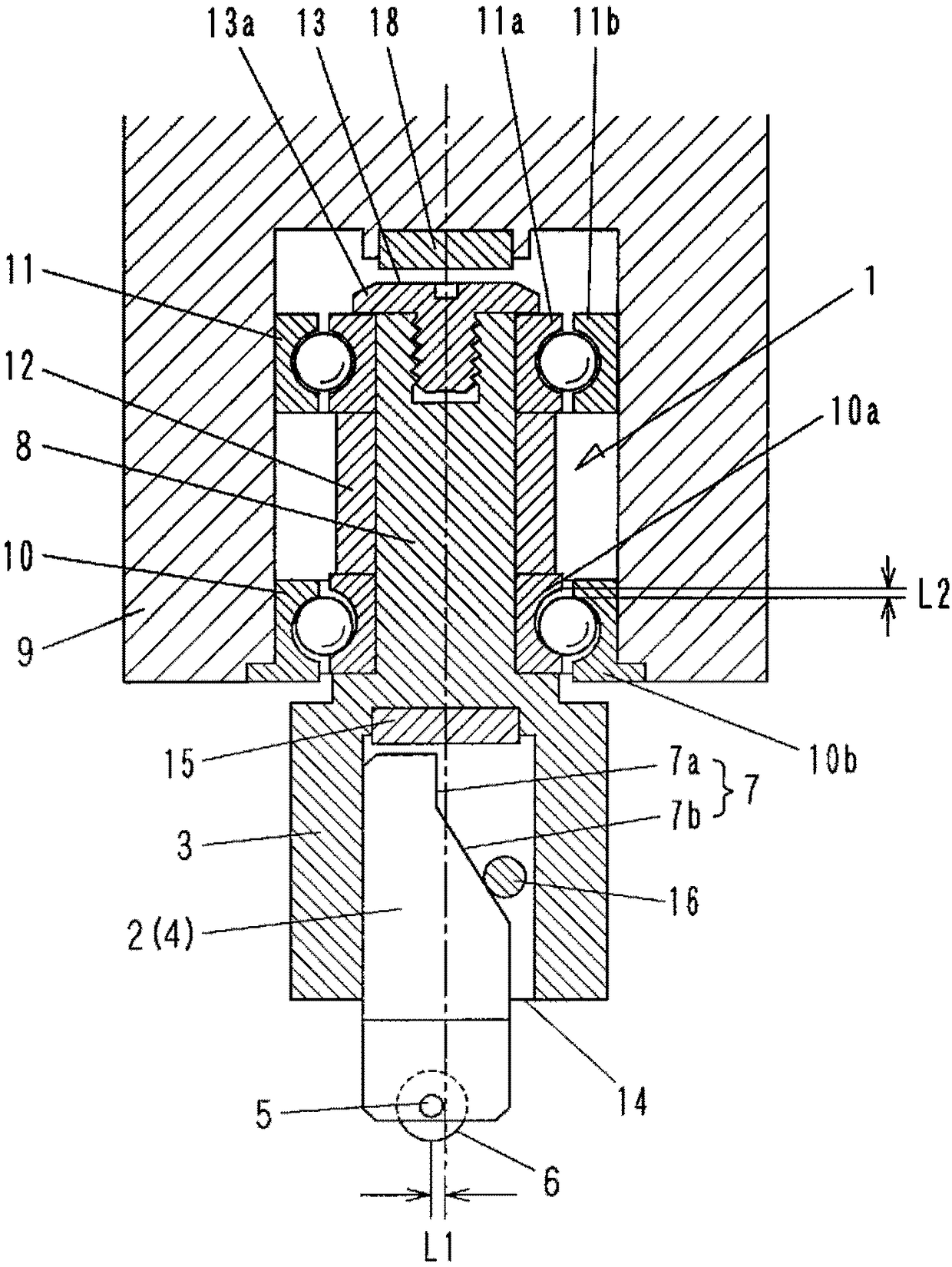

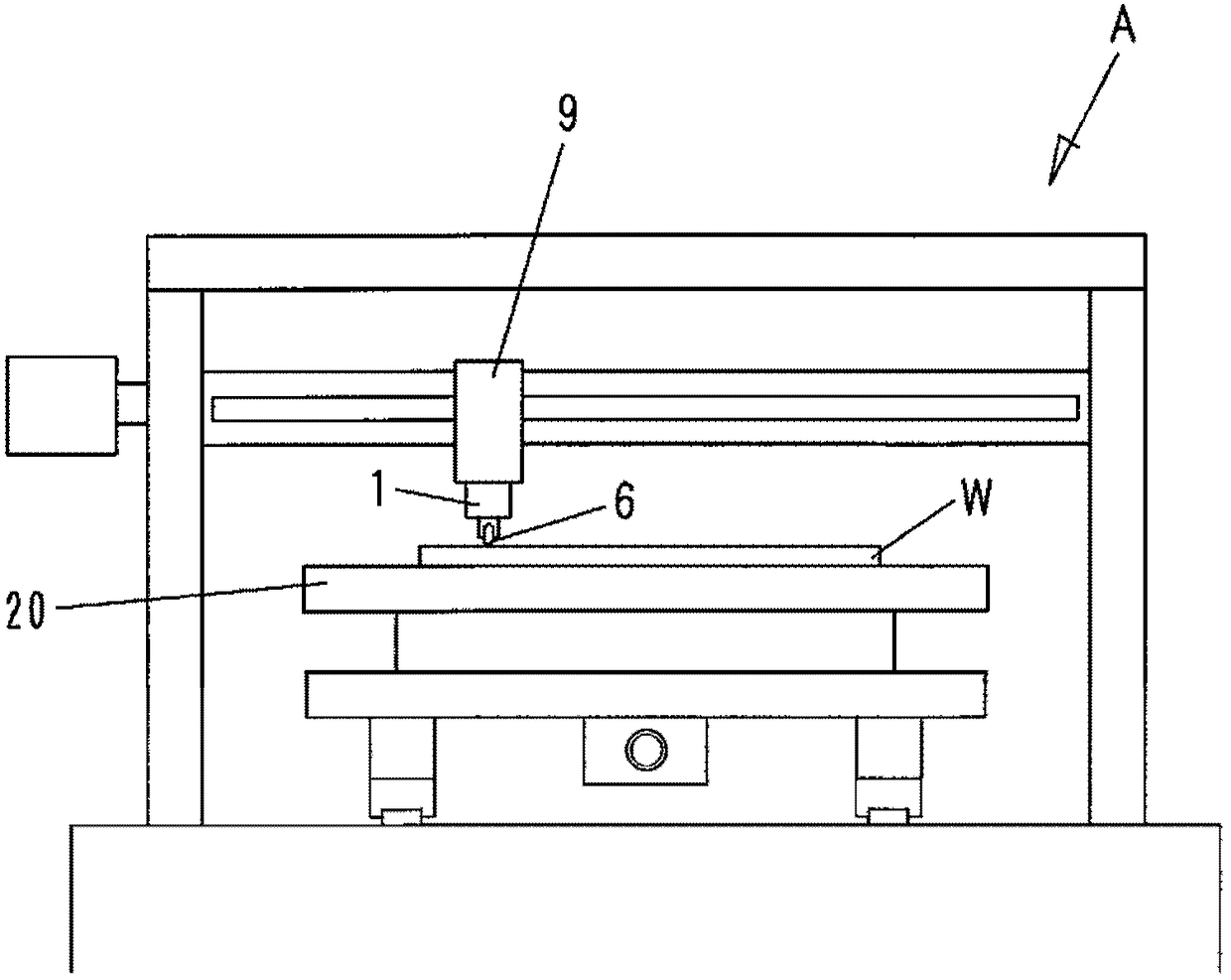

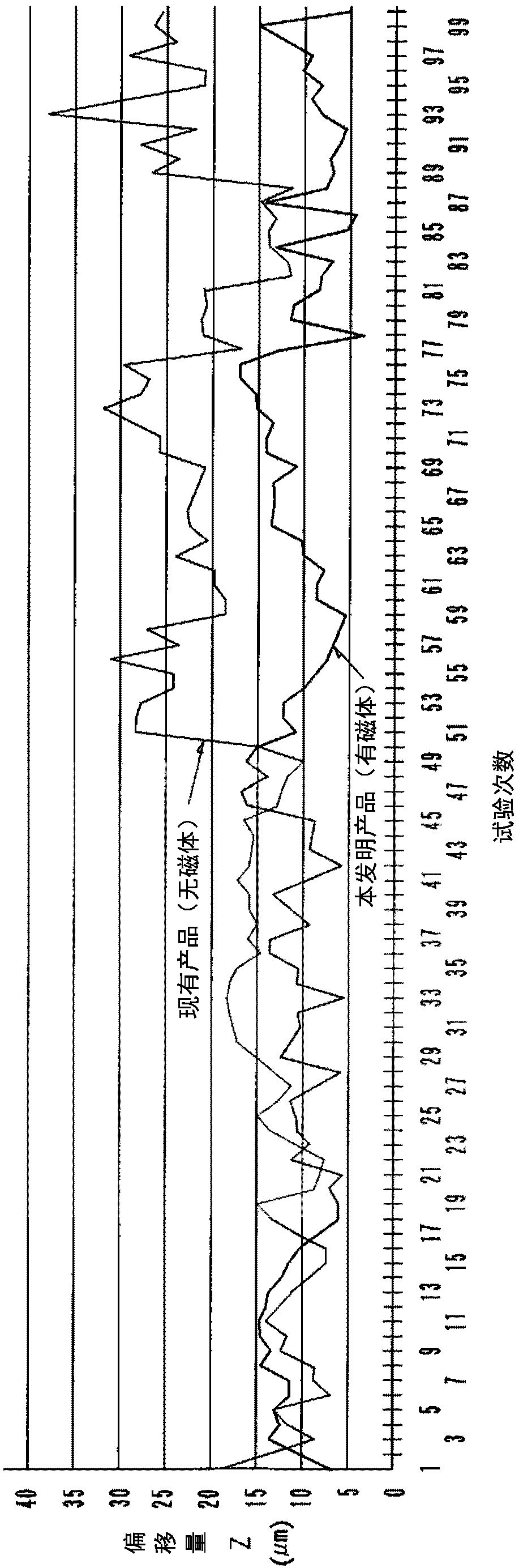

Cutter holder mounting structure and cutter holder joint

InactiveCN108503203AEliminate loosenessAvoid wiggle phenomenonGlass severing apparatusGlass productionBall bearingEngineering

The present invention provides a cutter holder mounting structure capable of preventing a cutter holder from being obliquely displaced at the initial stage of scribing and capable of accurately forming a scribe line. The revolving shaft (8) of the cutter holder mounting structure (1) having a cutter wheel (6) at the lower end is rotatably mounted on the scribing head (9) of a scribing device (A) via a ball bearing (10). The outer ring (10b) of the ball bearing (10) is mounted on the scribing head (9) or a portion connected to the scribing head (9), and the inner rings (10a, 11a) of the ball bearings (10, 11) are mounted on the revolving shaft (8). A magnet (18) that always sucks and lifts the revolving shaft (8) and the inner rings upward together is disposed above the revolving shaft (8),thereby suppressing the looseness of the cutter holder mounting structure (1) caused by the internal clearance (L2) of the ball bearing (10).

Owner:MITSUBOSHI DIAMOND IND CO LTD

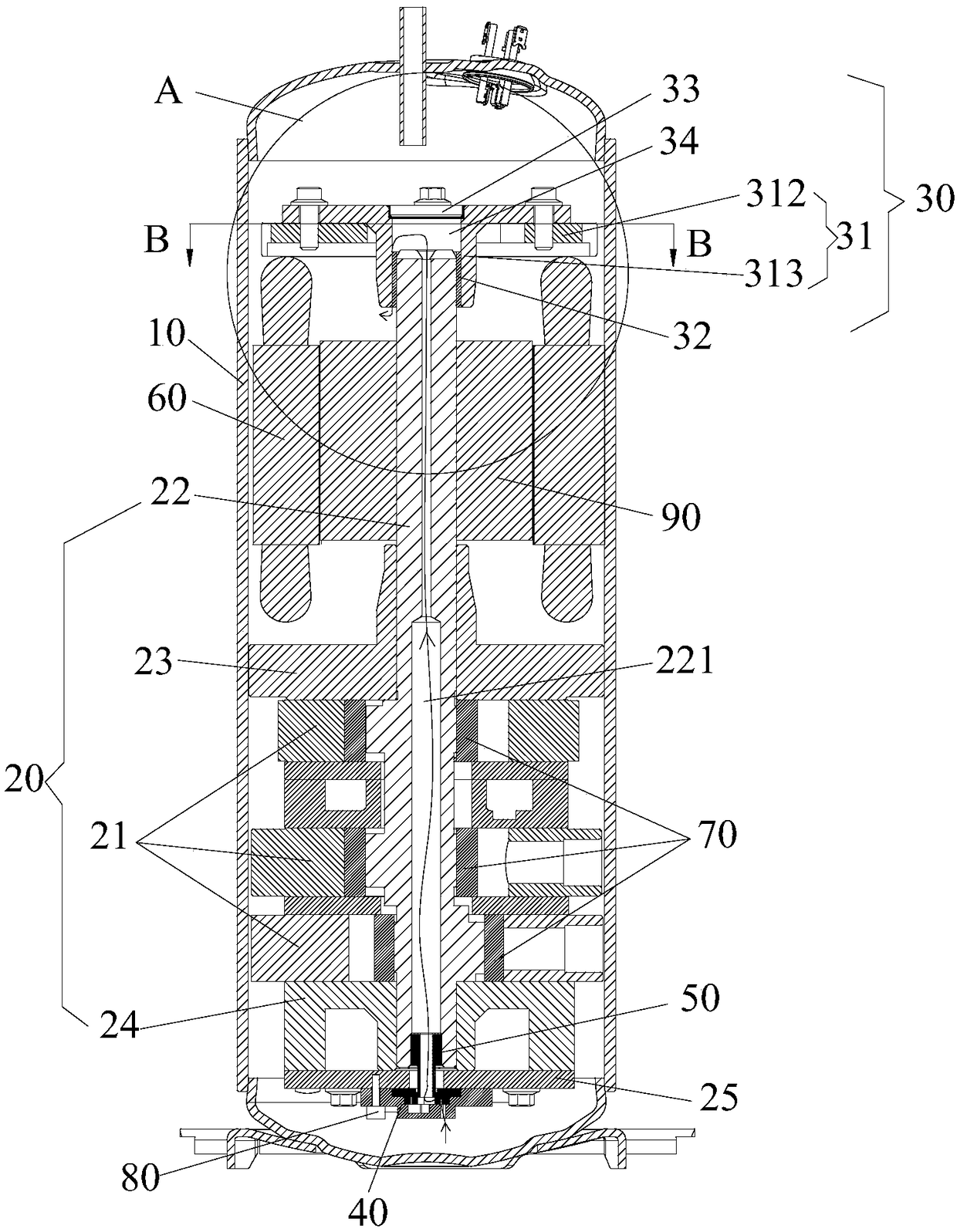

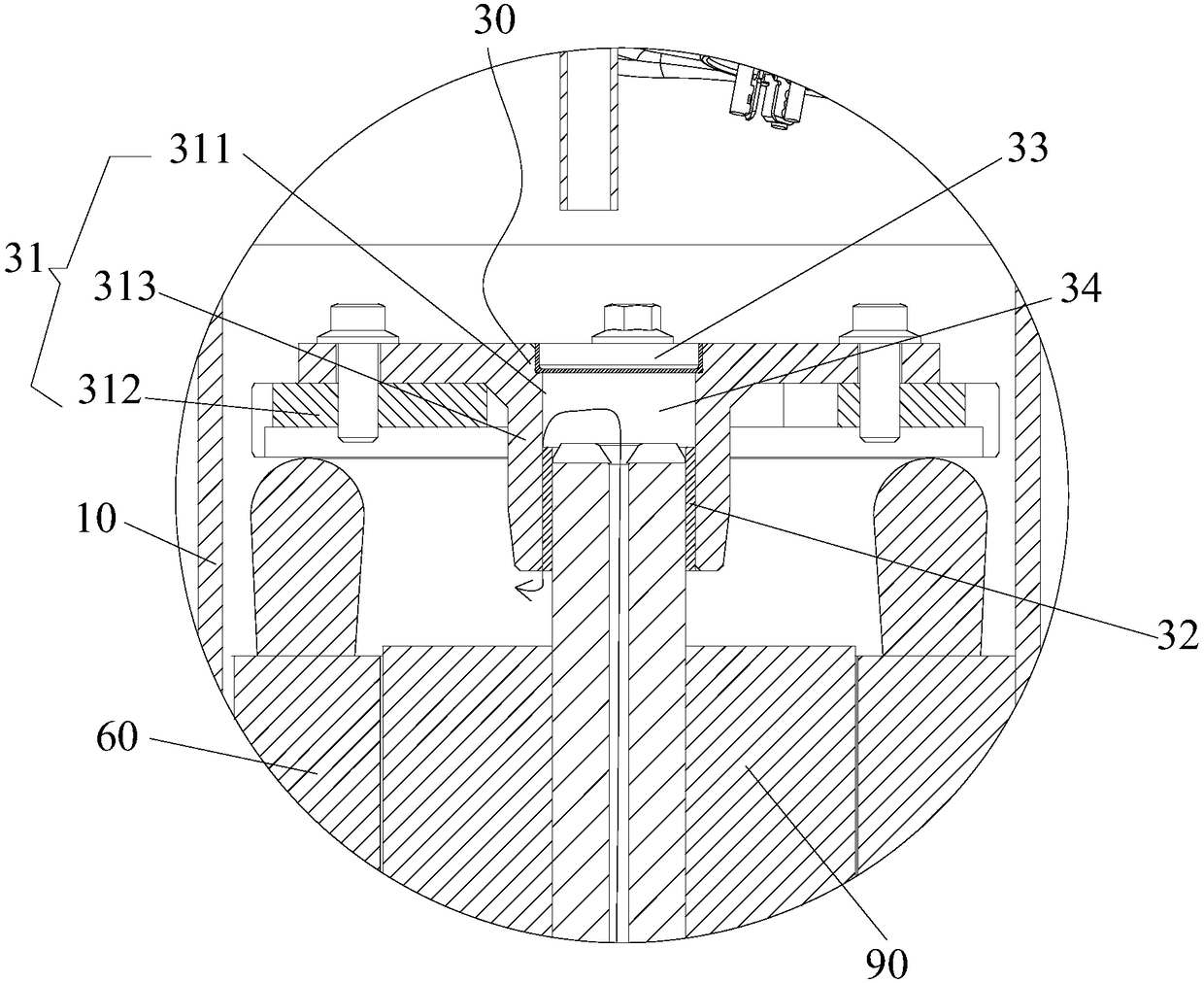

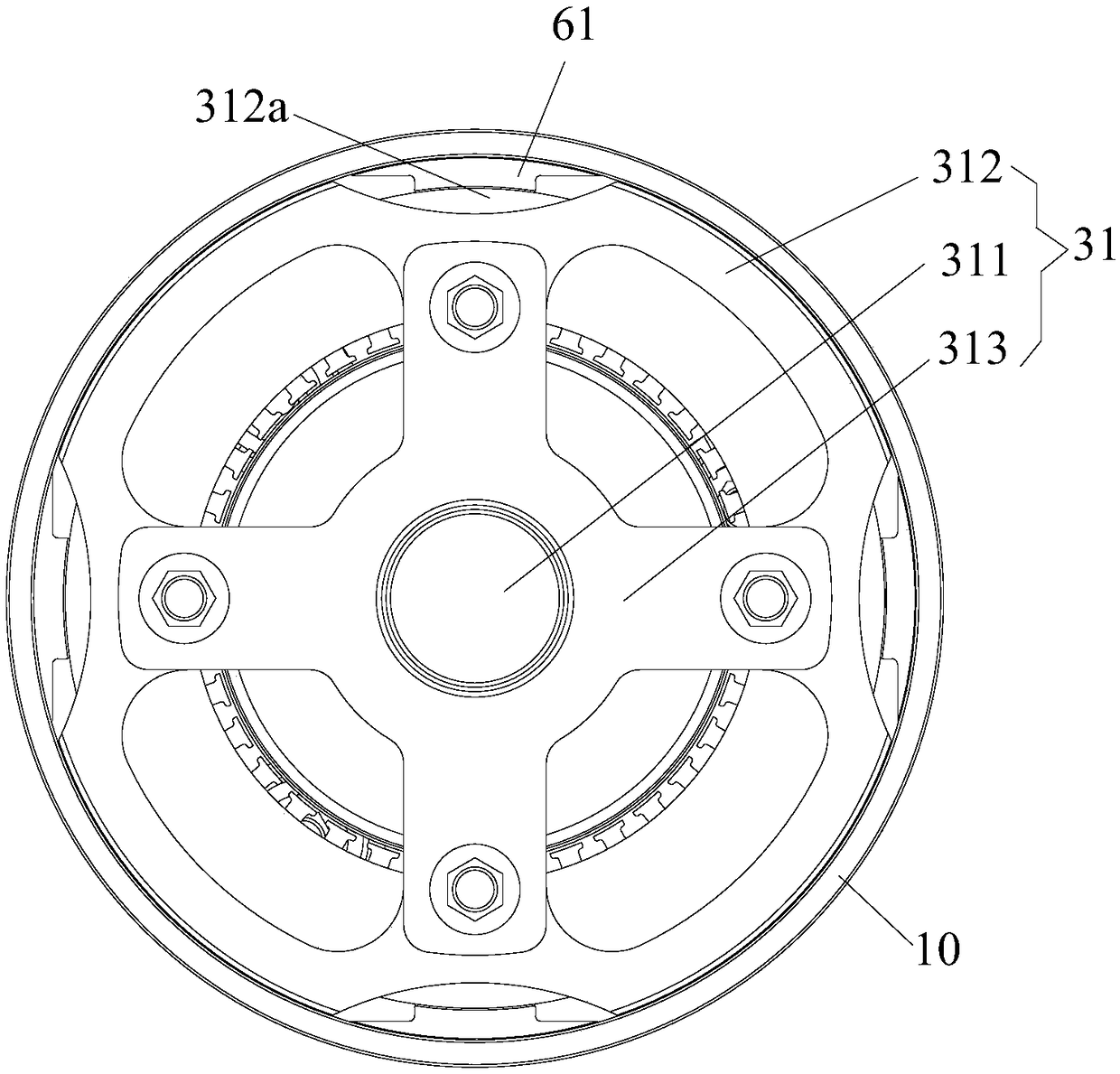

Rotor compressor and heat exchange equipment comprising same

PendingCN108425849AAvoid wiggle phenomenonAffect the service lifeRotary/oscillating piston pump componentsLiquid fuel engine componentsLubricationCrankshaft

The invention provides a rotor compressor and heat exchange equipment comprising the same. The rotor compressor comprises a crankshaft, a supporting structure and a power structure, wherein the crankshaft is provided with an oil supply hole extending in the axial direction of the crankshaft; the supporting structure is used for supporting the crankshaft so as to prevent the crankshaft from movingin the radial direction of the supporting structure; the power structure is used for delivering a lubrication medium in an oil sump to the place between the crankshaft and the supporting structure through the oil supply hole. Through the rotor compressor, the problem that a crankshaft of a rotor compressor and a supporting structure are lubricated insufficiently in the prior art is solved effectively.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

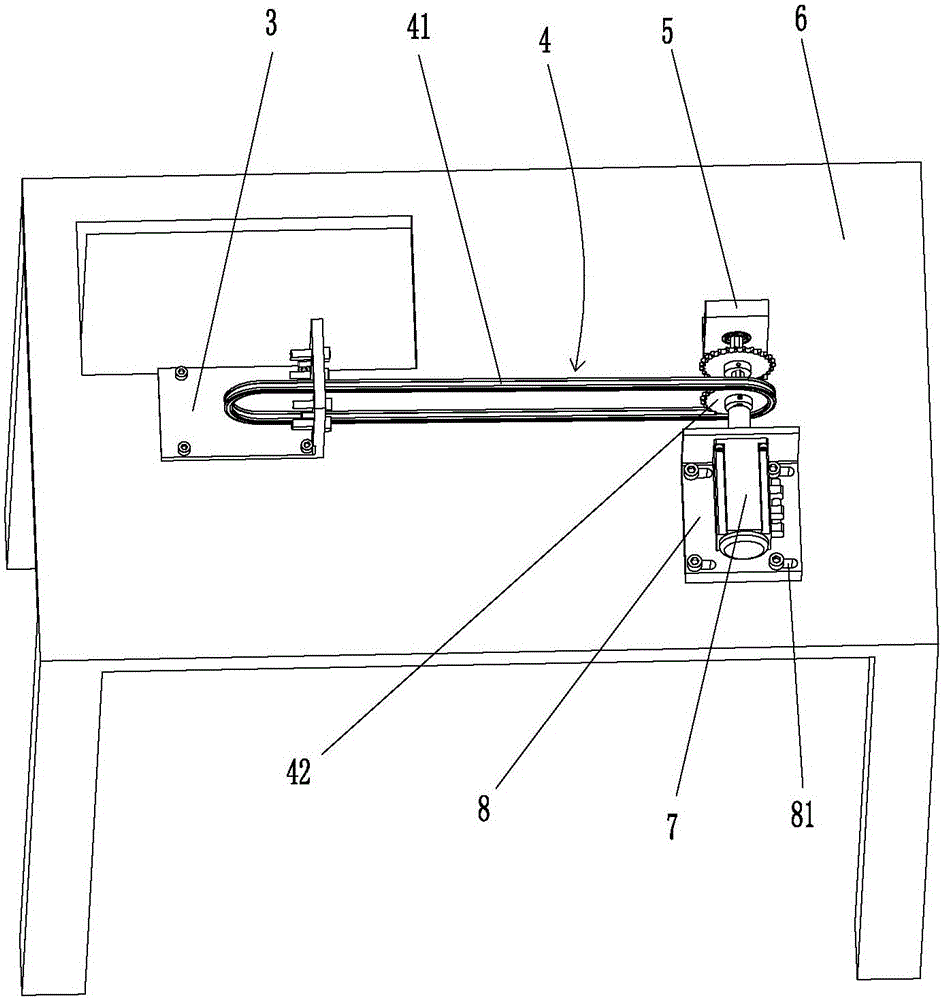

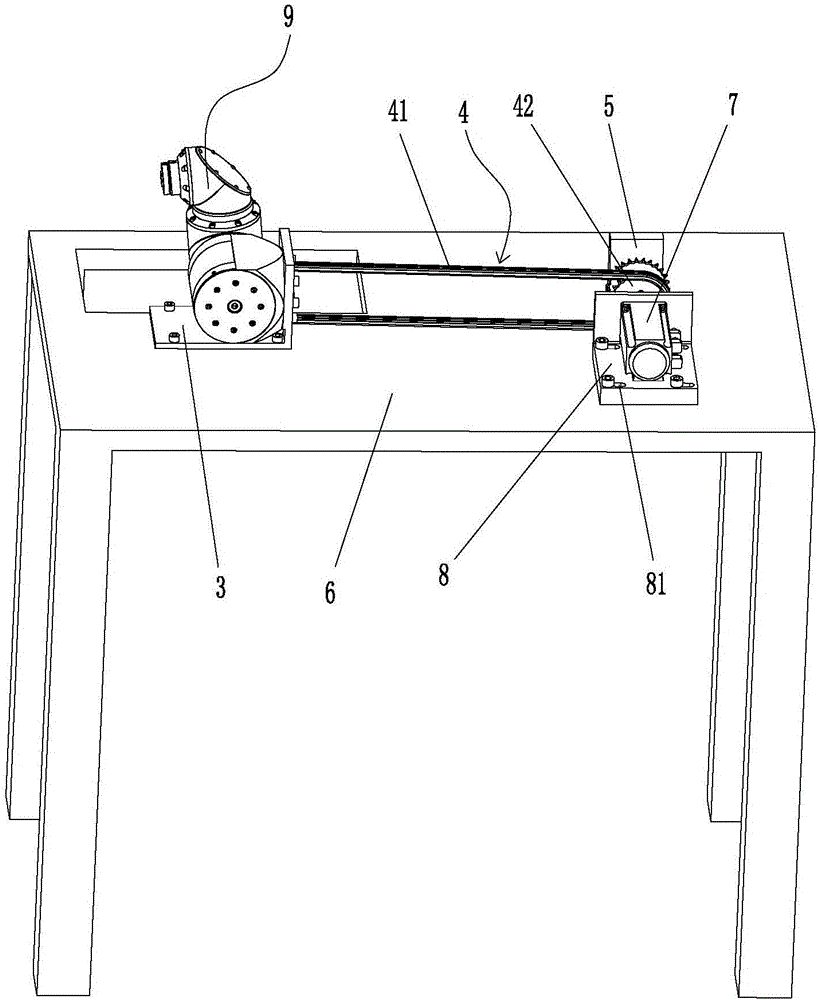

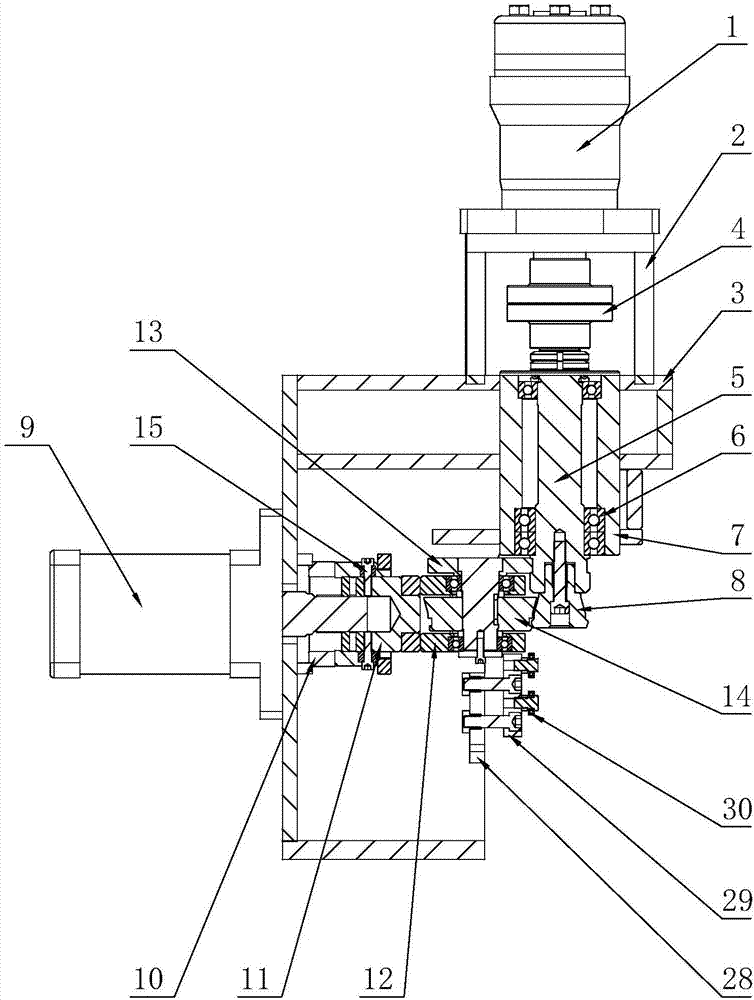

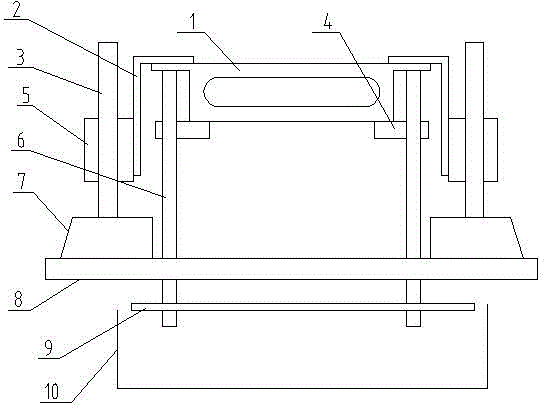

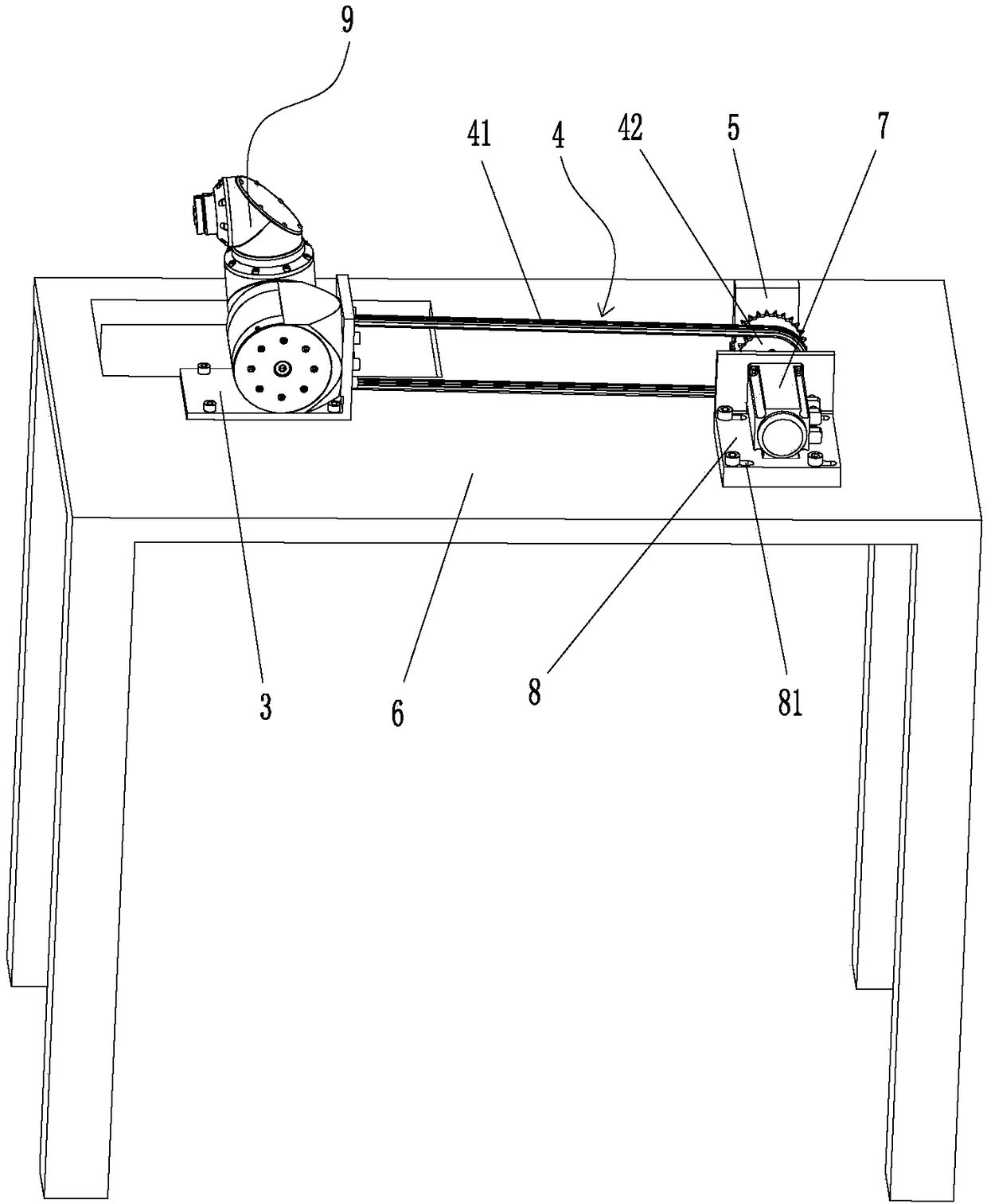

Tool for adjusting wrist clearances of industrial robot

InactiveCN106217412AReduce manufacturing costEliminate repeated disassembly and assembly proceduresManipulatorSprocketIndustrial engineering

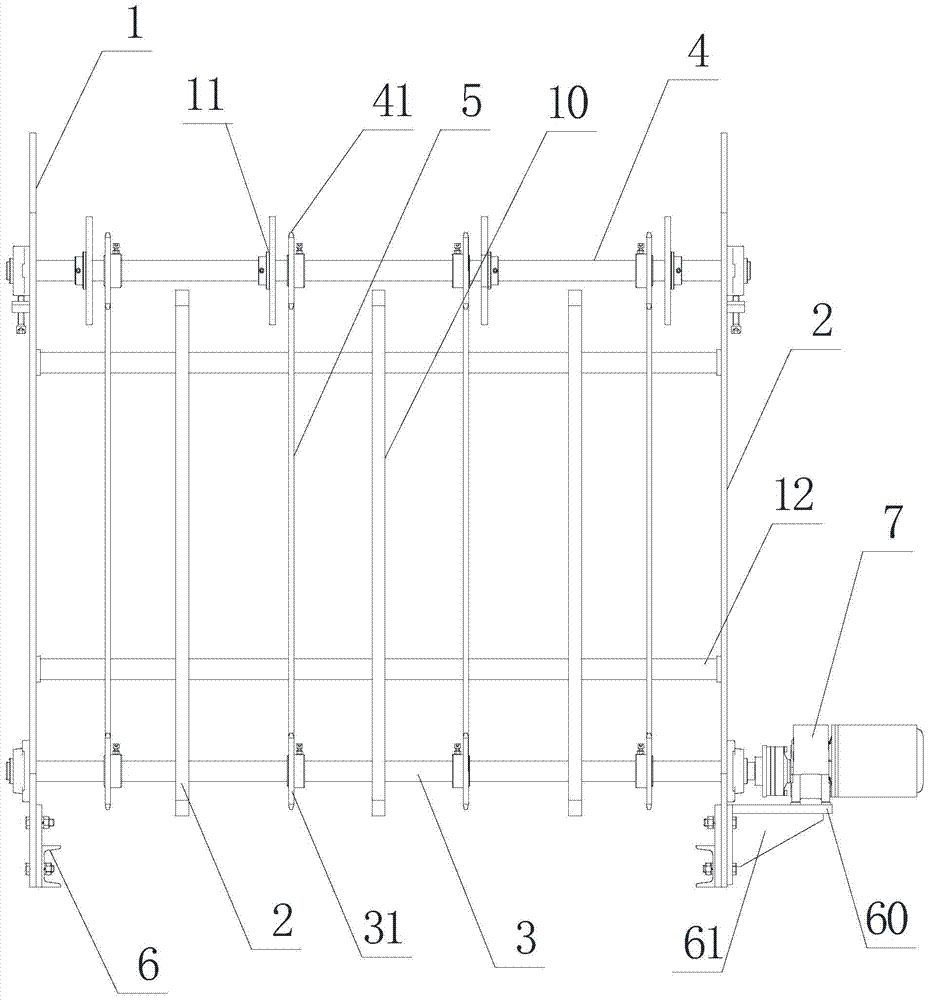

A tool for adjusting the wrist clearances of an industrial robot comprises a working table, a wrist fixing plate, a motor and a driving mechanism used for driving three shafts on a wrist to rotate, wherein the driving mechanism is connected with the motor, the wrist fixing plate and the motor are both mounted on the working table, the driving mechanism comprises a chain and a chain wheel, the chain wheel is mounted on a rotating shaft of the motor, one end of the chain is meshed with the chain wheel, and the other end of the chain, after penetrating through a through hole formed in the wrist fixing plate, is meshed with a chain wheel on the three shafts of the wrist. Before the wrist is assembled on the industrial robot, first, the wrist is mounted on the wrist fixing plate, then, the three shafts in the wrist are separately driven by the driving mechanism to continuously work for 120 hours, the clearances of the three shafts are fully displayed, and after no clearances exist after adjustment, the wrist is mounted on the industrial robot at a time. In conclusion, a following wrist disassembling and assembling procedure is omitted in a mode of previously adjusting the clearances of the wrist, so that the production cost of enterprises is greatly saved.

Owner:ANHUI LEADING PRECISION TECH

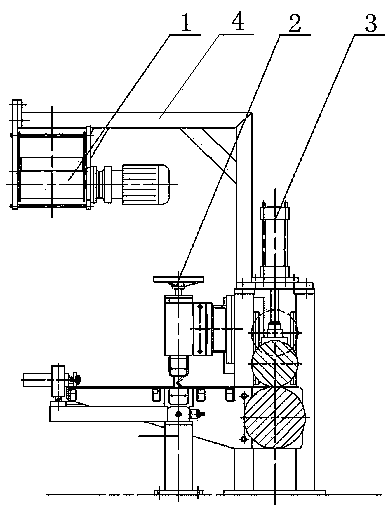

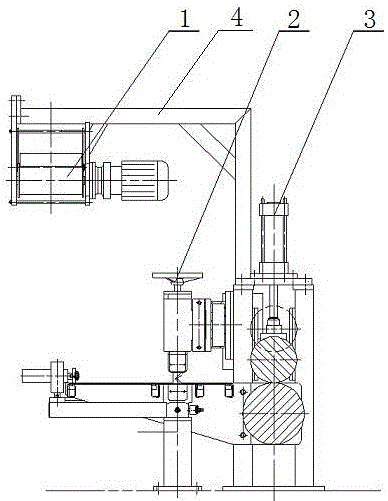

Improved non-die copy necking system and application of same in workpiece necking machining

ActiveCN107350370AEasy to processImprove coherenceMetal-working feeding devicesPress ramDrive wheelStructural engineering

The invention belongs to a workpiece forming and machining device and particularly relates to an improved non-die copy necking system and application of the same in workpiece necking machining. The improved non-die copy necking system comprises a driving wheel, wherein a driven wheel is coaxially and parallelly arranged on one side of the driving wheel in a spaced mode, the spacing between the driven wheel and the driving wheel is controlled by a driven wheel ejection mechanism, the edge of the driving wheel and the edge of the driven wheel are matched with the appearance of a mouth part of a workpiece undergoing necking machining, a working platform is parallelly arranged on one side of the driving wheel and the driven wheel in a spaced mode, and a crank sliding block rotation mechanism makes the working platform rotate in the same plane in the radial direction of the driving wheel. A height adjusting device is arranged at the bottom of the working platform, two ends of a clamping mechanism are arranged on the upper side and the lower side of the working platform, the action executing end clamps a workpiece cavity, and a positioning mechanism matched with the appearance of the workpiece to be machined is arranged on the upper surface of the working platform. The technical problem that the workpiece necking machining requirement is difficult to meet is effectively solved, and the improved non-die copy necking system has the advantages of better meeting the workpiece machining requirement and being ingenious in design, easy to control automatically and the like.

Owner:河北华春液压汽配有限公司

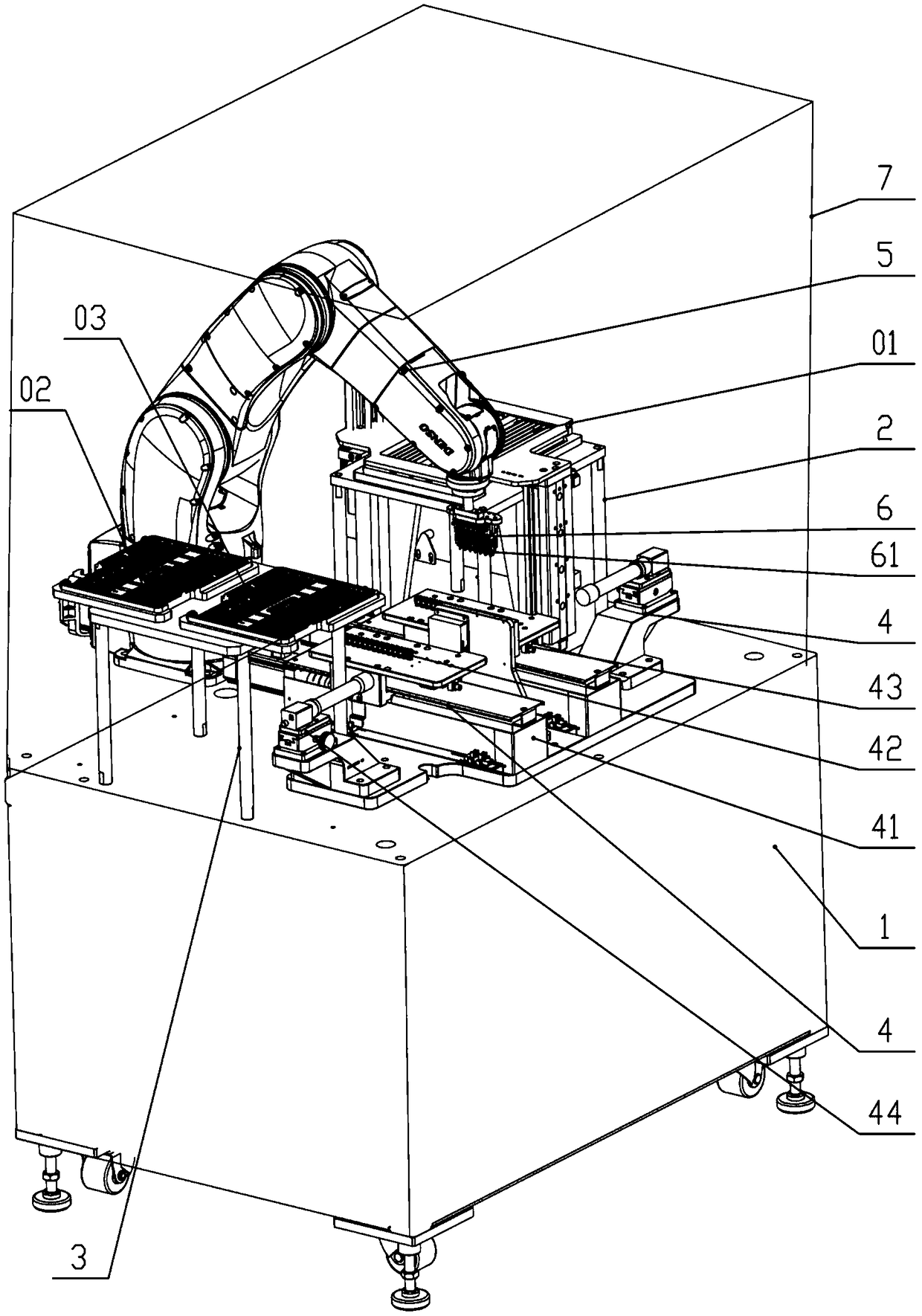

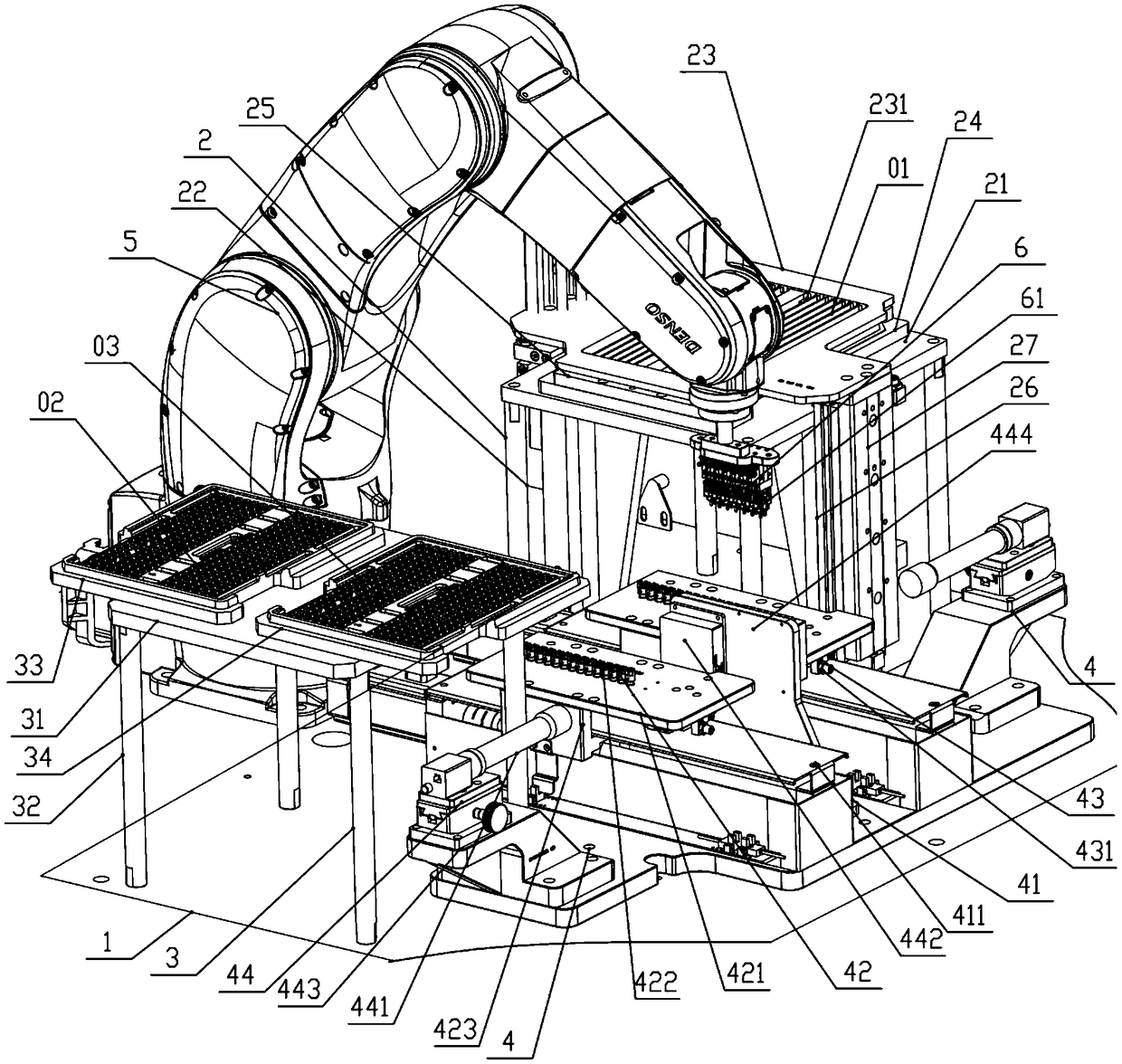

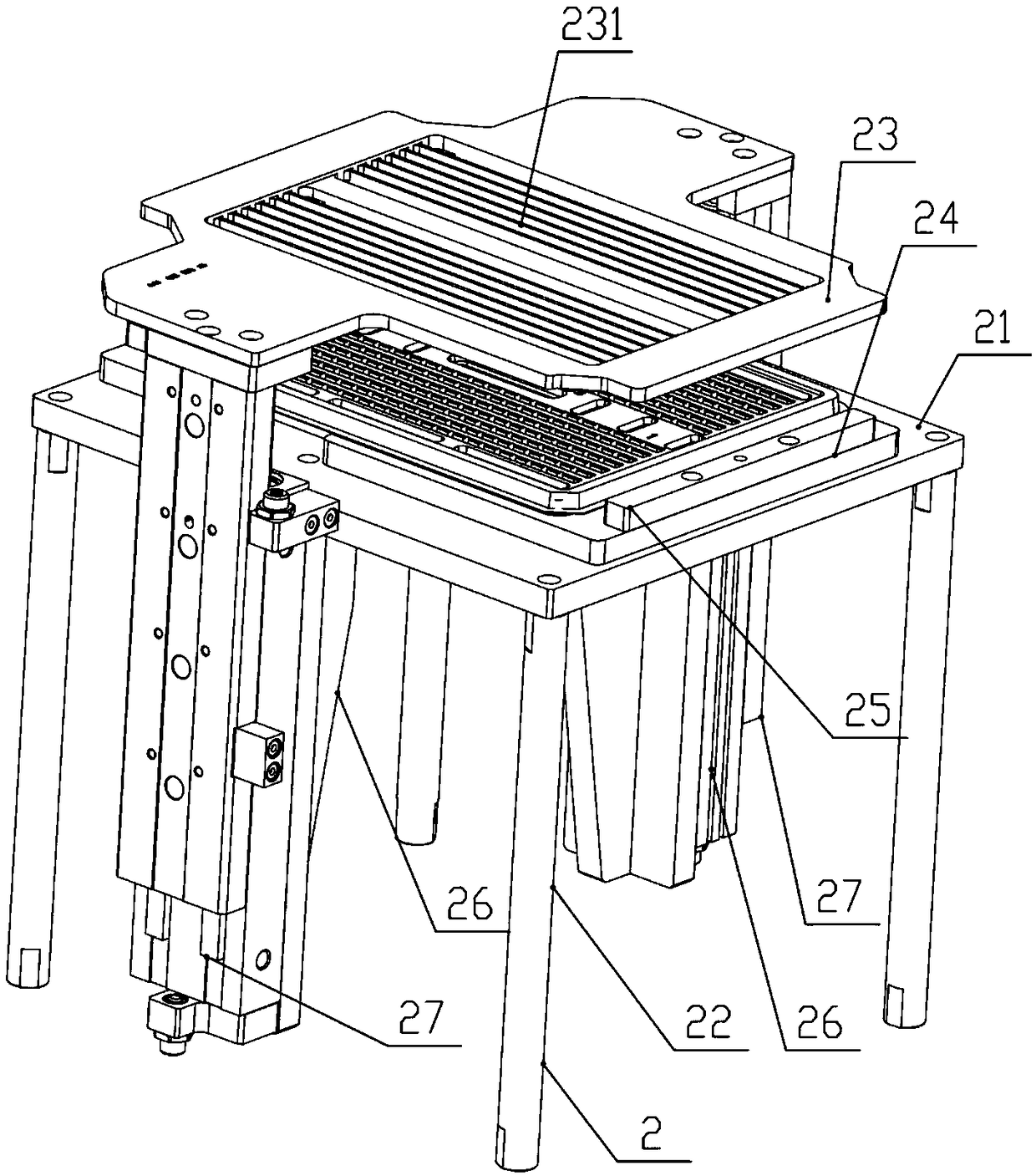

Automatic detection machine for perpendicularity and height of mute key

The invention discloses an automatic detection machine for the perpendicularity and height of a mute key. The automatic detection machine comprises a workbench; a loading part is fixed on one side ofthe front side of the workbench; a first plastic suction cup can be placed on the loading part; a discharge part is fixed on the other side of the front end of the workbench; an accepted-product plastic suction cup and a defective-product plastic suction cup can be placed on the discharge part side by side; a mechanical arm is fixed at the middle part of the rear end of the workbench; a clamping jaw module is installed at the lower end of the chunk of the mechanism arm; multiple suction nozzles are installed on the clamping jay module; the suction nozzles can absorb or release products; a sizedetection part comprises a straight line module, a positioning component, an angle adjustment component and a visual measurement component; the straight line module moves, so that the product on eachpositioning fixture enters a detection position in sequence, the product can rotate for 90 degrees via the angle adjustment component, and the visual detection component can sequentially detect the parameters of different surfaces of the product. The machine provided by the invention has the effect of being mechanical in placement and detection, high in placement position degree and high in measurement accuracy.

Owner:DONGGUAN SHENGXIANG PRECISION METAL

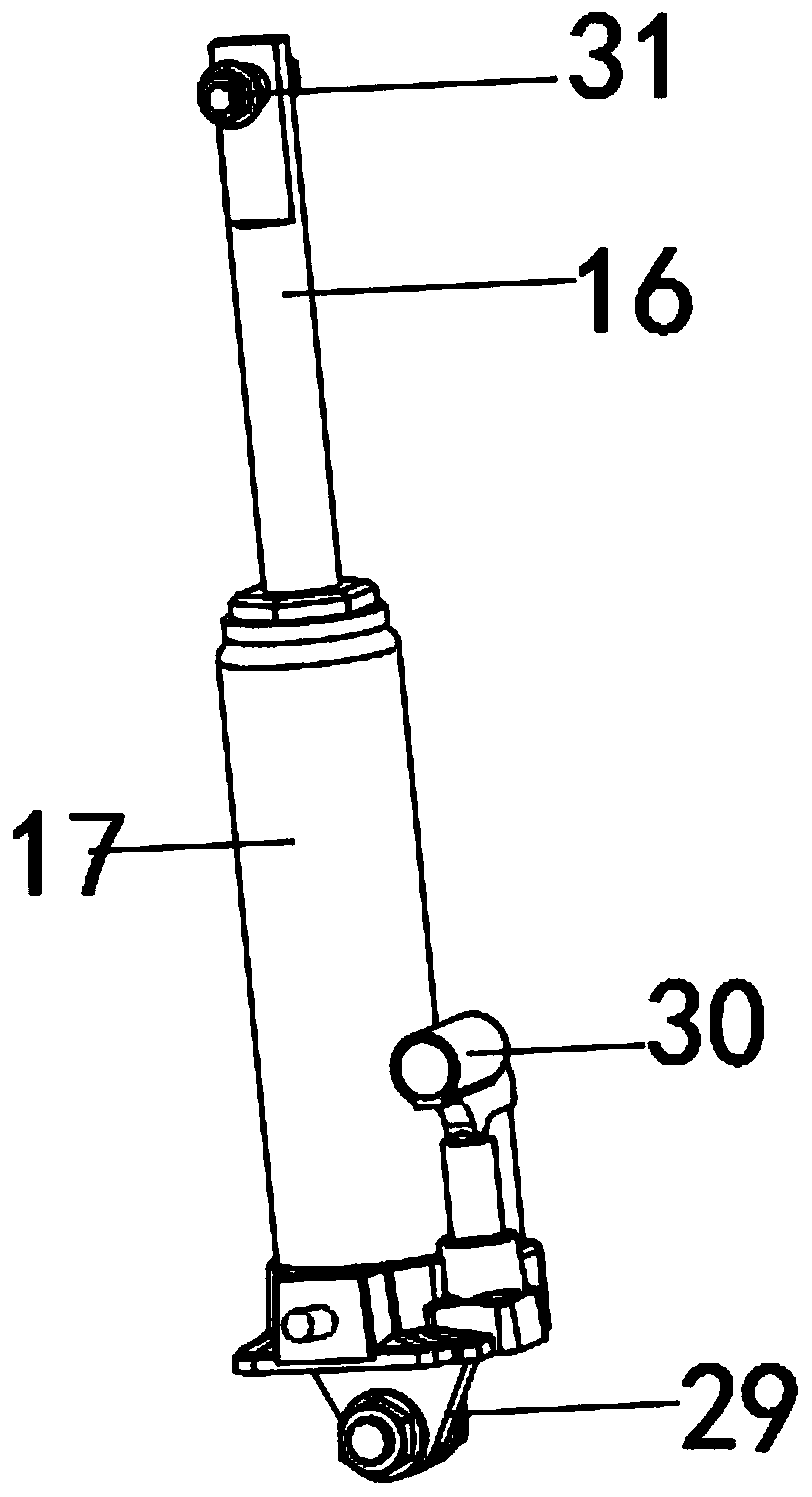

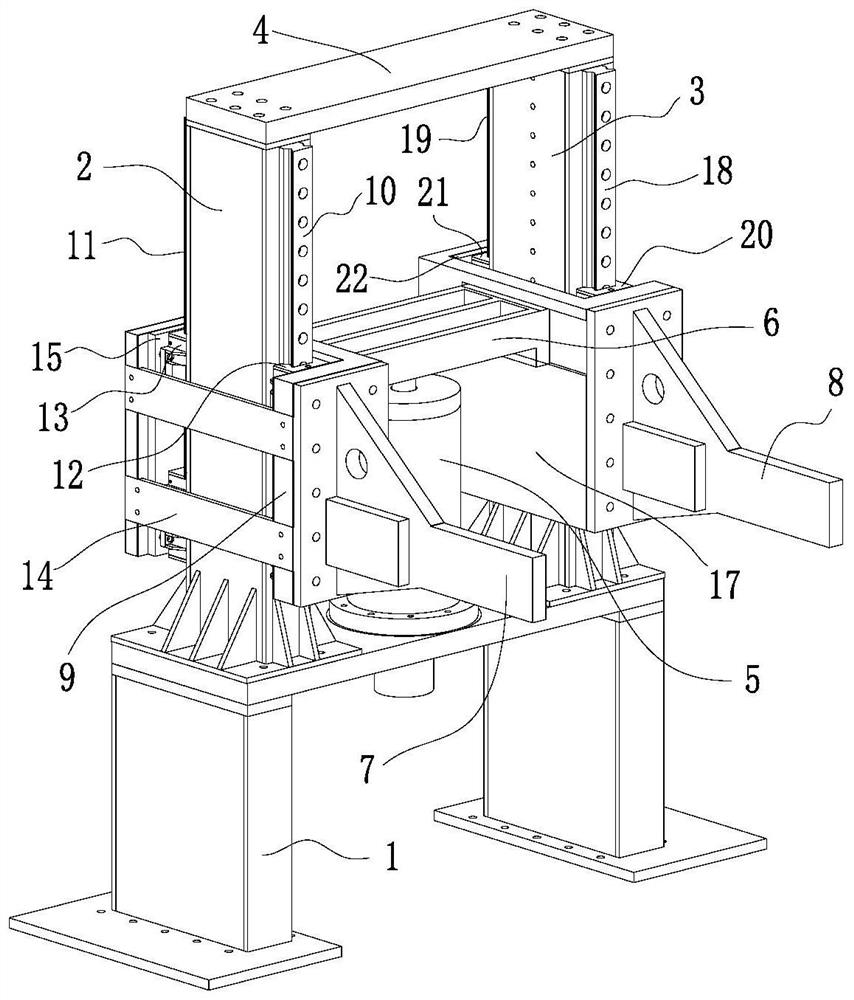

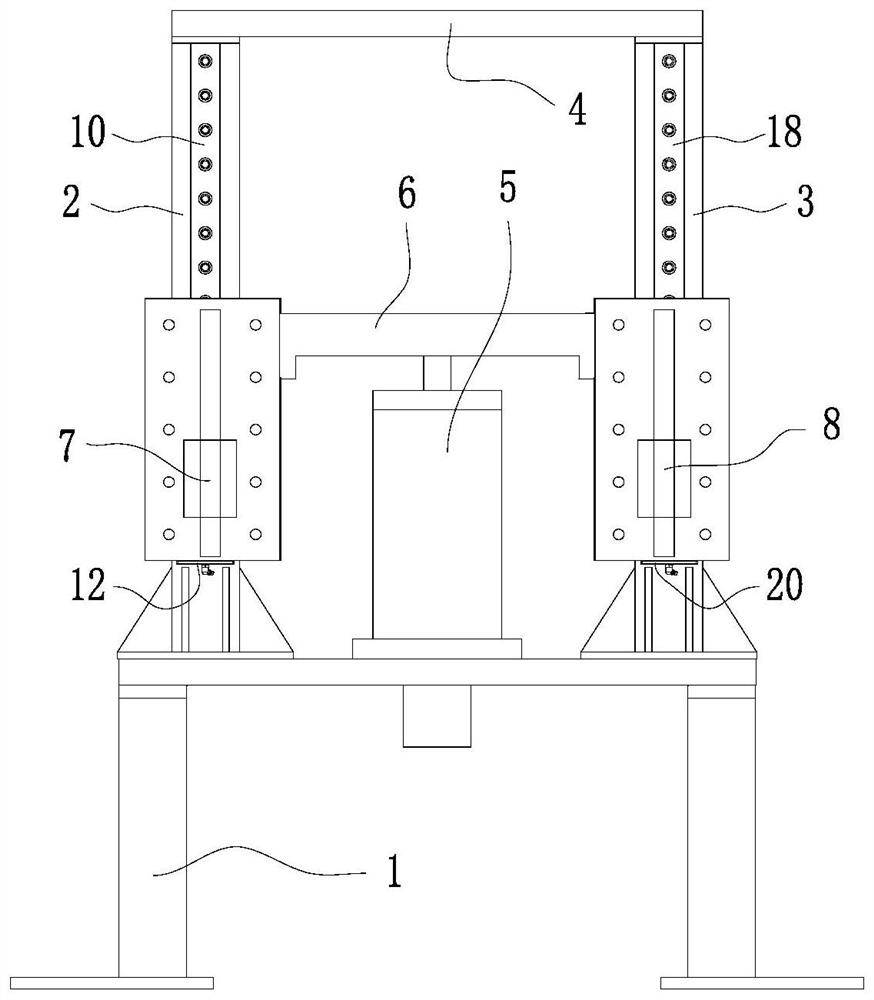

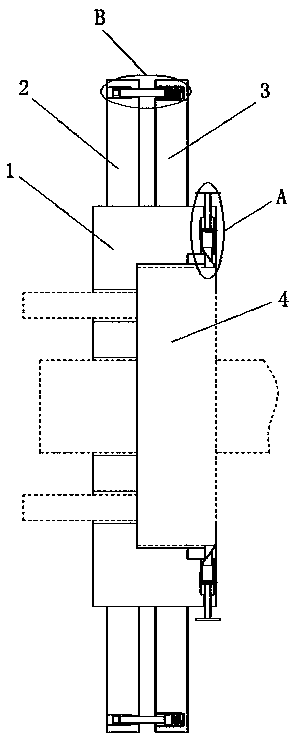

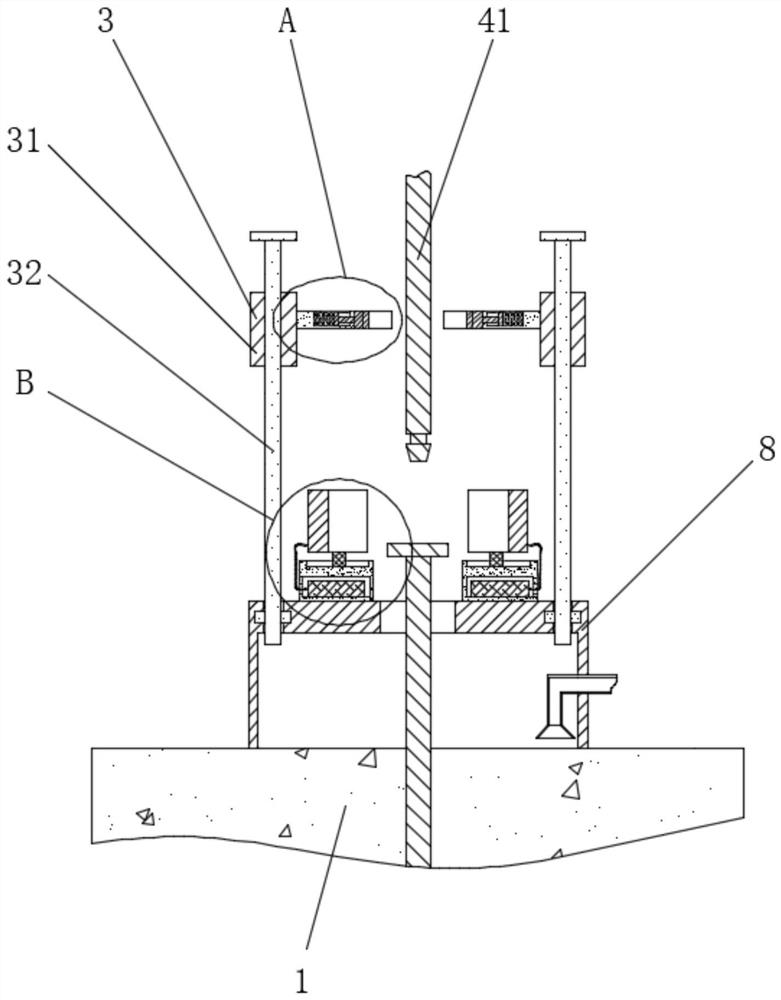

Hoisting device for rapid lifting of pressure chamber of true triaxial testing machine

PendingCN112816318AAvoid wiggle phenomenonImprove fatigue resistanceMaterial strength using tensile/compressive forcesHydraulic cylinderTriaxial shear test

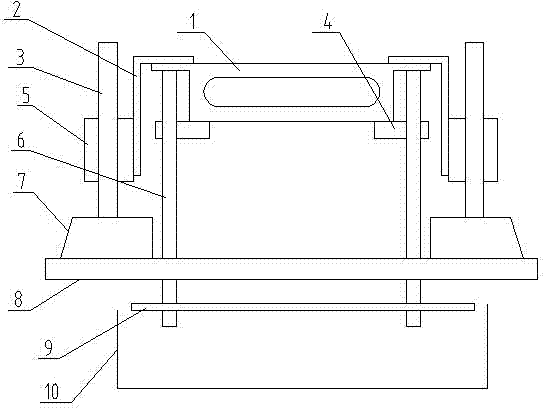

The invention discloses a hoisting device for rapidly lifting of a pressure chamber of a true triaxial testing machine. Two stand columns are vertically and fixedly arranged at the top of a base, and the top ends of the two stand columns are fixedly connected through a cross beam; a lifting hydraulic cylinder is vertically and fixedly installed on the top of the base, a piston rod is arranged upwards, and the lifting hydraulic cylinder is located in the middle of the two stand columns; a lifting beam is horizontally and fixedly arranged at the top end of the piston rod of the lifting hydraulic cylinder, one end of the lifting beam is connected with the first stand column through a first lifting guide assembly, and the other end is connected with the second stand column through a second lifting guide assembly; a first lifting support arm is mounted on the first lifting guide assembly and synchronously moves along with the lifting beam; a second lifting support arm is mounted on the second lifting guide assembly and synchronously moves along with the lifting beam; a first support arm insertion lifting lug and a second support arm insertion lifting lug are respectively mounted on the pressure chamber, and the two support arm insertion lifting lugs are in one-to-one correspondence with the two lifting support arms in position; and the first lifting support arm is matched with the first support arm insertion lifting lug in an insertion mode, and the second lifting support arm is matched with the second support arm insertion lifting lug in an insertion mode.

Owner:BACKFILL ENG LAB SHANDONG GOLD MINING TECH CO LTD +1

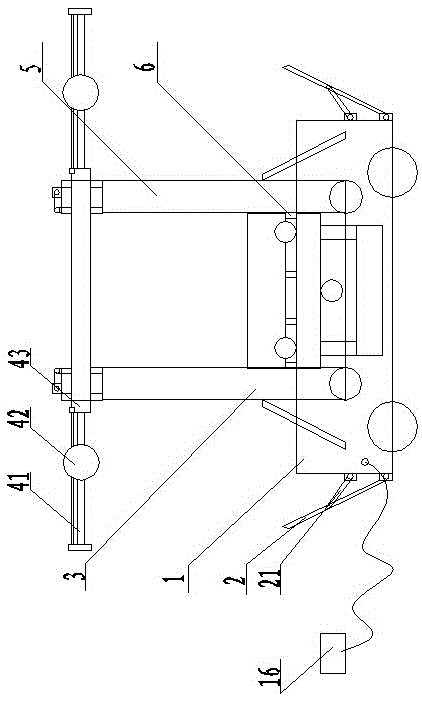

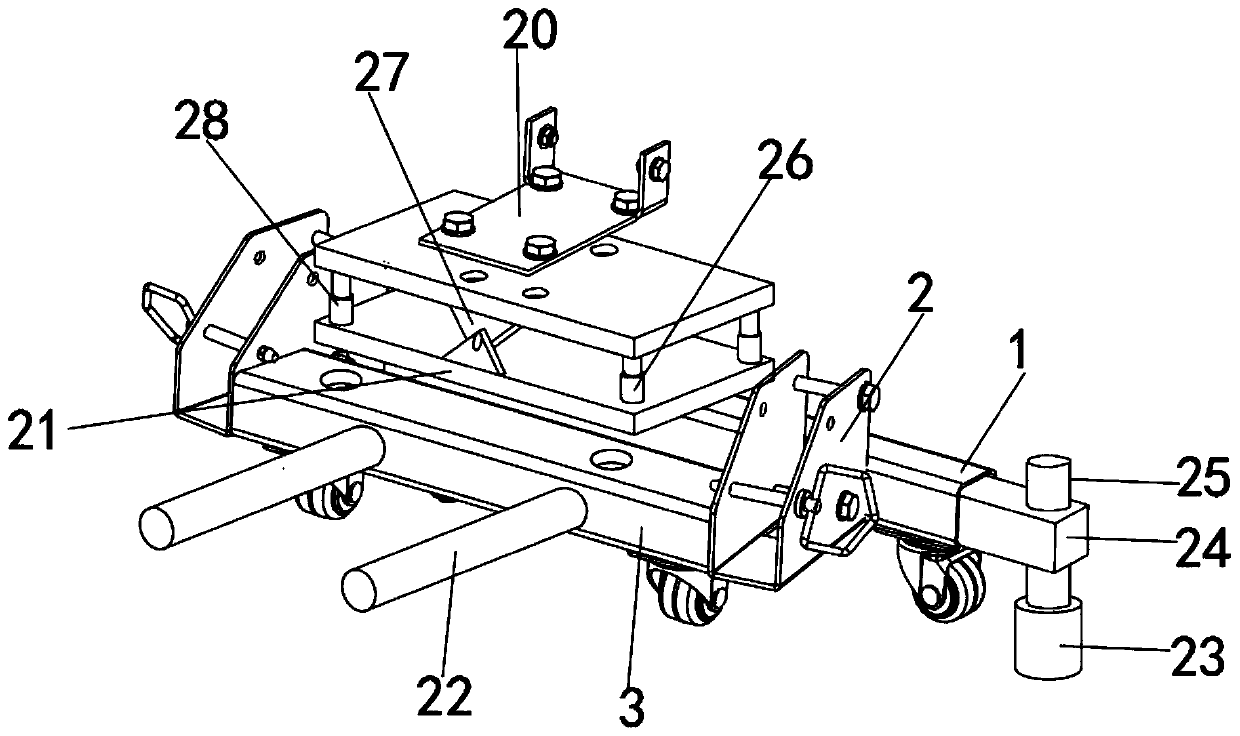

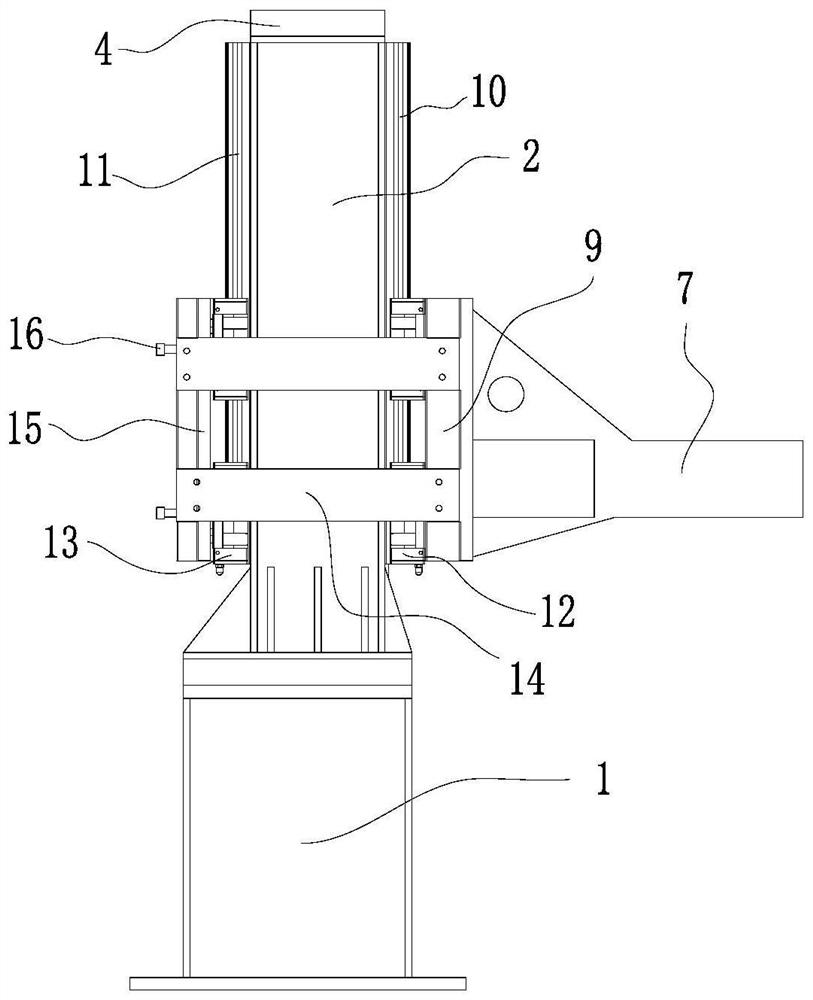

Double hook automatic hoisting structure and hoisting method

InactiveCN108263951AAvoid wiggle phenomenonEnsure safetyTravelling cranesTravelling gearSynchronous controlControl system

The invention relates to a double hook automatic hoisting structure and a hoisting method, and a front and back movement position, a lifting position and a hoisting position of each station are determined by a servo control system at a winding forming station, a cooling setting station and a demolding station in a composite pressure pipe production line so as to conduct precise hoisting. The hoisting structure includes a PLC, a moving crane rack, a left crane and a right crane; the left crane and the right crane are installed at the two ends of the moving crane rack, and the left crane and theright crane move up or down synchronously under the control of the PLC. The hoisting structure has the advantages that firstly, hook lifting guide shafts are used for guiding design to avoid the swing phenomenon of left and right lifting hooks during the lifting process, the synchronous control of lifting positions of the left and right lifting hooks is achieved in hoisting, and the stationarityof a hoisted mould in the lifting is ensured; secondly, hoisting rods are detected by detector switches on the lifting hooks, so that the safety of the hoisting is ensured.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

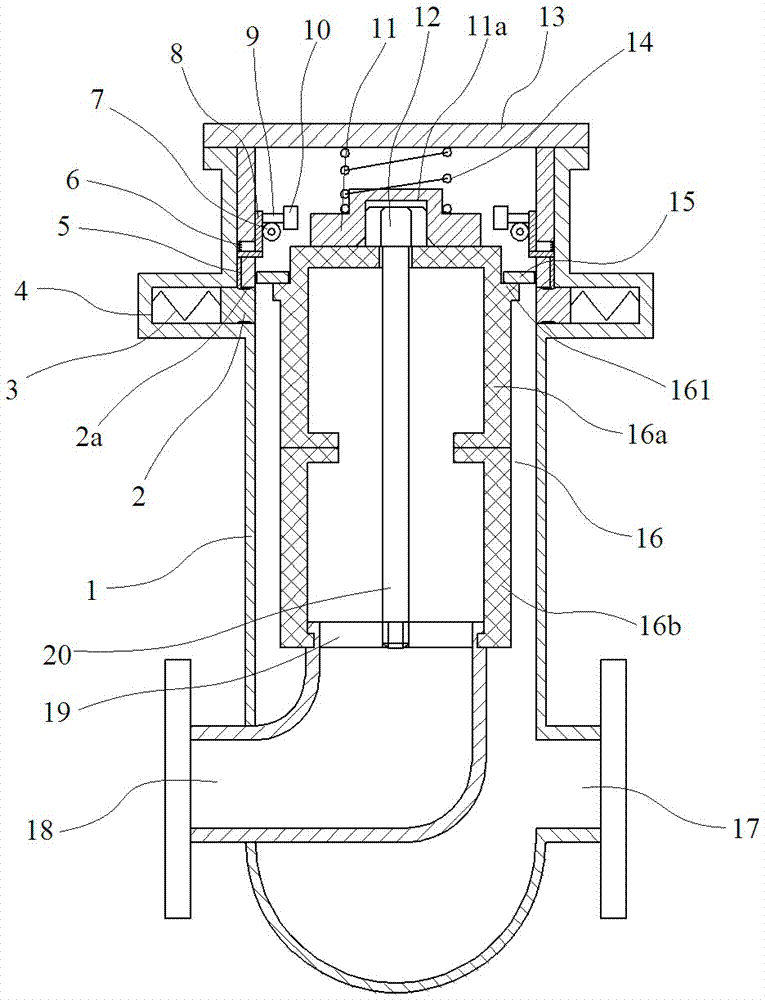

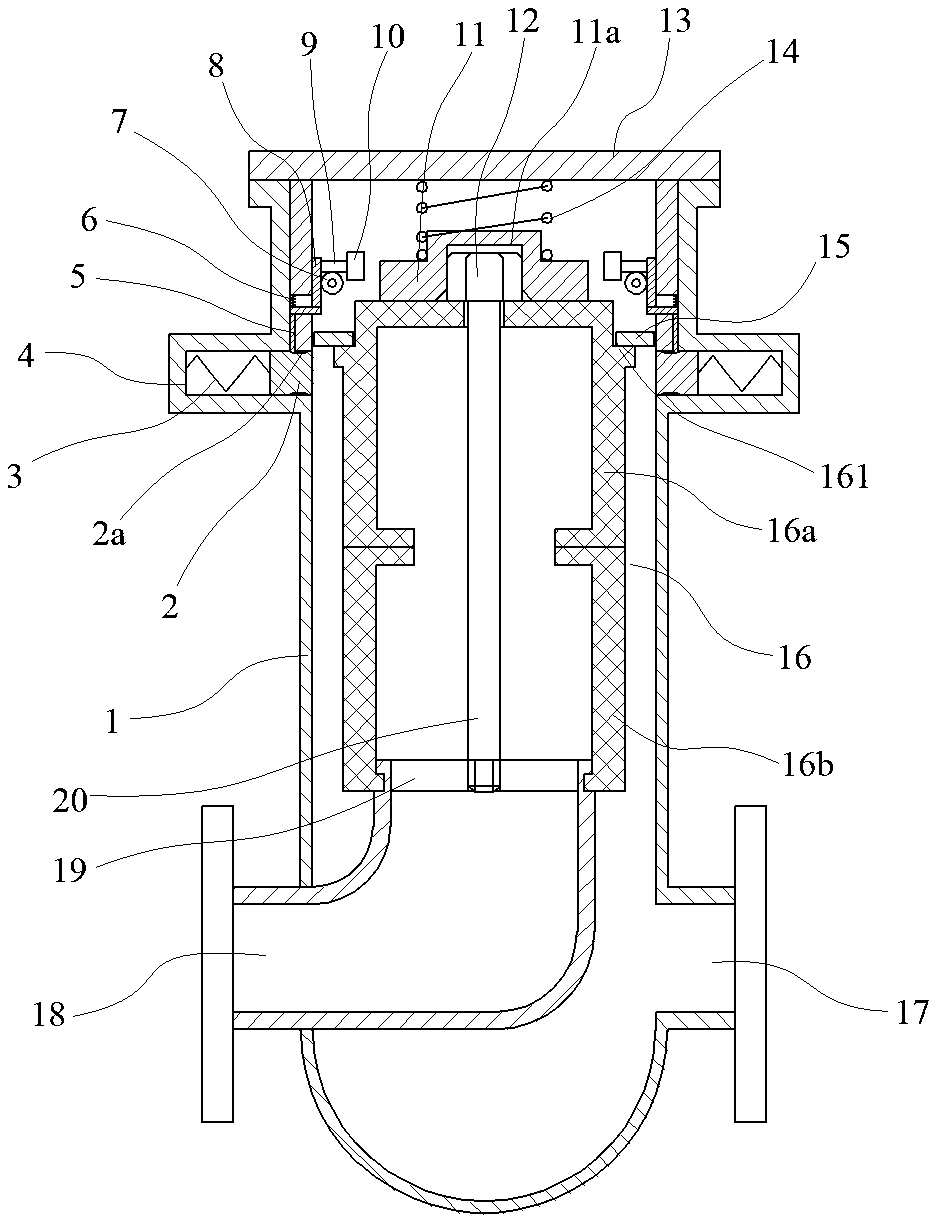

Natural gas inlet filter device

ActiveCN107224792APrecise positioningEasy to fixDispersed particle filtrationGaseous fuelsInlet channelEngineering

The invention discloses a natural gas inlet filter device. The natural gas inlet filter device comprises a filter cylinder and a filter element vertically arranged in the filter cylinder, wherein the filter cylinder is provided with an inlet channel communicating with the outside of the filter element and an outlet channel communicating with the inside of the filter element; the middle of the filter element is provided with a fixing screw rod vertically arranged; the filter element is fixedly connected with the top of the outlet channel through the fixing screw rod; the top of the filter element is provided with a positioning seat compacting the filter element downwards; an annular sheet capable of vertically moving along the filter cylinder under the action of the air pressure and a cushion chamber communicating with the filter cylinder are arranged in the filter cylinder; a piston and a piston spring for resetting the piston to the opening of the cushion chamber are arranged in the cushion chamber; and a spacing pin for releasing the spacing of the piston and the cushion chamber when the annular sheet moves upwards is arranged in the filter cylinder. The invention aims to provide a natural gas inlet filter device which effectively prevents a filter element from being damaged.

Owner:浙江大唐国际江山新城热电有限责任公司

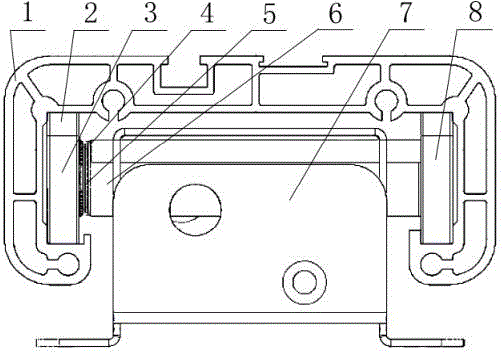

Brake disc capable of avoiding swing phenomenon

InactiveCN109386559AAvoid wiggle phenomenonWobble reliefBraking discsEngineeringMechanical engineering

The invention discloses a brake disc capable of avoiding a swing phenomenon, which comprises a sleeve, wherein one side of the sleeve is provided with an opening, a first disc is fixedly connected with the sleeve, a second disc fixedly connected with the sleeve in a sleeve mode is arranged on one side of the first disc, close to the opening of the sleeve, a chuck is arranged in the sleeve, a locking module is arranged between the sleeve and the chuck, and a disc adjusting module is arranged between the first disc and the second disc. According to the invention, the swing phenomenon caused by loosening of fixing screws can be effectively avoided through the locking module, and the swing phenomenon caused by abrasion of the disc can be relieved through the disc adjusting module, so that thesafety of the brake system is improved.

Owner:MEIZHOU HONGYU AUTO PARTS MFG CO LTD

Edge-trimming cutter device of belt core

ActiveCN104260124AAvoid wiggle phenomenonCan't solve itMetal working apparatusEngineeringDisc cutter

The invention discloses an edge-trimming cutter device of a belt core. The device comprises a glue returning portion (1), an edge trimming portion (2) and a compressing portion (3). The glue returning portion (1) is fixed to one end of a right-angle frame (4); the other end of the right-angle frame (4) is fixed to a support of the compressing portion (3); the edge trimming portion (2) is fixed to the side face of the compressing portion (3). According to the edge-trimming cutter device of the belt core, a manual edge-trimming cutter structure is adopted, the phenomena that a disc cutter cannot thoroughly cut the edge, and smoking happens are avoided, and the edge trimming quality is ensured. Due to the fact that a compressing roller structure is adopted in the design, in the cutting process, the belt core can be in the tightening state, and in the cutting process, the belt core is prevented from swinging. Due t o the fact that a straight-plate cutter structure of a groove blade is adopted in the design, it is ensured that cutting and feeding are smooth, and the cutting quality is ensured. Due to the fact that a glue side returning structure is adopted in the design, removal glue sides can be returned into a recycling hopper.

Owner:大连橡胶塑料机械有限公司 +1

Edge cutting device with core

ActiveCN104260124BAvoid wiggle phenomenonGuarantee trimming qualityMetal working apparatusCircular discEngineering

The invention discloses an edge-trimming cutter device of a belt core. The device comprises a glue returning portion (1), an edge trimming portion (2) and a compressing portion (3). The glue returning portion (1) is fixed to one end of a right-angle frame (4); the other end of the right-angle frame (4) is fixed to a support of the compressing portion (3); the edge trimming portion (2) is fixed to the side face of the compressing portion (3). According to the edge-trimming cutter device of the belt core, a manual edge-trimming cutter structure is adopted, the phenomena that a disc cutter cannot thoroughly cut the edge, and smoking happens are avoided, and the edge trimming quality is ensured. Due to the fact that a compressing roller structure is adopted in the design, in the cutting process, the belt core can be in the tightening state, and in the cutting process, the belt core is prevented from swinging. Due t o the fact that a straight-plate cutter structure of a groove blade is adopted in the design, it is ensured that cutting and feeding are smooth, and the cutting quality is ensured. Due to the fact that a glue side returning structure is adopted in the design, removal glue sides can be returned into a recycling hopper.

Owner:大连橡胶塑料机械有限公司 +1

A natural gas intake filter device

ActiveCN107224792BPrecise positioningEasy to fixDispersed particle filtrationGaseous fuelsInlet channelEngineering

The invention discloses a natural gas inlet filter device. The natural gas inlet filter device comprises a filter cylinder and a filter element vertically arranged in the filter cylinder, wherein the filter cylinder is provided with an inlet channel communicating with the outside of the filter element and an outlet channel communicating with the inside of the filter element; the middle of the filter element is provided with a fixing screw rod vertically arranged; the filter element is fixedly connected with the top of the outlet channel through the fixing screw rod; the top of the filter element is provided with a positioning seat compacting the filter element downwards; an annular sheet capable of vertically moving along the filter cylinder under the action of the air pressure and a cushion chamber communicating with the filter cylinder are arranged in the filter cylinder; a piston and a piston spring for resetting the piston to the opening of the cushion chamber are arranged in the cushion chamber; and a spacing pin for releasing the spacing of the piston and the cushion chamber when the annular sheet moves upwards is arranged in the filter cylinder. The invention aims to provide a natural gas inlet filter device which effectively prevents a filter element from being damaged.

Owner:浙江大唐国际江山新城热电有限责任公司

A Stirring Guide Positioning Mechanism for Diamond Cutting Wire Production Equipment

InactiveCN102862241BCause deteriorationSimple structureFine working devicesDiamond cuttingEngineering

The invention discloses a stirring guide and location mechanism for diamond cutting line production equipment, comprising a slide way, a stirring rod on the slide way, and a stirrer at the lower end of the stirring rod, wherein a plating solution groove is arranged below the stirrer; a fixed frame is arranged above the plating solution groove; oil receiving boxes are arranged at the both ends of the fixed frame; guide rods are arranged in the inner directions of the oil receiving boxes; slide blocks are sleeved on the guide rods; and the slide blocks are connected with the slide way via connection plates. During the use of the stirring guide and location mechanism, a lubricating grease is added between the slide blocks and the guide rods, a friction force between the guide rods and the slide blocks achieves the minimum under the action of the lubricating grease, and the redundant lubricating grease flows downwards into the oil receiving boxes and can be recycled; the lubricating effect is good, and the deterioration of plating solution caused by the falling-off of the lubricating grease in a plating solution box can be effectively prevented, thus keeping clean and being environment-friendly; the long-time stable and continuous working, and the high production efficiency of the equipment can be ensured; and a guarantee is provided for the stable and continuous production for qualified diamond cutting lines, of the diamond cutting line production equipment.

Owner:SINO CRYSTAL PRECISION MFG

Industrial robot wrist gap debugging tooling

InactiveCN106217412BEliminate repeated disassembly and assembly proceduresReduce manufacturing costManipulatorSprocketIndustrial engineering

A tool for adjusting the wrist clearances of an industrial robot comprises a working table, a wrist fixing plate, a motor and a driving mechanism used for driving three shafts on a wrist to rotate, wherein the driving mechanism is connected with the motor, the wrist fixing plate and the motor are both mounted on the working table, the driving mechanism comprises a chain and a chain wheel, the chain wheel is mounted on a rotating shaft of the motor, one end of the chain is meshed with the chain wheel, and the other end of the chain, after penetrating through a through hole formed in the wrist fixing plate, is meshed with a chain wheel on the three shafts of the wrist. Before the wrist is assembled on the industrial robot, first, the wrist is mounted on the wrist fixing plate, then, the three shafts in the wrist are separately driven by the driving mechanism to continuously work for 120 hours, the clearances of the three shafts are fully displayed, and after no clearances exist after adjustment, the wrist is mounted on the industrial robot at a time. In conclusion, a following wrist disassembling and assembling procedure is omitted in a mode of previously adjusting the clearances of the wrist, so that the production cost of enterprises is greatly saved.

Owner:ANHUI LEADING PRECISION TECH

Ground source heat pump hole well construction device with residual material collecting function

ActiveCN113898292APrevent movementAvoid wiggle phenomenonDrilling rodsConstructionsDetentWaste material

The invention discloses a ground source heat pump hole well construction device with a residual material collecting function. The ground source heat pump hole well construction device comprises a positioner, a power frame, a base and a protective cover, the base and the protective cover are both fixedly installed on the ground, the positioner comprises a positioning ring and a fixing seat, the fixing seat is fixedly installed above the protective cover, the positioning ring is installed above the fixing seat in a sliding mode, coils are fixedly installed at the front end and the rear end of the interior of the positioning ring, compared with a current construction device, the poisoner, a shock absorber, a collecting box, a cleaner and the protective cover are additionally arranged, the trouble that a constructor manually supports a drill rod is avoided through the positioner, the vibration amplitude of the drill rod can be effectively reduced through the shock absorber, the phenomenon of muddy water turbulence can be greatly avoided through cooperation of the protective cover and the collecting box, waste generated in the construction process is collected and treated in a unified mode, and the surface of the drill rod can be cleaned through the cleaner.

Owner:LONGYAN UNIV

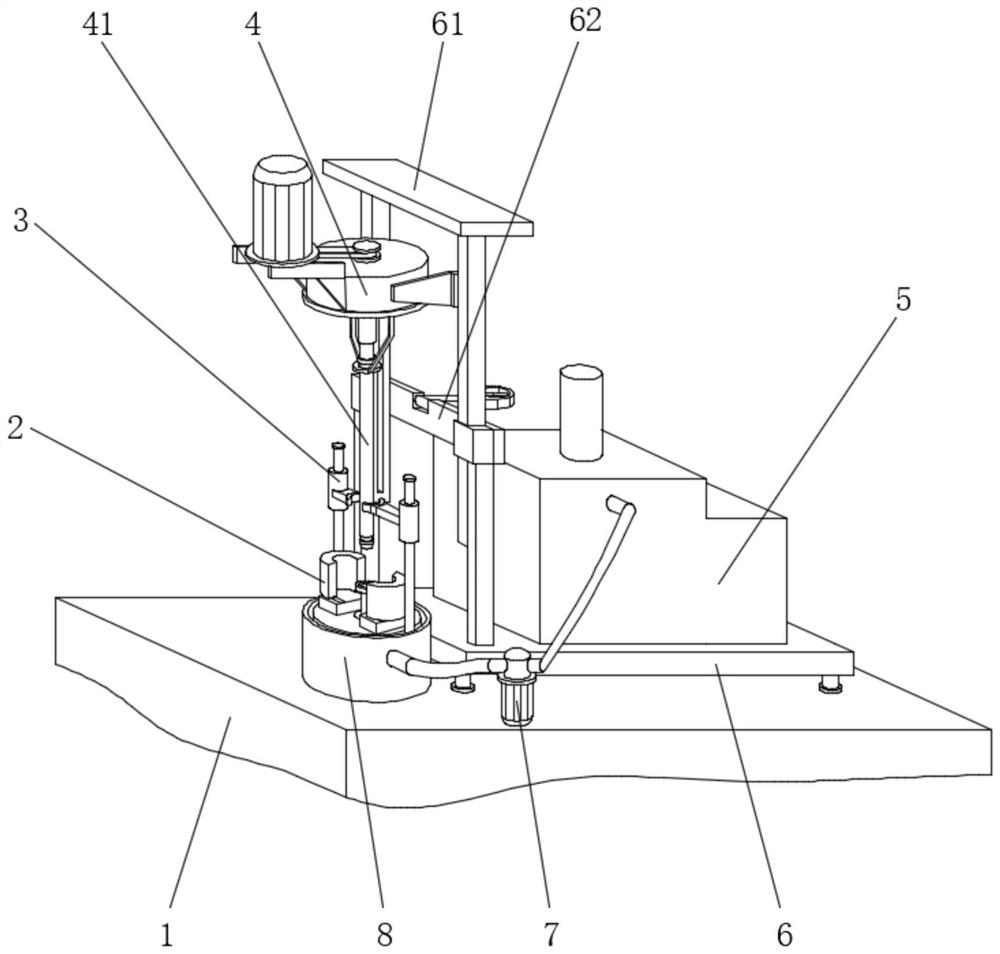

Rotation durability testing device for whip-shaped lock

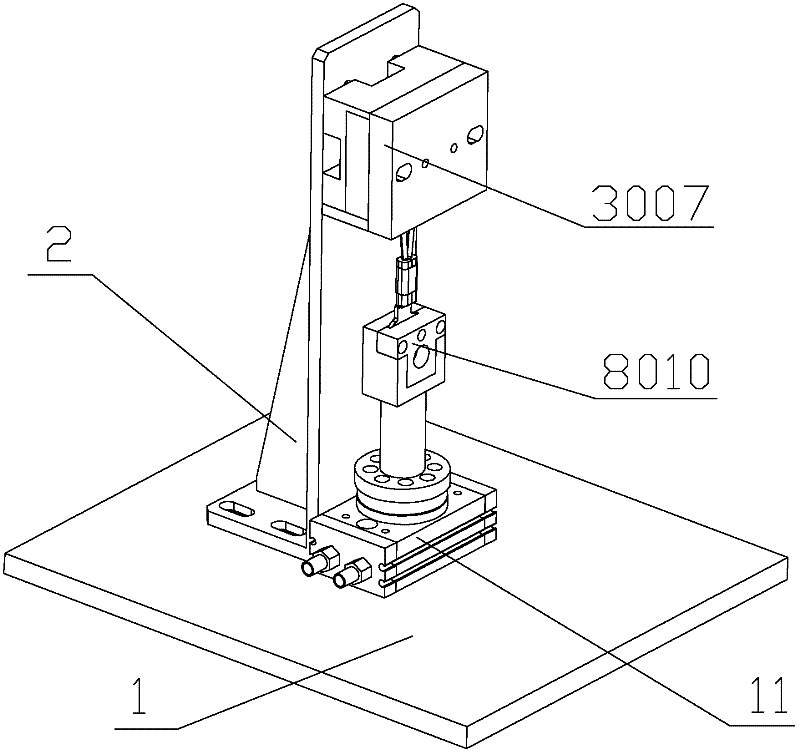

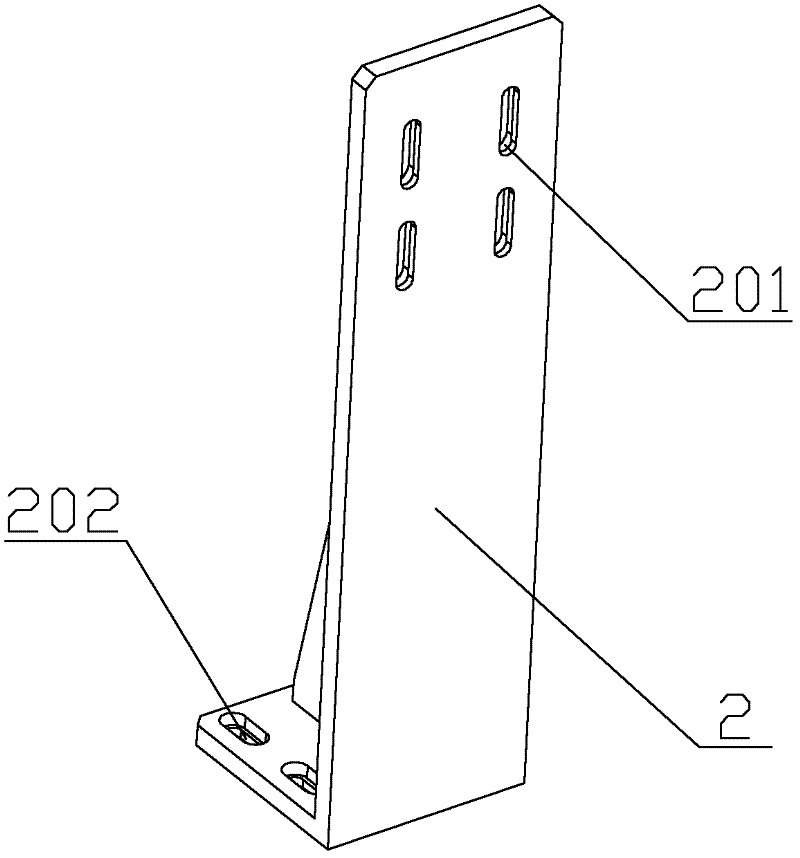

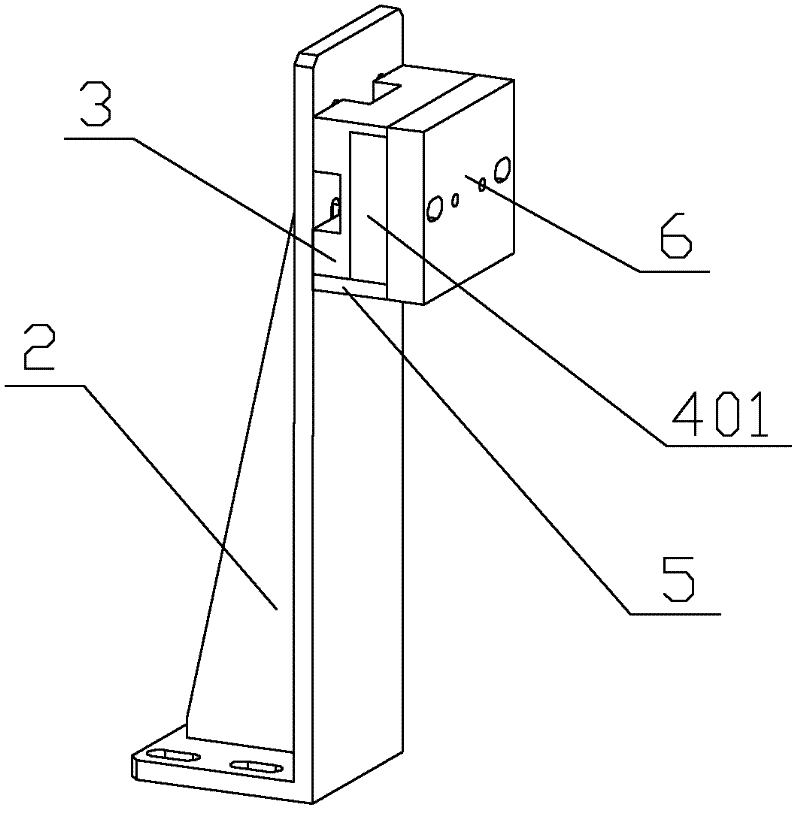

ActiveCN102445332AImprove accuracy and completenessSimple structureMachine part testingEngineeringDurability testing

The invention discloses a rotation durability testing device for a whip-shaped lock. The device comprises a working platform (1), a welding crow foot (2) and a swinging platform (11), wherein the welding crow foot (2) is fixed on the working platform (1); a lock catch clamp assembly (3007) for fixing a whip-shaped lock catch is fixed on the welding crow foot (2); the swinging platform (11) which is fixed on the working platform (1); and a rotation clamp assembly (8010) is fixed on the swinging platform (11). In the rotation durability testing device with a special structure for the whip-shaped lock, appropriate clamps are selected for measuring whip-shaped locks of different models, so that the problem of insufficient clamping force of a clamp on a whip-shaped lock can be effectively solved, and the phenomenon of swinging generated in the testing process of the whip-shaped lock is avoided; and the swinging frequency of the selected swinging platform is 30 times per minute, and the rotating angle is + / -80 degrees, so that the requirements of most testing can be met, and the accuracy and completeness of testing data are greatly increased.

Owner:CHERY AUTOMOBILE CO LTD

Large-scale wind turbine tower hoisting docking guide positioning device

InactiveCN103603772BAvoid wiggle phenomenonAchieve precise positioningWind motor assemblyWind energy generationWind drivenTower

A guiding and positioning device for tower barrel hoisting and abutting joint of a large wind driven generator set comprises an upper hoop device, a lower hoop device and a traction steel wire rope, wherein the upper hoop device and the lower hoop device are circular-arc-shaped and respectively comprise two half hoops symmetrical relative to a central shaft. The upper hoop device comprises an upper positioning and guiding module for positioning an upper tower barrel section and an upper tightening module for adjusting a distance between the two half hoops, wherein the upper positioning and guiding module is respectively installed in the middles of the half hoops, and the upper tightening module is connected between the two half hoops. The lower hoop device comprises a lower positioning and guiding module for positioning a lower tower barrel section and a lower tightening module for adjusting a distance between the two half hoops. One end of the traction steel wire rope penetrates a round hole in an upper hoop device chassis to be fixed in a rope feeding hole, and the other end of the traction steel wire rope penetrates a rope discharging hole and a round hole in a lower hoop device chassis to be connected with a motor on the ground. The guiding and positioning device can guide a flange bolt welded on a tower barrel to achieve quick positioning and is high in hoisting efficiency.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com