Edge cutting device with core

A trimming knife and core technology, applied in metal processing and other directions, can solve the problems of smoking, cutting through, blade pulling, etc., to achieve smooth cutting and feeding, ensure cutting quality, and ensure the effect of trimming quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

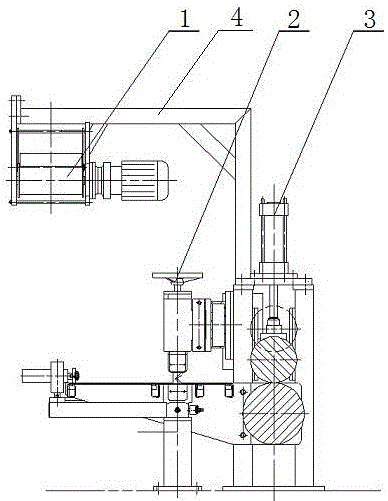

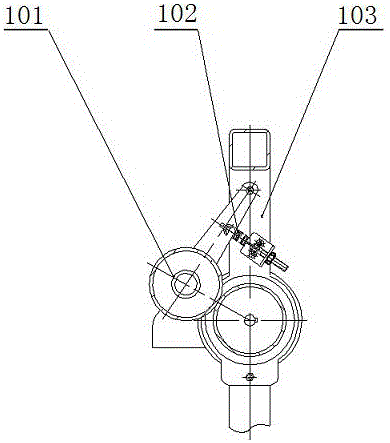

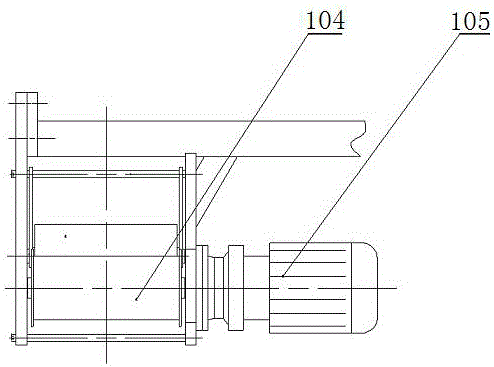

[0018] Such as Figure 1 to Figure 5 As shown, the edge trimming knife device with a core includes a glue-returning part 1, a trimming part 2 and a pressing part 3. The glue-returning part 1 is fixed on one end of the right-angle frame 4, and the other end of the right-angle frame 4 is fixed on the pressing part 3. On the bracket, the trimming part 2 is fixed on the side of the pressing part 3, and the glue returning part 1 includes a pressing roller 101, a spring 102, a pressing roller bracket 103, a traction roller 104 and a motor 105, and the pressing roller 101 is connected to the pressing part through a strut On the roller bracket 3, one end of the spring 102 is connected on the pole of the pressure roller 101, the other end is connected on the pressure roller bracket 103, the traction roller 104 is fixed on the pressure roller bracket 103, the motor 105 is connected with the traction roller 104, and the trimming Part 2 comprises handwheel 201, screw mandrel 202, sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com