Patents

Literature

52results about How to "Guarantee trimming quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

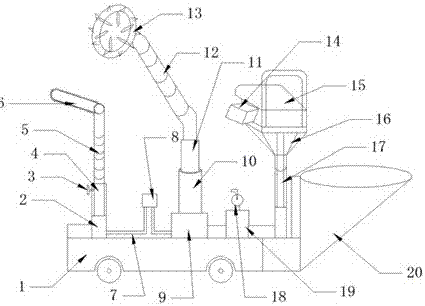

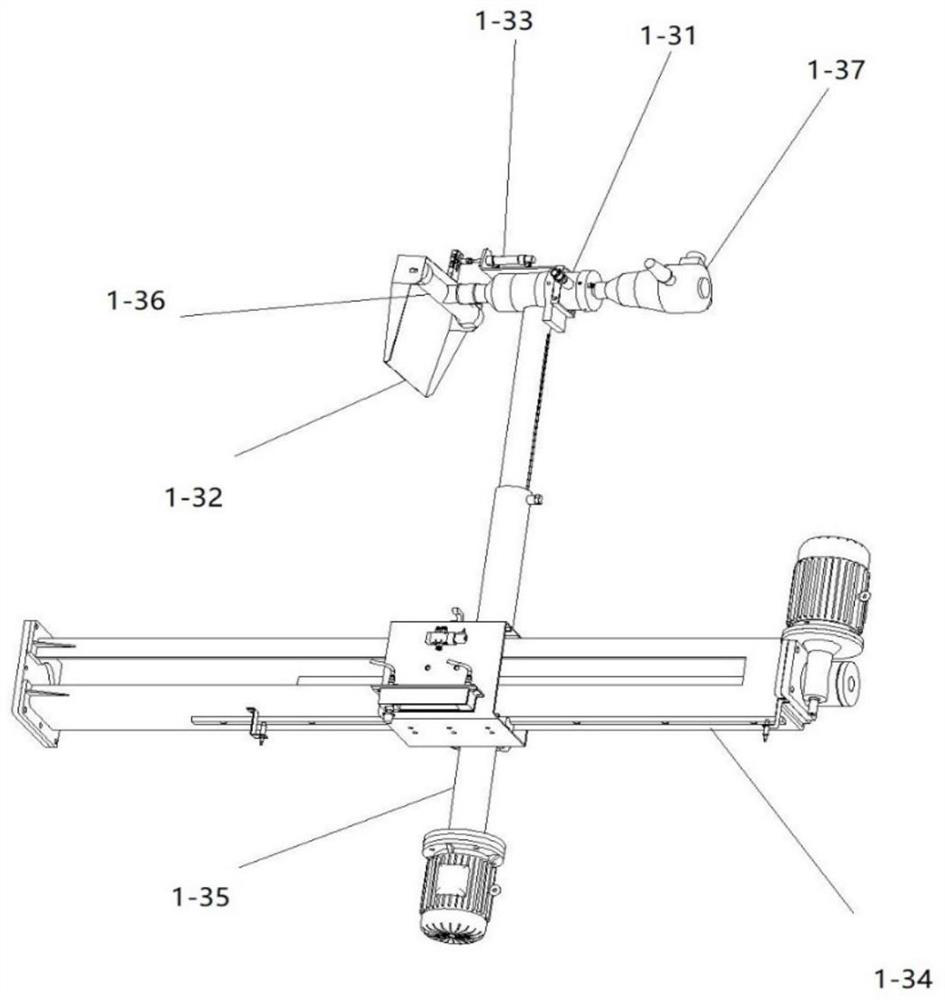

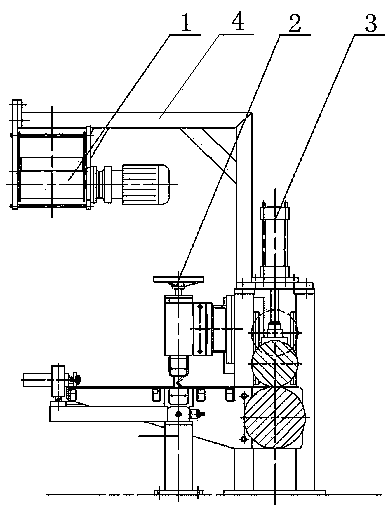

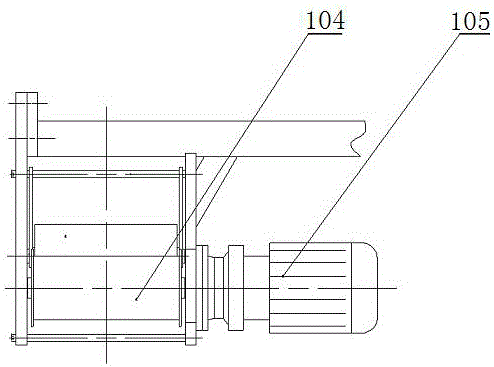

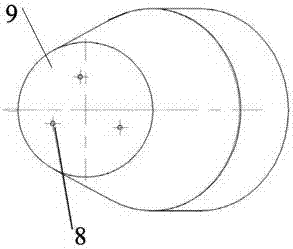

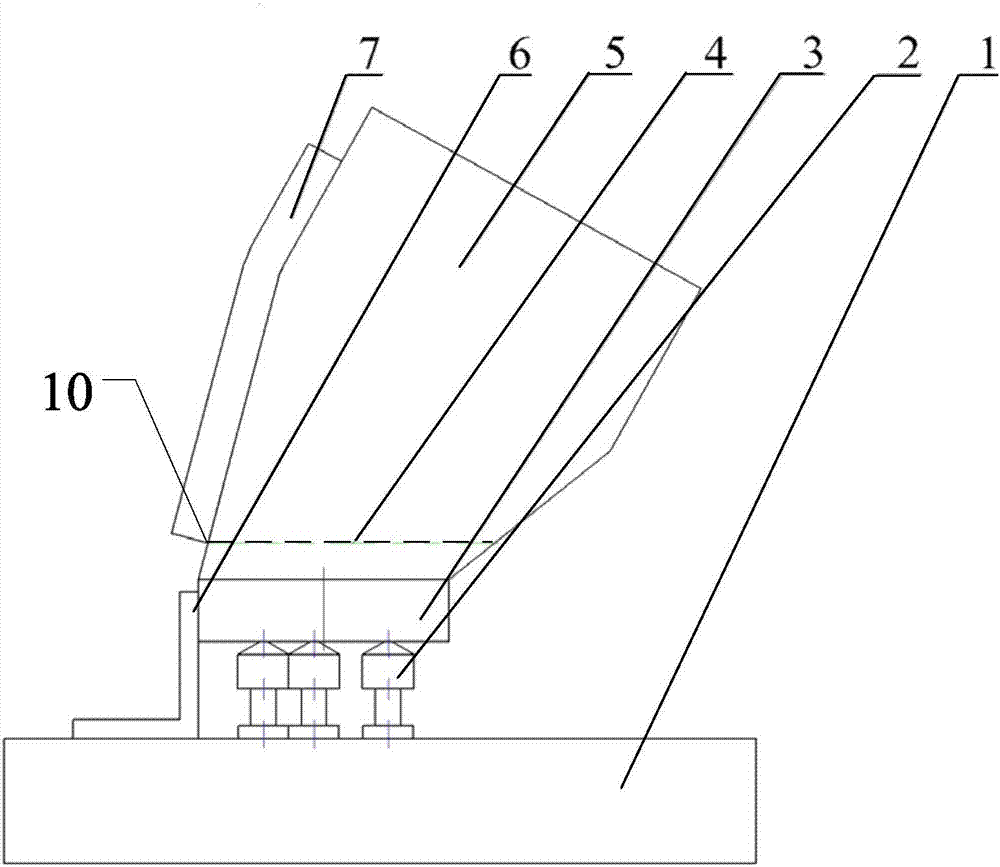

Garden trimmer

InactiveCN106212067AReduce operating intensityVariety of pruning stylesHedge trimming apparatusCuttersEngineeringVertical shear

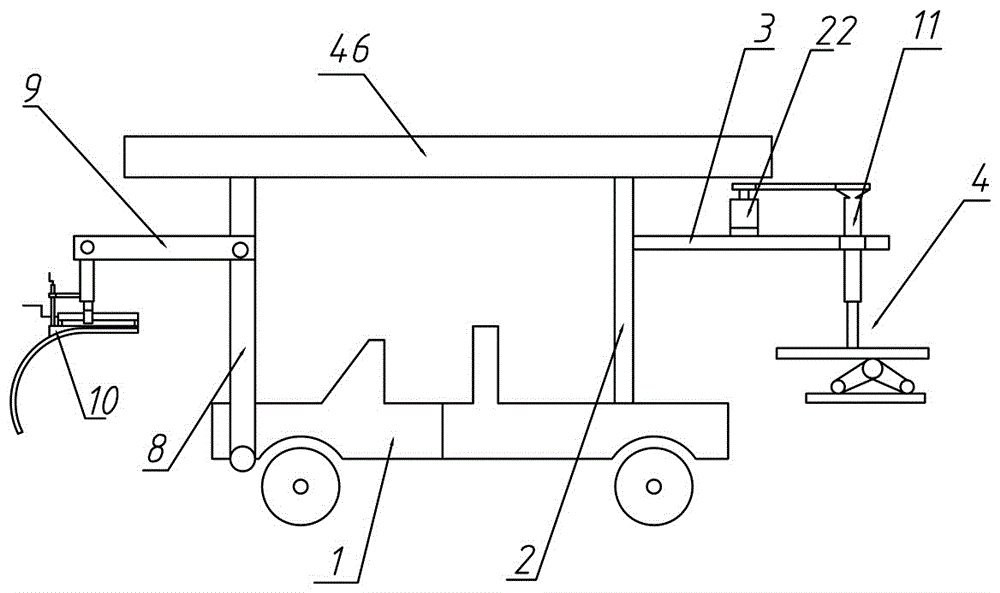

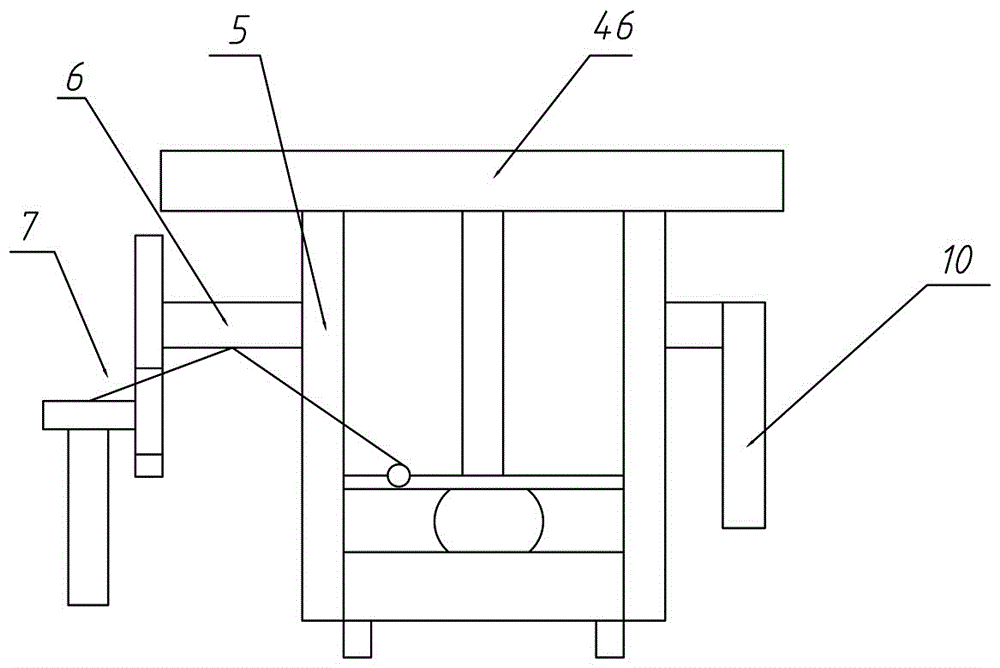

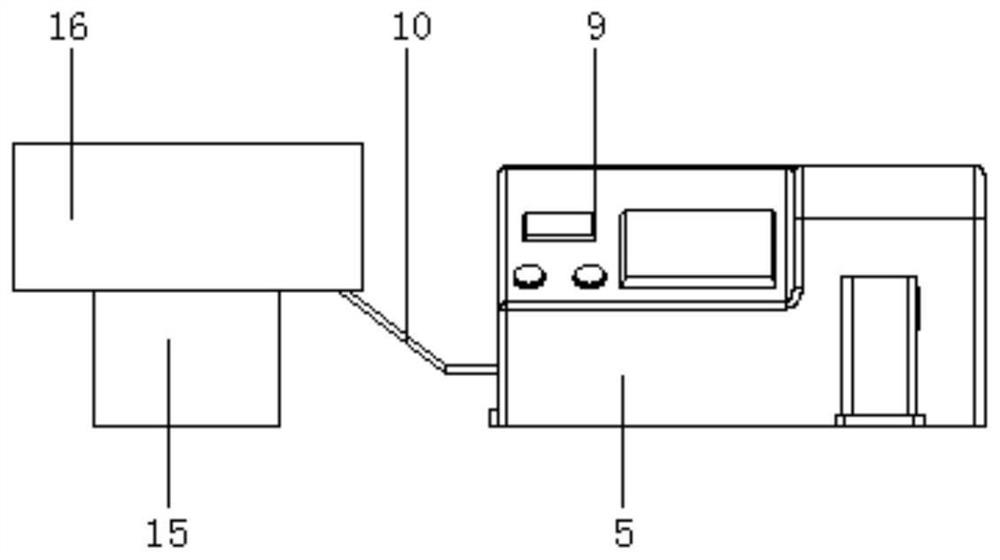

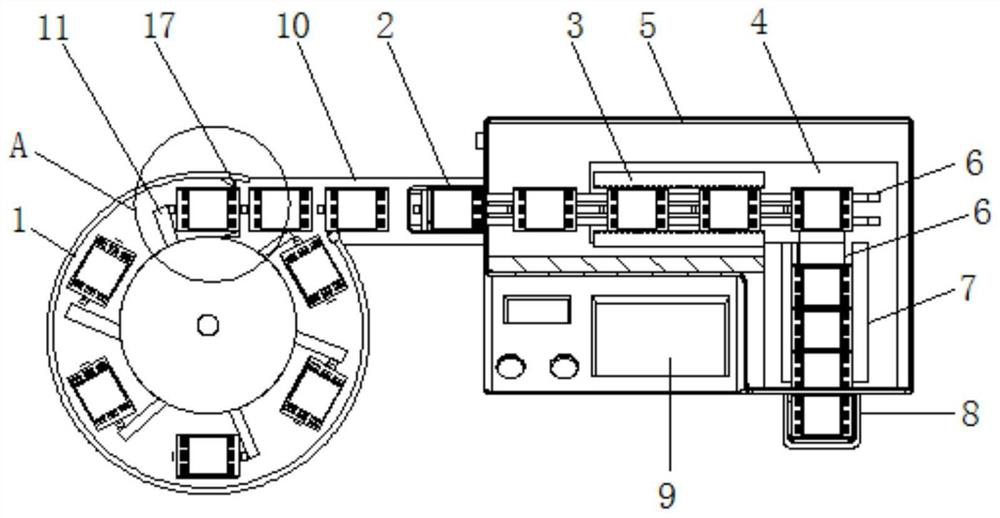

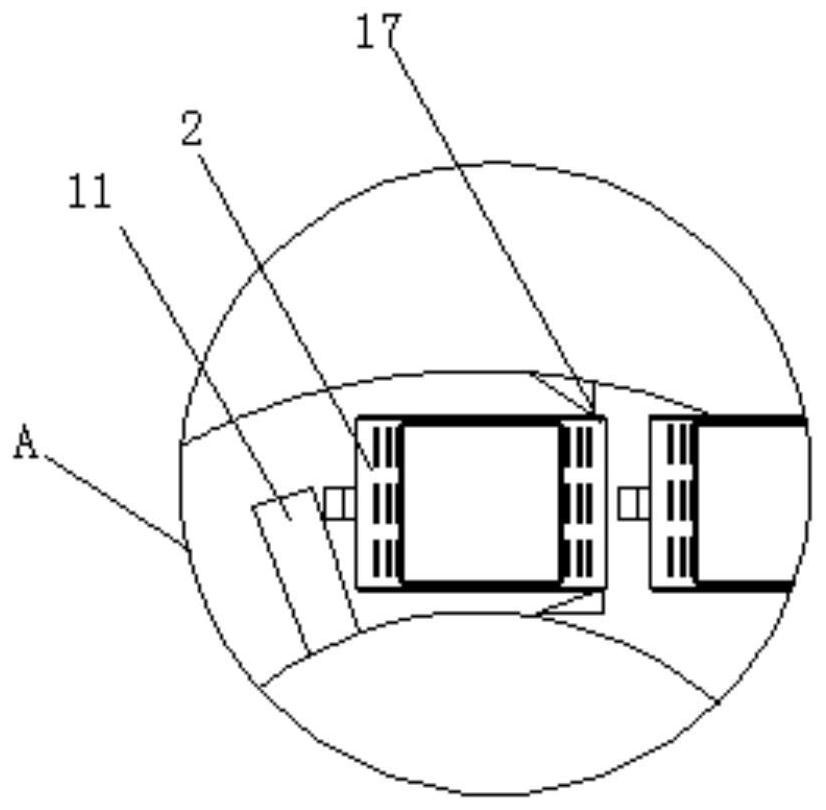

The invention discloses a garden trimmer, and relates to the field of garden maintaining equipment. The garden trimmer comprises a trimming vehicle and a support vertical column which is arranged on the trimming vehicle, wherein the support vertical column is connected with a horizontal trimming device through a horizontal shear fixing arm; the trimming vehicle is further provided with a vertical shear fixing rod and a circular-arc shear fixing rod; the vertical shear fixing rod is connected with a vertical trimming device through the vertical shear fixing arm; the circular-arc shear fixing rod is connected with a circular-arc trimming device through a circular-arc shear fixing arm; the horizontal trimming device, the vertical trimming device and the circular-arc trimming device are driven by a motor respectively. In the garden trimmer, the horizontal trimming device, the vertical trimming device and the circular-arc trimming device are adopted to meet different garden trimming requirements, so that various trimming styles are achieved, and operation is easy; the trimming vehicle is used for providing power, so that the trimming quality is ensured, the operation intensity of workers is lowered, and high trimming efficiency is achieved.

Owner:闫永健

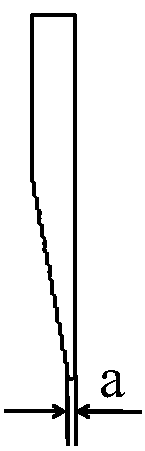

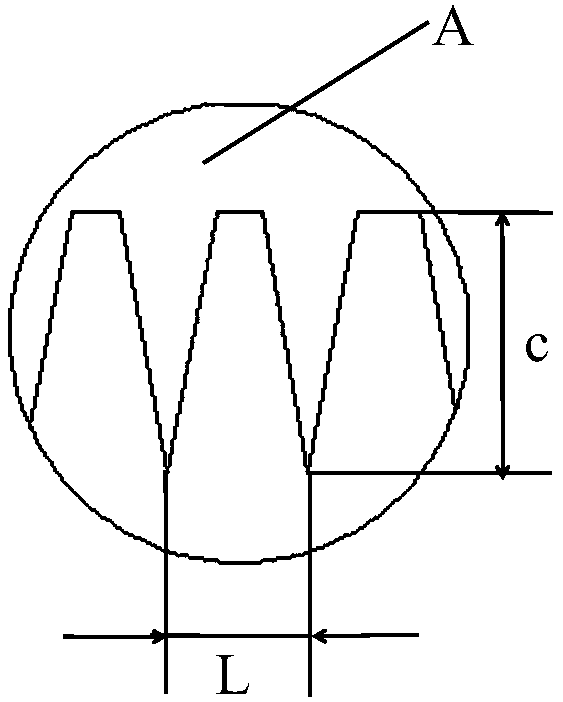

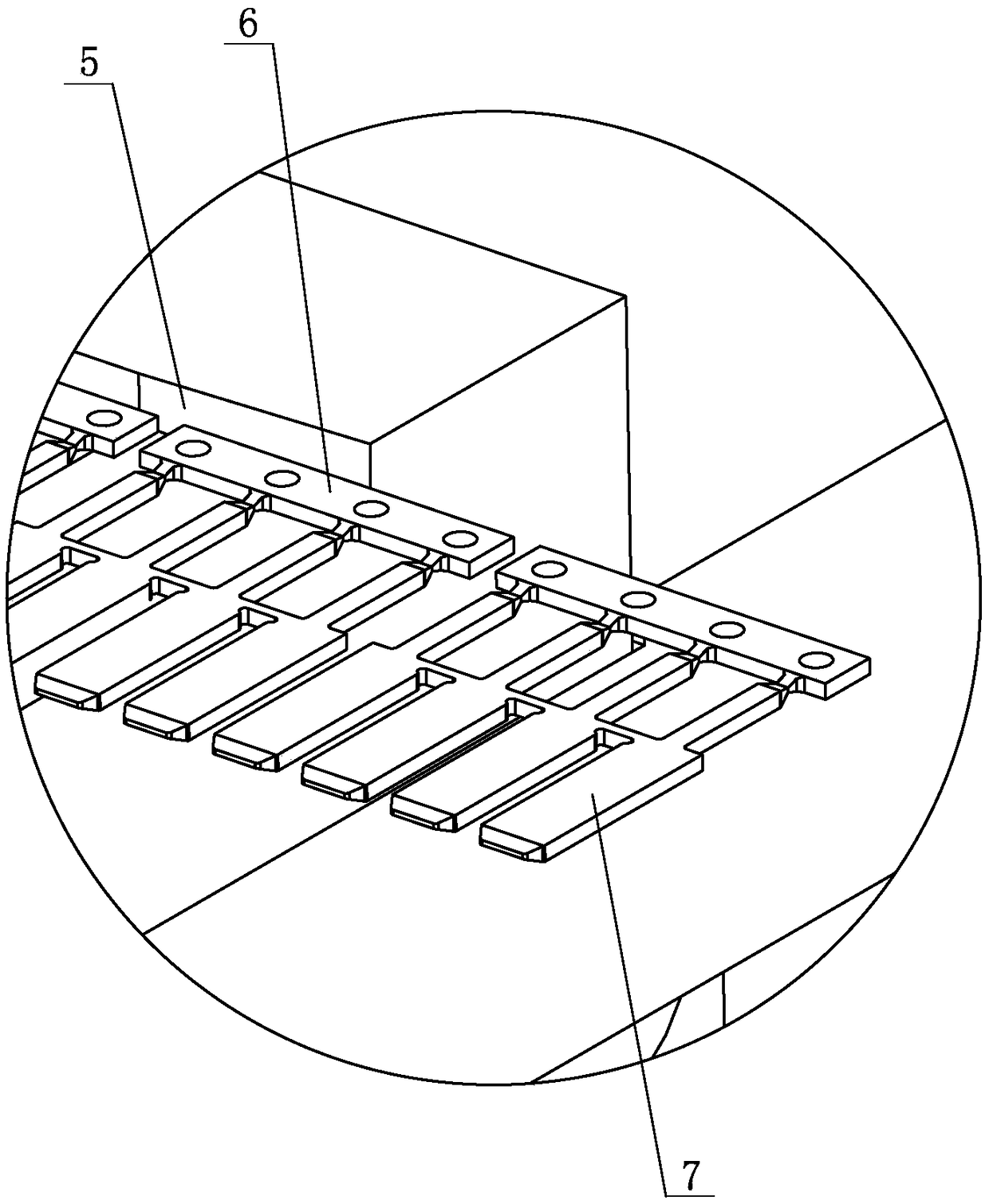

Serrated knife for high-speed carpet textile machine and machining method thereof

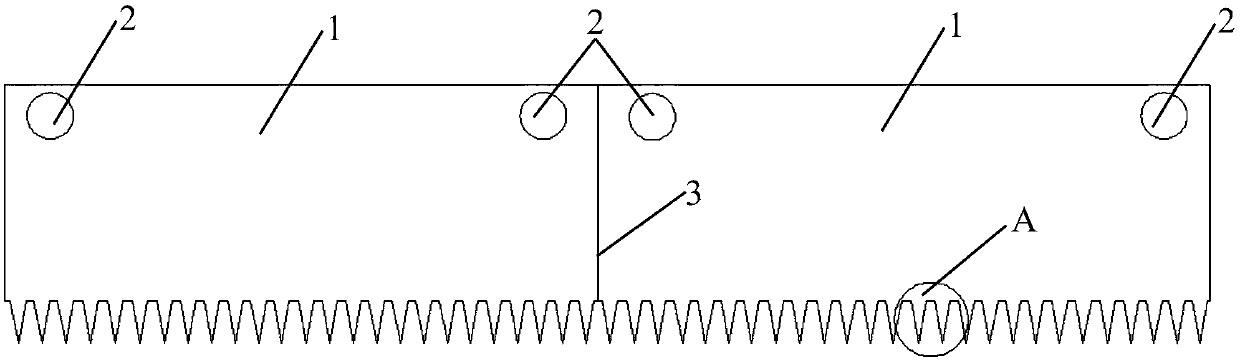

The invention discloses a serrated knife for a high-speed carpet textile machine. The serrated knife comprises a knife rest and a blade component, wherein the blade component comprises a plurality ofblade bodies; a plurality of sawteeth are arranged on one side of each blade body; the plurality of sawteeth are arranged at equal intervals; a plurality of mounting holes are formed in one side, farfrom the sawteeth, of each blade body; the plurality of blade bodies are detachably connected with the knife rest through the plurality of mounting holes; the end parts of the plurality of blade bodies are correspondingly spliced with one another; splicing lines are formed in spliced positions; the splicing lines are positioned at the roots of the sawteeth, so that the phenomena that the splicinglines have cracks at cutting edges of the splicing lines and the shearing quality of carpet fabric is reduced are avoided; meanwhile, the invention further discloses a machining method of the serratedknife. The serrated knife machined through the method is high in quality, sharp in cutting edges and long in service life, and improves the shearing efficiency of the carpet fabric.

Owner:昆山立达纺织实业有限公司

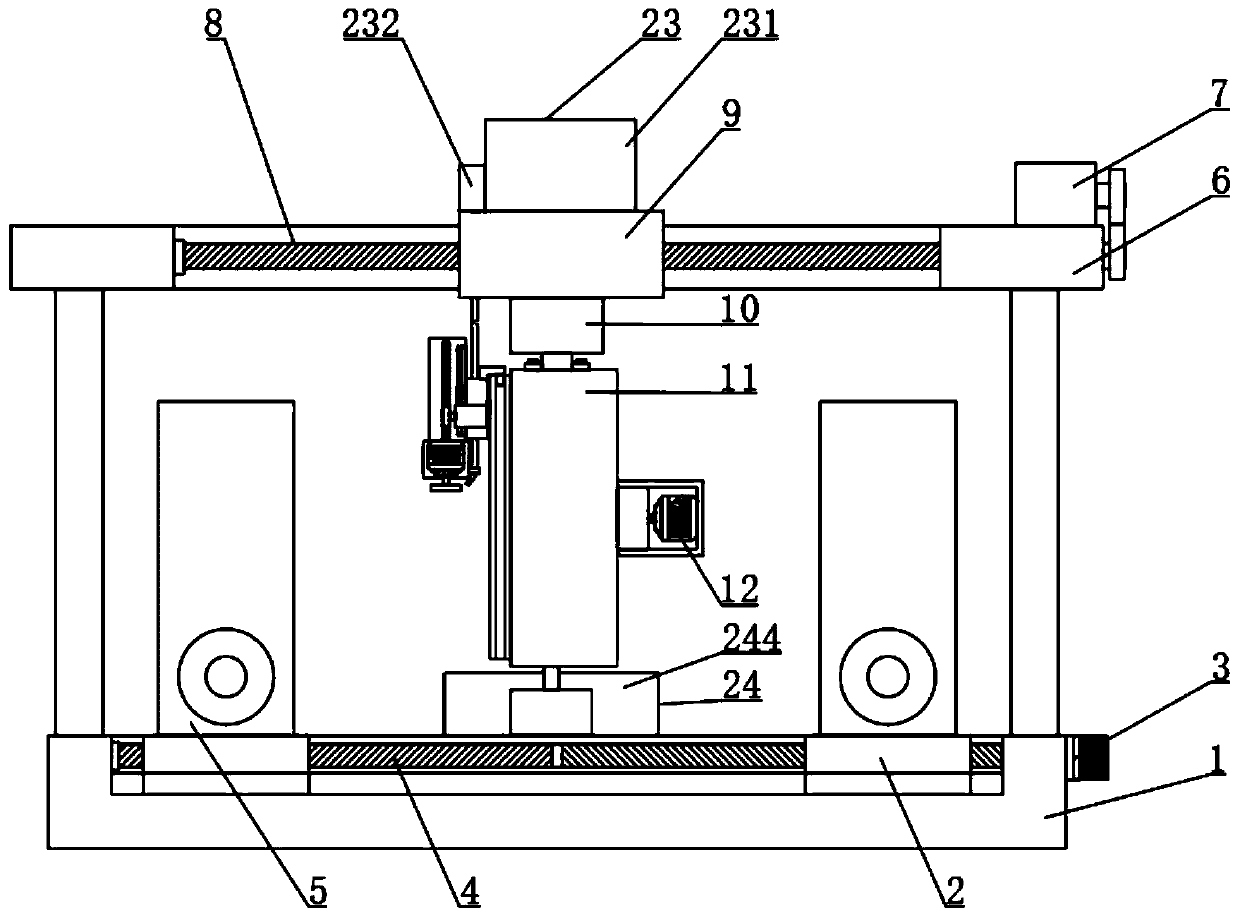

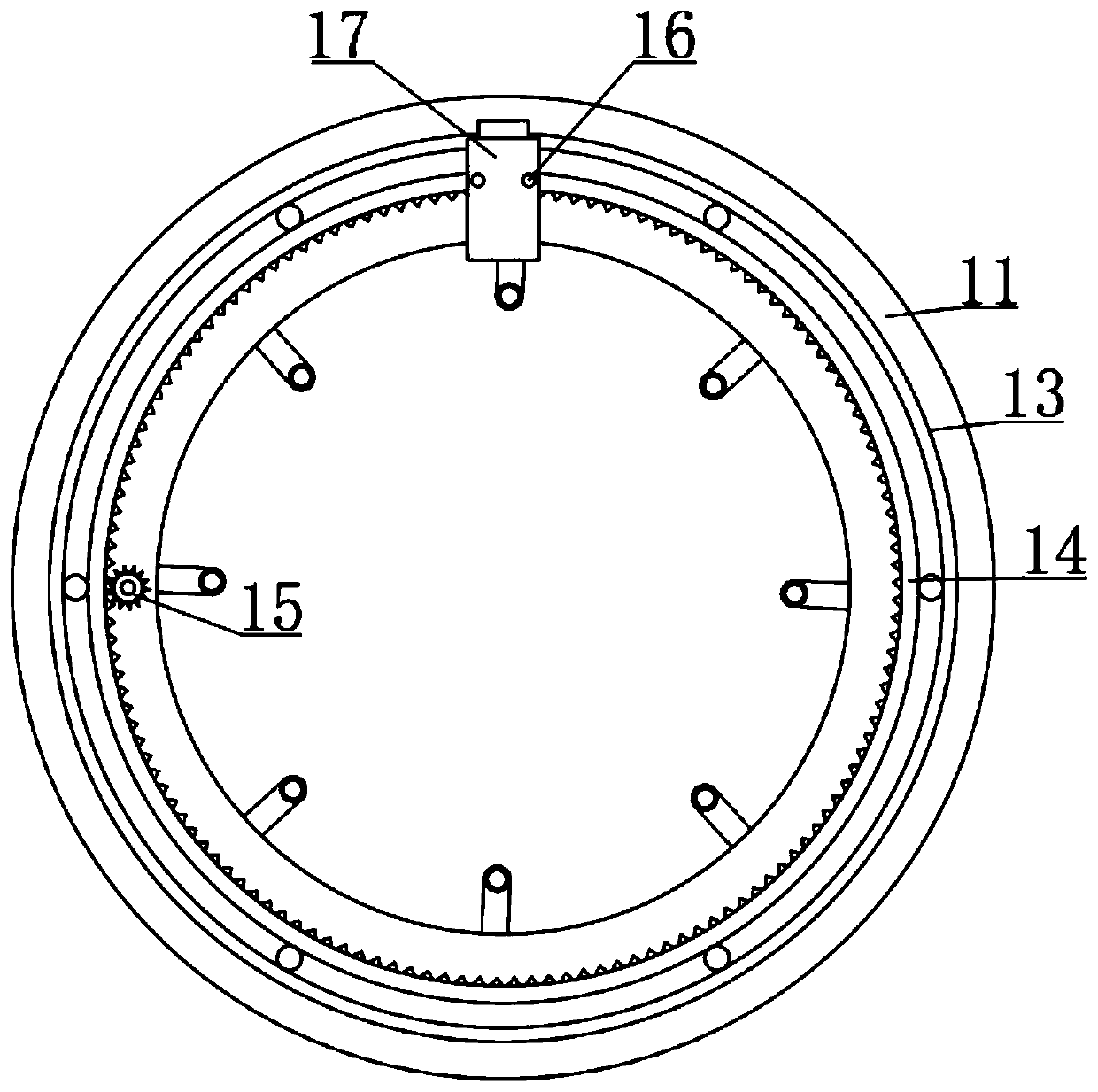

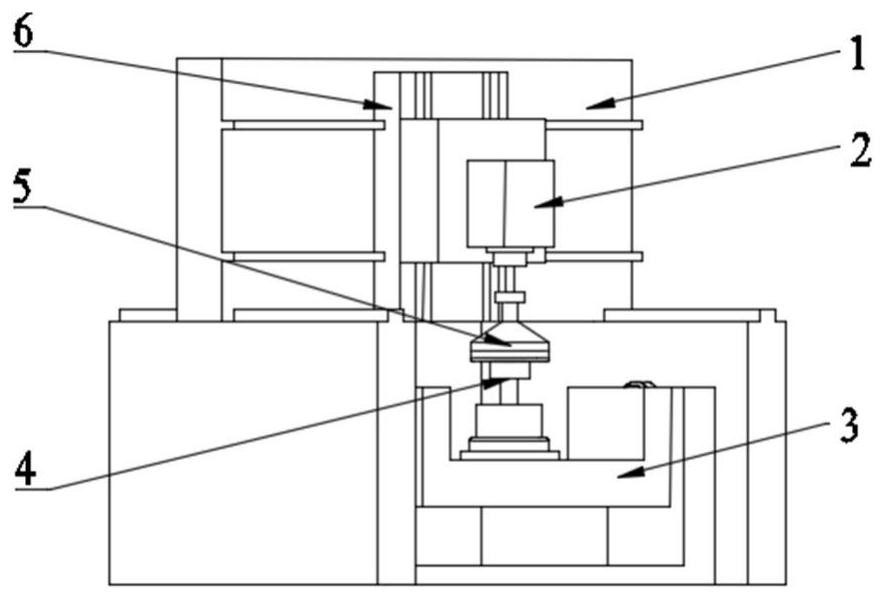

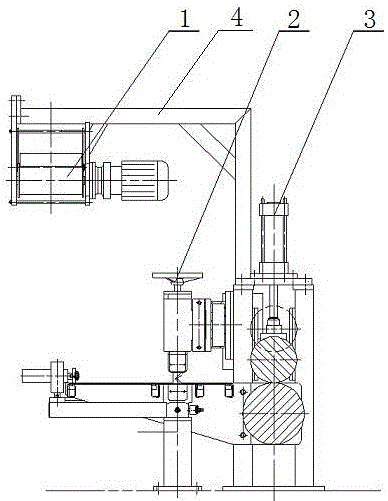

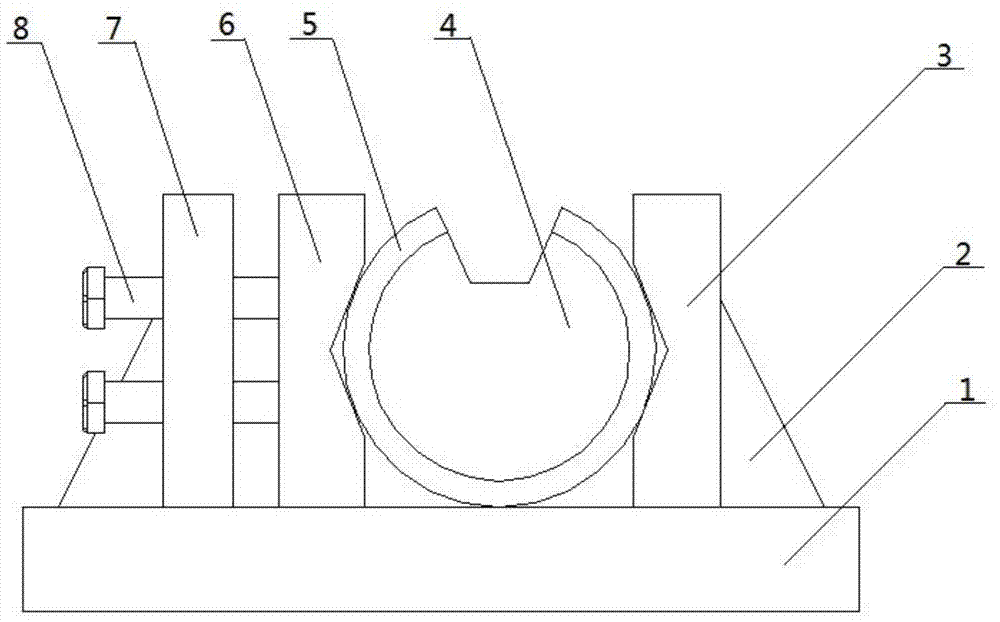

Conical pipe weld joint trimming device

InactiveCN110919491AGuaranteed stabilityGuarantee trimming qualityEdge grinding machinesGrinding drivesConical tubeStructural engineering

The invention discloses a conical pipe weld joint trimming device and belongs to the technical field of weld joint trimming. The device comprises a base. Conical pipe clamping mechanisms of the same structure are arranged at the tops of the two first T-shaped sliding blocks correspondingly. An annular piece is welded to the outer wall of the left side of an annular ring. A rotary inner gear ring is arranged at the inner side of the annular piece; the top of the outer wall of the left side of the rotary inner gear ring is connected with a supporting block through two groups of connecting rods;a grinding cooling mechanism matched with a grinding block is arranged at the top of a movable assembly block; and a dust collection mechanism is arranged on the inner wall of the annular ring. Conical pipes of different specifications can be conveniently clamped; the rotary inner gear ring is driven to rotate through cooperation of a second micro servo motor, a speed reducer and a small gear, then, a trimming mechanism is driven to rotate through the connecting rods to trim the weld joint, so that the working efficiency and the working quality are greatly improved; and meanwhile, the trimming device is flexible and convenient to use, and adapts to weld joint trimming operation of conical pipes of different specifications.

Owner:徐州市凯旭钢结构有限公司

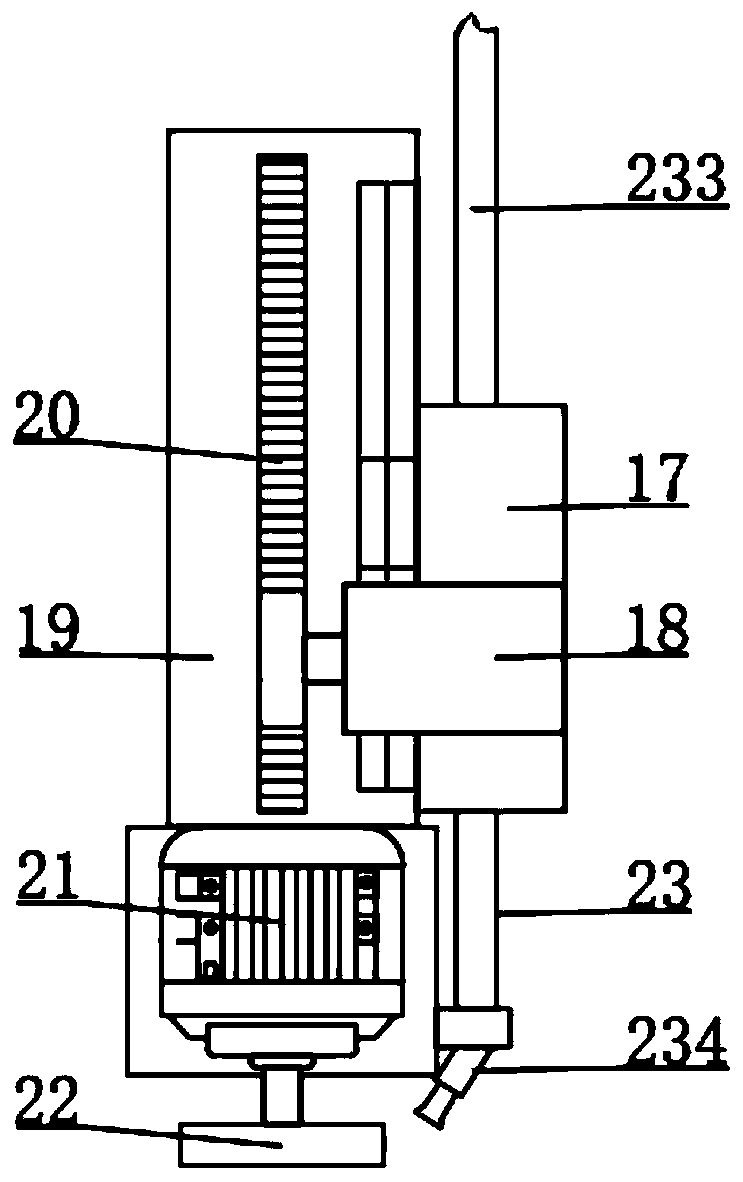

High-branch lifting cutting machine device and use method thereof

The invention relates to a high-branch lifting cutting machine device and a use method thereof, and belongs to the field of pruning machines. According to the cutting machine device, mechanical cutting and manual pruning are combined, coarse tree trunk can be rotatably and mechanically cut, complex branches can be manually trimmed when cannot be operated by a machine, the cutting machine device is diverse in trimming modes and simple to operate, various trimming modes can be selected, trimming quality can be ensured, operating intensity is low, different trimming modes can be selected according to the diameter of the branches operating safety is greatly improved, and trimming efficiency is improved.

Owner:常州市瑞泰物资有限公司

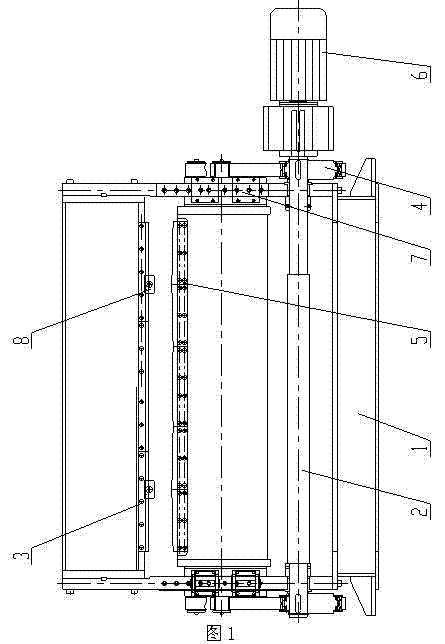

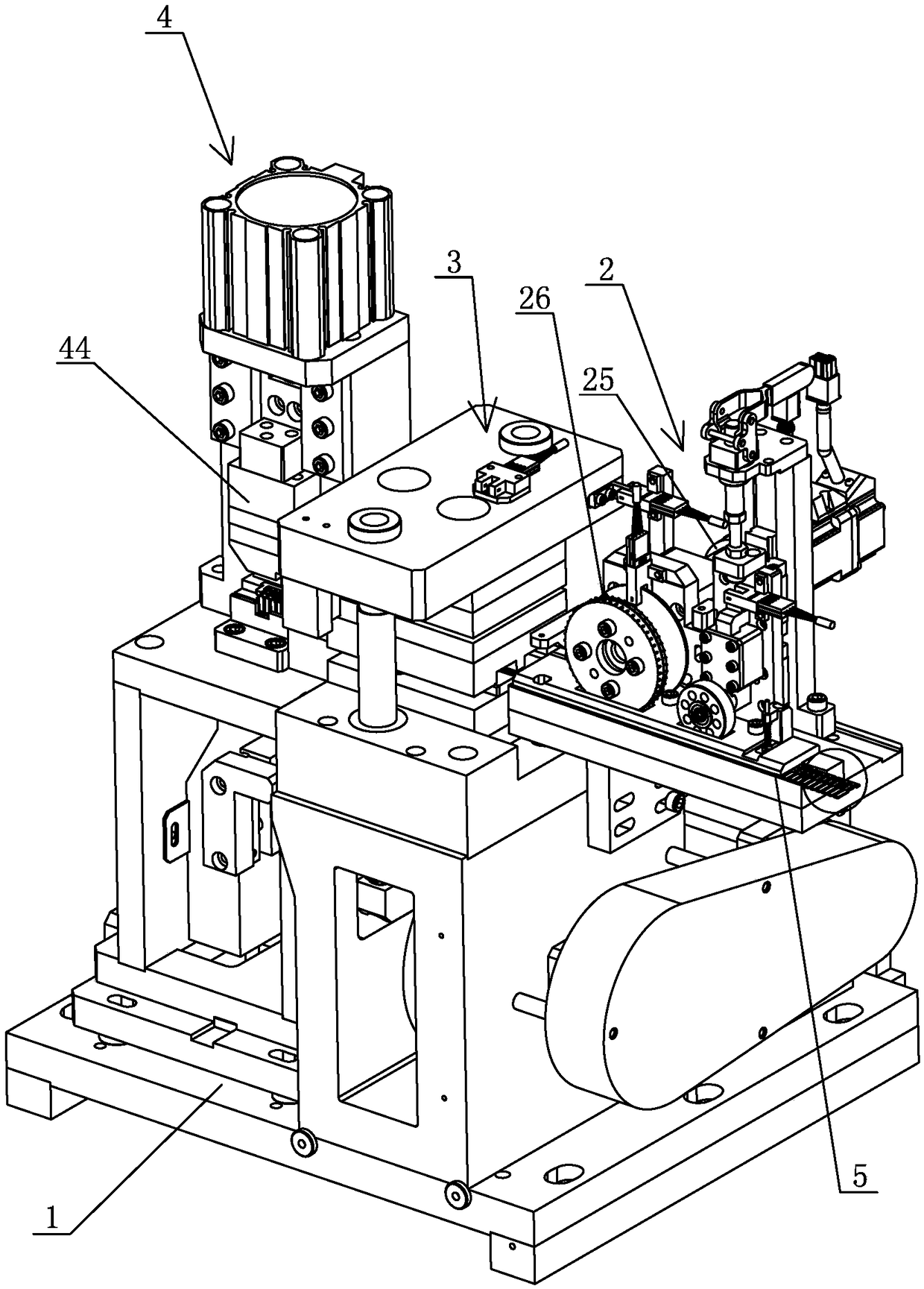

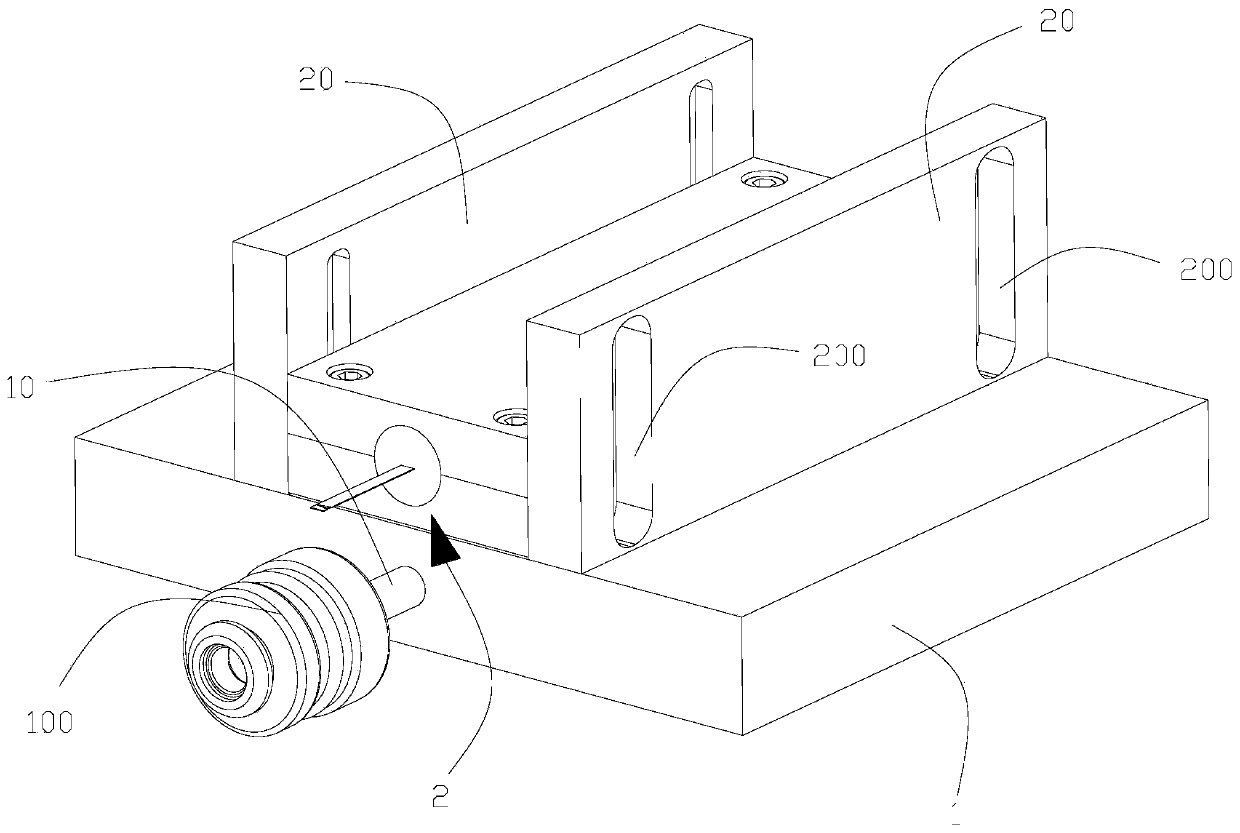

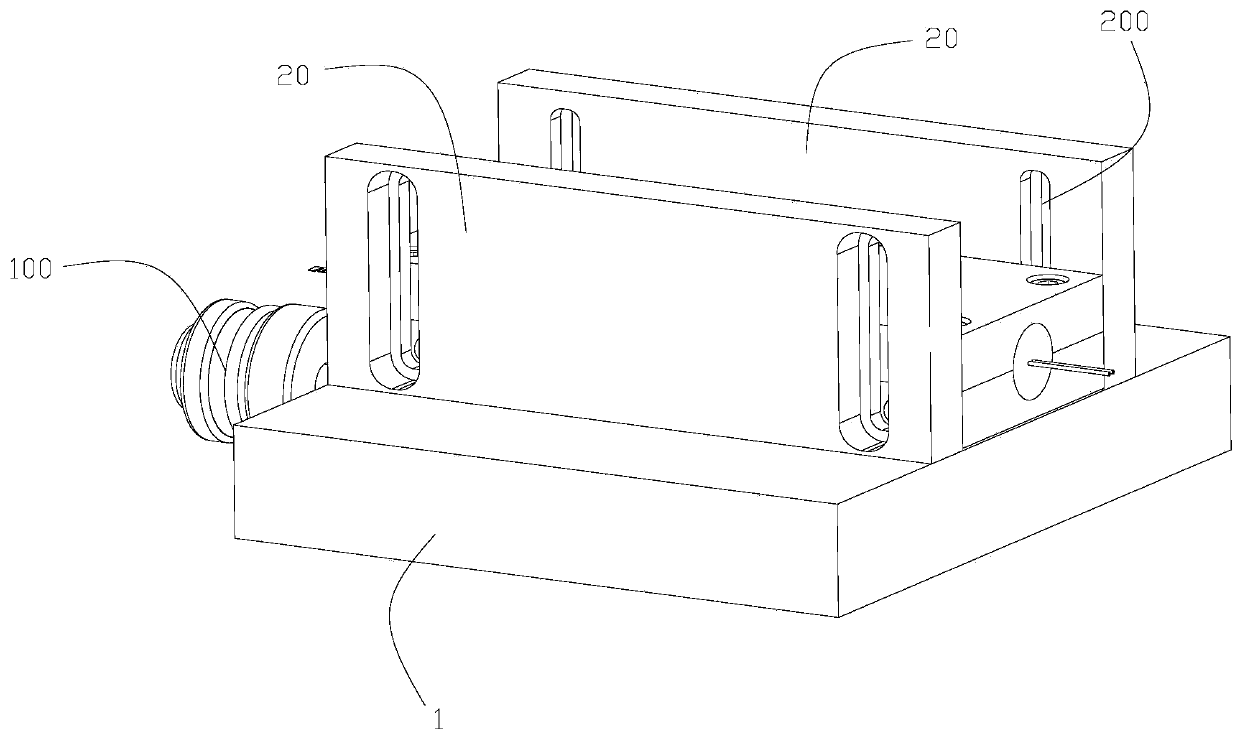

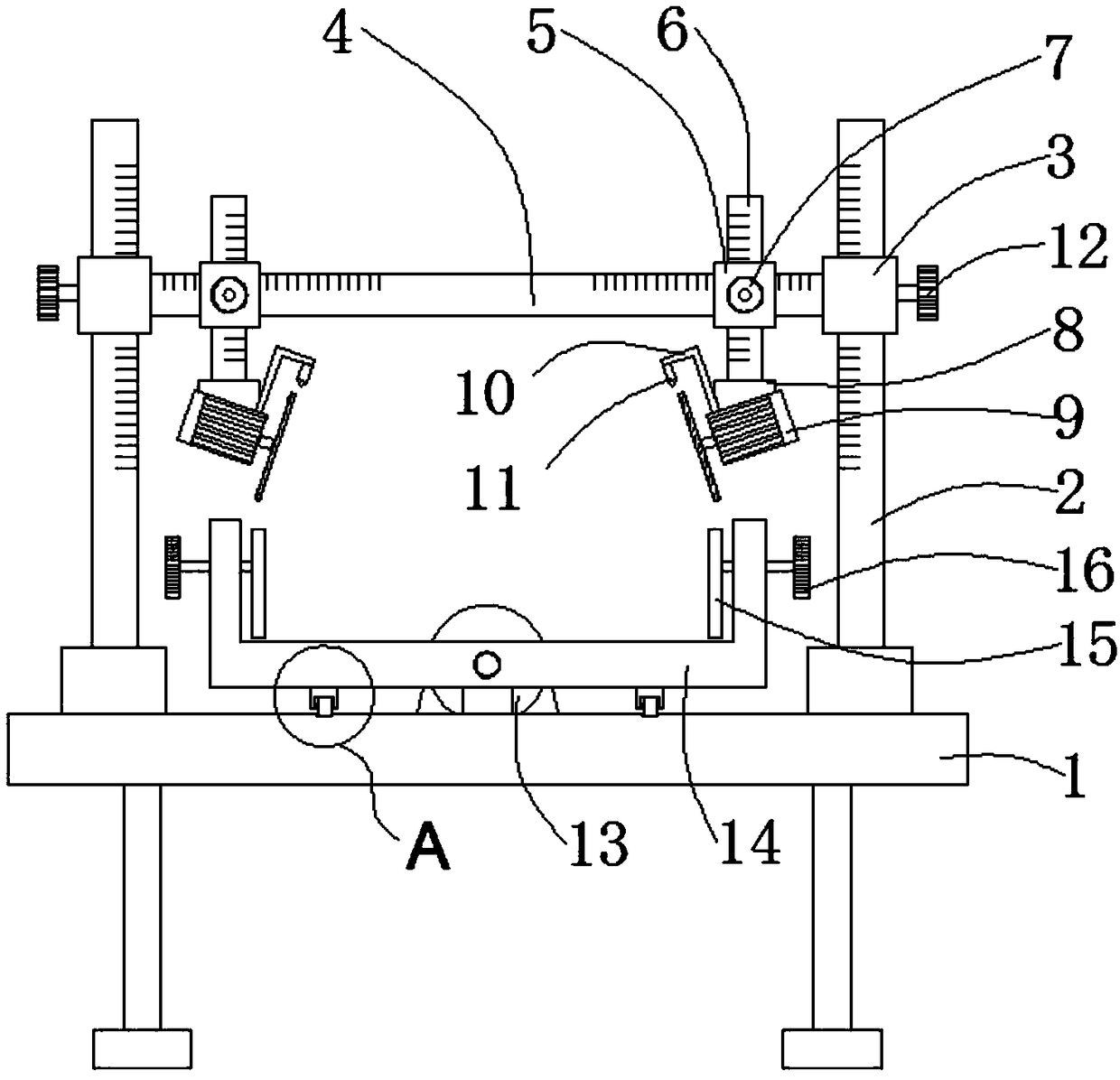

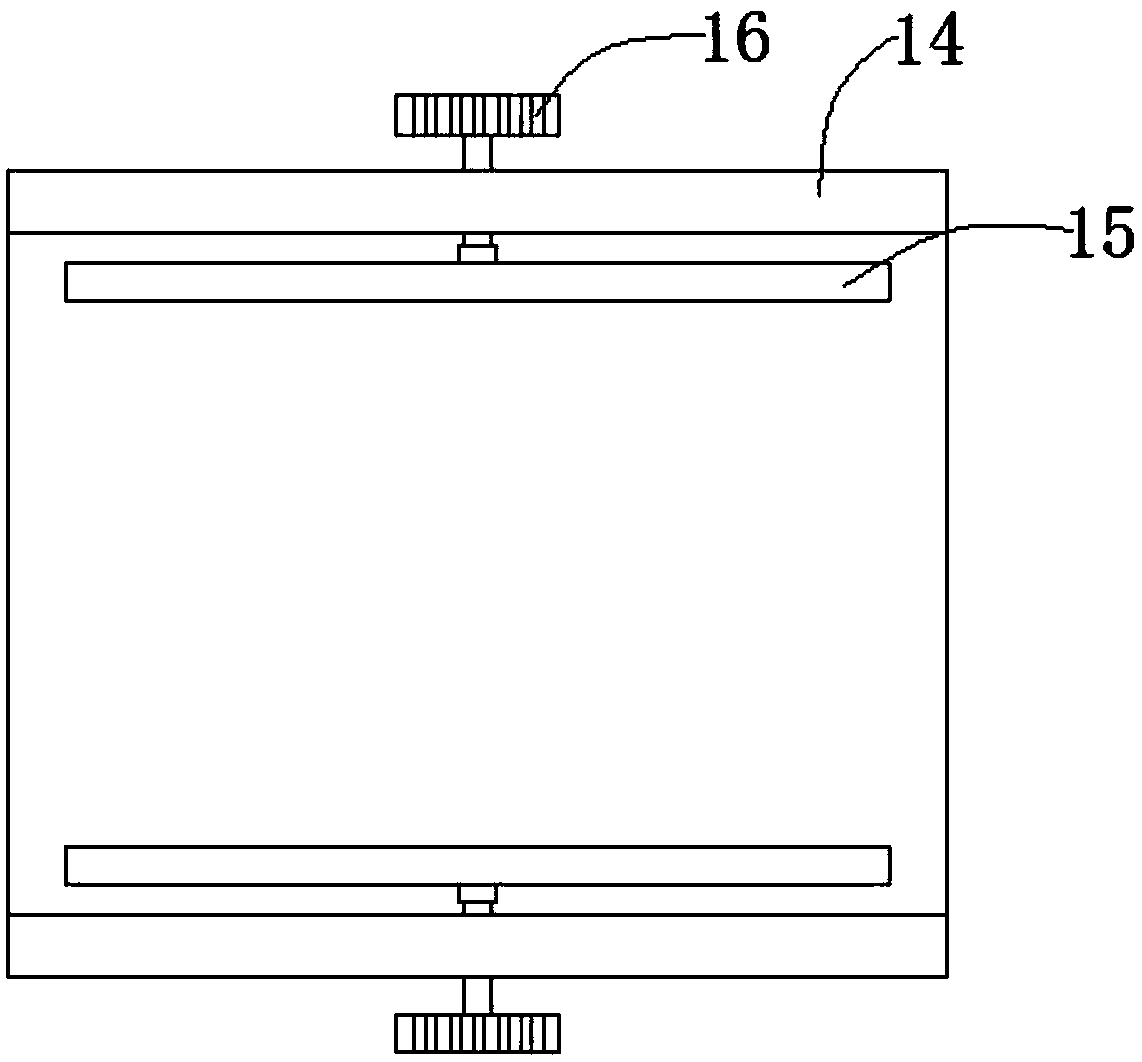

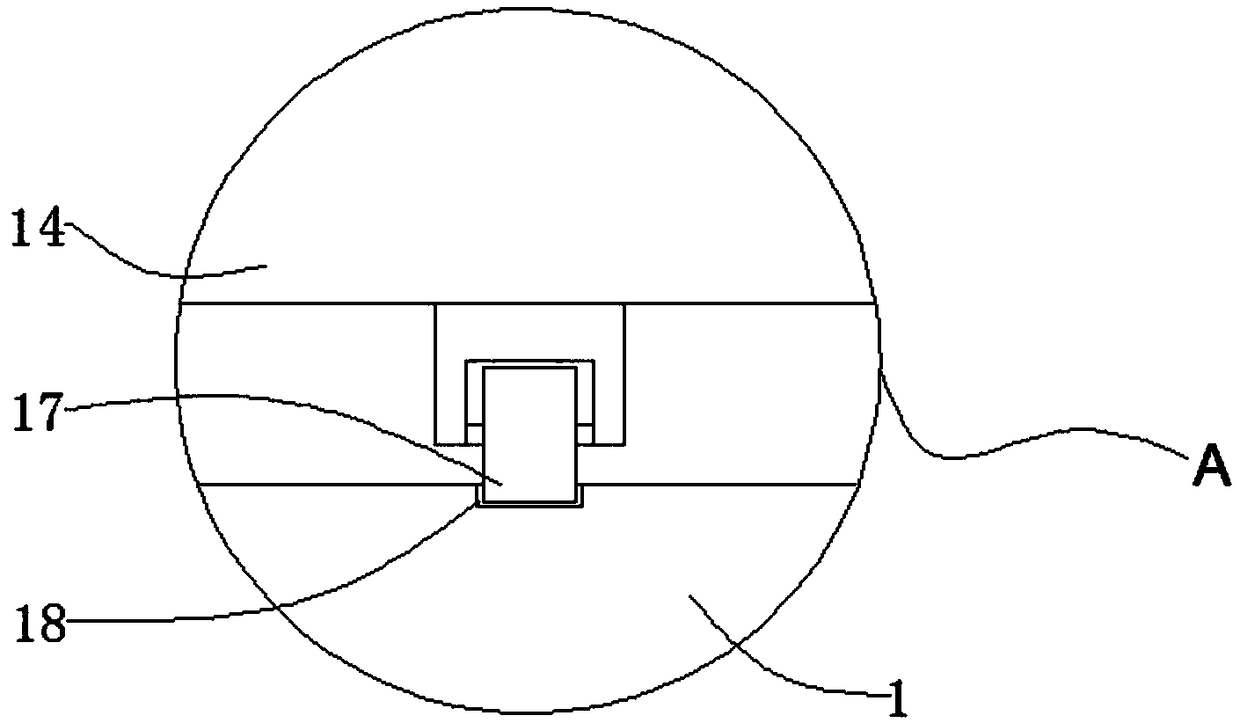

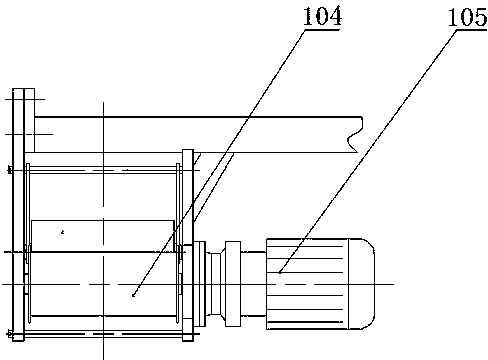

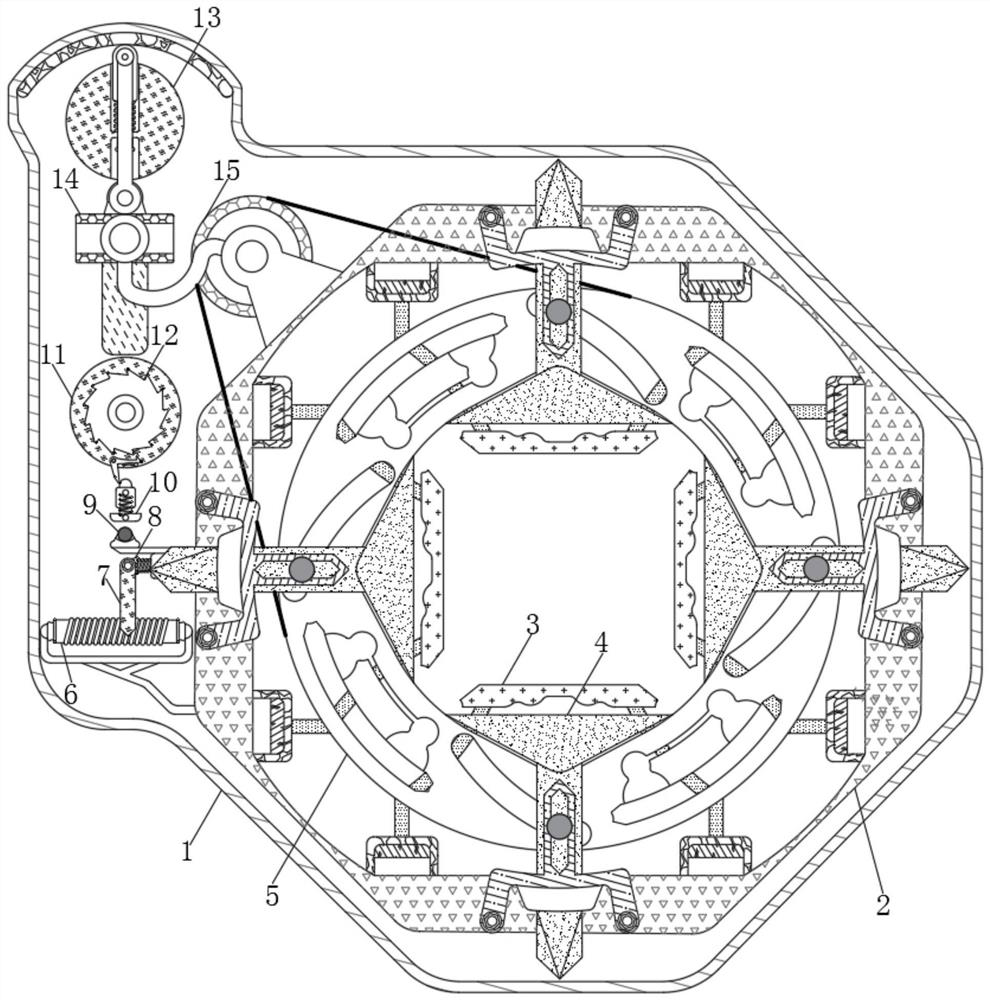

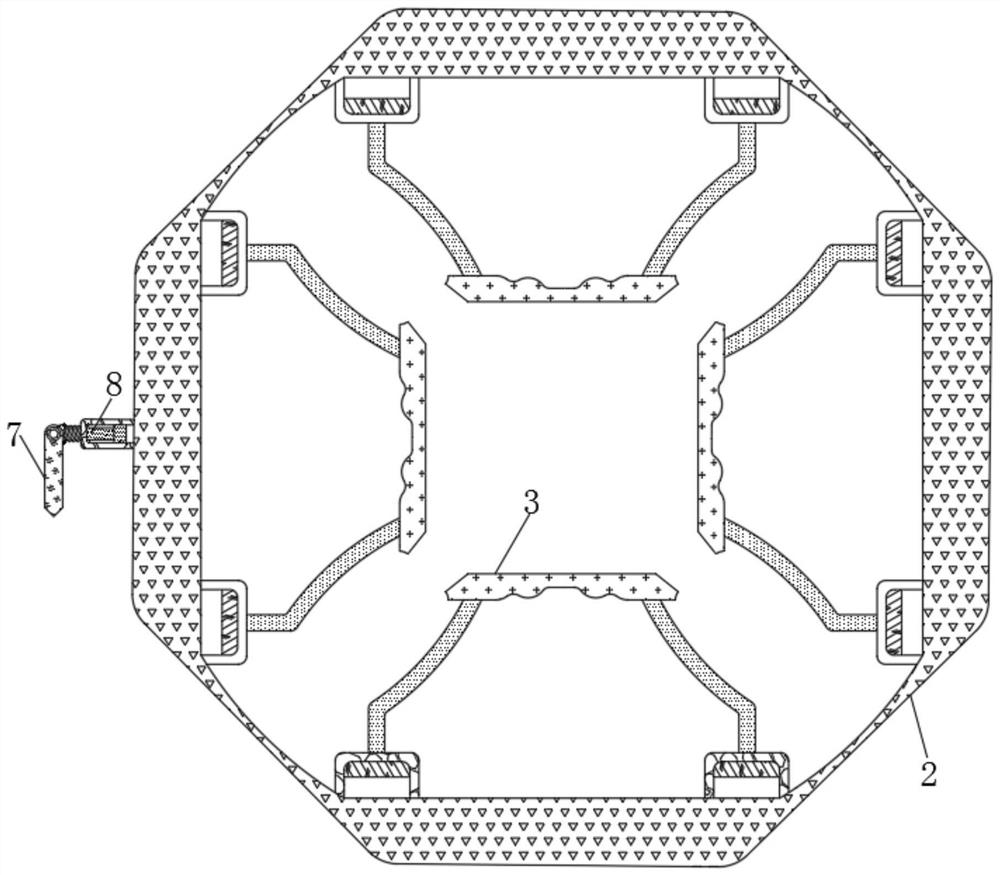

Automatic trimming device of multi-station molding machine

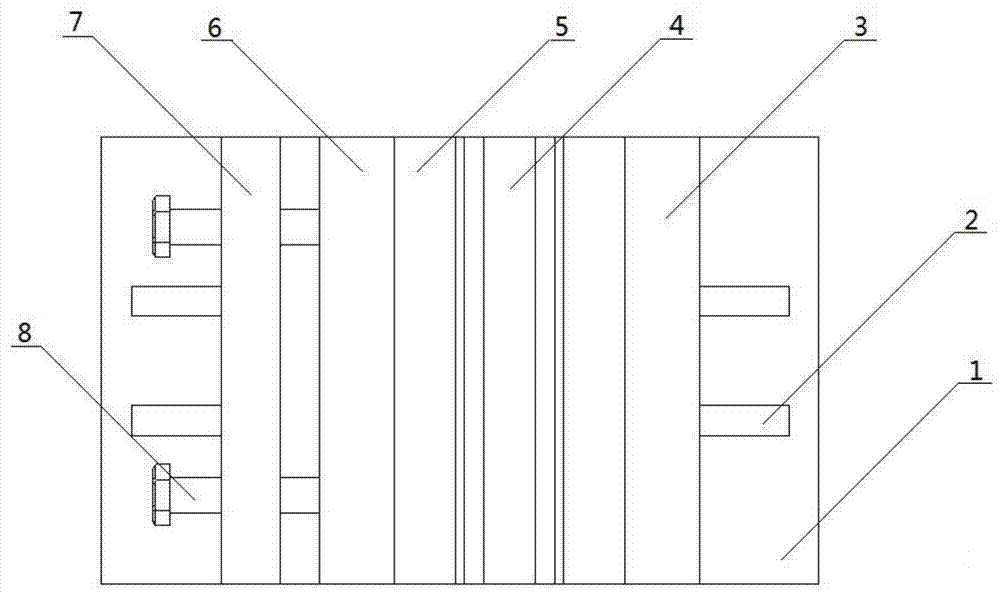

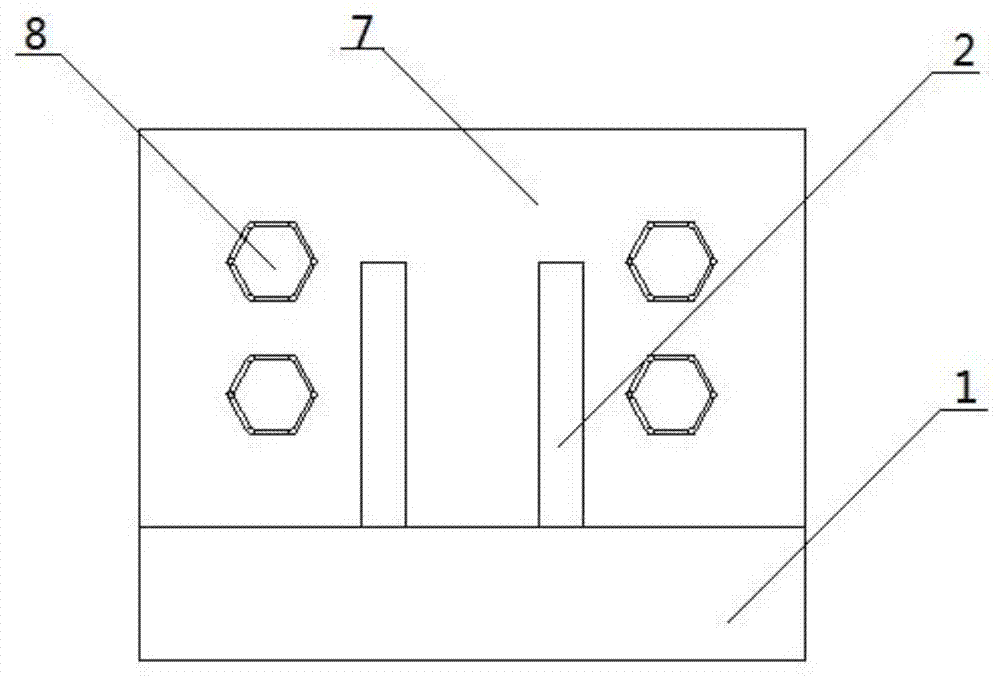

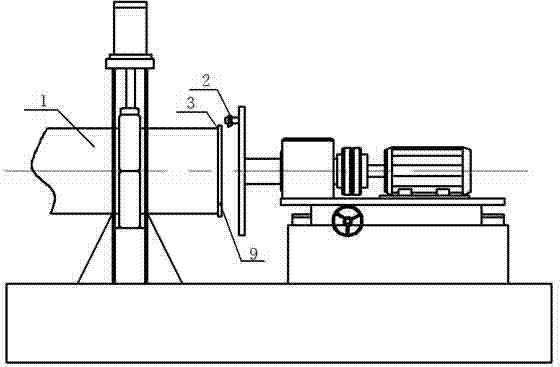

InactiveCN103481312AImprove work efficiencyGuarantee trimming qualityMetal working apparatusDrive shaftMolding machine

The invention relates to an automatic trimming device of a multi-station molding machine. The automatic trimming device comprise a mounting frame, a drive shaft is arranged on the mounting frame, a cam mechanism is mounted on each of two sides of the drive shaft, the cam mechanism on one side of the drive shaft is connected with a motor reducer, and with a linear guide rail pair arranged on a side part of the mounting frame as a guiding element, the motor reducer drives a lower cutter component mounted on the mounting frame to move upwardly on the mounting frame through the drive shaft and the cam mechanisms. An upper cutter component is mounted right above the lower cutter component, and a plurality of positioning components are arranged at the lower end of the upper cutter component. With the guiding of the linear guide rail pair and through the cam mechanisms and the drive shaft, the motor reducer is used for driving the lower cutter component to move upwardly on the mounting frame for cooperating with the positioning components, so that trimming is automatically completed, the automatic trimming device is time-saving and labor-saving, and working efficiency is improved and trimming quality can be guaranteed.

Owner:ANHUI PROVINCE ELITE HOUSEHOLD APPLIANCES MFG EQUIP

Cup-shaped arc grinding wheel in-place finishing method based on cradle type five-axis numerical control machine tool

ActiveCN112775839ASolve the problem that the arc is easy to interfere and difficult to trimReduce the impact of high precision requirementsGrinding carriagesGrinding feed controlNumerical controlWheel wear

The invention discloses a cup-shaped arc grinding wheel in-place finishing method based on a cradle type five-axis numerical control machine tool. The method is used for ultra-precision grinding and aims to solve the problem that an existing cup-shaped arc grinding wheel is not easy to finish. The finishing method comprises the steps that a finishing grinding wheel is installed on a rotary table of the numerical control machine tool, and a cup-shaped arc grinding wheel to be finished is installed on a machine tool spindle; intermittent trimming and opposite grinding of the inner arc and the outer arc of the finishing grinding wheel and the cup-shaped arc grinding wheel to be finished are achieved through an arc enveloping trimming track; and in-situ measurement is performed on the grinding wheel through a calibrated laser displacement sensor. According to the finishing method, the cup-shaped arc grinding wheel of the cradle type five-axis numerical control machine tool is subjected to in-place finishing, the problem that the cup-shaped arc grinding wheel is difficult to finish due to the fact that the arc is prone to interference is solved, the influence of grinding wheel abrasion on the high-precision requirement of a workpiece is reduced, the compensation machining frequency is reduced, deterministic machining is achieved, and the machining efficiency and the machining quality of the whole workpiece are improved.

Owner:XI AN JIAOTONG UNIV

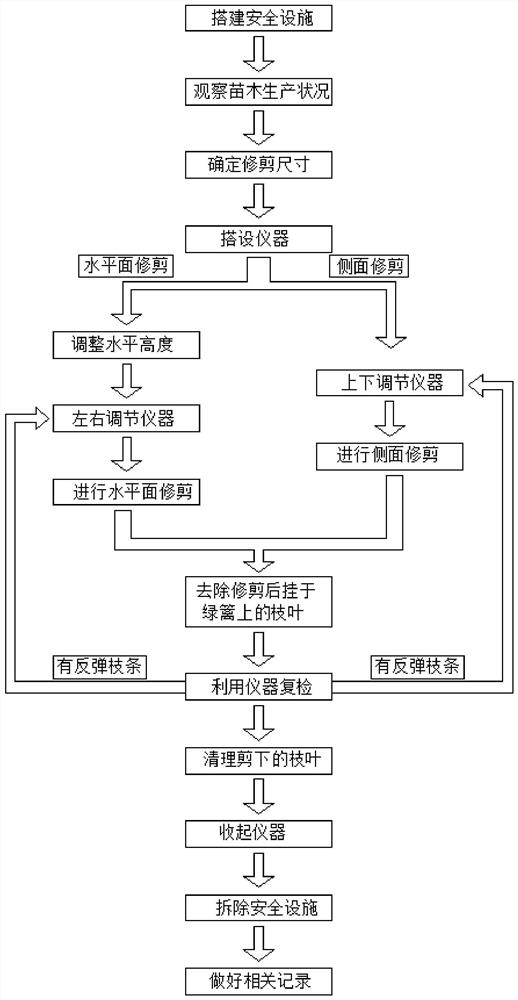

Construction method for finely trimming and normalizing hedgerow through laser calibration

PendingCN113575167ATrim levelGuarantee trimming qualityHedge trimming apparatusComputational physicsMechanical engineering

The invention relates to the technical field of hedge trimming, and discloses a construction method for finely trimming and normalizing a hedgerow through laser calibration. The construction method comprises the following steps of determining a trimming operation area, and building a safety protection facility; determining the pruning height; erecting an instrument; firstly conducting horizontal plane pruning on the hedgerow and then conducting side pruning; performing reinspection; after the pruning operation is finished, collecting and cleaning up pruned branches and leaves. After sweeping is finished, the laser calibrator is folded, warning lines, fences or roadblocks arranged around the trimming operation range are removed. After the operation is completed, leaving the field and making related work records. According to the construction method for finely trimming and normalizing the hedgerow through the laser calibration, the height and crown breadth of a nursery stock needing to be reserved are determined according to the standard and landscape requirements by utilizing the principle that light is propagated along a straight line, the standard height and the crown breadth are irradiated with laser, an exceeding part is cut off, and the hedge is trimmed more flatly.

Owner:南京市园林经济开发有限责任公司

Glass edge cutter

InactiveCN106380067AReduce dosageImprove cleanlinessGlass severing apparatusWorking environmentEngineering

The invention relates to a glass edge cutter which comprises a rack; the rack is provided with a roller way for conveying glass; the roller way is provided with clampers for positioning the glass; a cutting tool corresponding to the glass is arranged above the rack, and the side part of the cutting tool is provided with a cooling pipe and a lubricating pipe; cooling wind is introduced in the cooling pipe, and a lubricating liquid is introduced in the lubricating pipe. The side part of the cutting tool is provided with the cooling pipe and the lubricating pipe, and the cooling wind is introduced in the cooling pipe, so a wind cooling manner is adopted for radiating heat generated in an edge cutting process; at the same time, the cutting tool is lubricated by the lubricating liquid to reduce friction force, so that the amount of the lubricating liquid can be greatly reduced; during normal work, the cooling pipe is only needed to be opened for wind cooling, in necessity, the lubricating pipe is opened to spray the lubricating liquid for lubricating, and thus the liquid amount is greatly reduced, the cleanliness of a work environment is improved, and cooling and lubricating effects are not affected.

Owner:YANGZHOU BAOTAI GLASS CO LTD

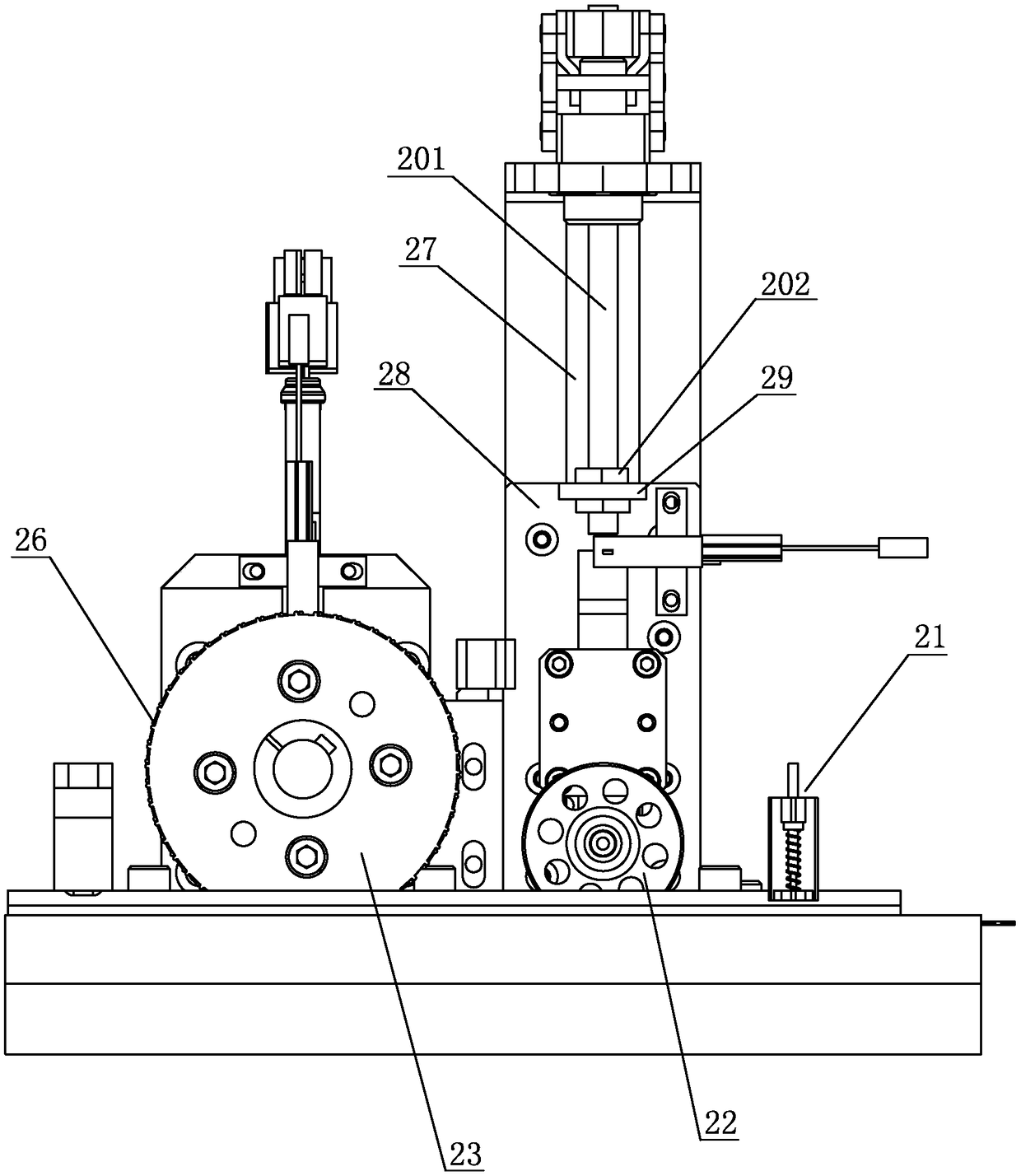

Connector contact pin bending trimming device

PendingCN109473848AReduce labor intensityImprove securityContact member manufacturingEdge surfaceEngineering

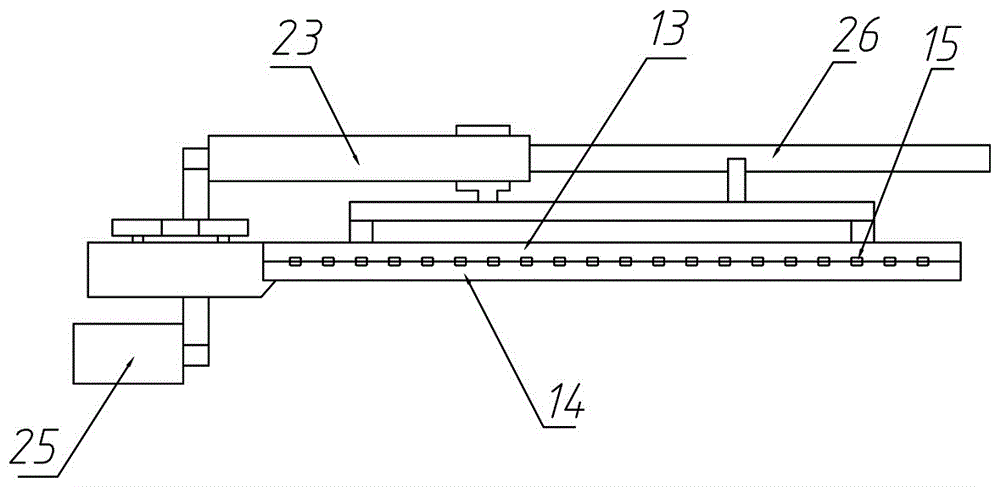

The invention discloses a connector contact pin bending trimming device. The connector contact pin bending trimming device is characterized by comprising a rack, a feeding mechanism arranged on the rack, a bending mechanism and a trimming mechanism, wherein the bending mechanism is arranged between the feeding mechanism and the trimming mechanism; a feeding sliding chute is formed in the rack, andthe feeding sliding chute is arranged among the feeding mechanism, the bending mechanism and the trimming mechanism in a penetrated manner; the feeding mechanism comprises a product positioning mechanism, a pinch roller and a conveying roller arranged above the feeding sliding chute, the pinch roller is arranged between the conveying roller and the product positioning mechanism, the rear end of the conveying roller is connected with a conveying motor, a plurality of longitudinal clamping bars are uniformly distributed on the outer edge surface of the conveying roller, the longitudinal clamping bars are arranged parallel to the axis of the conveying roller, and the conveying roller is arranged close to the bending mechanism. According to the connector contact pin bending trimming device, the product processing efficiency and quality are improved.

Owner:KUNSHAN BOGUTE ELECTROMECHANICAL EQUIP

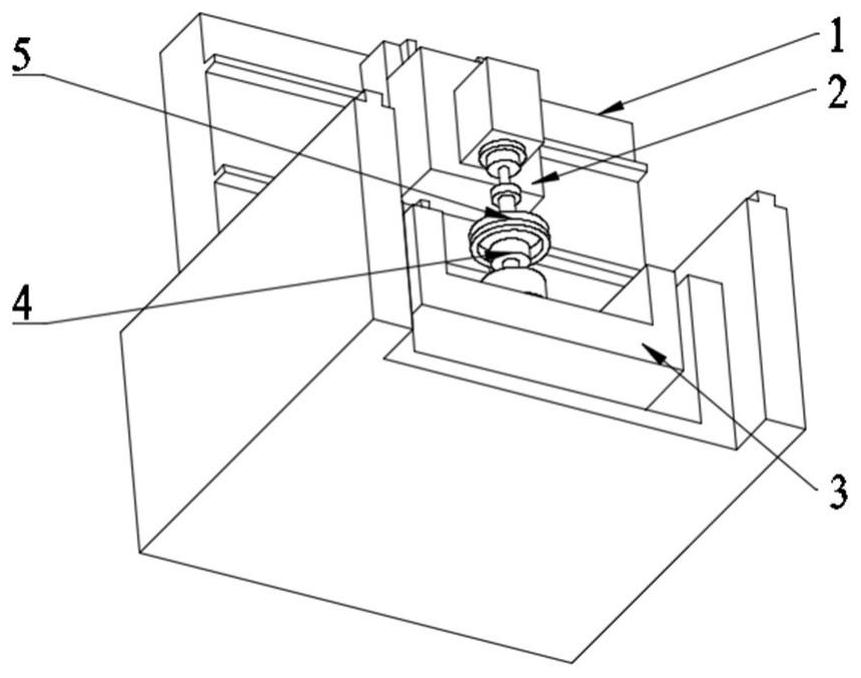

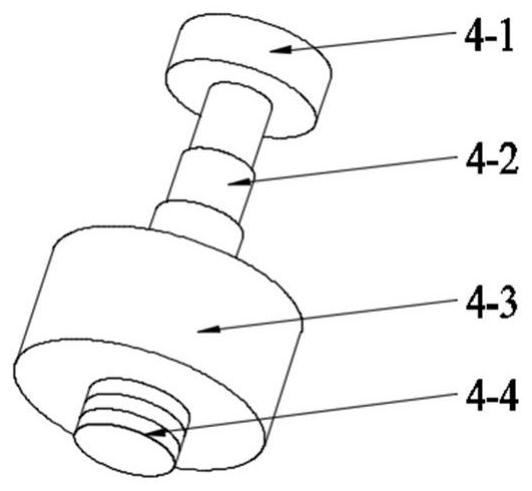

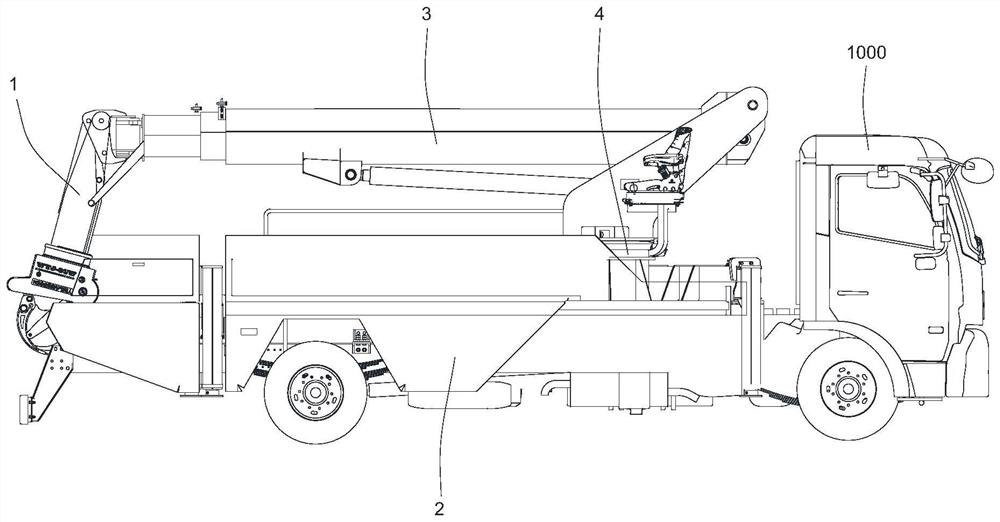

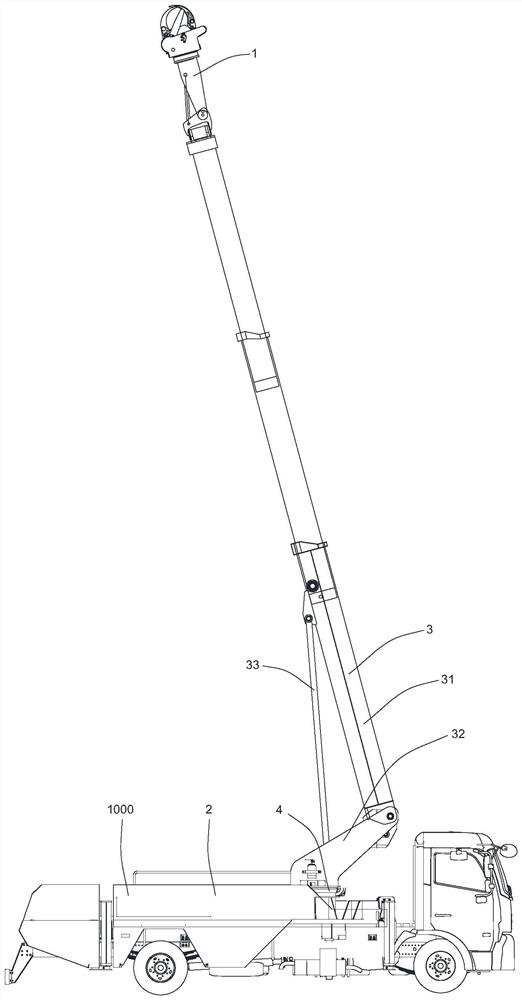

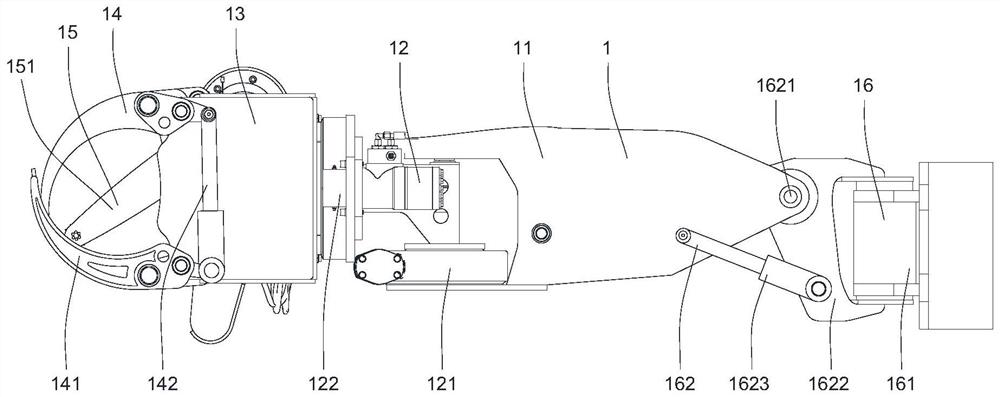

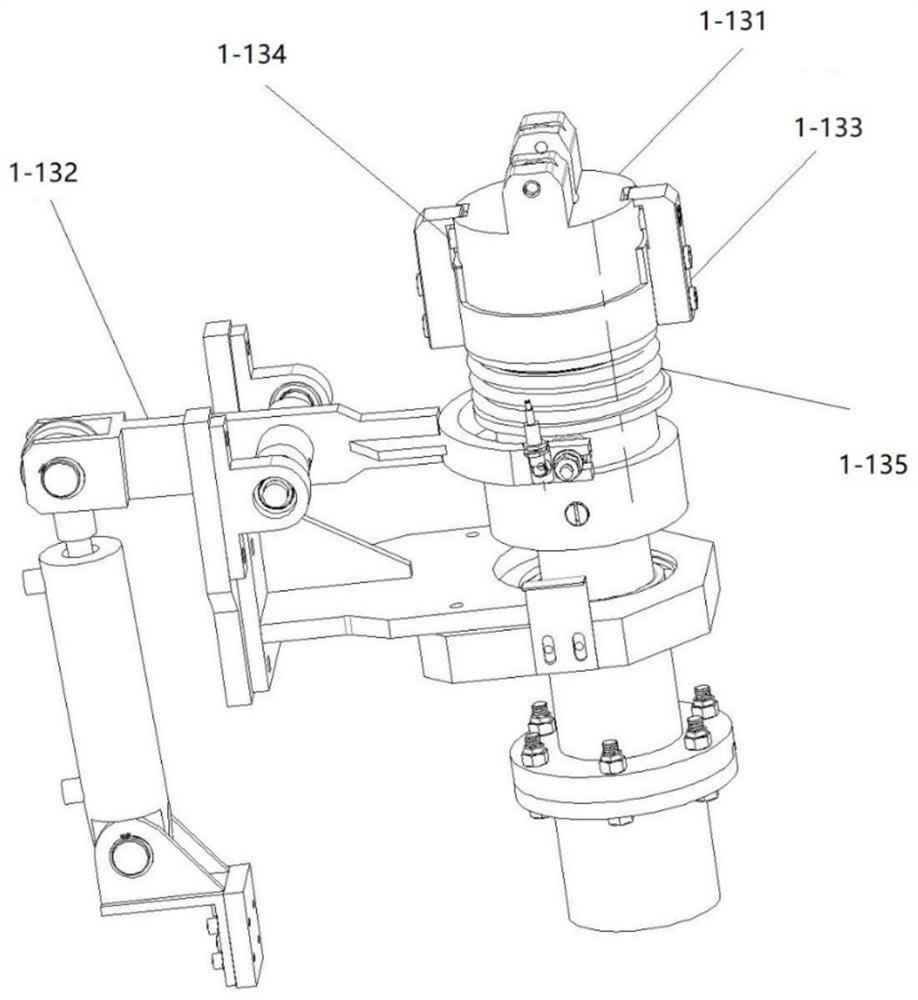

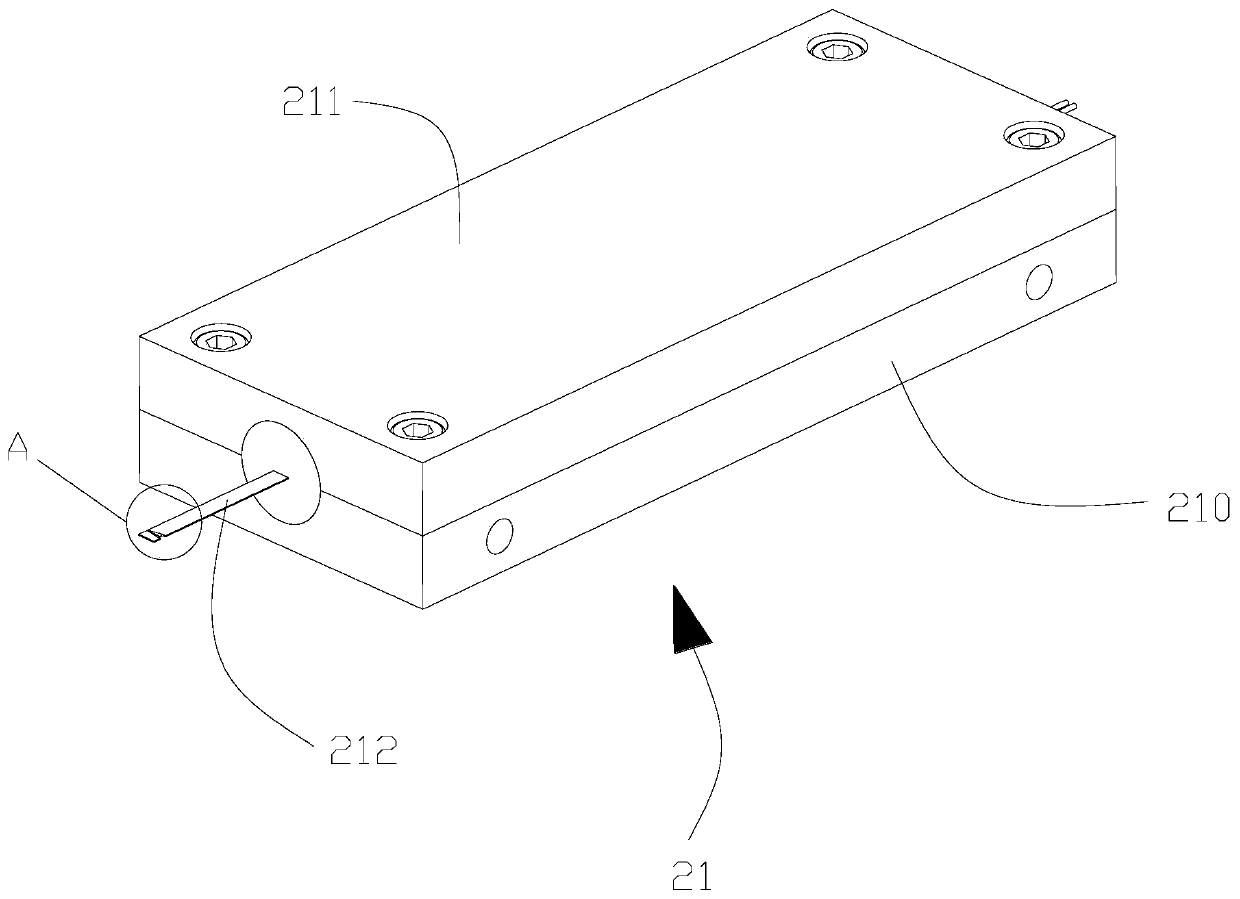

Branch trimming vehicle and branch trimming device thereof

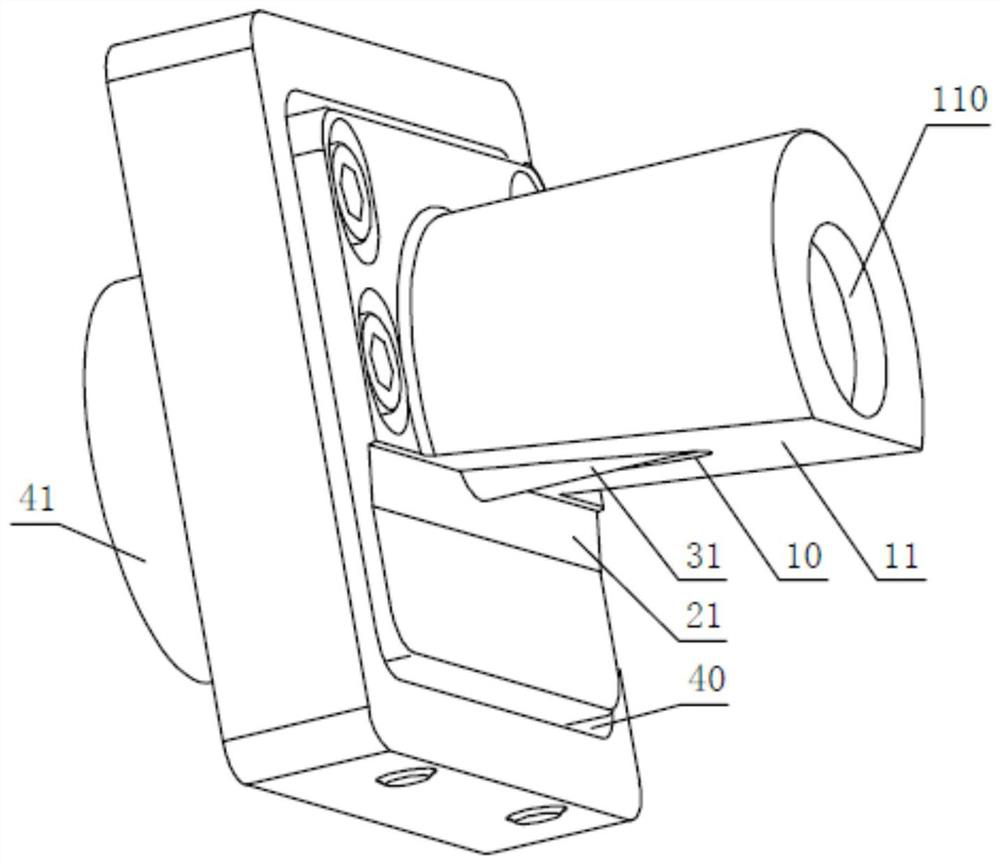

ActiveCN114342687ATrim flexibleFlexible adjustmentCuttersCutting implementsStructural engineeringControl theory

The invention discloses a branch pruning vehicle and a branch pruning device.The branch pruning device comprises a connecting arm, a first reversing mechanism and a mounting base which are connected in sequence, and a clamping mechanism and a cutting mechanism which are arranged on the mounting base; the connecting arm is used for being installed on a lifting arm frame of the branch pruning vehicle and driven by the lifting arm frame to move in a lifting mode, and the installation base achieves reversing rotation on the connecting arm through the first reversing mechanism. According to the branch pruning device, the mounting position of the mounting base is extended through the connecting arm, the mounting base is driven by the first reversing mechanism to rotate on the connecting arm in a reversing mode, the mounting base can rotate along at least two axes with included angles, the position and the angle are flexibly adjusted, and the practicability is high. Therefore, the clamping mechanism and the cutting mechanism on the mounting seat can be flexibly adjusted to proper operation positions and angles, branches at different growth angles can be flexibly clamped and trimmed, the branch trimming quality is guaranteed, and the branch trimming efficiency is improved.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

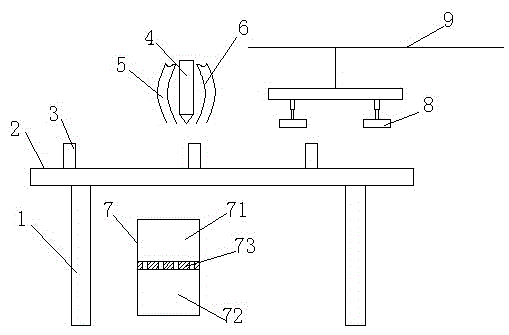

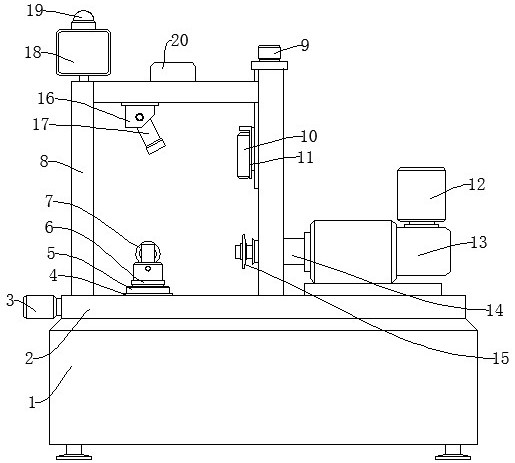

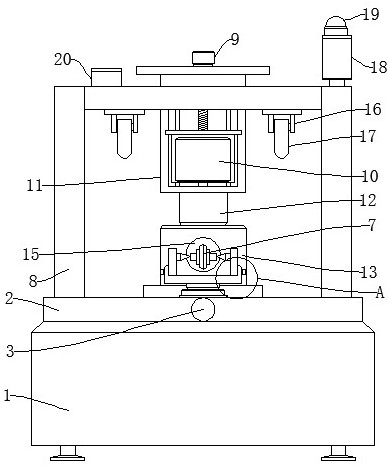

Digital monitoring system for diamond dressing rollers

PendingCN111843830AGuarantee trimming qualityAccurate measurementGrinding feed controlAbrasive surface conditioning devicesMonitoring systemGrinding wheel

The invention discloses a digital monitoring system for diamond dressing rollers. The system comprises a base, a workbench and a No. 1 servo motor, wherein the base is provided with the workbench, oneside of the workbench is provided with the No. 1 servo motor, and a support frame is arranged on the upper side of the workbench. The digital monitoring system for diamond dressing rollers has the beneficial effect that, through a No. 2 servo motor, a vertical sliding seat and a three-dimensional scanner provided in the invention, the system can accurately measure the size change of the outer surface of a grinding wheel, so as to ensure the trimming quality of the grinding wheel by the device; through a fixed seat, a high-definition camera, a display screen and a warning light provided, the system is enabled to monitor the correction process of the grinding wheel in real time, and use the warning light to warn and remind the operator to adjust the trimming process when the grinding wheelhas a trimming deviation, so as to improve trimming percent of pass of the grinding wheel.

Owner:郑州华菱超硬材料有限公司

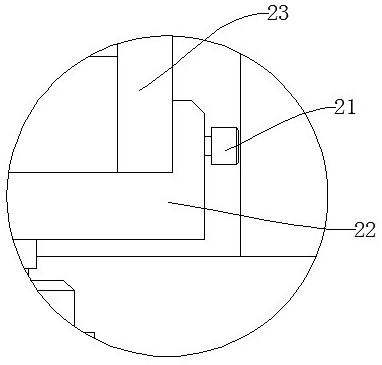

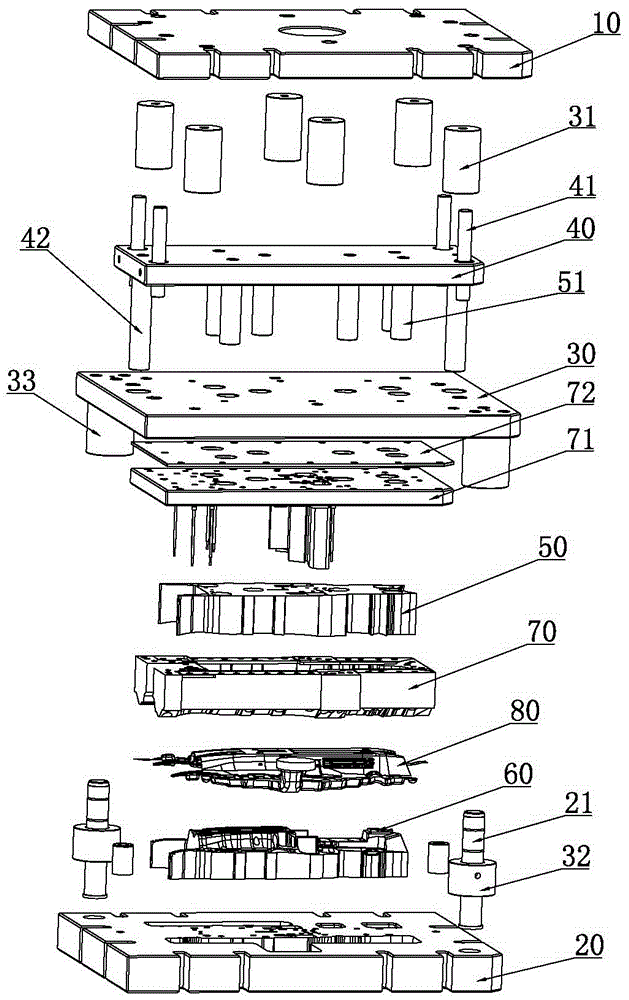

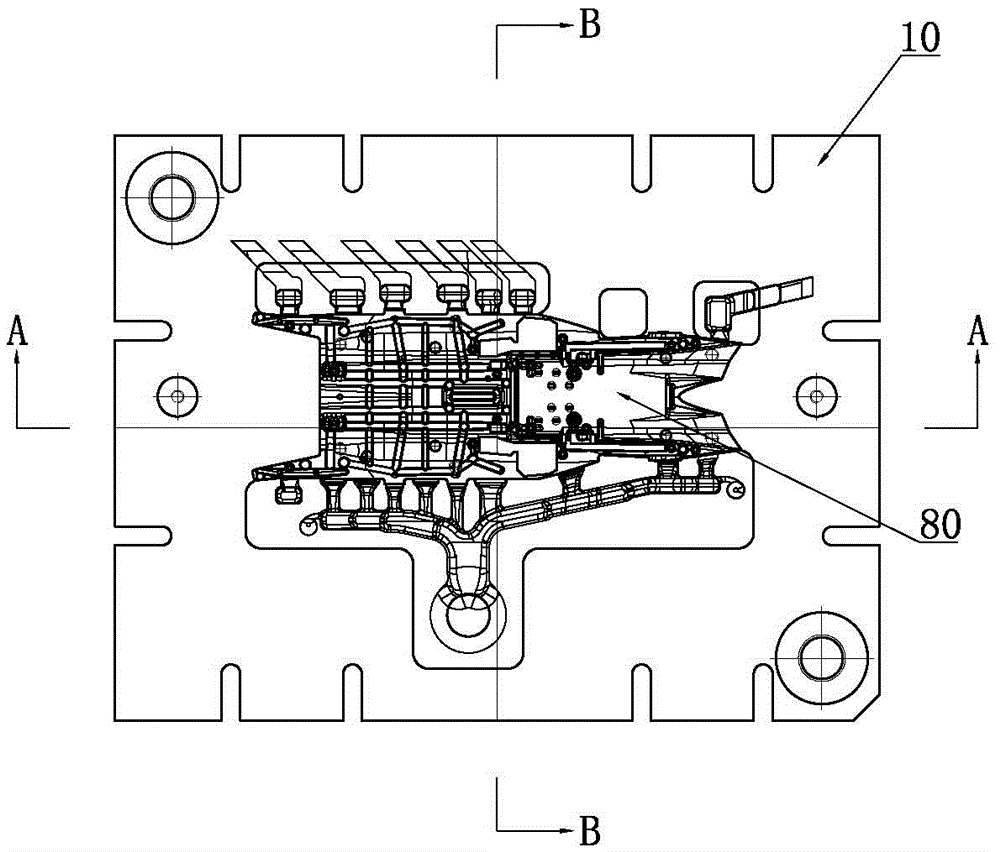

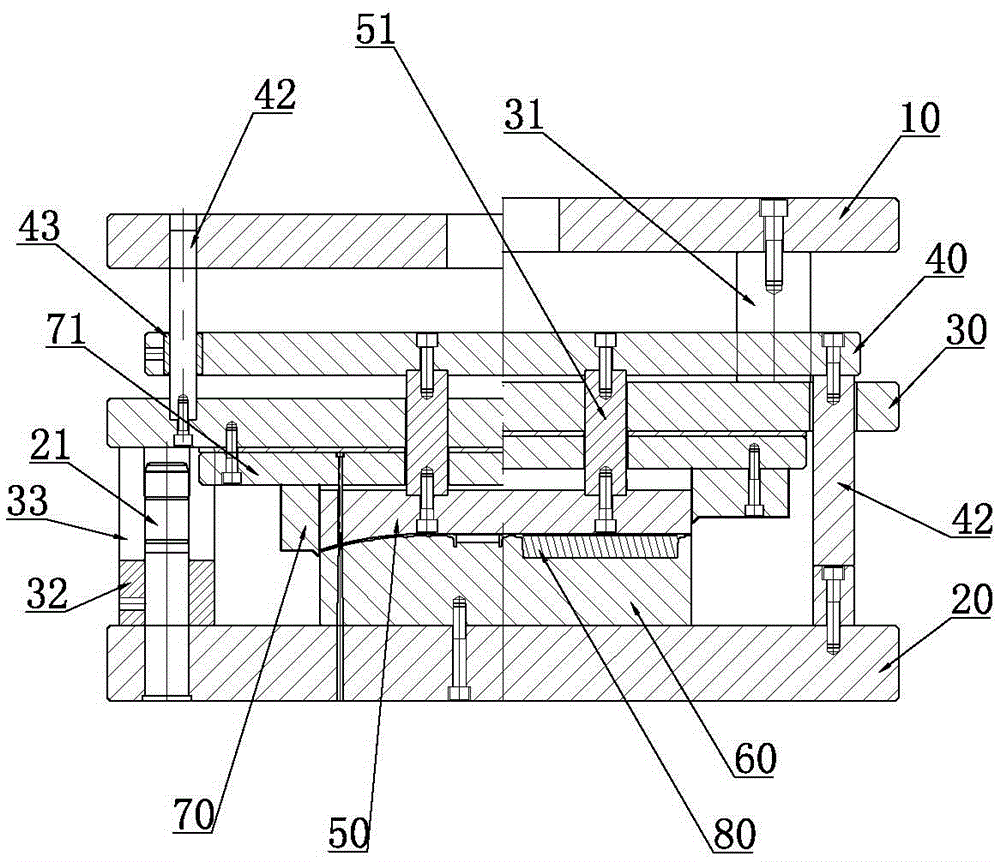

A trimming mold

The invention relates to the technical field of die-casting dies, in particular to a side shearing die. The side shearing die comprises an upper die plate and a lower die plate which are mutually matched, wherein lower die plate guide posts are symmetrically mounted at the opposite angles of the lower die plate; a middle plate is arranged between the lower die plate and the upper die plate; an upper pressing plate is arranged between the middle plate and the upper die plate; a product pressing plate is arranged between the middle plate and the lower die plate; the product pressing plate is fixedly connected with the upper pressing plate by a product pressing plate connecting pillar which is arranged in the middle plate in a penetrating way; a product base plate is arranged between the product pressing plate and the lower die plate; a side shearing tool which is connected with the middle plate is arranged on the outer side of the product pressing plate. Runners, cinder ladles, burrs and the like on die castings are cut off at the same time by single side shearing of the die castings, the deformation of the die castings, which is caused by the sequential side shearing of the runners, the cinder ladles and the burrs on the die castings is prevented, the side shearing quality of a product is ensured, no manual operation is needed, and the side shearing working efficiency of the die castings is thus improved.

Owner:DONGGUAN DONGSHENG DIE CASTING MOLD

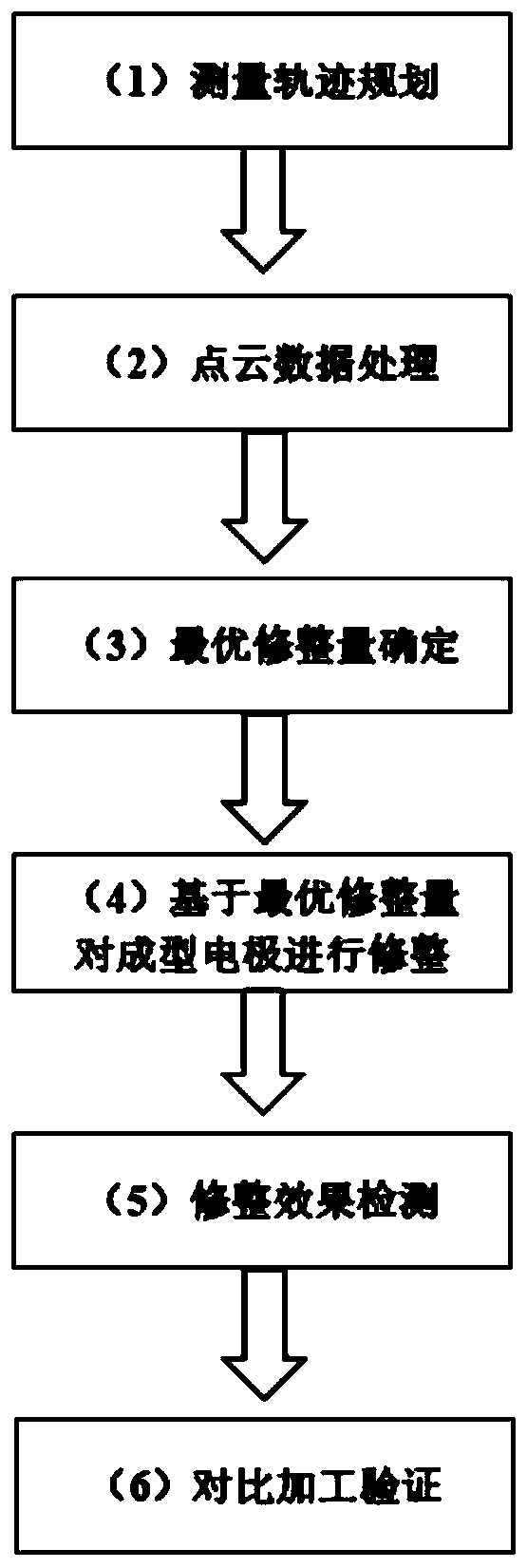

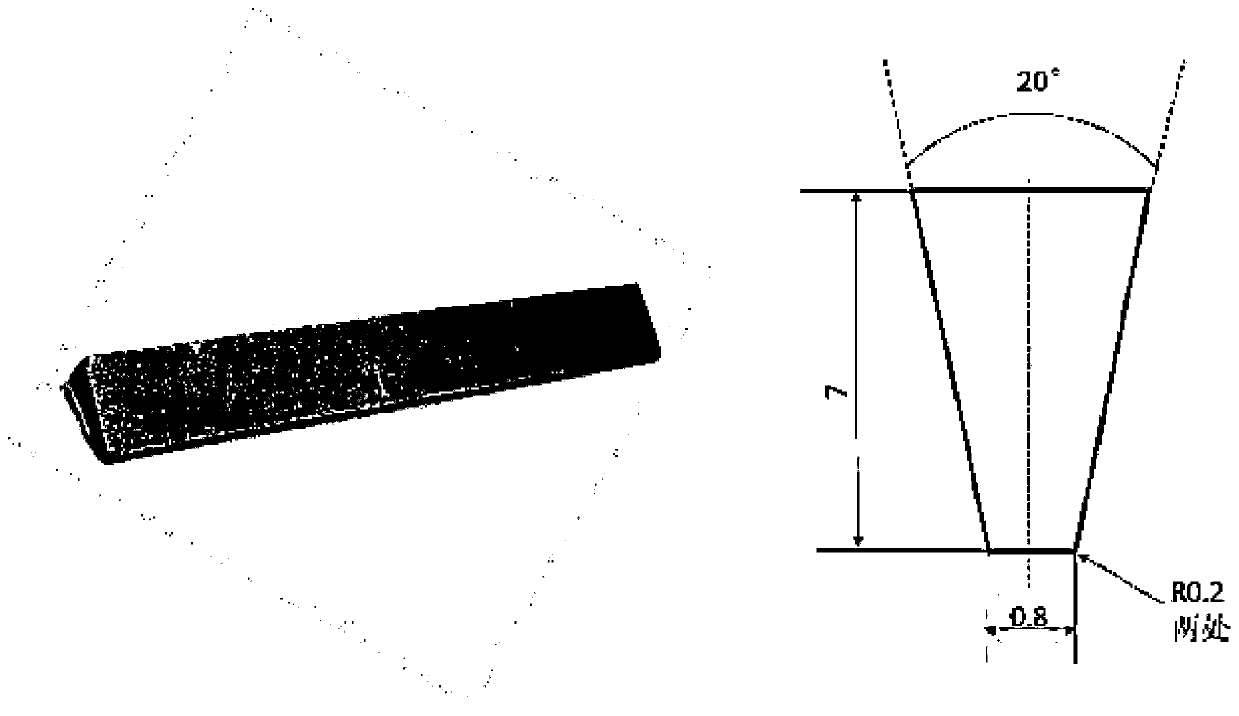

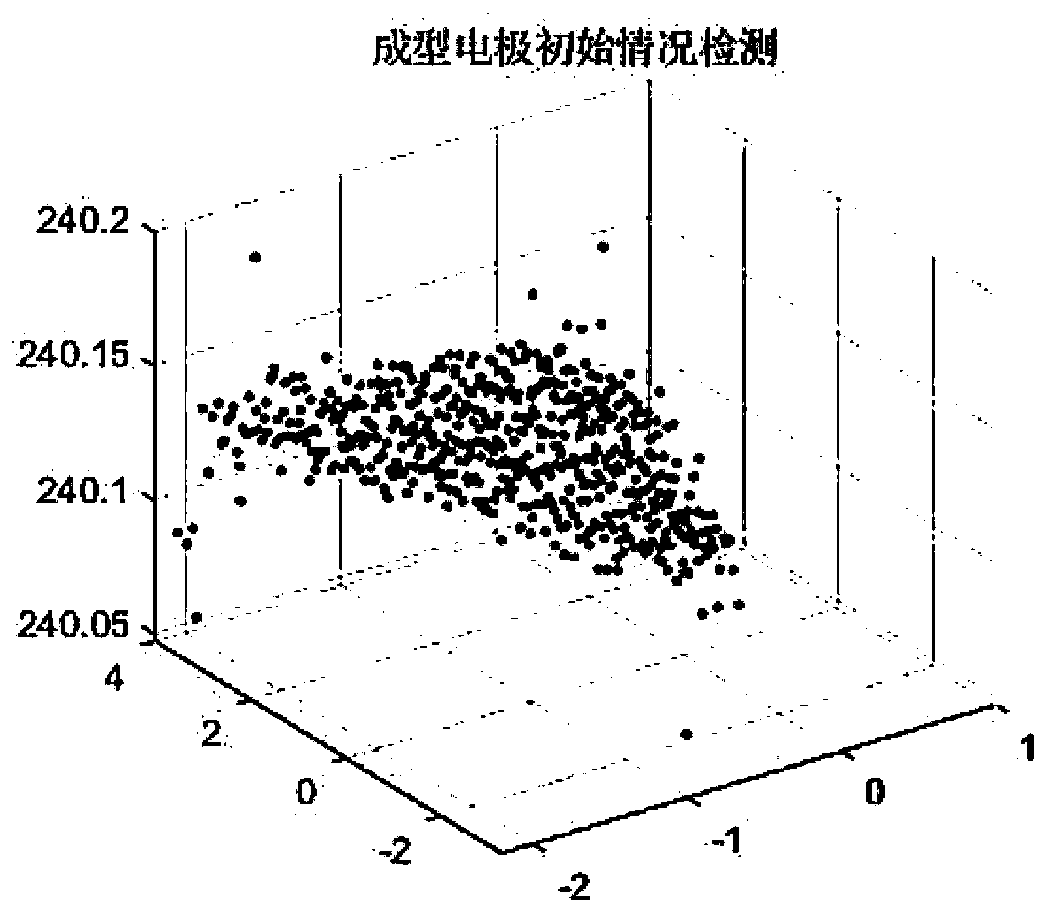

Method for realizing optimal finishing amount of formed electrode loss based on point cloud data processing

ActiveCN110977064AAccurately determineImprove processing efficiencyUsing optical meansElectrical-based machining electrodesProcess engineeringCoordinate-measuring machine

The invention discloses a method for realizing the optimal finishing amount of the formed electrode loss based on point cloud data processing. The formed electrode loss situation is measured through alaser three-coordinate measuring machine, point cloud data are obtained, and the point cloud data are transformed from a machine tool coordinate system to a workpiece coordinate system and denoised;and then approximate plane fitting is conducted through a least square method to obtain the optimal finishing amount, and by adopting a reverse-forming finishing technology and combining the optimal finishing amount, a dissipated formed electrode is finished through a reverse copying block. The optimal finishing amount of the tool electrode loss in electric spark non-traditional machining can be accurately determined, the machining efficiency is improved, and the finishing quality is ensured.

Owner:SHANGHAI JIAO TONG UNIV

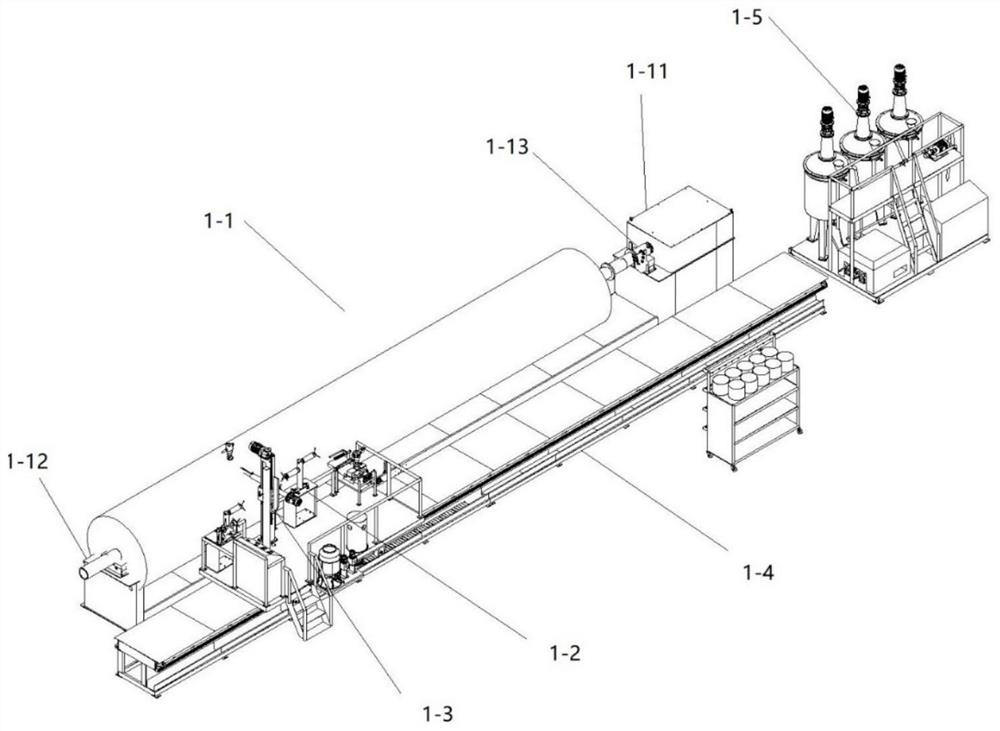

Bamboo winding composite pipe manufacturing equipment

PendingCN113370333AAchieve swingExtended service lifeCane mechanical workingAdhesive application devicesSystem structureWinding machine

The invention discloses bamboo winding composite pipe manufacturing equipment, and belongs to the field of bamboo winding composite pipes. The bamboo winding composite pipe manufacturing equipment comprises a lining preparing machine, a winding machine, a demolding machine, a trimming machine and a feeding machine; the lining preparing machine is used for preparing a lining layer of a bamboo winding composite pipe on a pipe mold; the winding machine is used for winding a bamboo-based reinforcing layer on the lining layer; the trimming machine is used for trimming the end part of the bamboo winding composite pipe which is cured and coated with an outer protective layer so as to prepare a bell and spigot; the demolding machine is used for separating the pipe mold from the bamboo winding composite pipe; and the feeding machine is used for supplying bamboo powder. In the lining manufacturing process, pouring is very flexible and controllable, a winding station is provided with double workbenches, the mold moving space is sufficient, a backflow system is omitted, sealing is achieved through a cutter grinding shaft at a trimming station, spraying can be conducted after grinding is completed, the clamping and grabbing process in the demolding process is more powerful and reasonable, the structure of the feeding machine is simpler, and material conveying is stable and reliable. The whole system structure of the equipment is more reasonable, and production is more efficient.

Owner:中林鑫宙竹缠绕发展有限公司

Edge cutting device for suspension rubber washer

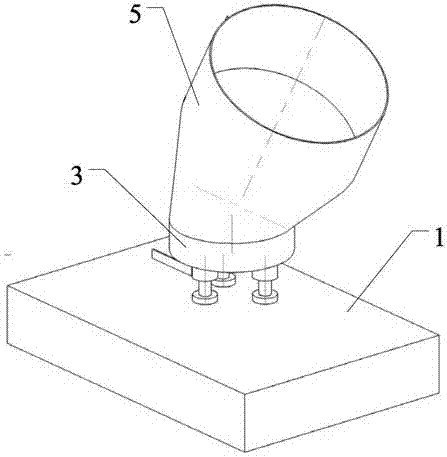

PendingCN111055309AImprove trimming efficiencyGuarantee trimming qualityMetal working apparatusStructural engineeringWasher

The invention discloses an edge cutting device for a suspension rubber washer. The edge cutting device comprises a bottom plate, a positioning column and a cutting mechanism, wherein the positioning column is arranged on the bottom plate and is detachably connected with the bottom plate to facilitate replacing different sizes of positioning columns and mount different specifications and sizes of suspension rubber washers; the suspension rubber washer is rotationally mounted on the positioning column; the cutting mechanism is mounted on the bottom plate; and during the process of rotating the suspension rubber washer, the cutting mechanism can cut leftover materials of the suspension rubber washer. By trimming the suspension rubber washer rotationally mounted on the positioning column by the cutting mechanism, the edge cutting efficiency is improved, the edge cutting quality is improved, the working efficiency is improved, and the qualified rate of a product is improved.

Owner:ZHONGSHAN XIONGBING RUBBER

Portable trimming device for refractory bricks

InactiveCN108582518AEasy to determineEasy to trimWorking accessoriesStone-like material working toolsFire brickEngineering

The invention discloses a portable trimming device for refractory bricks in the technical field of production of the refractory bricks. The portable trimming device comprises a rack; two sets of height adjusting rods are fixedly installed on the rack and sleeved with first slide sleeves; the height adjusting rods and the first slide sleeves are fastened by first locking knobs; a horizontal adjusting rod is fixedly connected between the two sets of first slide sleeves and sleeved with a second slide sleeve; and the second slide sleeve is longitudinally and movably connected with a height fine-adjusting rod in an inserted mode. The trimming size is adjusted through the height adjusting rods, the horizontal adjusting rod and the height fine-adjusting rod, the trimming position is convenient to determine through alignment of a laser lamp, the trimming errors are reduced, the refractory bricks are fixed through a brick pushing board, and the trimming quality is ensured conveniently during stable traveling.

Owner:CHANGXING RUIHONG REFRACTORY MATERIAL CO LTD

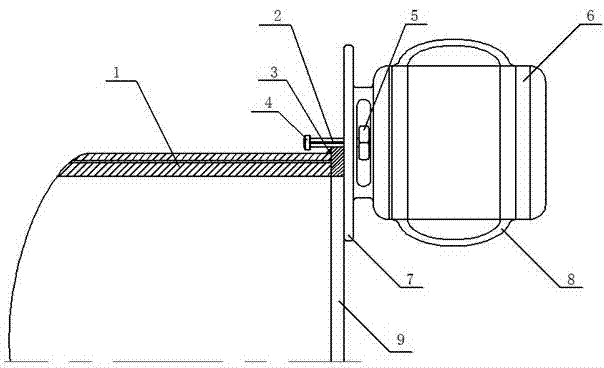

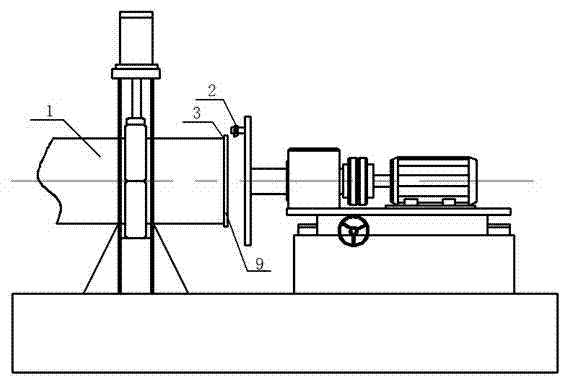

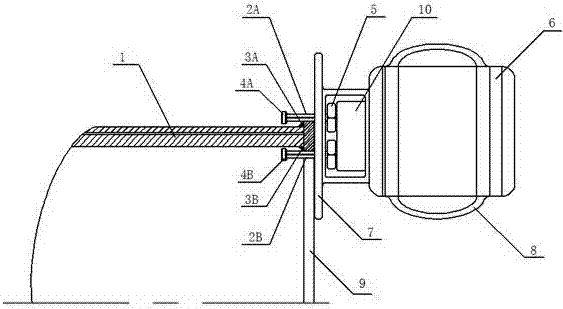

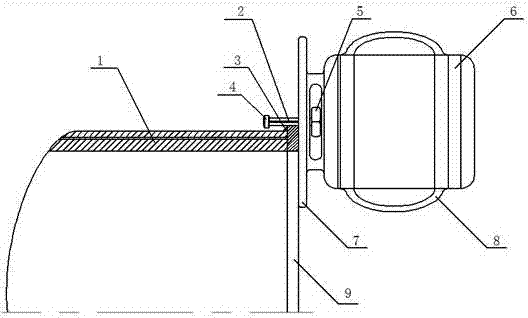

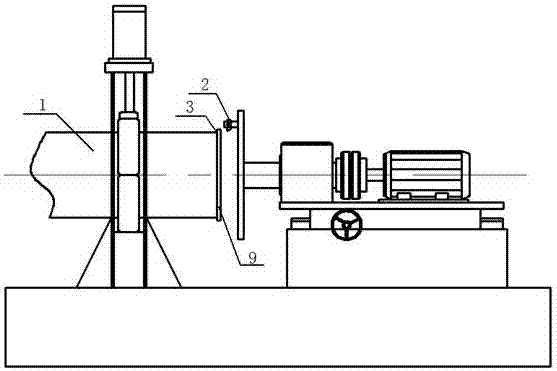

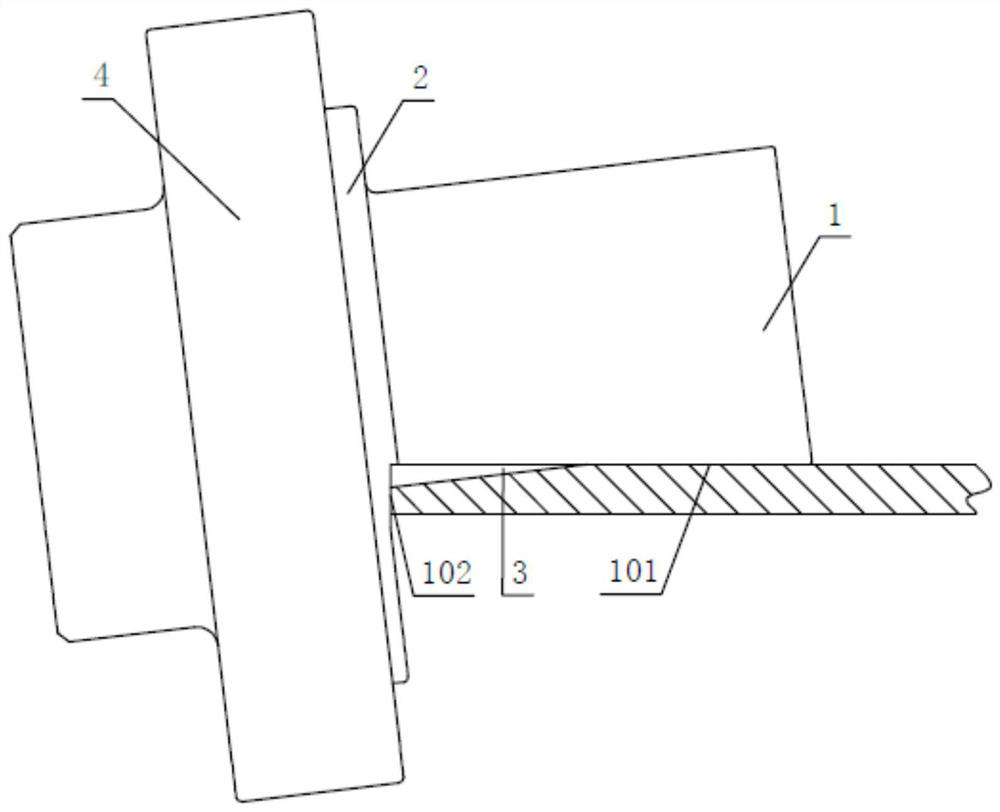

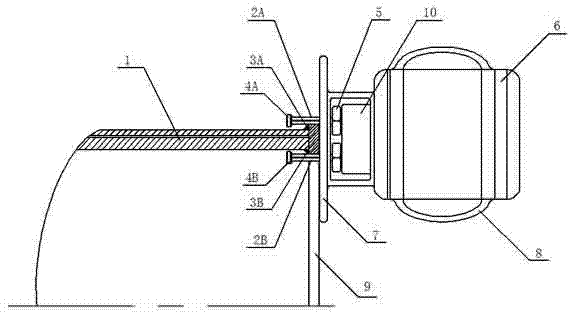

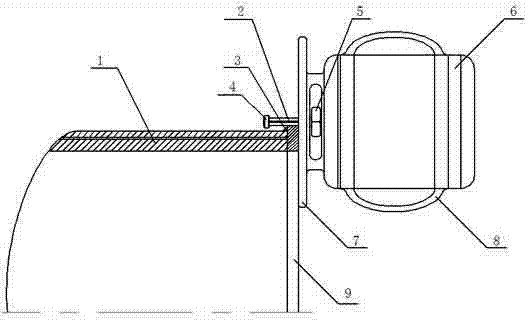

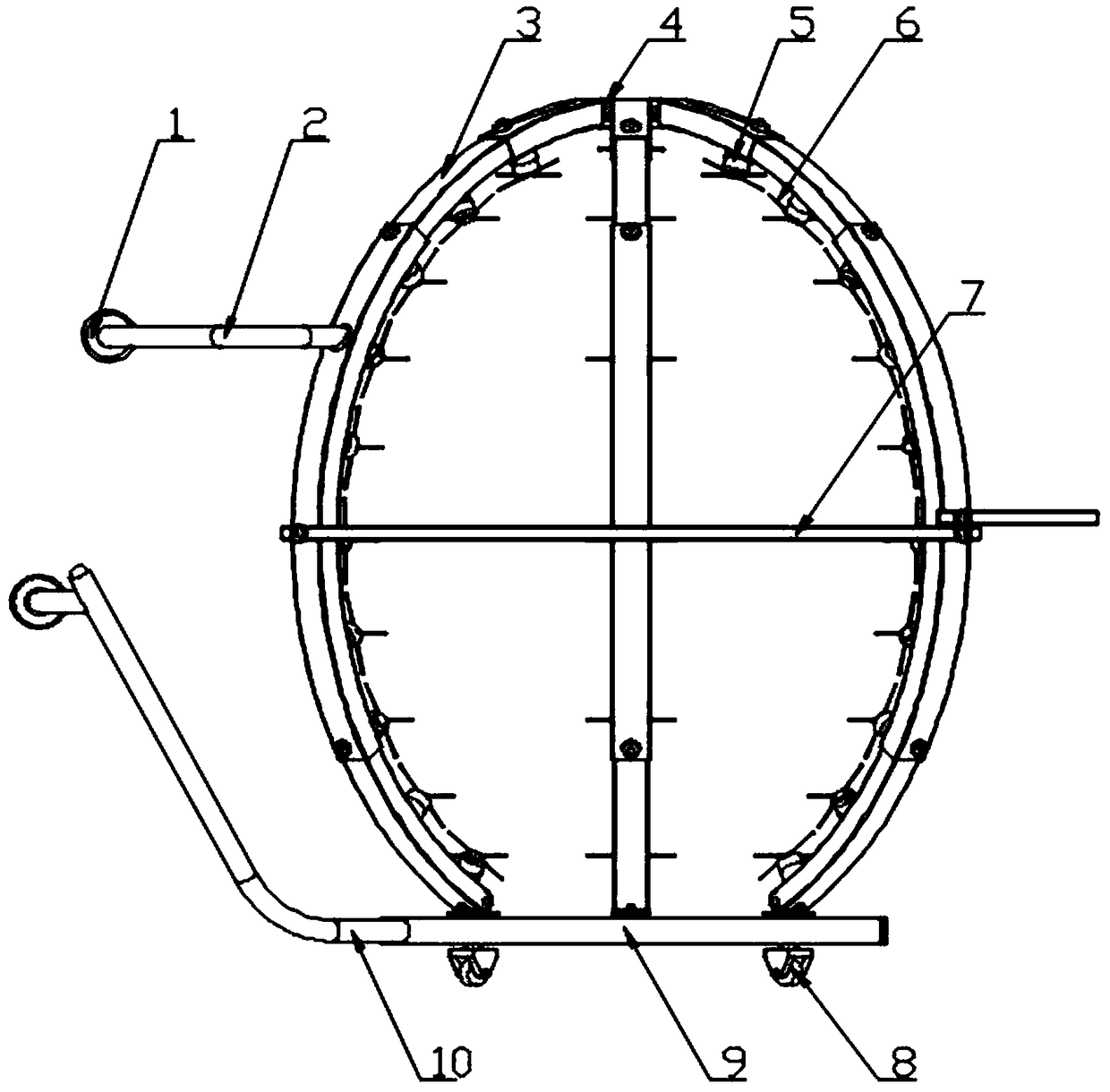

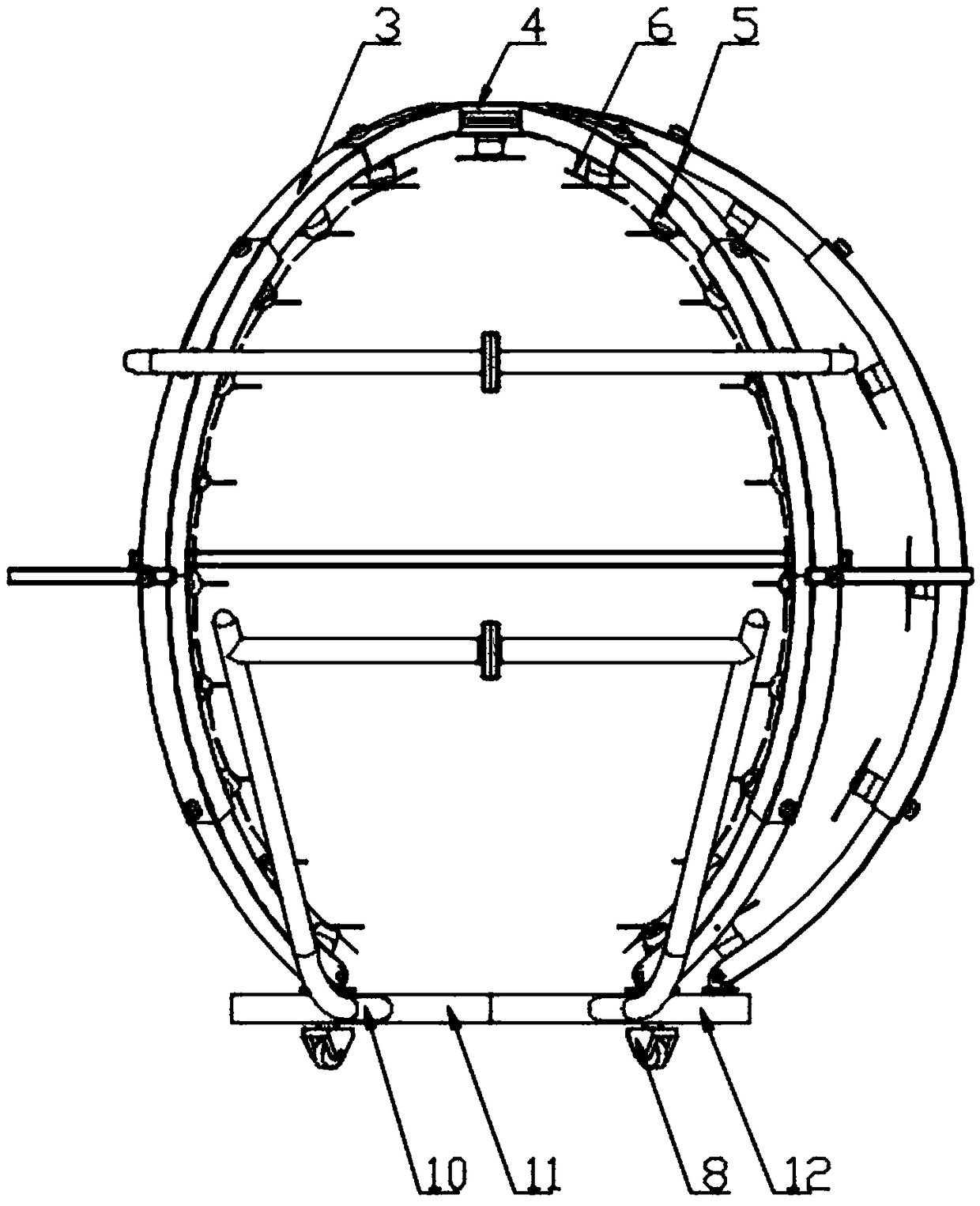

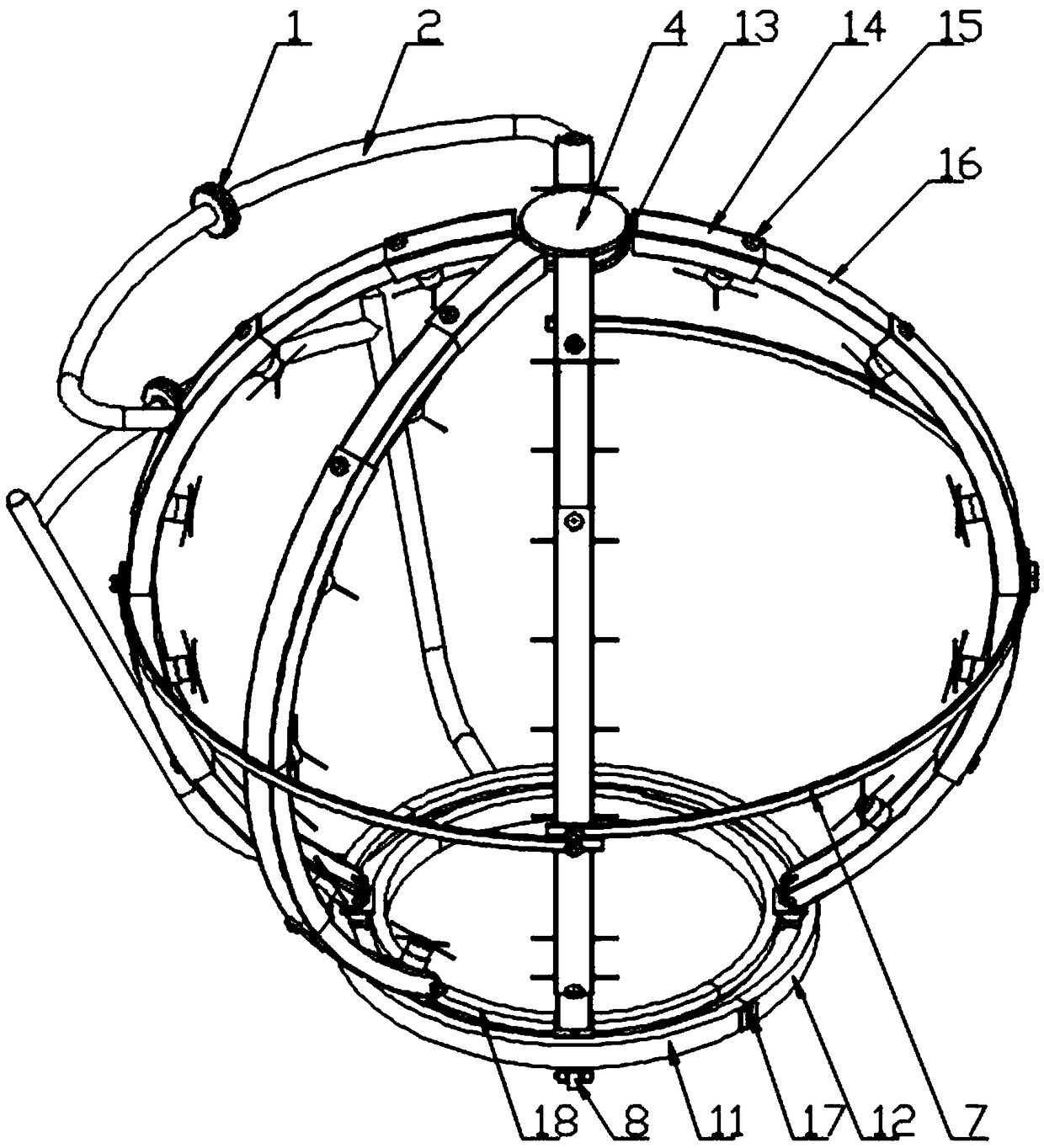

Trimming device for end face of large-diameter steel-plastic composite water feeding pipe

ActiveCN104742286AGuarantee trimming qualityImprove pass rateMetal working apparatusMechanical engineeringSewerage

The invention provides a trimming device for an end face of a large-diameter steel-plastic composite water feeding pipe. The trimming device for the steel-plastic composite pipe comprises a rotary cutting tool, a surface positioning ball, an end face positioning baffle, a rotary cutting tool locking device, a high-speed motor, a handle and a trimming device assembly; the trimming device is positioned by the outer surface of the pipe so that the trimming quality is guaranteed; and meanwhile, a special field is not occupied and the edge of the steel-plastic composite pipe is movably trimmed, and the trimming device can be widely applied to the field of water supply and sewerage works.

Owner:云南傲远智能环保科技有限公司

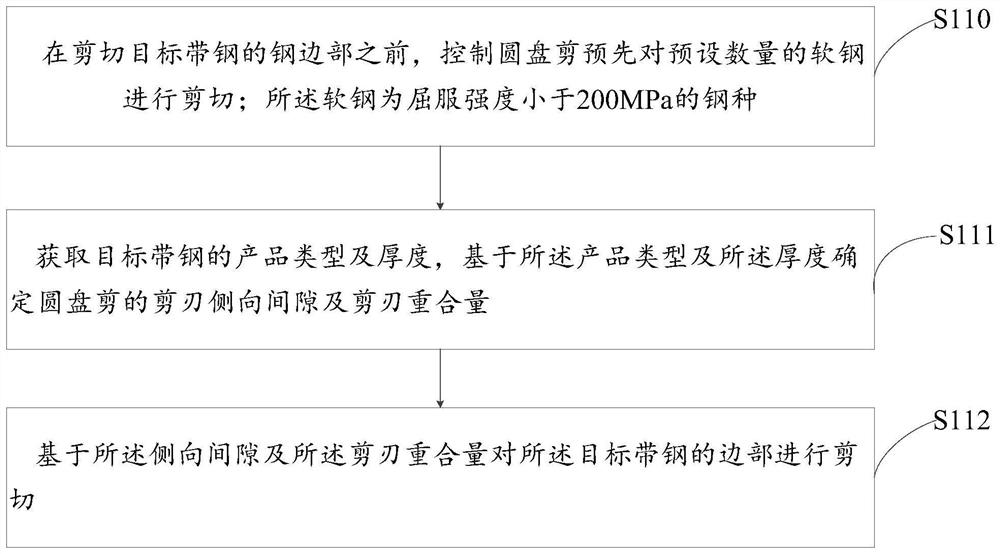

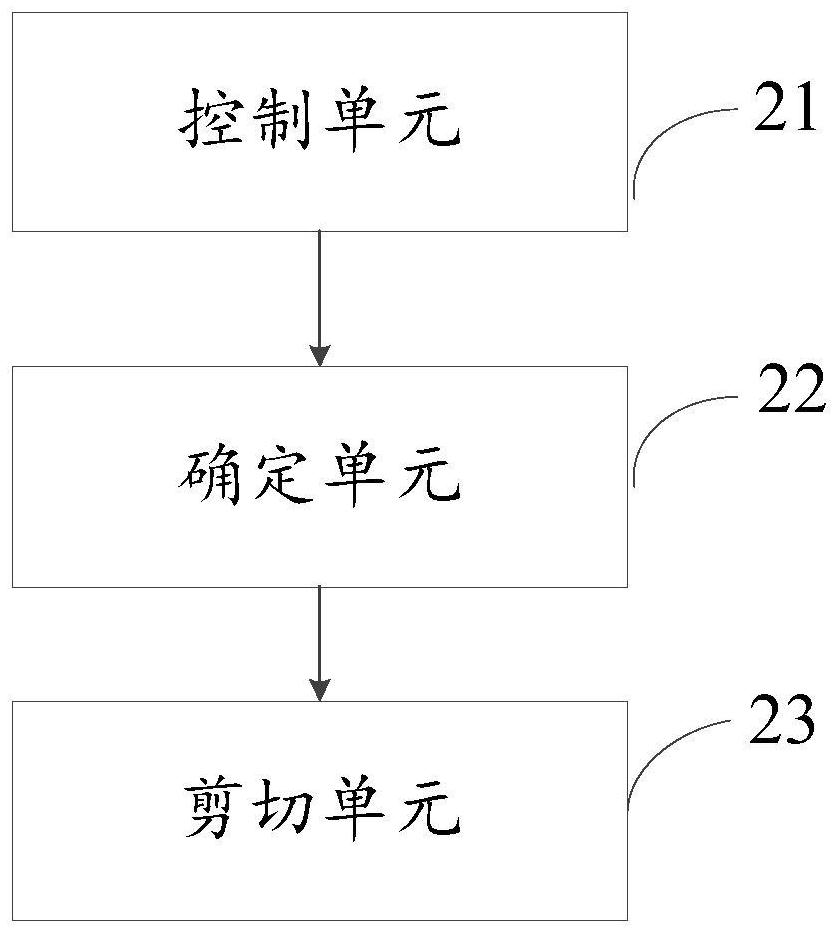

Method, device, medium and equipment for improving trimming quality of high-strength steel

PendingCN114871490AGuaranteed cutting accuracyGuarantee trimming qualityShearing machinesStructural engineeringStrip steel

According to the method, the device, the medium and the equipment for improving the trimming quality of the high-strength steel, after a preset number of soft steel is sheared through a circle shear, due to the fact that the yield strength of the soft steel is smaller than 200 MPa, the uniformity of the temperature of a shear blade can be ensured, local hard points or local soft points are prevented from occurring in the shear blade, and the trimming quality of the high-strength steel is improved. Cracks on the edge part of the subsequently sheared strip steel are avoided; then the corresponding shear blade lateral gap and shear blade coincidence amount are determined based on the actual thickness and the product type of the target strip steel, the influence of the product characteristics of the target strip steel on the shearing parameters of the circle shear is fully considered, then the shearing precision of the circle shear can be ensured, and the trimming quality of high-strength series continuous annealing products and galvanized products is ensured.

Owner:SHOUGANG CORPORATION +1

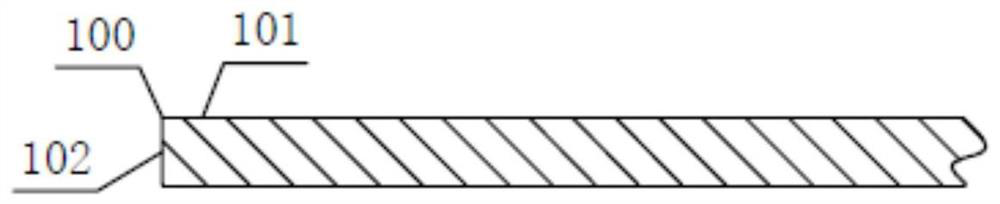

Edge-trimming cutter device of belt core

ActiveCN104260124AAvoid wiggle phenomenonCan't solve itMetal working apparatusEngineeringDisc cutter

The invention discloses an edge-trimming cutter device of a belt core. The device comprises a glue returning portion (1), an edge trimming portion (2) and a compressing portion (3). The glue returning portion (1) is fixed to one end of a right-angle frame (4); the other end of the right-angle frame (4) is fixed to a support of the compressing portion (3); the edge trimming portion (2) is fixed to the side face of the compressing portion (3). According to the edge-trimming cutter device of the belt core, a manual edge-trimming cutter structure is adopted, the phenomena that a disc cutter cannot thoroughly cut the edge, and smoking happens are avoided, and the edge trimming quality is ensured. Due to the fact that a compressing roller structure is adopted in the design, in the cutting process, the belt core can be in the tightening state, and in the cutting process, the belt core is prevented from swinging. Due t o the fact that a straight-plate cutter structure of a groove blade is adopted in the design, it is ensured that cutting and feeding are smooth, and the cutting quality is ensured. Due to the fact that a glue side returning structure is adopted in the design, removal glue sides can be returned into a recycling hopper.

Owner:大连橡胶塑料机械有限公司 +1

The Method of Trimming the End Surface of Large Diameter Steel-plastic Composite Water Supply Pipe

The method of trimming the end face of the large-diameter steel-plastic composite water supply pipe, the steps of trimming the end face of the large-diameter steel-plastic composite water supply pipe: welding the plastic sealing ring and the cut section of the steel-plastic composite water supply pipe by hot-melt butt welding; unilateral trimming The edge device performs fine trimming of the outer surface; the single-side trimming device performs fine trimming of the inner surface; the double-sided trimming device performs rough trimming of the outer surface and the inner surface at the same time, and does not occupy a special site at the same time, mobile repair steel-plastic composite Pipe edge; improve the pass rate of products, reduce product costs and improve economic benefits. It can be used in water supply and drainage projects.

Owner:云南傲远智能环保科技有限公司

Trimming device

InactiveCN111618353AGuaranteed service lifeGuarantee trimming qualityMilling equipment detailsMechanical engineeringPhysics

The invention relates to the technical field of material molding, and discloses a trimming device. The trimming device is used for trimming an edge of a workpiece, and includes a profiling pipe used for abutting against a first side face of the edge, a master plate connected to one end of the profiling pipe and used for abutting against a second side face of the edge, and a cutter that extends from the profiling pipe. In the trimming device of the invention, the cutter extends out of the profiling pipe to trim the edge of the workpiece, during trimming and processing, the profiling pipe abutsagainst the first side face of the edge, the master plate abuts against the second side face of the edge, and so, a trimming path of the cutter is restricted, and the trimming quality and the servicelife of the cutter are ensured.

Owner:COMAC +1

Edge cutting device with core

ActiveCN104260124BAvoid wiggle phenomenonGuarantee trimming qualityMetal working apparatusCircular discEngineering

The invention discloses an edge-trimming cutter device of a belt core. The device comprises a glue returning portion (1), an edge trimming portion (2) and a compressing portion (3). The glue returning portion (1) is fixed to one end of a right-angle frame (4); the other end of the right-angle frame (4) is fixed to a support of the compressing portion (3); the edge trimming portion (2) is fixed to the side face of the compressing portion (3). According to the edge-trimming cutter device of the belt core, a manual edge-trimming cutter structure is adopted, the phenomena that a disc cutter cannot thoroughly cut the edge, and smoking happens are avoided, and the edge trimming quality is ensured. Due to the fact that a compressing roller structure is adopted in the design, in the cutting process, the belt core can be in the tightening state, and in the cutting process, the belt core is prevented from swinging. Due t o the fact that a straight-plate cutter structure of a groove blade is adopted in the design, it is ensured that cutting and feeding are smooth, and the cutting quality is ensured. Due to the fact that a glue side returning structure is adopted in the design, removal glue sides can be returned into a recycling hopper.

Owner:大连橡胶塑料机械有限公司 +1

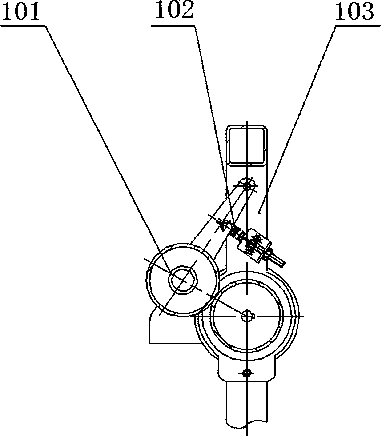

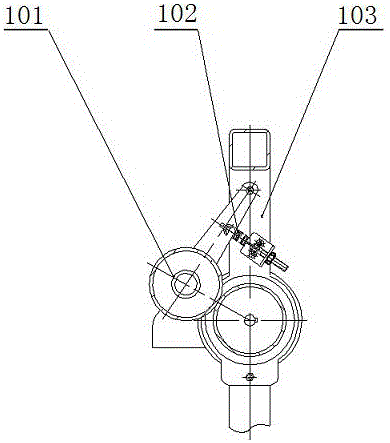

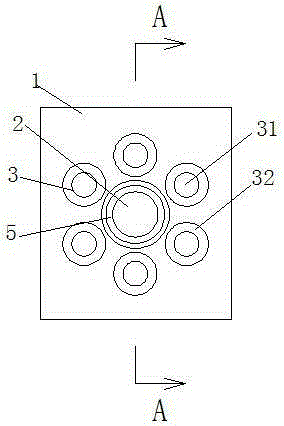

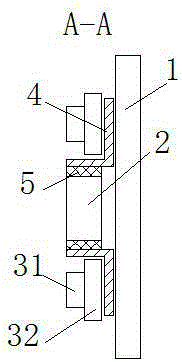

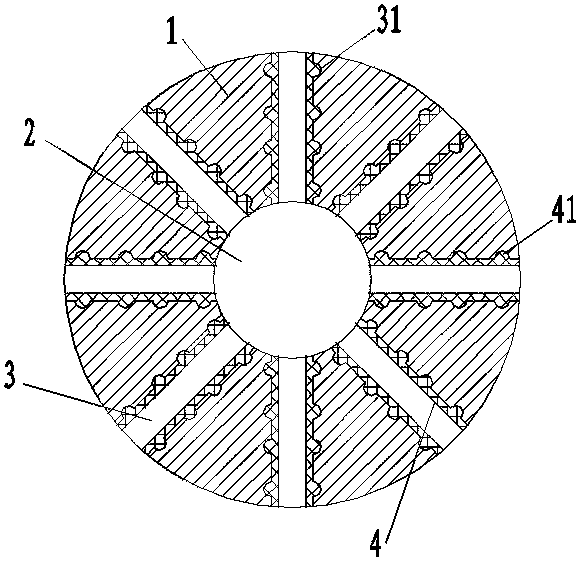

Round tube flanging trimming device

The invention relates to a round tube flanging trimming device. The round tube flanging trimming device comprises a frame (1). A rotating wheel (2) and pressing wheels (3) are arranged on the frame (1); the rotating wheel (2) and the pressing wheels (3) are arranged to meet the condition that the rotating wheel (2) is arranged in the middle while a plurality of pressing wheels (3) are annularly arranged centered by the rotating wheel (2), the pressing wheels (3) can radially move relative to the rotating wheel (2), round tube flanging (4) enters a gap formed by the pressing wheels (3) and the side wall of the frame (1), and the pressing wheels (3) can move horizontally relative to the side wall of the frame (1). According to the round tube flanging trimming device provided by the invention, a round tube is driven by the rotating wheel to rotate, and in the rotating process, the round tube is subjected to pressing of the plurality of pressing wheels. The pressing wheels provided by the invention are annularly arranged, so that in the rotating process, the flanging port of the round tube can be pressed in almost time, and therefore, the trimming quality of flanging is guaranteed.

Owner:扬州市邗江科达涂装有限公司

Mold for seam trimming of titanium alloy straight pipe and method for machining seam trimming

InactiveCN103264184BGuarantee trimming qualityEasy to weldMilling equipment detailsPositioning apparatusMetallurgyMilling cutter

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

Formed grinding wheel trimming wheel

InactiveCN107553332AImprove cooling effectReduce shockAbrasive surface conditioning devicesGrinding/polishing safety devicesCooling effectEngineering

The invention relates to a shaping grinding wheel dressing wheel. Including a base body (1), the base body (1) is provided with a cooling medium inlet (2), and the base body (1) is provided with a number of cooling mediums arranged in the radial direction and communicating with the cooling medium inlet (2) A pipe (3), the end of the cooling medium pipe (3) extends to the outer circular surface of the base (1) to allow the cooling medium to flow out from the base (1). In the present invention, a cooling medium inlet and a cooling medium pipeline are provided on the base body, and the cooling medium flows out from the inside of the base body to cool the grinding wheel and the dressing wheel. This structural form can make the cooling more sufficient and further improve the cooling effect.

Owner:江苏万金工具有限公司

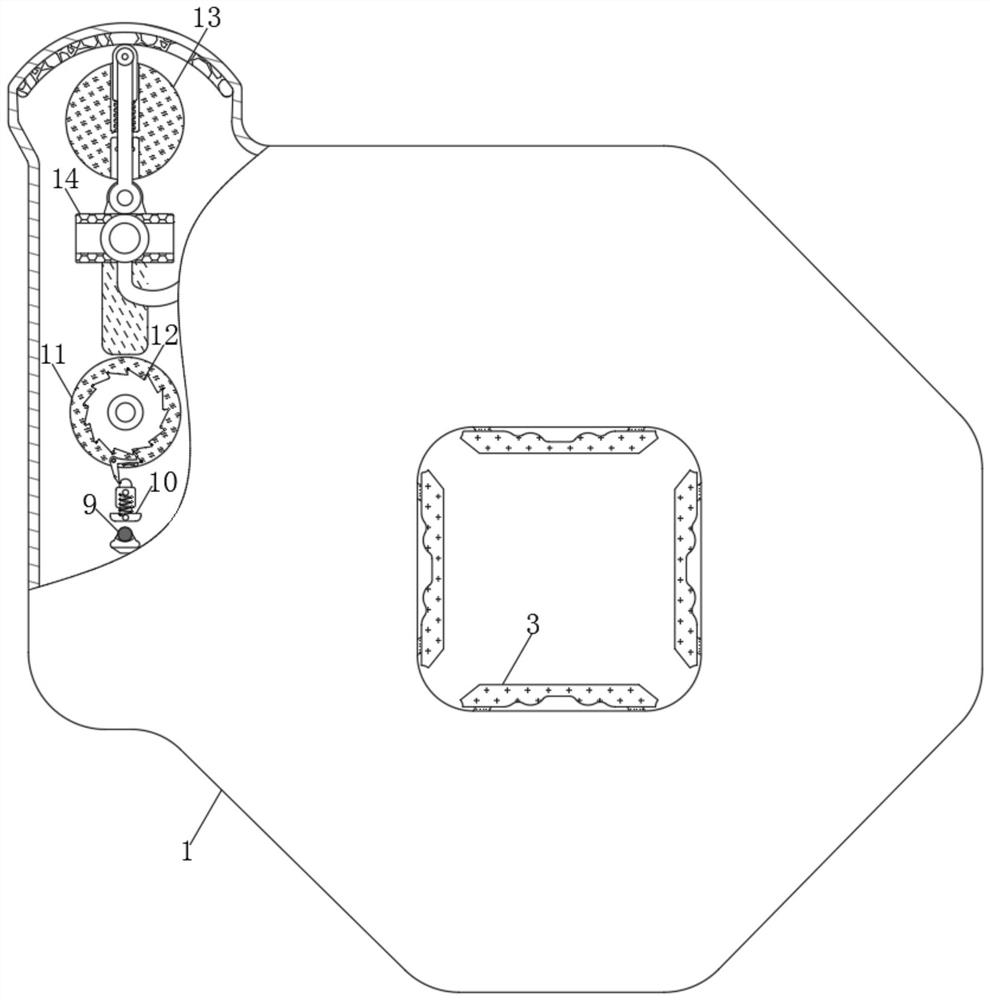

Trimming device for solving problem of irregular shape of insulating layer of square tube

The invention relates to the technical field of electric power, and discloses a trimming device for solving a problem of an irregular shape of an insulating layer of a square tube. The trimming device comprises a shell, wherein an air ring is fixedly connected to the interior of the shell. Through the combined action of the air ring, a detection mechanism, an insulating tube, a metal slip sheet, an ejector rod, an electromagnet, a brake rod, a first rotary disc and a ratchet wheel, heating operation is automatically triggered by utilizing a bulge on the surface of a cable, so that the bulge of the insulating layer is broken by heating, the trimming operation is facilitated, the trimming operation is started, the linkage between structures is improved, the operation is convenient and fast, and the automation degree is high; and through the combined action of a second rotary disc, a sliding plate, a third rotary disc, a pressing tool and a ring plate, the four faces of the cable are extruded automatically, the other faces of the cable are supported while the insulating layer face where the bulge exists is flattened, the situation that the cable is distorted due to non-uniformity is effectively avoided, and the trimming quality is guaranteed.

Owner:朱宽雄

Large-caliber steel-plastic composite water supply pipe end face trimming method

The invention relates to a large-caliber steel-plastic composite water supply pipe end face trimming method. The large-caliber steel-plastic composite water supply pipe end face trimming steps include: welding a plastic sealing ring and a steel-plastic composite water supply pipe cutting section by means of hot melting butt welding; conducting outer surface fine trimming by a single side trimming device; performing inner surface fine trimming by the single side trimming device; and conducting rough trimming on the inner surface and outer surface simultaneously by a double side trimming device. Also, the edge of the steel-plastic composite pipe can be trimmed movably without occupying special field. The qualified rate of the product is improved, the product cost is reduced, and the economic benefits are improved. The method can be applied in water supply and drainage engineering.

Owner:云南傲远智能环保科技有限公司

Round plant trimming device

The invention relates to a round plant trimming device. The round plant trimming device is characterized in that one ends of a plurality of telescopic supporting rods are installed on a bottom plate at intervals, the other ends of the telescopic supporting rods are installed on a top plate at intervals, micro servo motors are arranged on the telescopic supporting rods at intervals, cutting knivesare connected to the micro servo motors, a trimming handle connected through a magnet is arranged between any two adjacent telescopic supporting rods, the bottom plate comprises a left bottom plate body and a right bottom plate body, one ends of the left bottom plate body and the right bottom plate body are connected through a hinge, and the other ends of the left bottom plate body and the right bottom plate body are connected through a magnet. The round plant trimming device is scientific and reasonable in structural design, the trimming device can be adjusted according to the size of round plants, automatic trimming is facilitated, the trimming neatness is high, the working efficiency is improved, labor is saved, and the round plant trimming device is wide in application range.

Owner:CHONGQING CITY MANAGEMENT COLLEGE

A tissue wax repair instrument

ActiveCN110793835BQueue guaranteeArrange correctlyPreparing sample for investigationSurgeryMechanical engineering

Owner:广州耐确医疗器械有限责任公司

Method for utilizing regular surface for transmitting datum reference

ActiveCN107971776AGuarantee the appearance qualityReduce manufacturing costPositioning apparatusMetal-working holdersDatum referenceMarking out

The invention discloses a method for utilizing a regular surface for transmitting a datum reference. The method is used for processing a sheet metal component with an irregular space, and comprises the steps of (1) additionally arranging a cylindrical barrel with a regular cylindrical surface on the lower end of the sheet metal component with the irregular space, wherein the lower end of the cylindrical barrel is provided with an end surface; (2) processing at least three center holes in the end surface; (3) arranging at least three support pieces with adjustable heights on a horizontally-placed flat plate, wherein each support piece is supported under the corresponding center hole; adjusting the heights of the at least three support pieces, and enabling the regular cylindrical surface tobe perpendicular to the flat plate; (4) enabling one side edge of a sample plate to get close to an outer side wall of the sheet metal component with the irregular space; and (5) determining an extreme lower position enabling one side edge of the sample plate to make contact with the outer side wall of the sheet metal component with the irregular space, measuring the height from the extreme lowerposition to the flat plate, and marking out according to the height. According to the method provided by the invention, the datum reference is transmitted through the regular cylindrical surface, so that the marking-out precision is improved, and the trimming quality is ensured.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com