Edge cutting device for suspension rubber washer

A shock-absorbing rubber and gasket technology, applied in metal processing and other directions, can solve the problems of low work efficiency, high labor cost, and high product rework rate, and achieve the effect of ensuring trimming quality, improving trimming efficiency, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

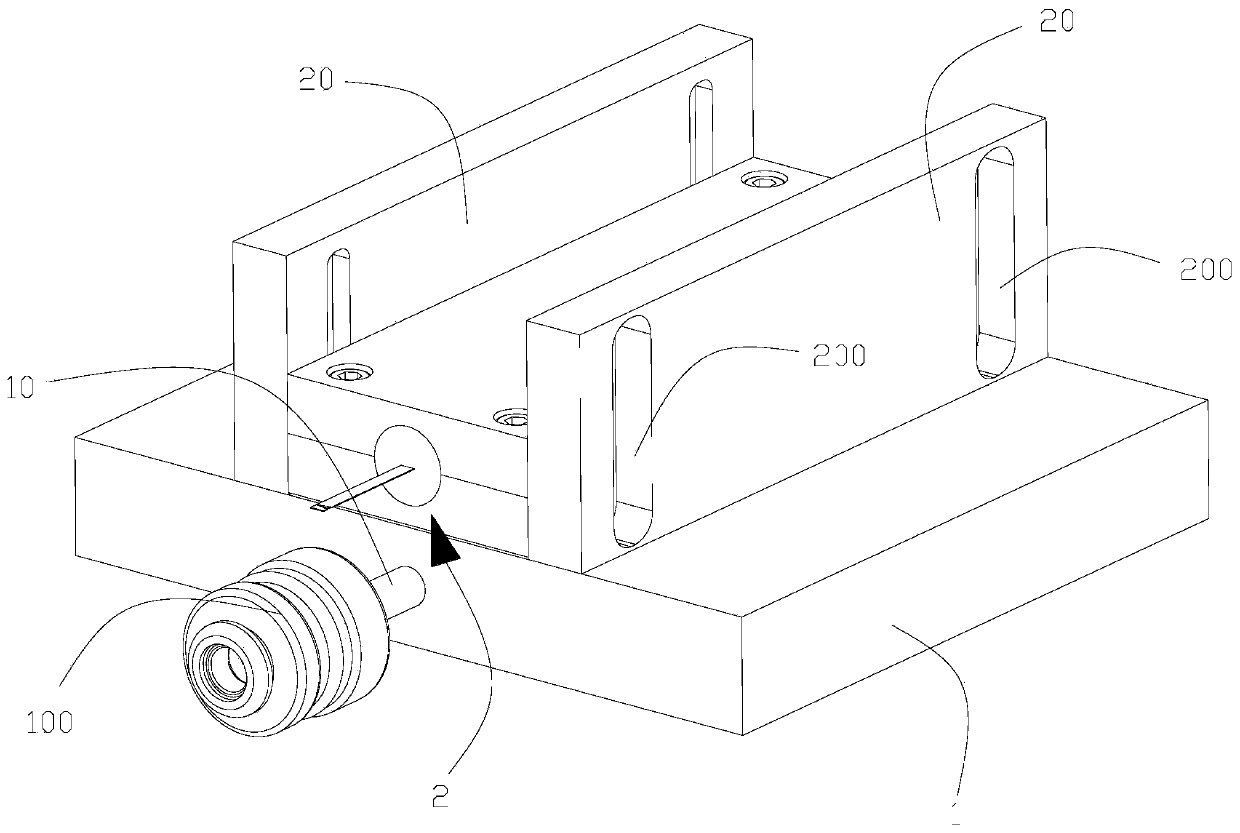

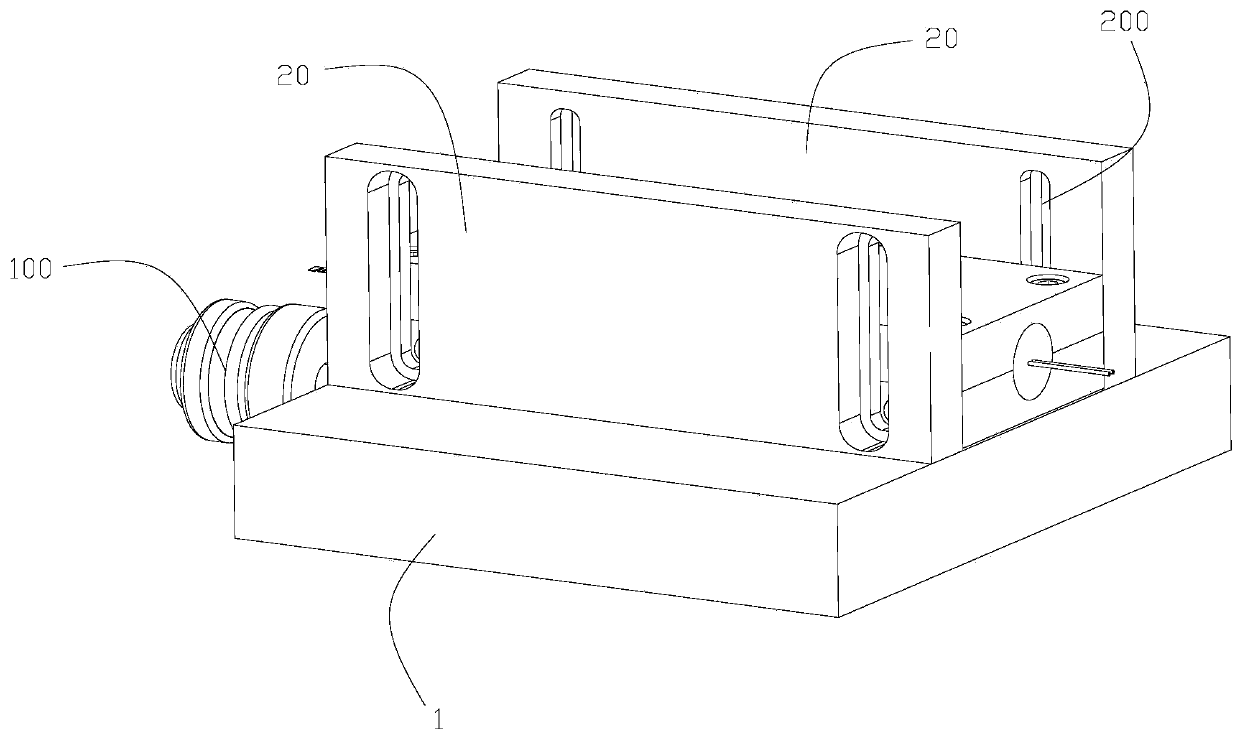

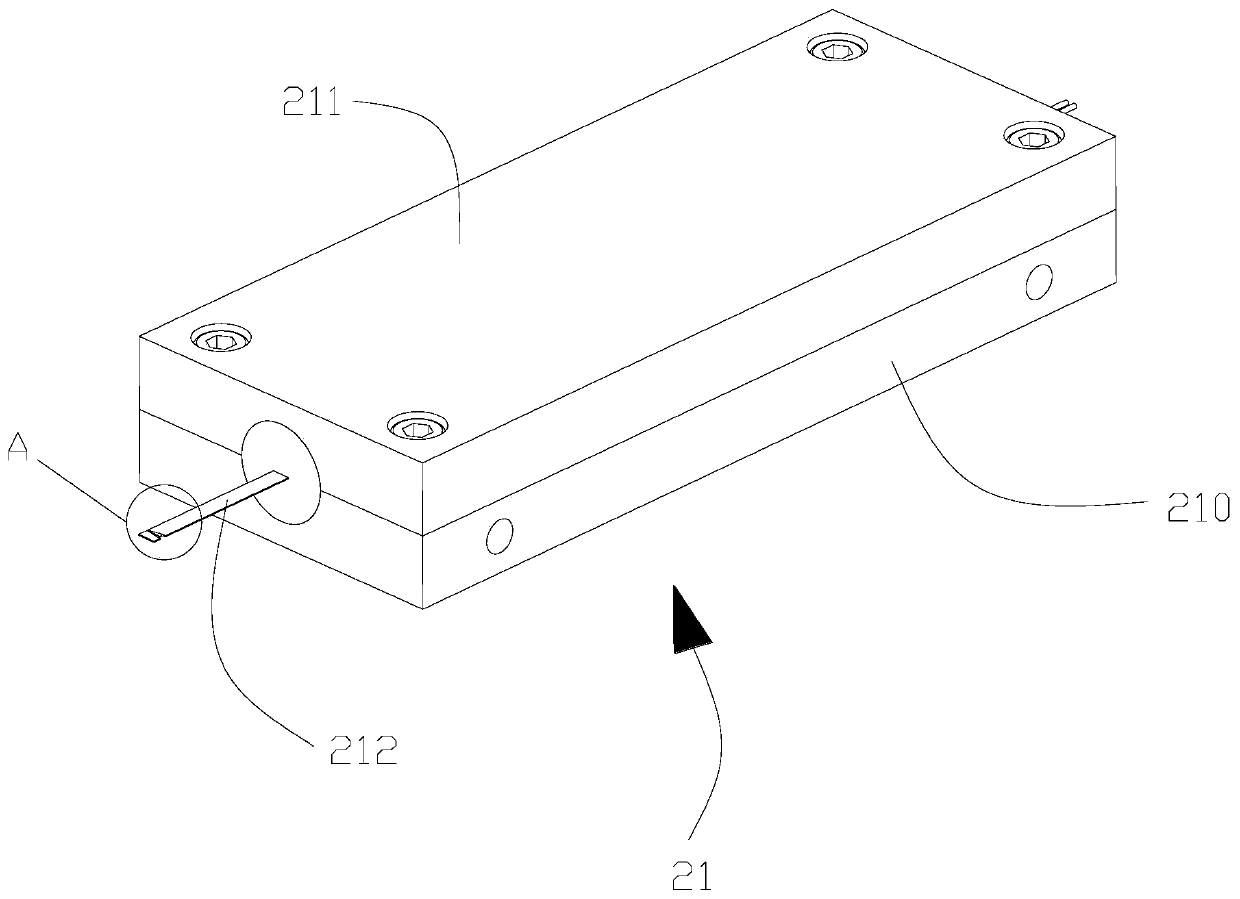

[0025] Such as Figure 1-5 As shown, the present invention shows a shock-absorbing rubber gasket 100 trimming device, including a bottom plate 1, a positioning column 10 and a cutting mechanism 2, the positioning column 10 is arranged on the bottom plate 1 and can be connected with the bottom plate 1 The connection is disassembled so as to facilitate the replacement of positioning posts 10 of different sizes to meet the installation of shock-absorbing rubber washers 100 of different specifications and sizes. The shock-absorbing rubber washers 100 are rotatably mounted on the positioning posts 10. Bottom plate 1 is threaded, so as to realize the detachable connection between bottom plate 1 and positioning column 10. When it is necessary to install and position shock-absorbing rubber gaskets 100 of different specifications, the size and specification of the corresponding shock-absorbing rubber gasket 100 can be replaced by disassembling the positioning column 10. The positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com