Glass edge cutter

An edge trimming machine and glass technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of large liquid consumption, glass jumping, peripheral device damage, etc., to reduce liquid consumption, improve cleanliness, reduce The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

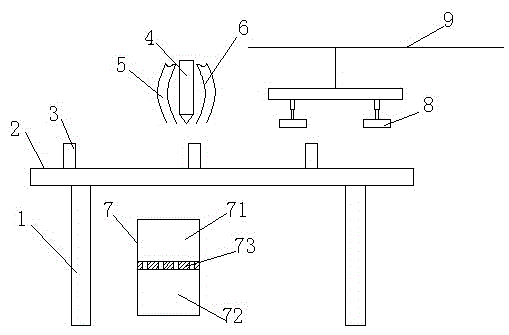

[0016] The present invention comprises a frame 1, the frame 1 is provided with a roller table 2 for conveying glass, the roller table 2 is provided with a jig 3 for positioning the glass, and the above frame is provided with a cutter 4 corresponding to the glass. A cooling pipe 5 and a lubricating pipe 6 are arranged on the side of the tool 4, the cooling air is passed through the cooling pipe 5, and the lubricating liquid is passed through the lubricating pipe 6.

[0017] A receiving bin 7 which moves synchronously with the glass is arranged below the roller table 2, and a suction device is arranged on the receiving bin 7.

[0018] The receiving bin 7 includes a front bin 71 and a rear bin 72, and the front bin 71 and the rear bin 72 are separated by a baffle plate 73 with several small holes.

[0019] A plurality of suction cups 8 are arranged on the upper part of the glass, and the suction cups 8 are arranged on the transmission rod 9 on the upper part of the frame 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com