Cup-shaped arc grinding wheel in-place finishing method based on cradle type five-axis numerical control machine tool

A CNC machine tool and grinding wheel dressing technology, which is applied to the parts of the grinding machine tool, the grinding frame, the grinding bed, etc., and can solve the problems of cup-shaped arc grinding wheel dressing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

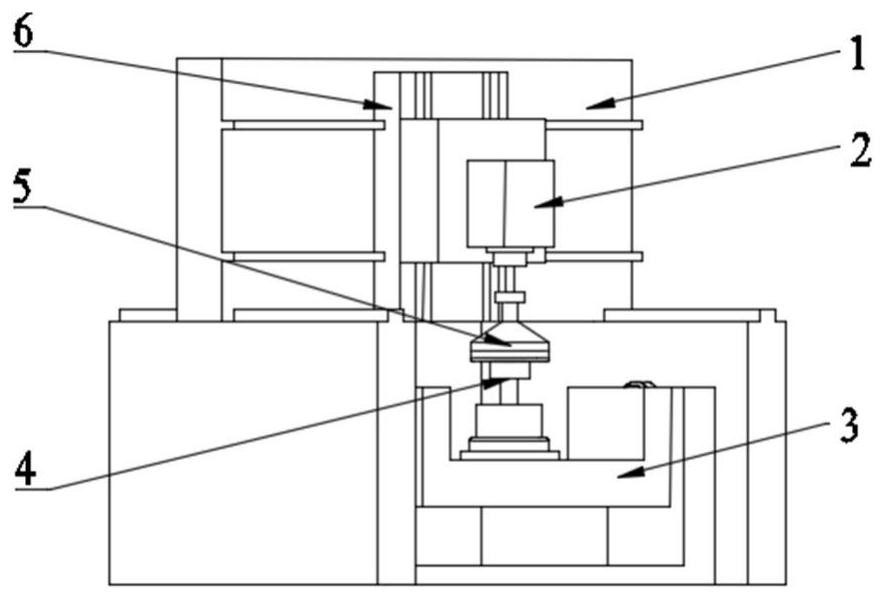

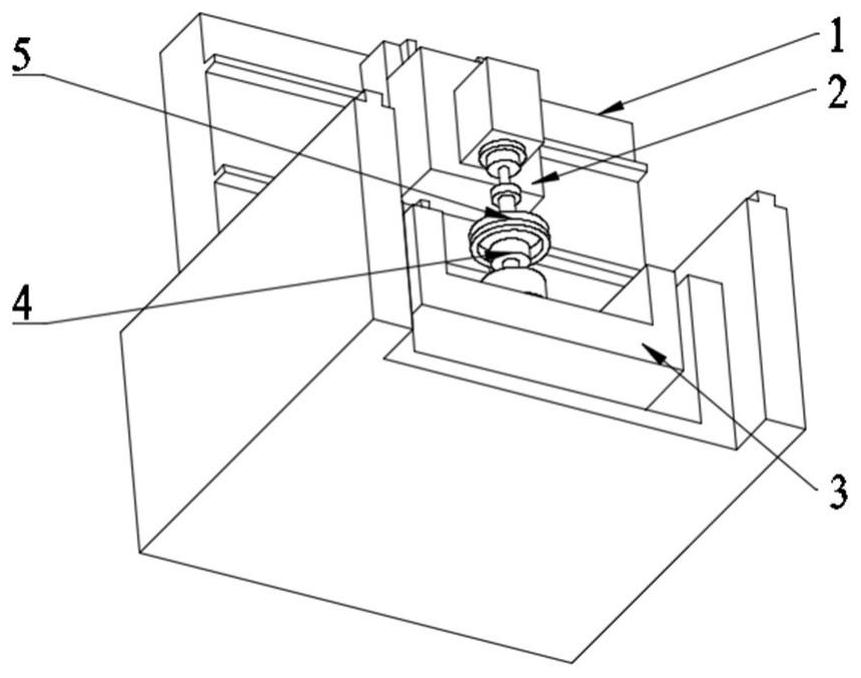

[0032] Embodiments of the present invention will be further described in conjunction with the accompanying drawings.

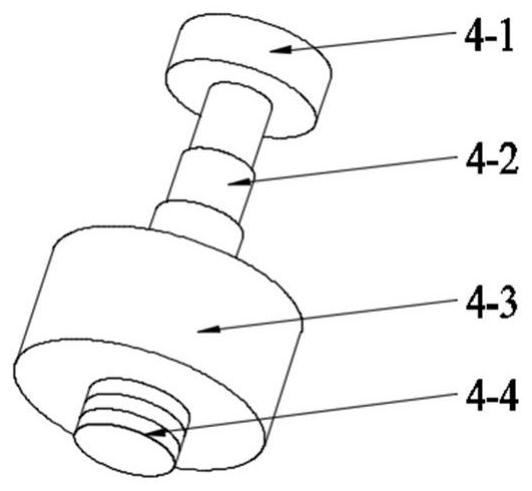

[0033] The present invention provides an in-situ dressing method for a cup-shaped arc grinding wheel based on a cradle-type five-axis CNC machine tool. The dressing method is to install the cup-shaped arc grinding wheel 5 to be trimmed and the dressing wheel 4-1 on the five-axis CNC machine tool , the composite movement of the tool shaft and the turntable 3 is controlled by the numerical control system, so that the cup-shaped arc grinding wheel 5 and the dressing wheel 4-1 are trimmed in the manner of grinding, and the inner circular surface and the outer circular surface of the cup-shaped arc grinding wheel 5 Trim separately.

[0034] Specifically, the dressing method of the present invention is based on a five-axis processing machine tool and a cylindrical SiC dressing wheel, such as image 3 As shown, the specific device structure includes a fixture, a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com