A tissue wax repair instrument

A technology of wax repairing instrument and tissue, which is applied in the preparation of test samples, etc., and can solve problems such as unevenness around and the bottom of tissue wax blocks, failure to reach, and impact on diagnosis work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

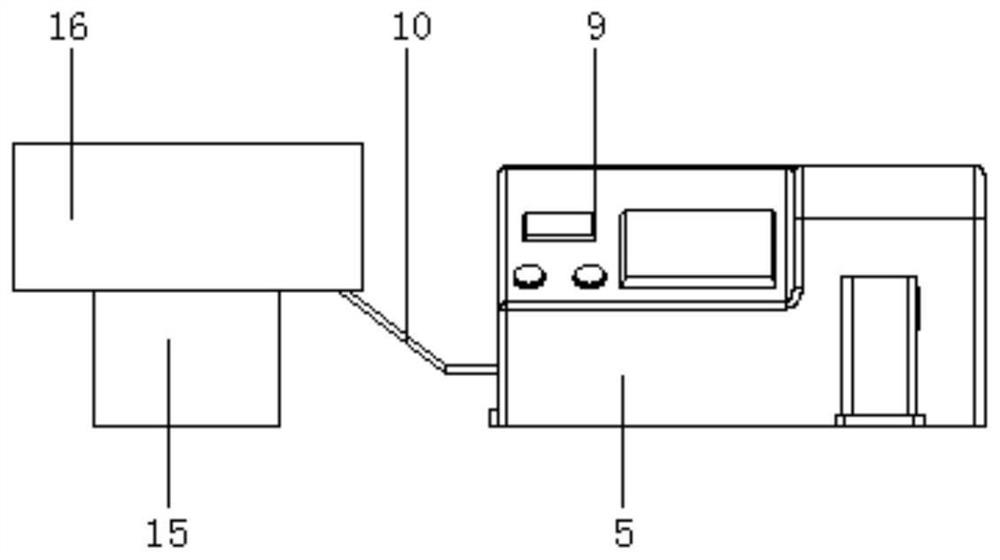

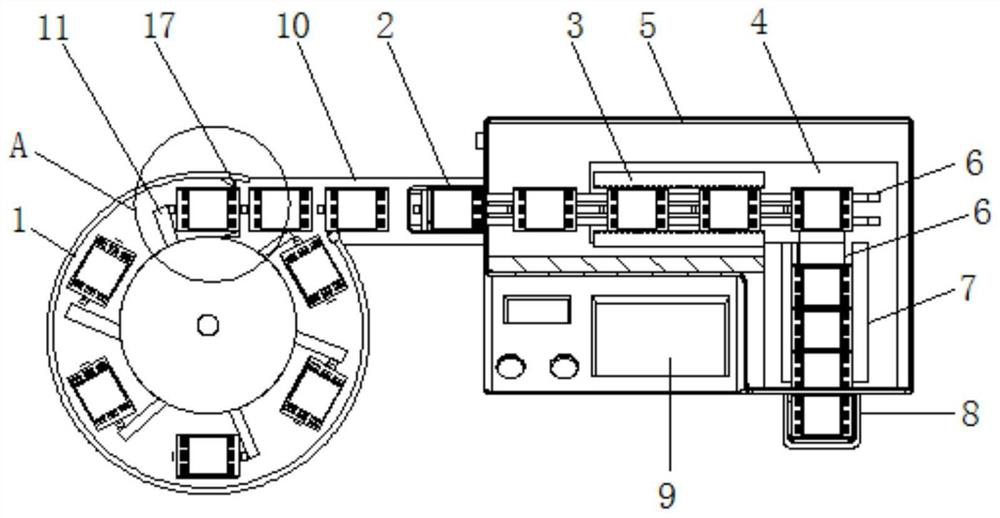

[0030] Embodiment 1: A tissue wax repairing instrument, comprising a box sorting tray 1, a base 15, a body shell 5, a tissue wax block trimming unit and a tissue wax block moving unit 13, and a box sorting tray 1 is provided at the edge of the upper end of the base 15. The box tray 1 is convenient for wax transportation, and also provides support for the installation of the upper structure. The box sorting tray 1 is a curved panel structure with a high upper end and a low surrounding area. Evenly distributed feeding stations are placed on the upper edge of the box sorting tray 1. 2. Facilitate the transportation of the wax body. The body shell 5 provides a mounting and supporting platform. The inner rear side of the body shell 5 is provided with two horizontally flat sliding guide rails 6. The openings are arranged correspondingly, and the inner right side of the body shell 5 is provided with two longitudinally flat sliding guide rails 6, and the two longitudinally flat sliding...

Embodiment 2

[0032] This embodiment differs from Embodiment 1 in that:

[0033] In the present embodiment: also comprise guardrail 16 and rubber pad 18, guardrail 16 avoids wax body and station to drop, and rubber pad 18 avoids wax body collision damage, and guardrail 16 is arranged on the upper edge place of box sorting tray 1, and guardrail 16 is provided with the corresponding gap at the discharge port of the unpacking tray 1, and the rubber pads 18 are respectively arranged on the upper surface of the unpacking tray 1 and the inner wall of the guardrail 16, and the left end of the feed guide rail 10 and the wall of the guardrail 16 The notch corresponds to the setting.

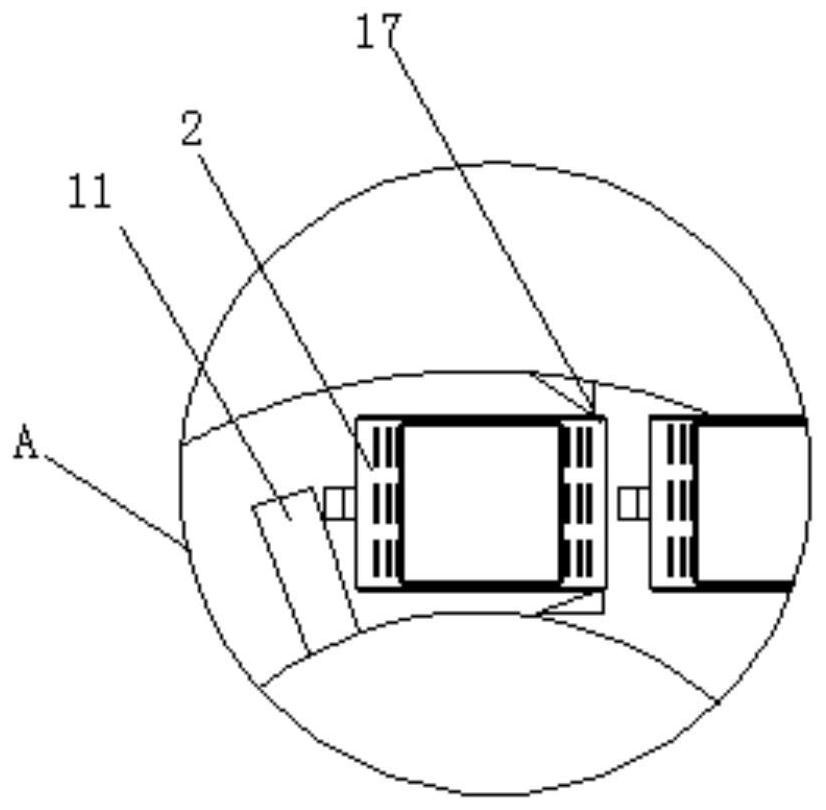

[0034] Wherein: also comprise arrangement guide piece 17, arrange guide piece 17 to be arranged at the discharge port of the upper edge of box arrangement tray 1, two arrangement guide piece 17 are arranged symmetrically, to outputting wax body and station put right, for Later repairs are guaranteed.

[0035] Wherein...

Embodiment 3

[0037] This embodiment differs from Embodiment 1 in that:

[0038] In this embodiment: it also includes a tissue wax block protection unit, the tissue wax block protection unit includes an electric cooling plate 12, and the electric cooling plate 12 is arranged on the top inner wall of the body shell 5 and has its own temperature monitoring system, electric cooling The number of plates 12 is two and is respectively located above the horizontally flat sliding guide rail 6 and the vertically flat sliding guide rail 6. The electric cooling plate 12 is connected with the control system and the temperature monitoring system, and the input is set through the liquid crystal touch screen 9. The upper part of the working area is refrigerated by an electric cooling plate 12 with a semiconductor structure, which can effectively avoid damage to the tissue at the center of the box.

[0039] Wherein, it also includes an emergency stop protection unit, the emergency stop protection unit incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com