Non-return valve for a petrochemical reactor

A petrochemical and reactor technology, applied in the field of one-way devices, can solve problems such as increased man-hours and costs, and difficulty in disassembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

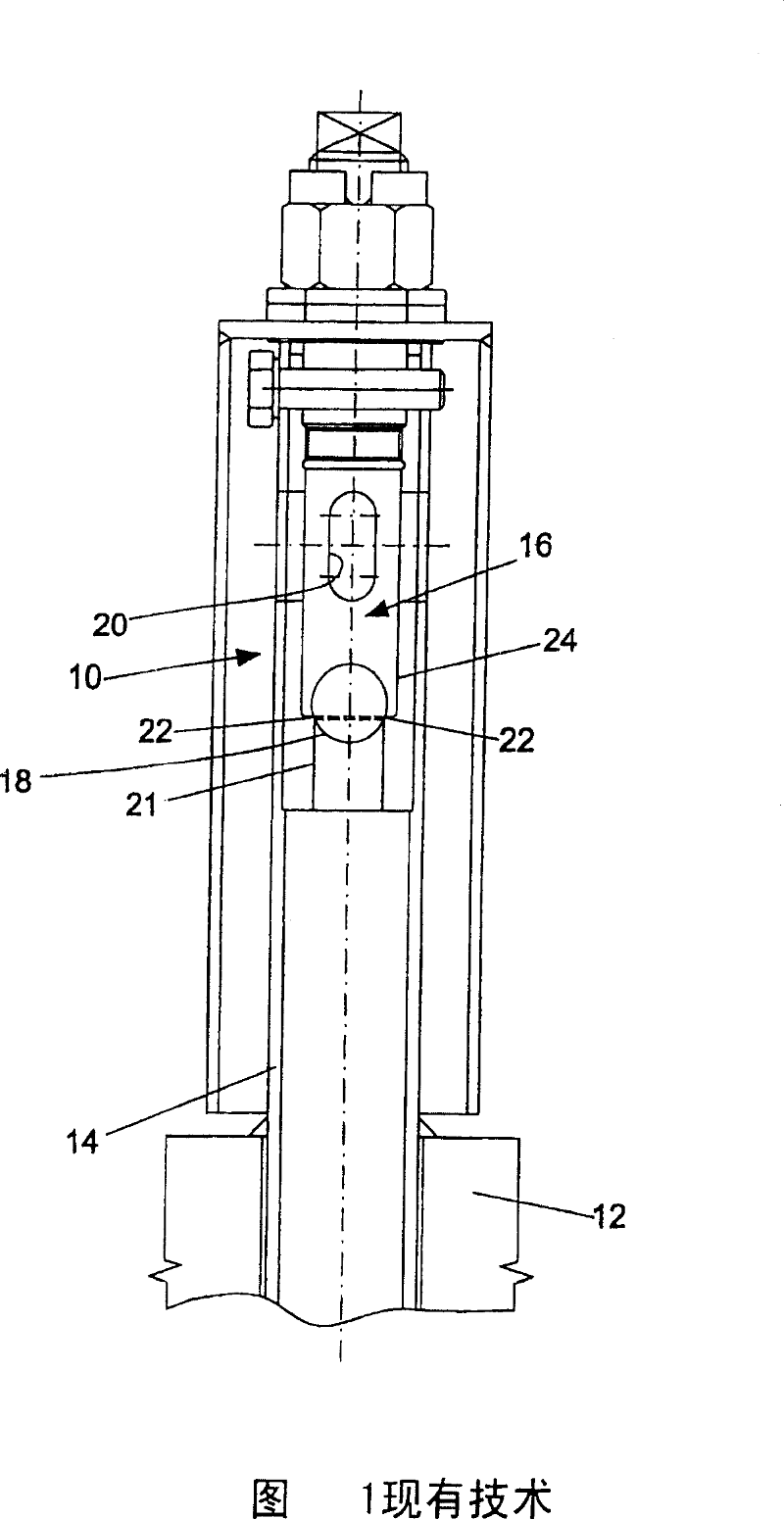

[0030] Referring to Figure 1, there is shown a one-way unit 10 for a petrochemical refinery reactor 12 according to known techniques.

[0031] The one-way unit 10 includes a support tube 14 connected to a portion of the reactor 12 . A cylindrical barrel 16 containing balls 18 is mounted within the support tube.

[0032] The cartridge 16 has lateral slots 20 for the outflow of process fluid. The fluid also passes through corresponding holes in the support tube 14 inserted into the cartridge 16 .

[0033] The barrel 16 has, at its lower end portion, around the inlet opening 21 for the process fluid, a seat 22 for receiving the ball 18 .

[0034] As can be seen in the example of FIG. 1, the support tube 14 is welded to a part of the reactor 12 in a vertical position. Alternatively, this support tube 14 can be secured by mechanical means.

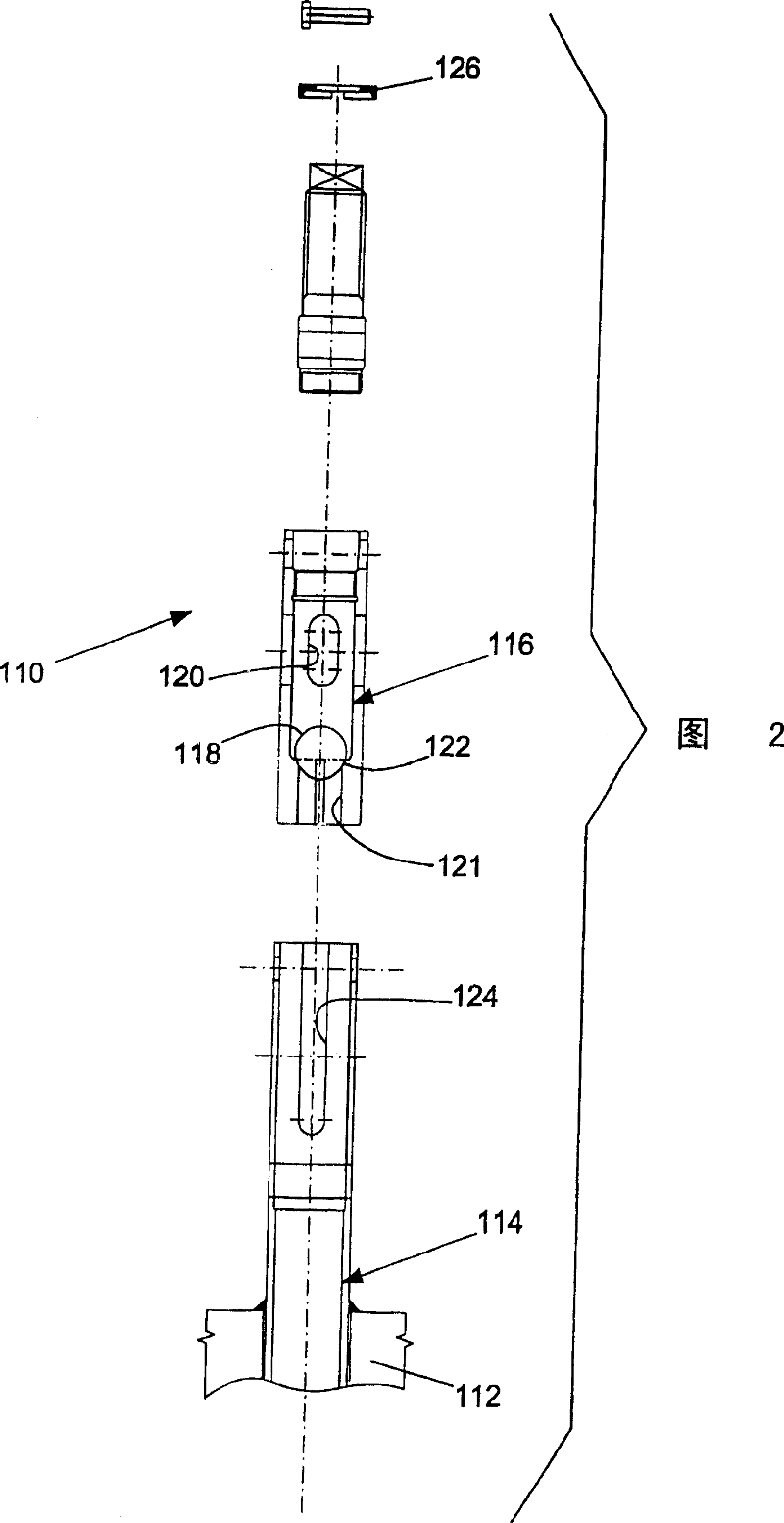

[0035] Figure 2 shows a quick replaceable one-way device 110 for a petrochemical refinery reactor 112 according to the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com