Digital monitoring system for diamond dressing rollers

A diamond roller and monitoring system technology, applied in the field of diamond dressing roller digital monitoring system, can solve problems such as inability to accurately measure the size change of the grinding wheel surface, lack of real-time monitoring and alarming of the grinding wheel dressing process, and affecting the grinding wheel dressing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

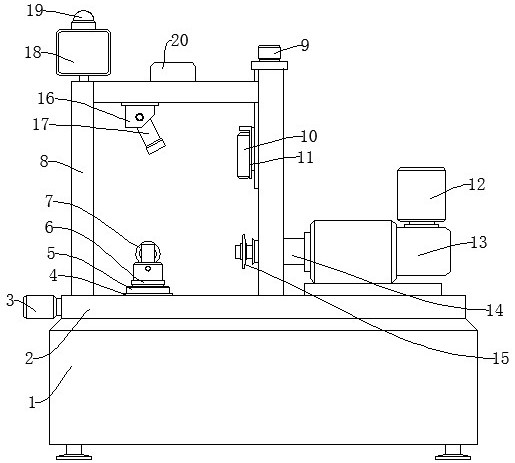

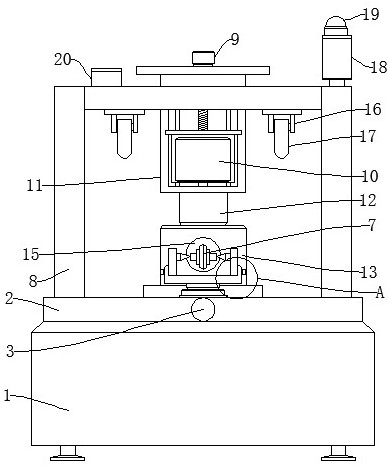

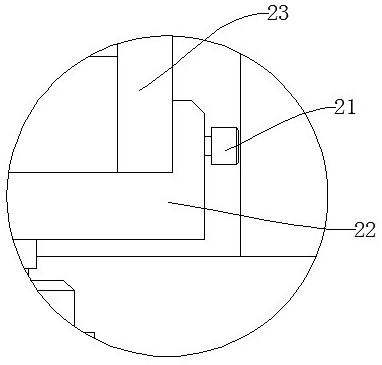

[0031] The present invention will be further described below in conjunction with accompanying drawing:

[0032] Such as Figure 1-Figure 3 As shown, a diamond dressing roller digital monitoring system includes a base 1, a workbench 2 and a No. 1 servo motor 3, the workbench 2 is arranged on the upper side of the base 1, and the workbench 2 is arranged on one side. Describe the No. 1 servo motor 3, the upper side of the workbench 2 is provided with a support frame 8, and a corner of the upper end of the support frame 8 is provided with a display screen 18, and the upper side of the display screen 18 is provided with a warning light 19, and the support frame 8 is provided with a signal transmission module 20, the center of the other side of the upper end of the support frame 8 is provided with a No. 2 servo motor 9, and the lower side of the No. 2 servo motor 9 is provided with a vertical sliding seat 11, and the vertical sliding One side of the seat 11 is provided with a three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com