Large-caliber steel-plastic composite water supply pipe end face trimming method

A technology for steel-plastic composite and water supply pipes, which is applied in the field of devices for bilaterally repairing and processing edges after the end faces of steel-plastic composite water supply pipes are sealed, and can solve the problems affecting the fitting tolerance and appearance quality of the outer diameter of the pipes, occupying a fixed space and low processing efficiency. and other problems to achieve the effect of reducing product cost, improving qualification rate and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

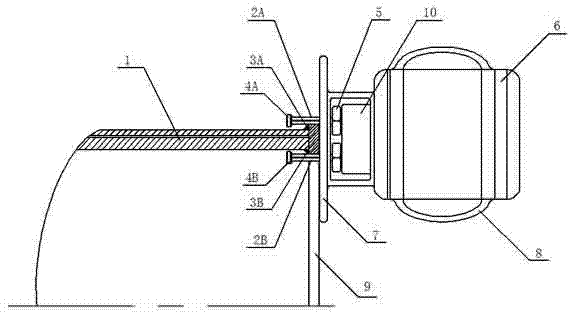

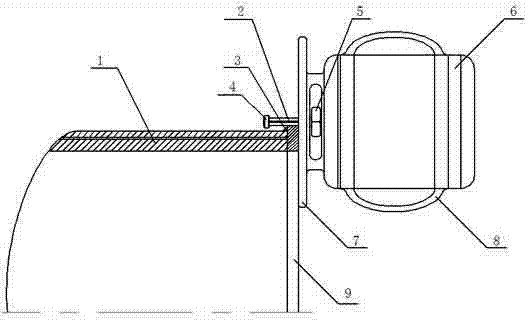

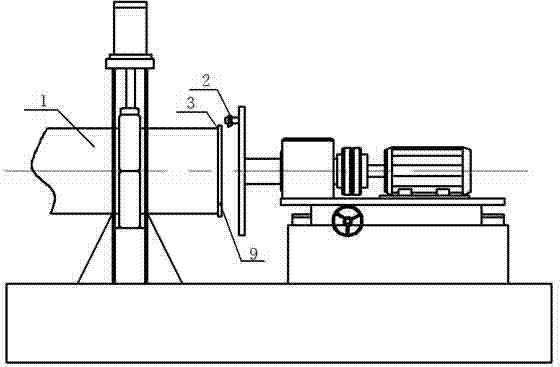

[0024] Such as image 3 As shown, the existing device for repairing and processing the edge of the steel-plastic composite water supply pipe is to use a special fixture to fix the steel-plastic composite water supply pipe, and the processing tool is fixedly installed on the spindle box of a similar cutting machine tool, that is, to repair and process the steel-plastic composite water supply pipe The edge is positioned on the center line of the composite pipe. Since the diameter of the steel-plastic composite water supply pipe ranges from 50 mm to 800 mm, the larger the pipe diameter, the greater the non-concentricity, commonly known as the greater the ellipticity, which leads to repair and processing. The edge of the steel-plastic composite water supply pipe will be damaged, and even needs to be reworked and repaired; at the same time, the fixed machine tool type device for repairing and processing the edge of the steel-plastic composite water supply pipe occupies a fixed site,...

Embodiment 2

[0033] Embodiment 2: When the diameter of the steel-plastic composite water supply pipe is 400 mm, the repair amount of the end face trimming of the rough trimming is 7.5 mm, and the repair amount of the end face trimming of the fine trimming is 2.5 mm. Others are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0034] Embodiment 3: When the diameter of the steel-plastic composite water supply pipe is 800 mm, the repair amount of the end face trimming of the rough trimming is 10 mm, and the repair amount of the end face trimming of the fine trimming is 3 mm. Others are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com