Method for utilizing regular surface for transmitting datum reference

A positioning datum and rule technology, which is applied in the field of transferring positioning datum by using regular surface, can solve the problems of difficulty in alignment, affecting the machining accuracy of edge trimming of special-shaped space sheet metal parts, and low scribing accuracy, so as to ensure the quality of edge trimming and improve the The effect of scribing accuracy and short cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

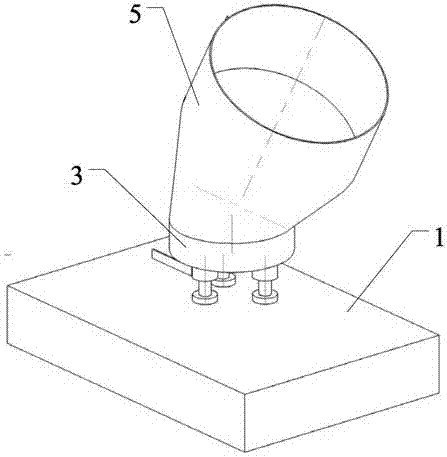

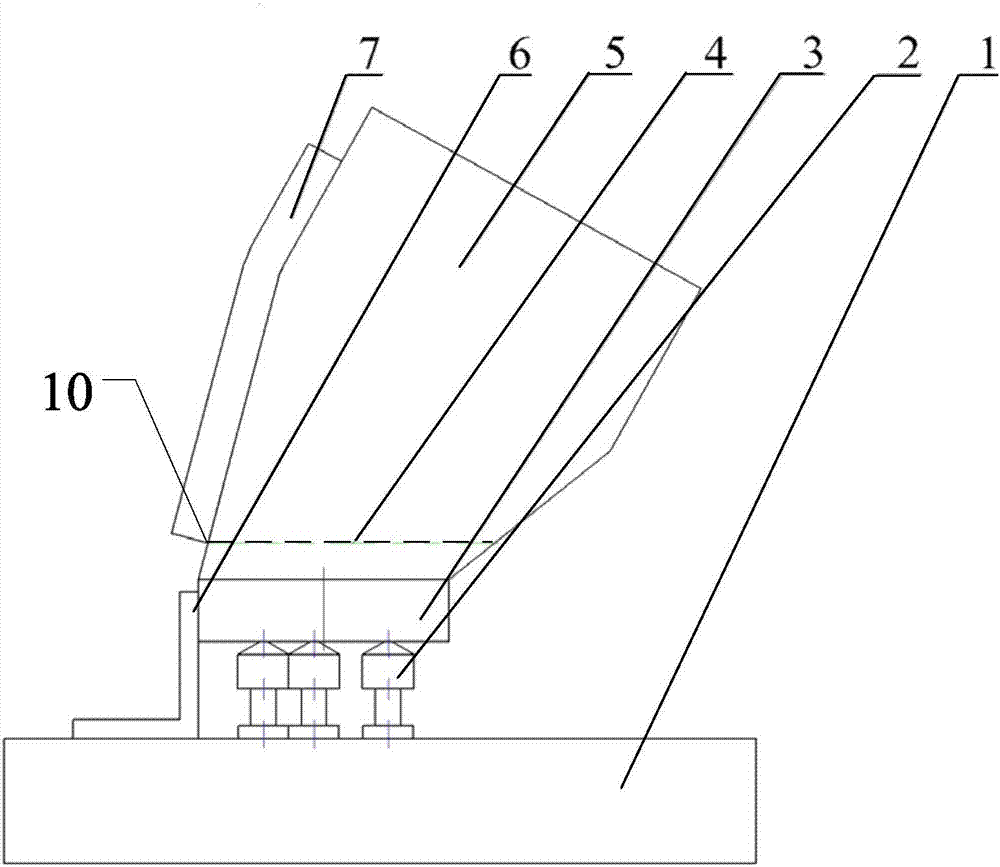

[0023] Such as figure 1 with figure 2 As shown, the present invention provides a method for using a regular surface to transfer positioning references for processing special-shaped space sheet metal parts 5, including the following steps:

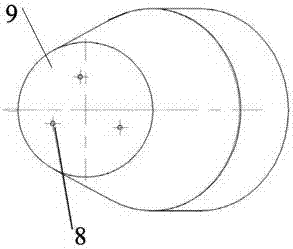

[0024] Step 1. Add a cylindrical barrel with a regular cylindrical surface 3 at the lower end of the special-shaped space sheet metal part 5, and the lower end of the cylindrical barrel has an end face 9 (such as image 3 shown);

[0025] Step 2, processing at least three center holes 8 on the end surface 9, and the at least three center holes 8 are not distributed on the same straight line;

[0026] Step 3: Set at least three height-adjustable supports 2 on a flat plate 1 placed horizontally, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com