Formed grinding wheel trimming wheel

A technology for forming grinding wheels and dressing wheels, which is applied in the direction of abrasive surface adjustment devices, grinding machine parts, metal processing equipment, etc., can solve the problems of affecting the quality of grinding wheel dressing, unevenness, and unsatisfactory cooling effect of cooling devices, etc., to achieve Improved cooling effect, sufficient cooling, improved effect and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

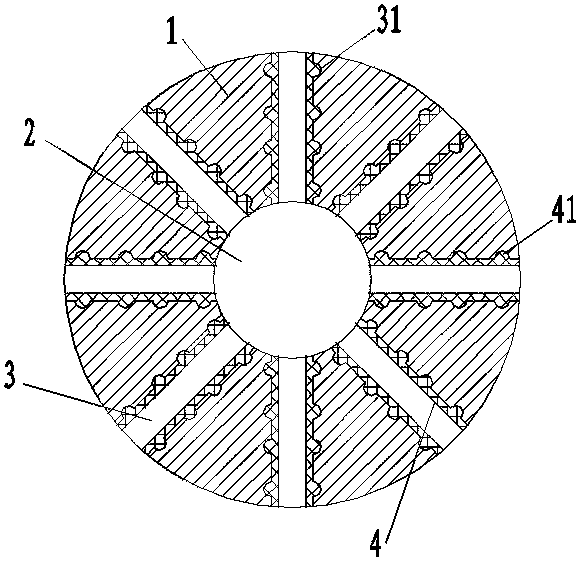

[0015] The present invention includes a base 1 on which a cooling medium inlet 2 is opened, and a plurality of cooling medium pipes 3 arranged in a radial direction and communicating with the cooling medium inlet 2 are arranged in the base 1. The cooling medium pipes The end of 3 extends to the outer surface of the base body 1 so that the cooling medium flows out of the base body 1.

[0016] The cooling medium inlet 2 is arranged in the middle of the base body 1, and the cooling medium pipes 3 are arranged symmetrically in the base body 1.

[0017] The cooling medium pipe 3 is provided with an elastic pipe 4 closely attached to the cooling medium pipe 3, and the elastic pipe 4 forms a flow channel of the cooling medium.

[0018] The wall of the cooling medium pipe 3 is provided with a plurality of concave grooves 31, and the outer wall of the elastic tube 4 is provided with a plurality of convex points 41 corresponding to the grooves 31.

[0019] The working process of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com