Ultra-large combined fire-fighting equipment special for super high-rise building

A super-high-rise and super-large technology, applied in the direction of fire rescue, etc., can solve problems such as inability to carry out timely rescue, high cost, and complicated on-site conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

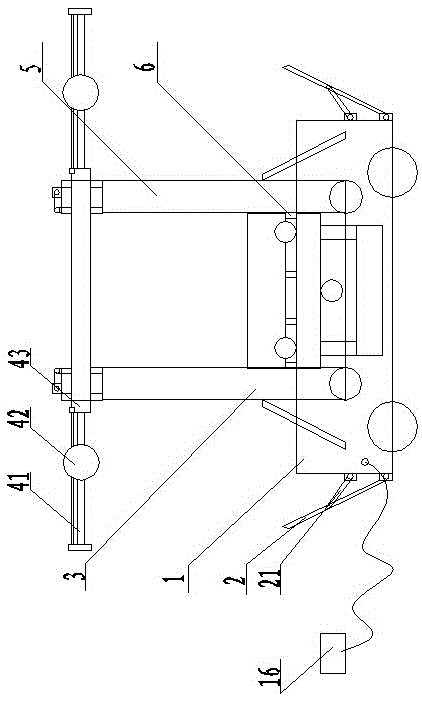

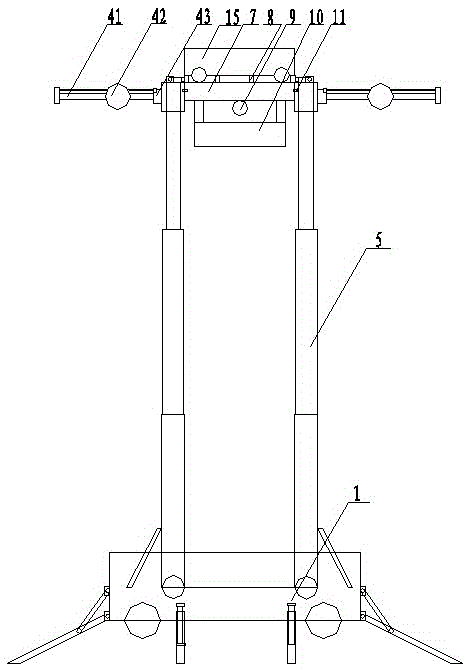

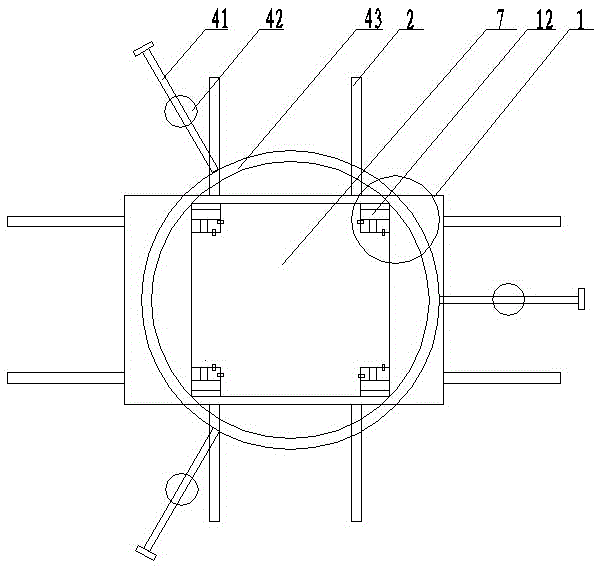

[0032] Example one, such as Figure 1-5 Shown: Super-large composite fire extinguishing equipment for super high-rise buildings, using a crawler trailer as the mobile carrier 1, on which the lifting mechanism, support mechanism and control mechanism are set, and the adopted lifting mechanism is set on the upper part of the mobile carrier 1, the support mechanism It is set on the peripheral side of the mobile carrier 1 and the balance module is set on the upper part of the lifting mechanism; the adopted supporting mechanism includes eight hydraulic support legs 2 arranged on the peripheral side of the mobile carrier 1, and the upper part of the hydraulic support leg 2 and the bottom side of the mobile carrier 1 Side hinged, the middle part is provided with a hydraulic support rod 21 matching the side of the mobile carrier 1, which can be easily supported and reset, and the support mechanism can be dynamically adjusted through the data fed back by the gyroscope 9 to ensure that th...

Embodiment 2

[0033] Example two, such as Figure 1-5 Shown: Super-large composite fire extinguishing equipment for super high-rise buildings, using ordinary trailers as the mobile carrier 1, on which the lifting mechanism, support mechanism and control mechanism are set, and the used lifting mechanism is set on the upper part of the mobile carrier 1, and the support mechanism is set On the peripheral side of the mobile carrier 1, a balance module is set on the upper part of the lifting mechanism; the supporting mechanism used includes six hydraulic support legs 2 arranged on the peripheral side of the mobile carrier 1, and the upper part of the hydraulic support leg 2 and the bottom side of the mobile carrier 1 Articulated, the middle part is provided with a hydraulic support rod 21 matching the side of the mobile carrier 1, which can facilitate support and reset, and can dynamically adjust the support mechanism through the data fed back by the gyroscope 9 to ensure that the upper part of th...

Embodiment 3

[0034] Example three, such as Figure 1-5 Shown: Super-large composite fire extinguishing equipment for super high-rise buildings, using ordinary trailers as the mobile carrier 1, on which the lifting mechanism, support mechanism and control mechanism are set, and the used lifting mechanism is set on the upper part of the mobile carrier 1, and the support mechanism is set On the peripheral side of the mobile carrier 1, a balance module is set on the upper part of the lifting mechanism; the supporting mechanism used includes six hydraulic support legs 2 arranged on the peripheral side of the mobile carrier 1, and the upper part of the hydraulic support leg 2 and the bottom side of the mobile carrier 1 Articulated, the middle part is provided with a hydraulic support rod 21 matching the side of the mobile carrier 1, which can facilitate support and reset, and can dynamically adjust the support mechanism through the data fed back by the gyroscope 9 to ensure that the upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com