Cutter holder mounting structure and cutter holder joint

A technology of installation structure and tool holder, which is applied in glass cutting devices, manufacturing tools, glass manufacturing equipment, etc., can solve the problem of inability to obtain high-precision and high-quality products, and achieves suppression of inclined driving or position deviation, elimination of looseness, The effect of accurate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

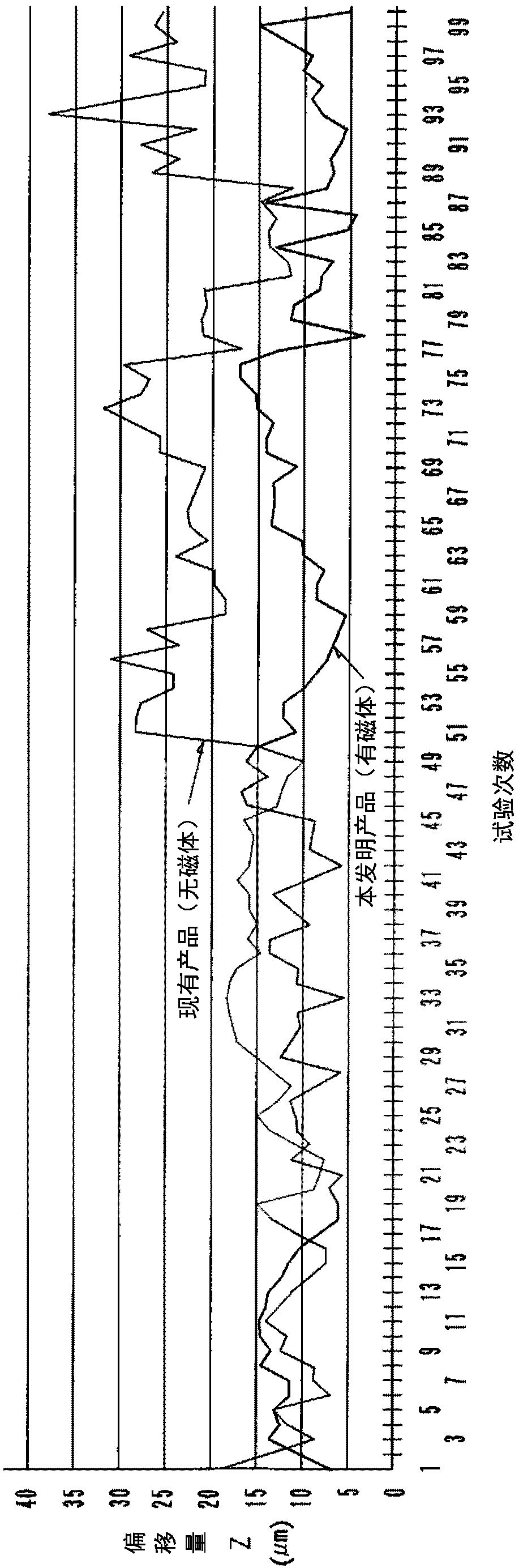

Examples

Embodiment Construction

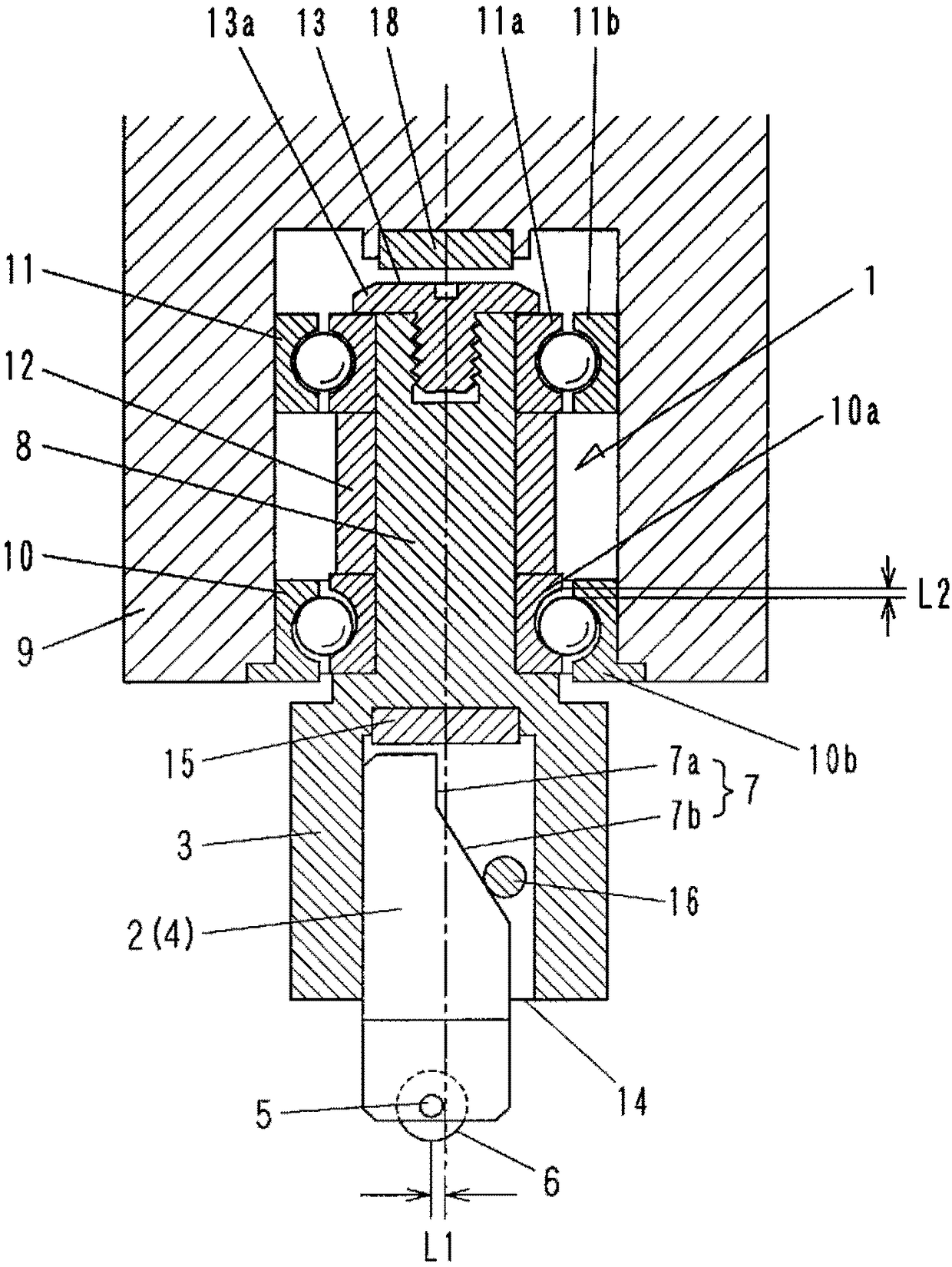

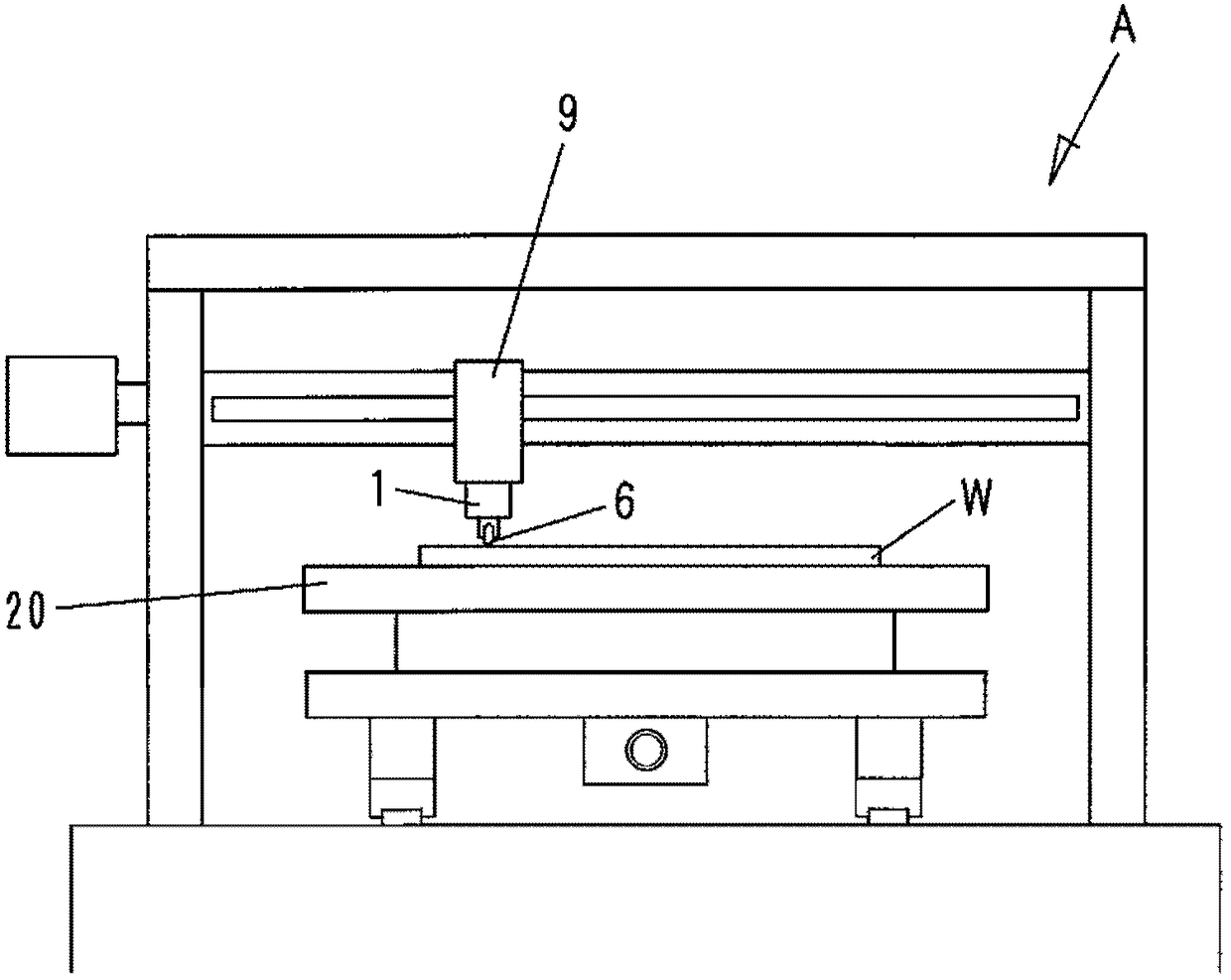

[0050] Hereinafter, the mounting structure of the tool post of the present invention will be described in detail. A part of the installation structure of the tool post of the present invention includes a Figure 5 ~ Figure 7The structural elements of the same function as the conventional tool holder mounting structure shown. Therefore, the same reference numerals will be attached to the parts having the same functions for description.

[0051] like figure 1 As shown, the tool post mounting structure 1 of the present invention includes a tool post 2 and a tool post joint 3 for holding the tool post 2 . The tool holder 2 has a substantially columnar main body 4 , and a cutter wheel 6 is rotatably attached to the lower end of the main body 4 via an axle 5 perpendicular to the axis of the main body 4 .

[0052] In addition, an attachment portion 7 for positioning when attached to the tool holder joint 3 is provided on the upper portion of the main body portion 4 . The attachme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com