Improved non-die copy necking system and application of same in workpiece necking machining

A technology of necking and profiling, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problem that welding quality can only be checked by process samples and destructive tests, tensile strength and fatigue of lap joints. Low strength, inability to process workpieces of various specifications, etc., to achieve the effects of easy overload protection and pressure retention, flexible layout, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the examples, but it should not be interpreted as a limitation of the present invention. The protection scope of the present invention is based on the contents recorded in the claims. protection scope of the present invention.

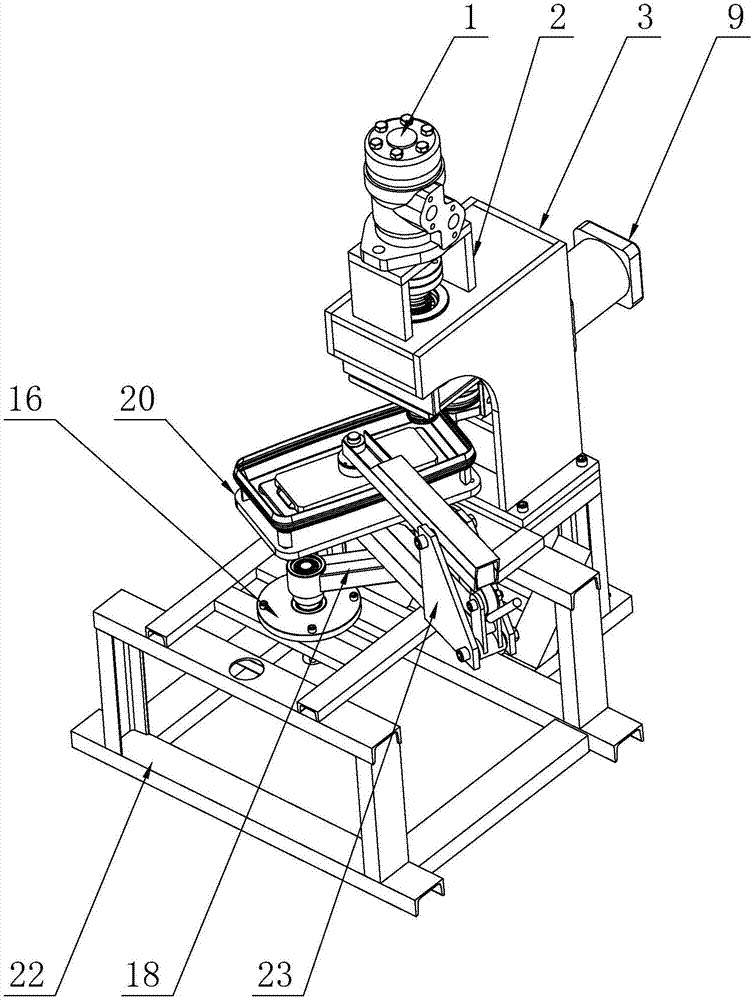

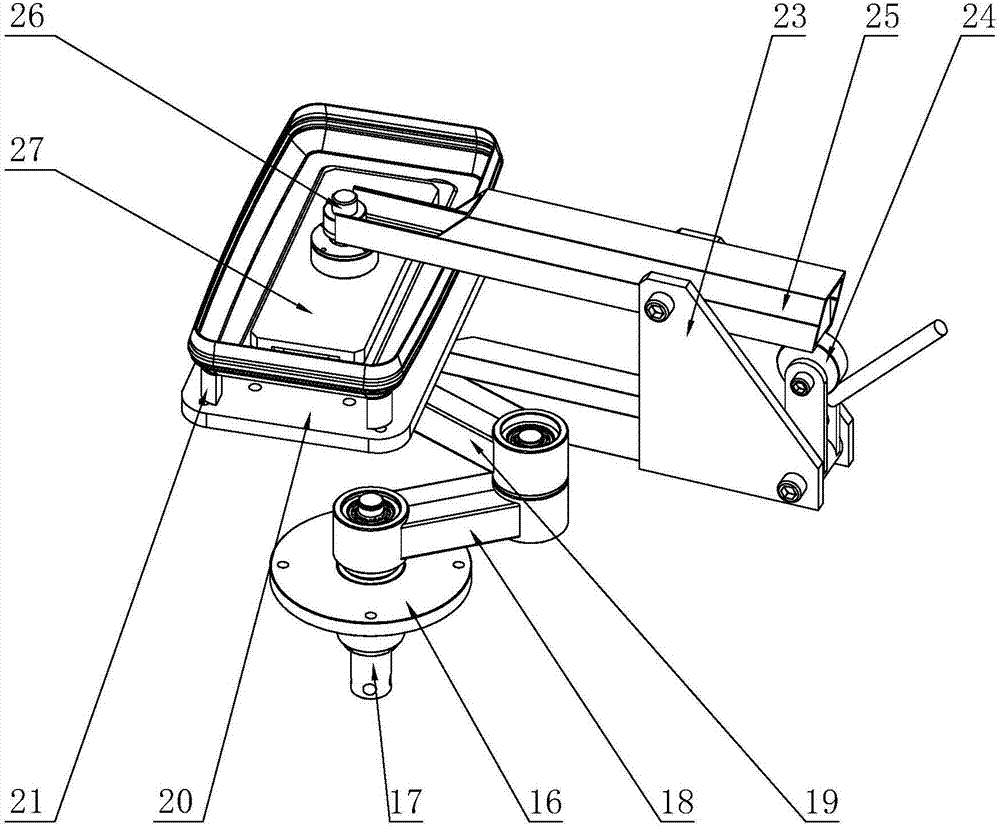

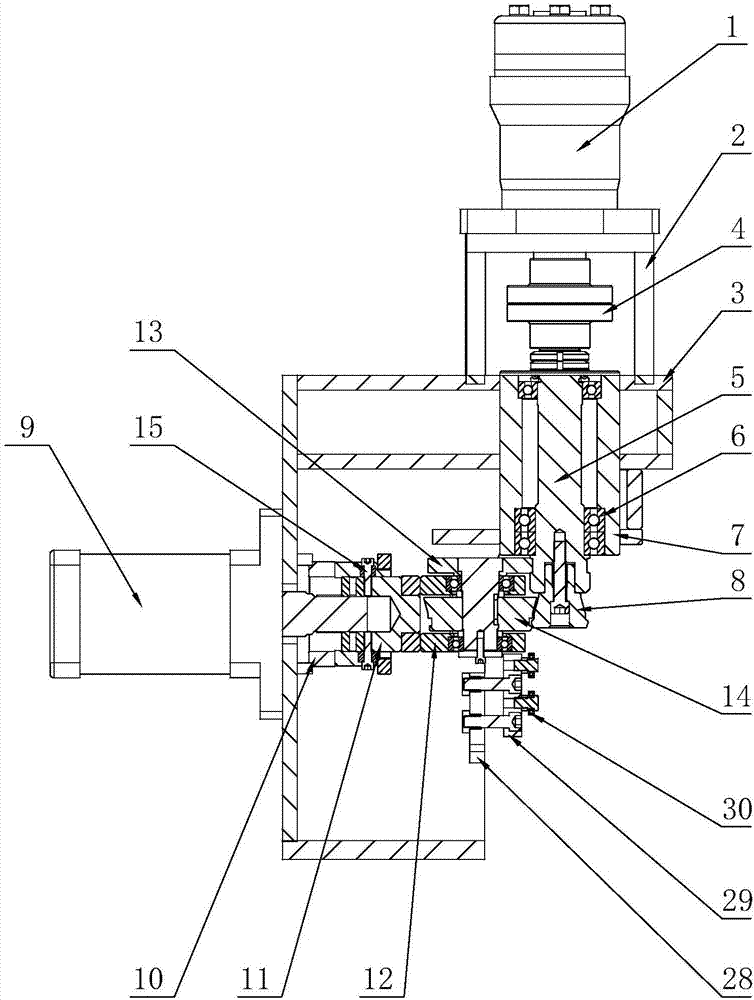

[0056] The improved formless necking system in this embodiment is as shown in the figure, including a driving wheel 8 driven and rotated by a power source 1, the power source is arranged on the fixed bracket 2 on the upper part of the frame 3, and the driven wheels 14 are spaced parallel to the axial direction It is installed on the side of the driving wheel 8 and the distance between it and the driving wheel 8 is controlled by the ejection mechanism of the driven wheel. The rim of the driving wheel 8 and the rim of the driven wheel 14 are respectively adapted to the shape of the mouth of the workpiece after shrinking processing. The working platform 20 are arranged in par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com