Connection device between packaging substrate and chip thereon

A technology of connecting device and packaging base, which is applied to printed circuits, printed circuit components, electrical components and other directions where non-printed electrical components are connected, can solve the problem of low yield of connecting leads, multiple waste products, and long connecting lead lengths. and other problems, to achieve the effect of low cost, avoiding excessive sagging and reducing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein similar structures in the accompanying drawings use the same reference numerals.

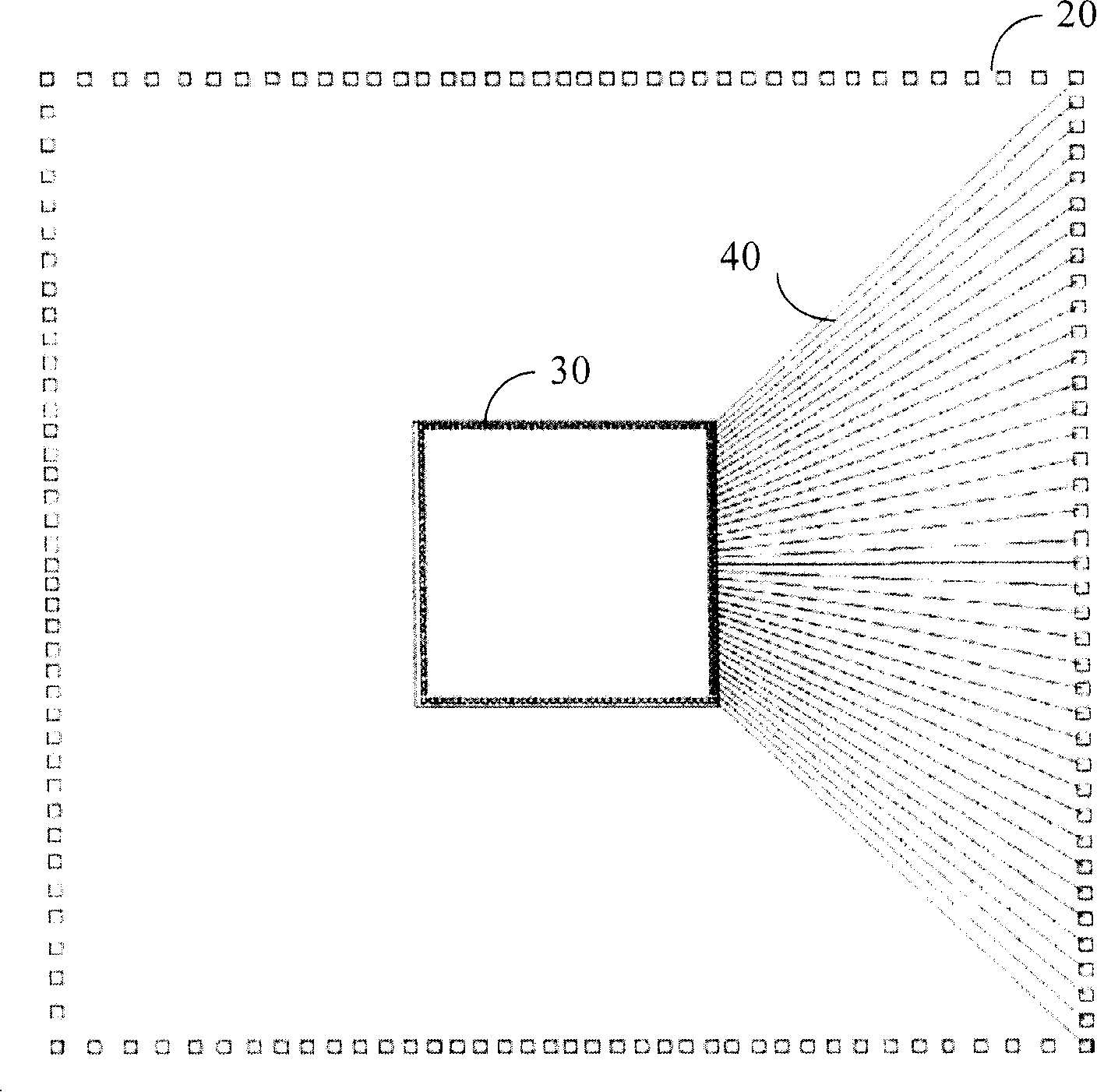

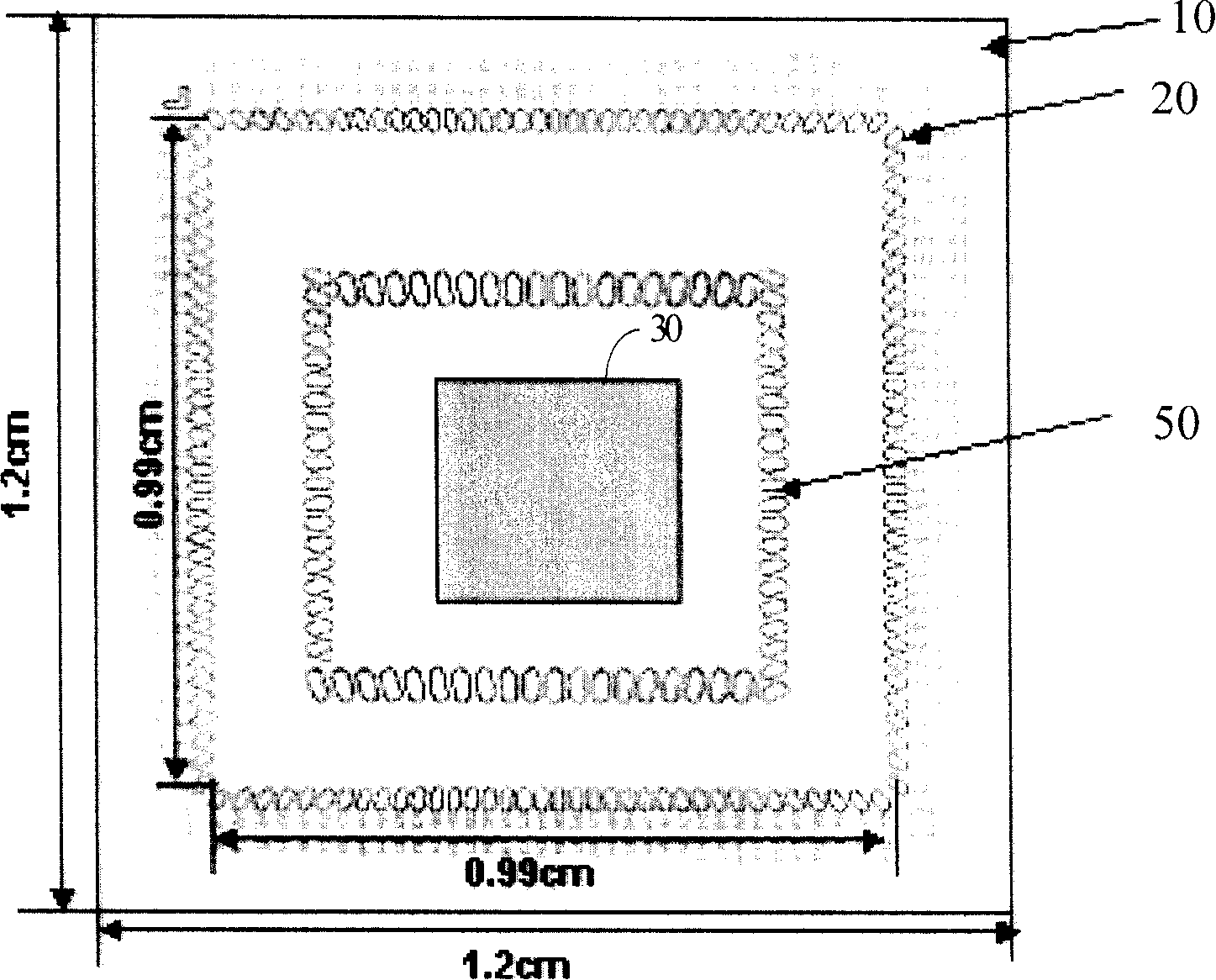

[0022] According to the present invention, there is provided a connection device between a packaging substrate and a chip thereon, comprising: a plurality of finger pad rings surrounding the chip on the packaging substrate, each finger pad ring including multiple and a plurality of connection leads for connecting the chip to the pad fingers of the innermost ring of pad fingers and for connecting pad fingers of adjacent pad finger rings.

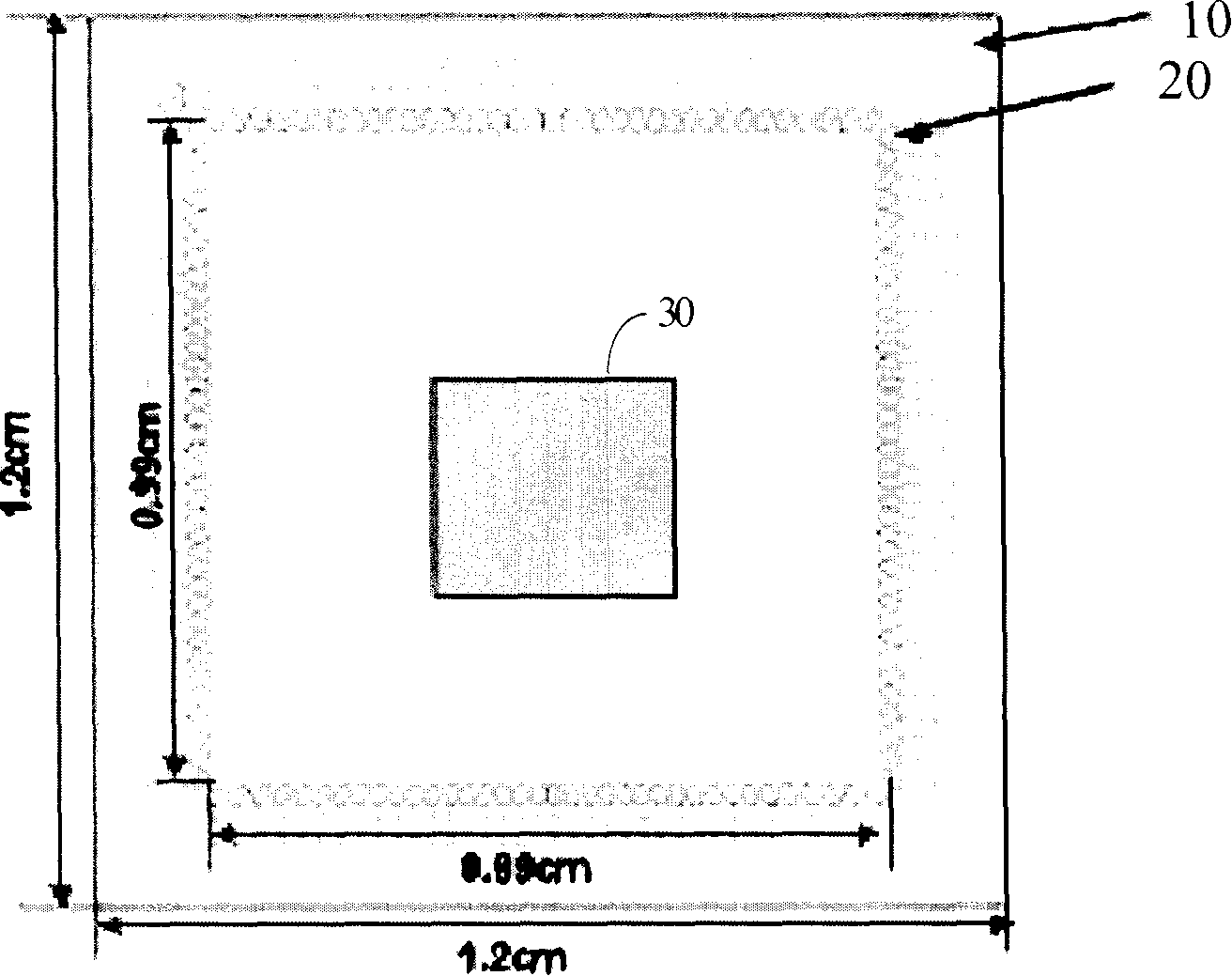

[0023] Such as figure 1 As shown, the PCB includes a package substrate 10, a ring of solder fingers 20 and a chip 30 located in the center of the package substrate, and the ring of solder fingers 20 includes a plurality of solder fingers made of gold or other materials materials known in the art. The pins of the solder fingers a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com