Cutting and moving system for stone cutting machine

A mobile system and cutting machine technology, used in stone processing equipment, work accessories, manufacturing tools, etc., can solve problems such as increasing production costs and affecting stone cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

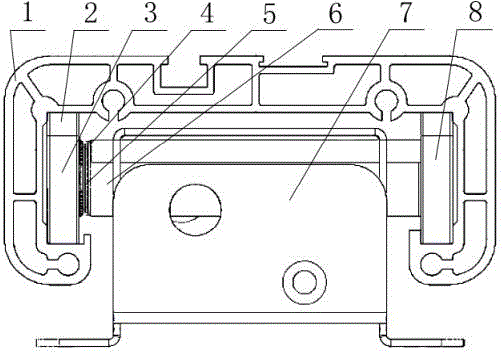

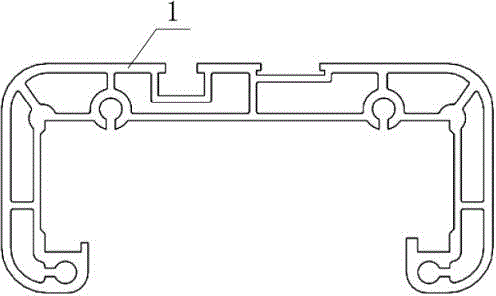

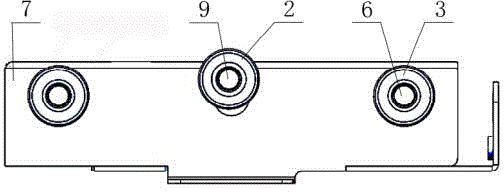

[0011] figure 1 , figure 2 and image 3 Among them, a cutting moving system of a stone cutting machine includes a guide rail 1 and a motor fixing frame 7 . The left side and the right side of the motor holder 7 are respectively provided with a bearing fixed shaft and a tensioning shaft, i.e. a left bearing fixing shaft 6, a left tensioning shaft 9, a right bearing fixing shaft and a right tensioning shaft. Bearing 8 is housed on the left bearing fixed shaft that is provided with on the right side of motor fixed mount 7 , the inner ring of this bearing 8 is interference fit with the right bearing fixed shaft, and the right tensioner shaft that is provided with on the right side of motor fixed mount 7 is equipped with Bearing, the inner ring of the bearing is interference fit with the right tensioner shaft. Bearing 2 is housed on the tensioning shaft 9 provided on the left side of the motor fixing frame 7, and the inner ring of the bearing 2 forms an interference fit with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com