Locating support for cutting machine

A technology for positioning brackets and cutting machines, applied in the field of brackets, can solve the problems of unsatisfactory cutting effect, not due to the same plane, poor stability, etc., to achieve the effect of convenient and flexible cutting direction, prevention of violent shaking, and guaranteed cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

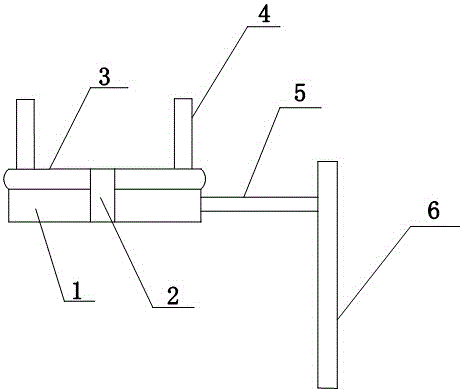

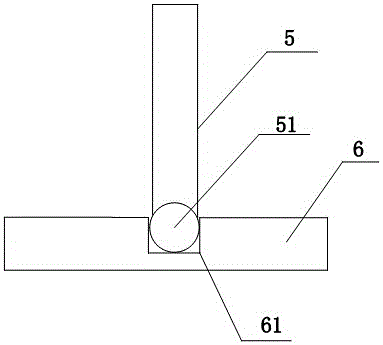

[0013] Such as figure 1 and figure 2 As shown, the present invention provides a cutting machine positioning bracket, including a support platform 1, the center of the support platform 1 is provided with an upwardly extending rotating shaft 2, and a rotating platform 3 is provided above the support platform 1. The rotating platform 3 and the rotating shaft 2 are integrally formed. The rotating platform 3 is provided with two positioning plates 4 perpendicular to the rotating platform 3 for fixing the cutting machine. The two positioning plates 4 are relative to the longitudinal axis of the rotating shaft 2. Symmetrically arranged, one side of the support platform 1 is provided with a horizontal connecting rod 5, one end of the connecting rod 5 is fixed on the support platform 1, and the other end is snapped into the longitudinal groove 61 of the vertical frame 6, the The connecting rod 5 can move up and down in the longitudinal groove 61, the connecting end of the connecting ...

Embodiment 2

[0015] First place the cutting machine between the two positioning plates 4 on the rotating platform 3, then turn the rotating platform 3 to adjust the cutting position of the cutting machine, start the gas cutting machine, the operator controls the cutting machine to cut and press down, the rotating platform 3 is on Driven by the connecting rod 5, it gently moves downwards. Since the connecting rod 5 moves vertically in a straight line in the longitudinal groove 61, the cutting track of the cutting machine is on the same straight line, realizing linear cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com