Auxiliary linear shear

A straight-line shearing and scissor blade technology, applied in metal processing and other directions, can solve the problems of raw material waste, cutting materials, inconvenient work, etc., and achieve the effect of reducing raw material waste, trimming regularity, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

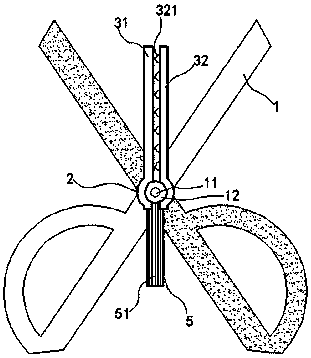

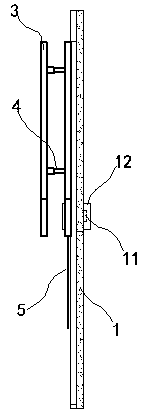

[0015] exist figure 1 , figure 2 In the shown embodiment, the auxiliary linear shears include two scissors 1, and the scissors 1 include a front end and a handle end; the scissors 1 are symmetrically installed on the rotating shaft 11, and two fastening ring 12;

[0016] The calibrator 2 is sleeved on the fastening ring 12; the calibrator 2 includes two sets of clamping parts 3, and the two groups of clamping parts 3 are connected by telescopic rods 4; each set of clamping parts 3 Including a strut 31 and a pressing bar 32, the strut 31 is made of a ferromagnetic material, and the pressing bar 32 is made of a permanent magnetic material; the strut 31 and the pressing bar 32 extend parallel to each other toward the front end of the scissor blade 1; Roller 321 is installed on the opposite side with pole 31 of described depression bar 32, and the axis of each roller 321 is perpendicular to scissors blade 1; The planes where they are located are parallel; each of the rollers 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com