Guiding and positioning device for tower barrel hoisting and abutting joint of large wind driven generator set

A technology for guiding and positioning wind turbines, which is applied to wind turbine components, wind engines, and wind power generation. It can solve problems such as slow boom adjustment, hoisting efficiency, tower swing, and positioning difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

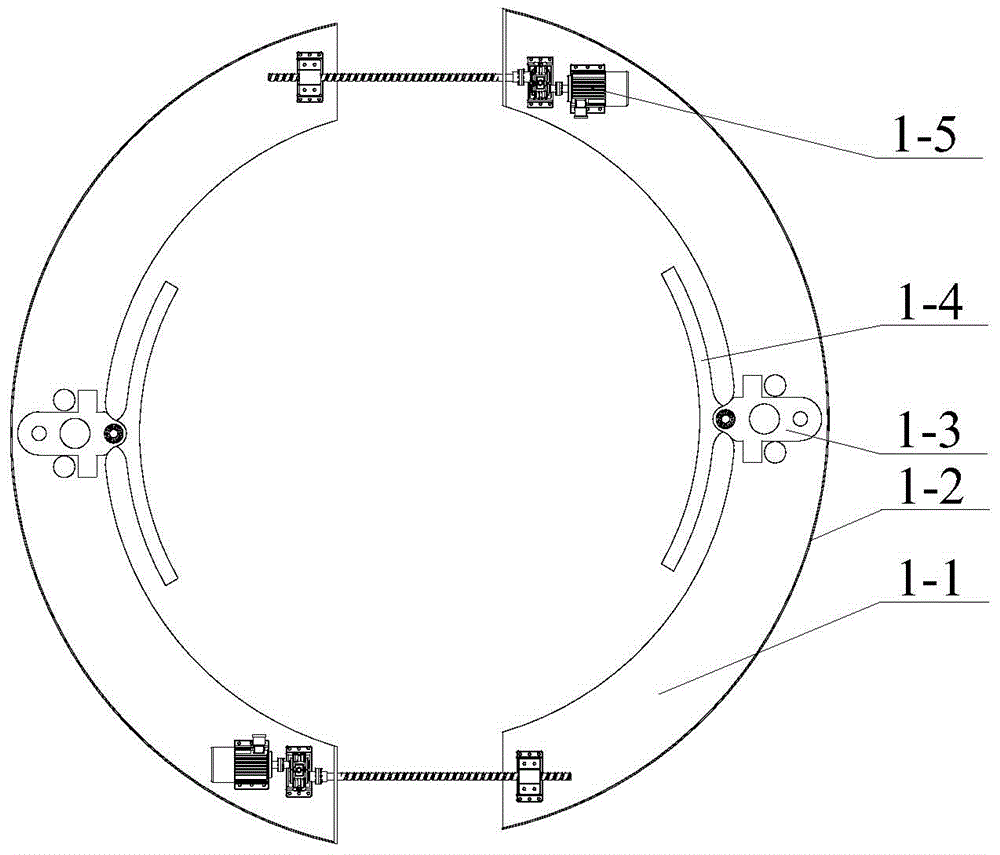

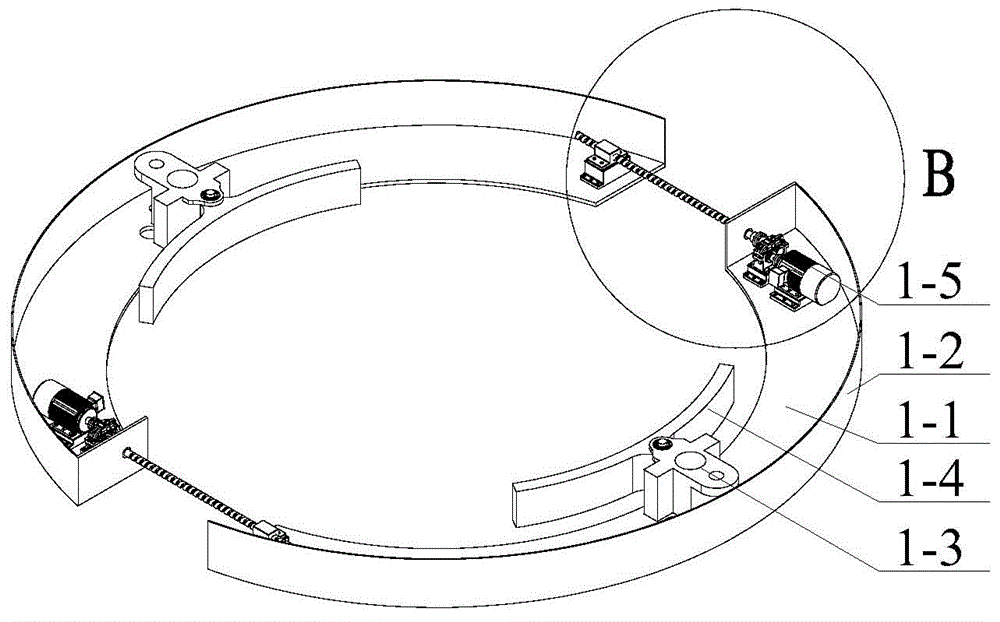

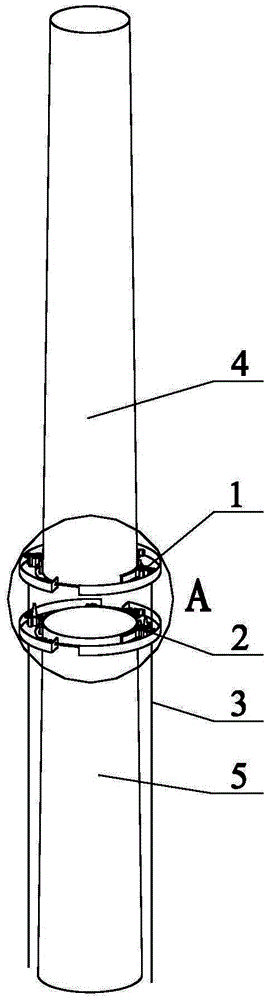

[0021] refer to Figure 1 to Figure 7 , a large-scale wind turbine tower hoisting docking guide positioning device, which includes an upper hoop device 1, a lower hoop device 2 and a traction wire rope 3, and the upper hoop device 1 and the lower hoop device 2 are arc-shaped shape, the upper hoop device 1 and the lower hoop device 2 both include two halves of the hoop that are symmetrical about the central axis, and the upper hoop device 1 includes an upper positioning guide module 1 for positioning the upper tower section -3 and the upper elastic module 1-5 for adjusting the distance between the two upper half hoops, the upper positioning guide modules 1-3 are respectively installed in the middle of the half hoops, and the two half hoops are connected The upper elastic module 1-5, the upper positioning guide module 1-3 is an upper positioning seat, and the upper posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com