Full-automatic anti-swing control system of stereo garage

A three-dimensional garage and control system technology, applied in the field of automatic anti-swing control systems, can solve the problems of switch failure, parking difficulties, inaccurate positioning, etc., and achieve the effects of preventing switch failure, improving service life, and positioning accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

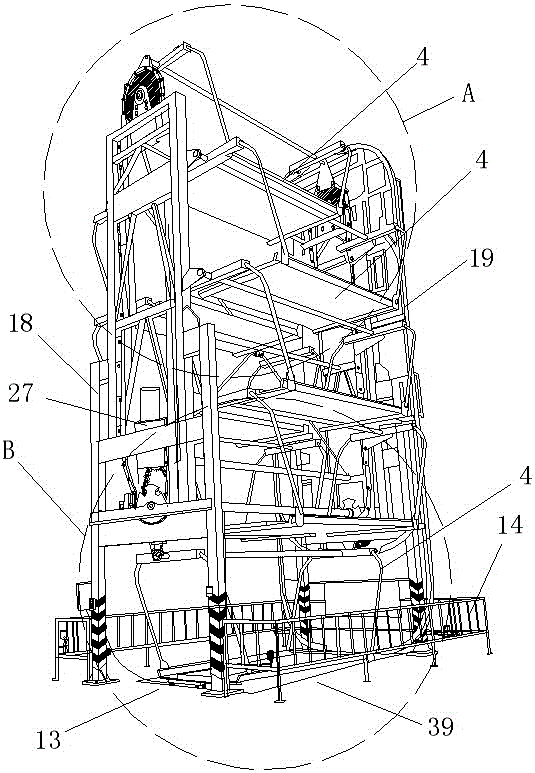

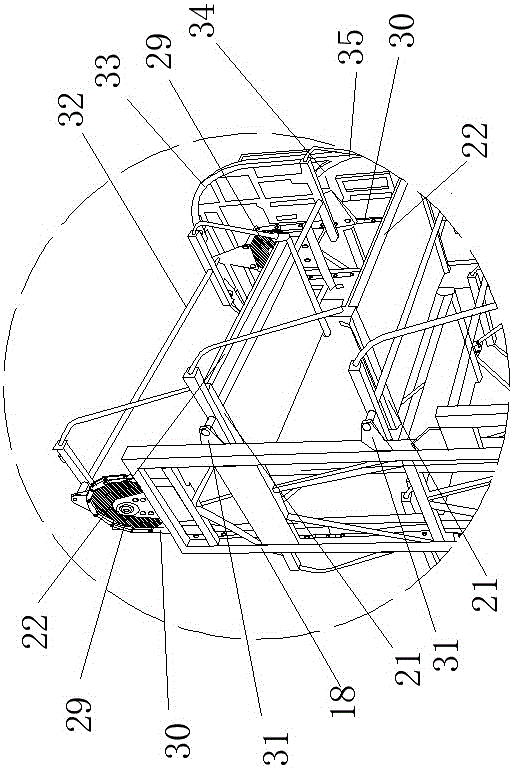

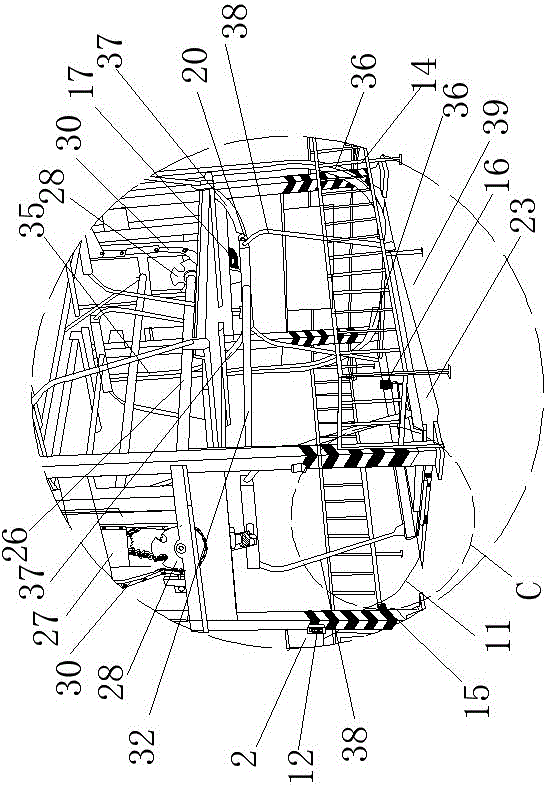

[0044] Example 1. like Figure 1 to Figure 11 As shown, a fully automatic anti-swing control system of a three-dimensional garage, the three-dimensional garage includes a frame body 18, and the frame body 18 is provided with a number of cyclically movable car-carrying mechanisms 4 with an iron bottom; The mechanism anti-swing control system includes an electromagnet block 1; the electromagnet block 1 is connected to the power supply 2 through a control circuit 11; the electromagnet block 1 is vertically provided with several jacks 3, and each jack 3 is inserted with a column 6, each Column 6 is installed on the bottom of each vehicle-carrying mechanism 4 on the frame body 18 that can move to the ground 39 below the lowest position and the top surface of the electromagnet block 1 and the bottom of the vehicle-carrying mechanism 4 on the frame body 18 are movable There is a gap 25 between the lowest positions. The lengths of the column 6 and the jack 3 are both greater than th...

Embodiment 2

[0053] Example 2. like Figure 12 As shown, the difference between this embodiment and Embodiment 1 is that a base 5 is provided on the ground 39 , and a column 6 is installed on the base 5 . The radially outer peripheral surface of the column 6 is provided with threads 9 and is fitted with adjusting bolts 10 . A damping device is set between the bottom position of the electromagnet block 1 and the top position of the adjusting bolt 10 on the radially outer peripheral surface of the column 6 ; the damping device is a damping spring 7 . Adjusting bolts are provided to further adjust the height of the top surface of the electromagnet block 1, so that the distance between the electromagnet block and each vehicle-carrying plate is within the magnetic force range of the electromagnet block; the sensitivity of the device is ensured, and energy consumption is reduced. A shock-absorbing device is provided, which can slow down the impact force when the electromagnet block 1 descends,...

Embodiment 3

[0058] Example 3. like Figure 13 As shown, the difference between this embodiment and Embodiment 1 lies in: the shock absorbing pad 8 of the shock absorbing device. The shock pad is a rubber pad. A base 5 is provided on the ground 39 , and a column 6 is installed on the base 5 . The bottom of the frame body 18 is provided with a guardrail 14 to prevent people and vehicles from entering by mistake. The guardrail 14 outside the frame body is provided with a second sensor 16 that can perceive whether the vehicle has completely entered the vehicle-carrying mechanism 4. The second sensor 16 communicates with the programmable logic controller. 12 connected. Electromagnet block 1 is cube-shaped, and its length is 0.5-1.0 times of the width of vehicle-carrying mechanism 4 bottom surfaces, and its width is 0.2-1.0 times of its length, and its height is 0.2-0.5 times of its length.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com