Hoisting device for rapid lifting of pressure chamber of true triaxial testing machine

A hoisting device and pressure chamber technology, which is applied in the field of hoisting devices for rapid lifting of the pressure chamber of a true triaxial testing machine, can solve problems affecting the measurement accuracy of sensors on the assembly, potential safety hazards, and low service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

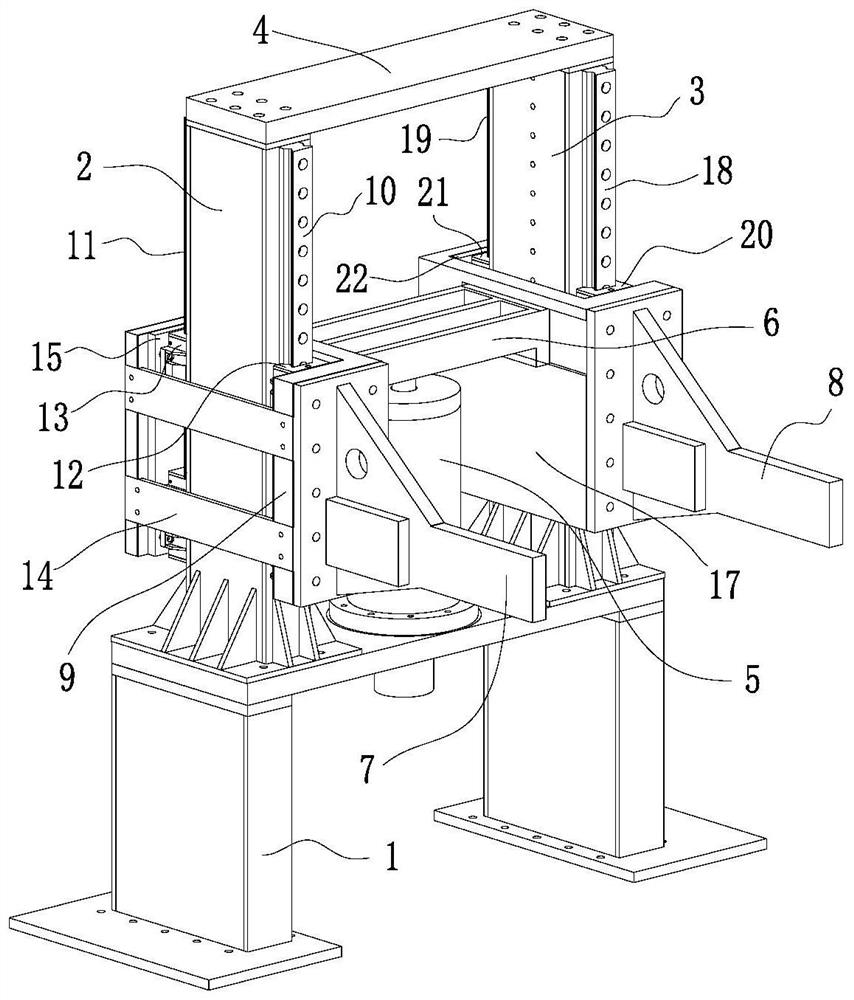

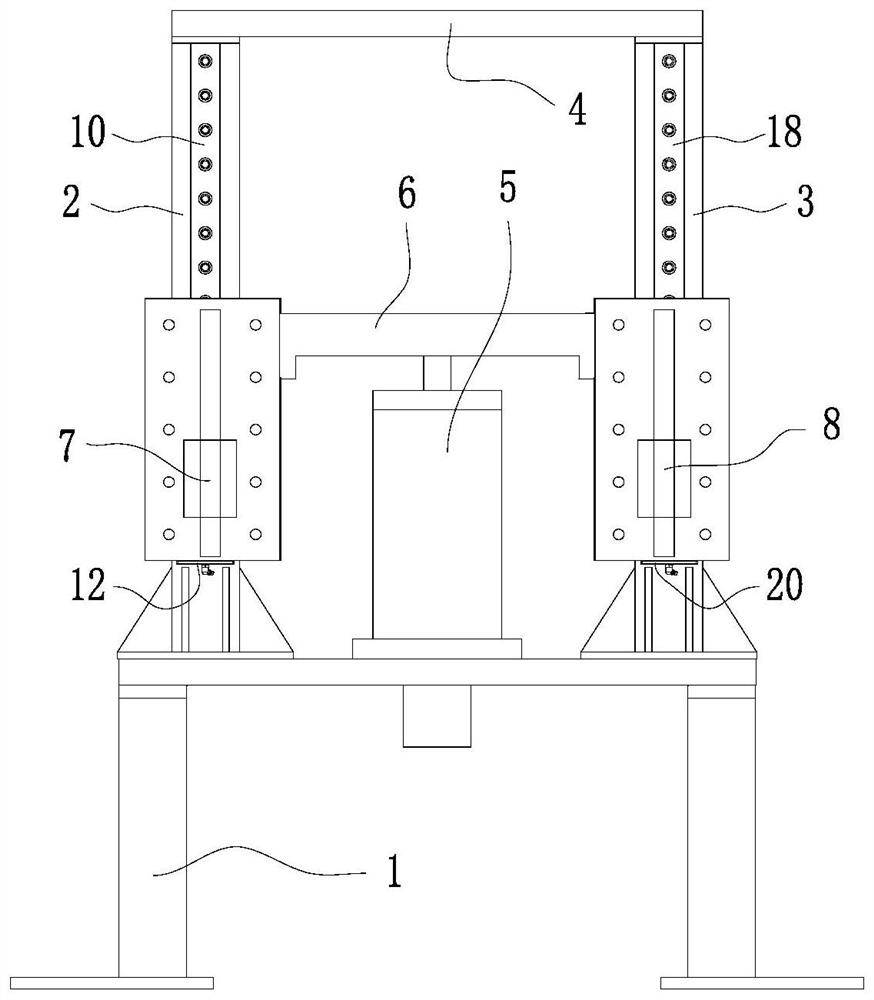

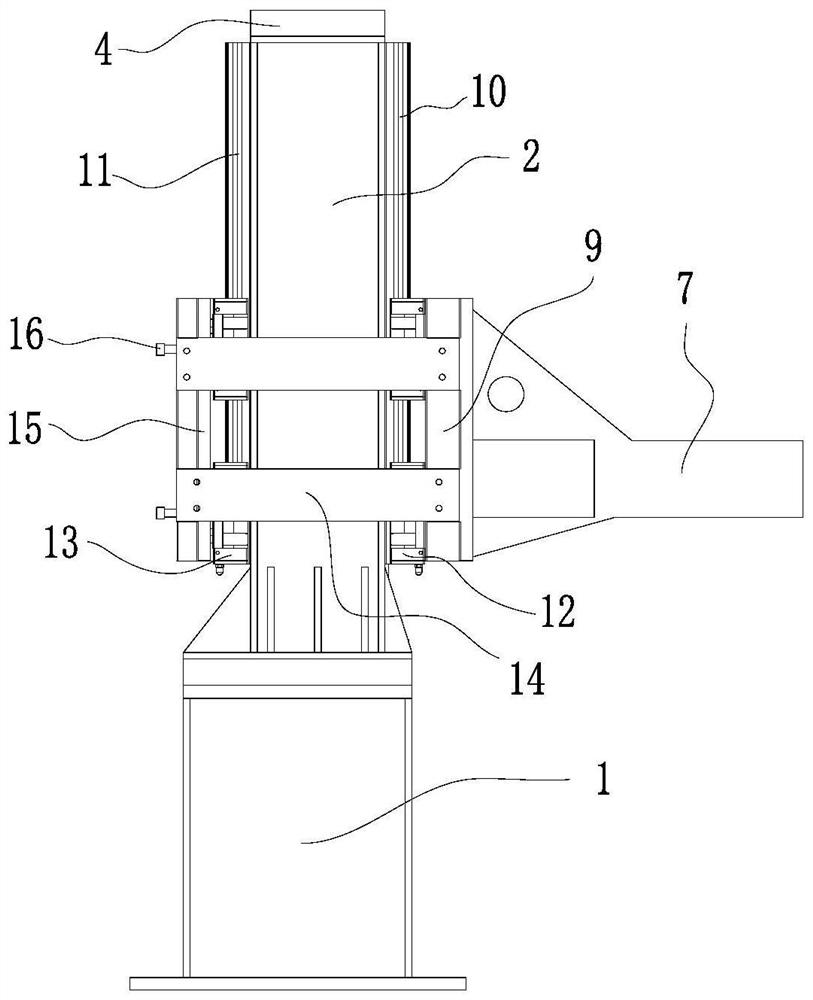

[0016] like Figure 1~4 As shown, a hoisting device for rapid lifting of the pressure chamber of a true triaxial testing machine, including a base 1, a first column 2, a second column 3, a beam 4, a lifting hydraulic cylinder 5, a lifting beam 6, a first lifting Guide assembly, the second lifting guide assembly, the first lifting arm 7 and the second lifting arm 8; the first column 2 and the second column 3 are vertically fixed on the top of the base 1, the first column 2 and the second column The tops of the two columns 3 are fixedly connected by a beam 4; the lifting hydraulic cylinder 5 is vertically fixed on the top of the base 1 with the piston rod facing upwards, and the lifting hydraulic cylinder 5 is located in the middle of the first column 2 and the second column 3 The lifting beam 6 is horizontally fixed on the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com