Cut hot-rolled angle steel combined cross-shaped buckling restrained brace and manufacturing method thereof

A buckling constraint, cross-shaped technology, applied in building types, building components, earthquake resistance, etc., can solve the problems of high production cost, low production efficiency, complex production process, etc., to reduce production costs, convenient and flexible use, and broad market promotion. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to show the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention. In order to avoid obscuring the essence of the present invention, well-known methods, procedures and procedures are not described in detail.

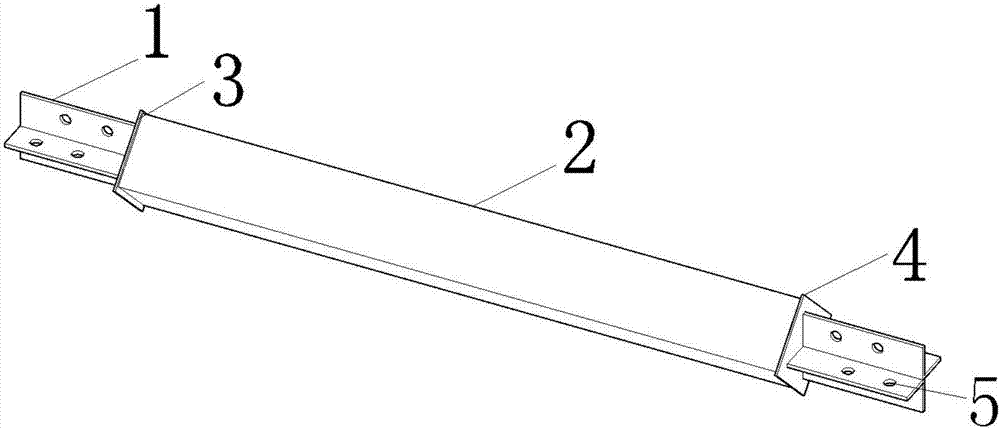

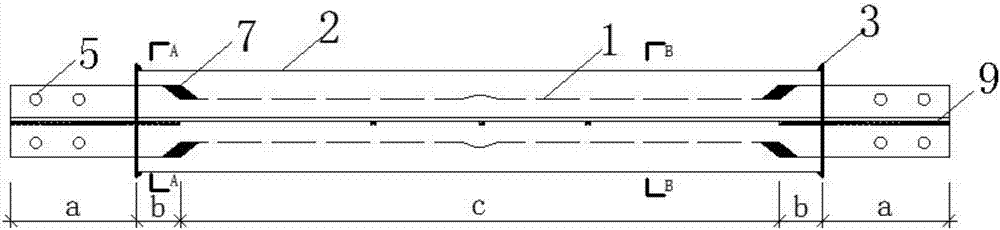

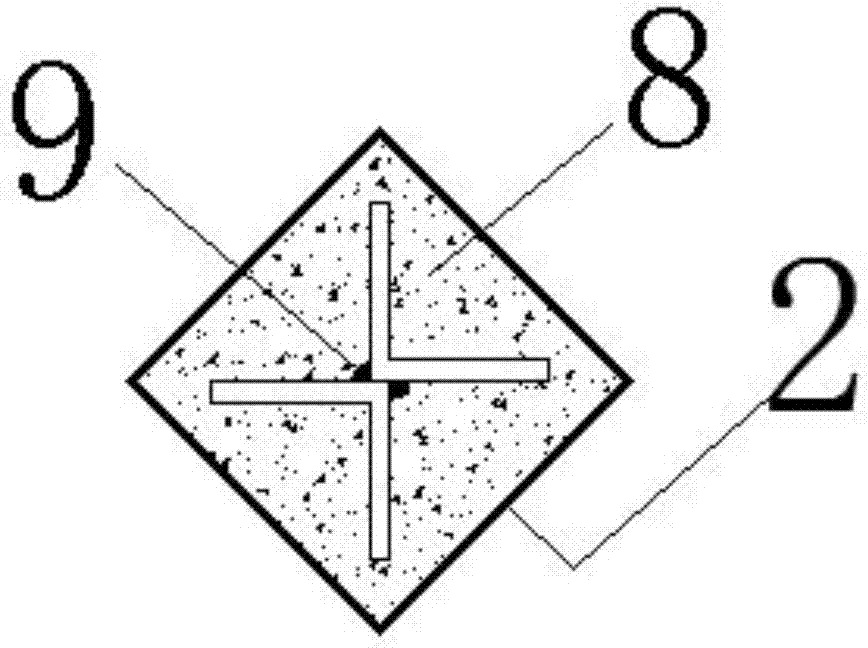

[0036] Such as Figure 1 to Figure 8 As shown, the cutting hot-rolled angle steel combined cross-shaped buckling restraint support proposed by the present invention includes a core material support member 1, a square steel pipe 2, an upper end plate 3 and a lower end plate 4, and is characterized in that: the core material support member 1 is made of Two hot-rolled angle steels are combined on top of each other, and the cross-section is cross-shaped. The core ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com