Shear wall jointing template reinforcing bolt

A formwork reinforcement and shear wall technology, which is applied to formwork/formwork/work frame connectors, construction components on-site preparation, construction, etc., can solve the problem that the upper formwork does not have enough support, increase the work of cutting bolts, Reinforce the problems of low bolt strength, etc., to achieve the effect of reducing workload, high promotion and application value, and improving anchorage strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

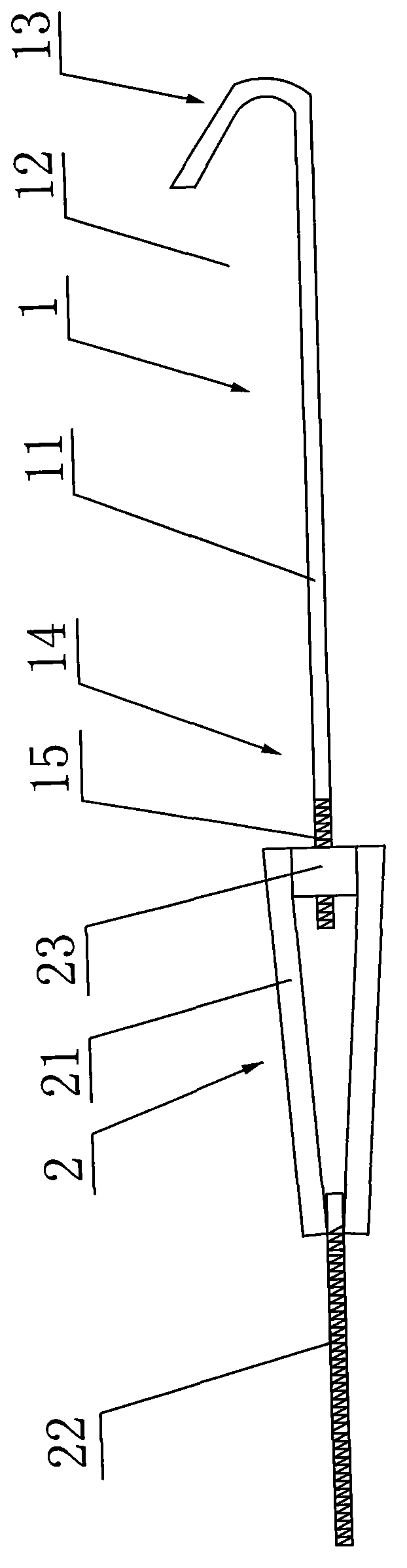

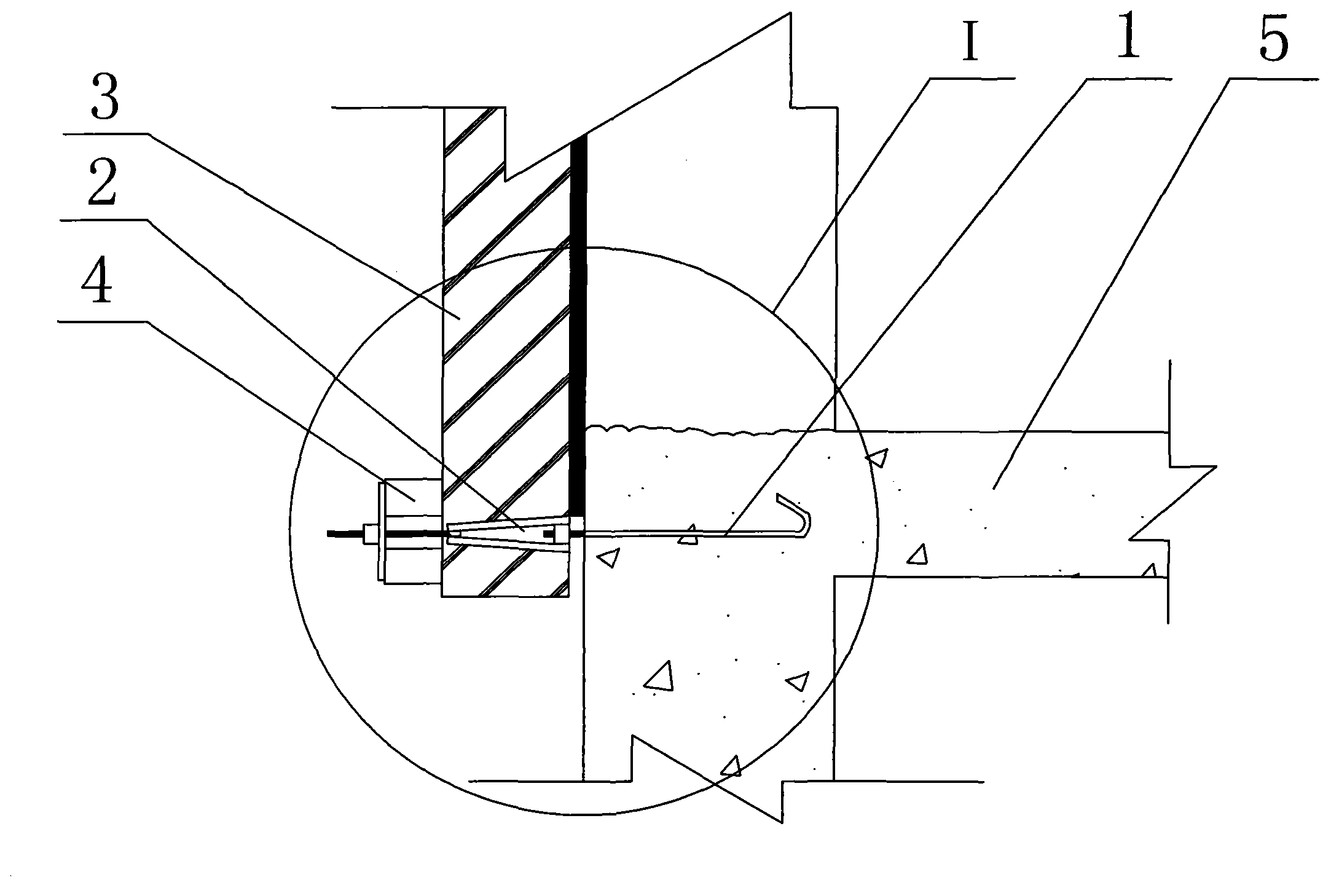

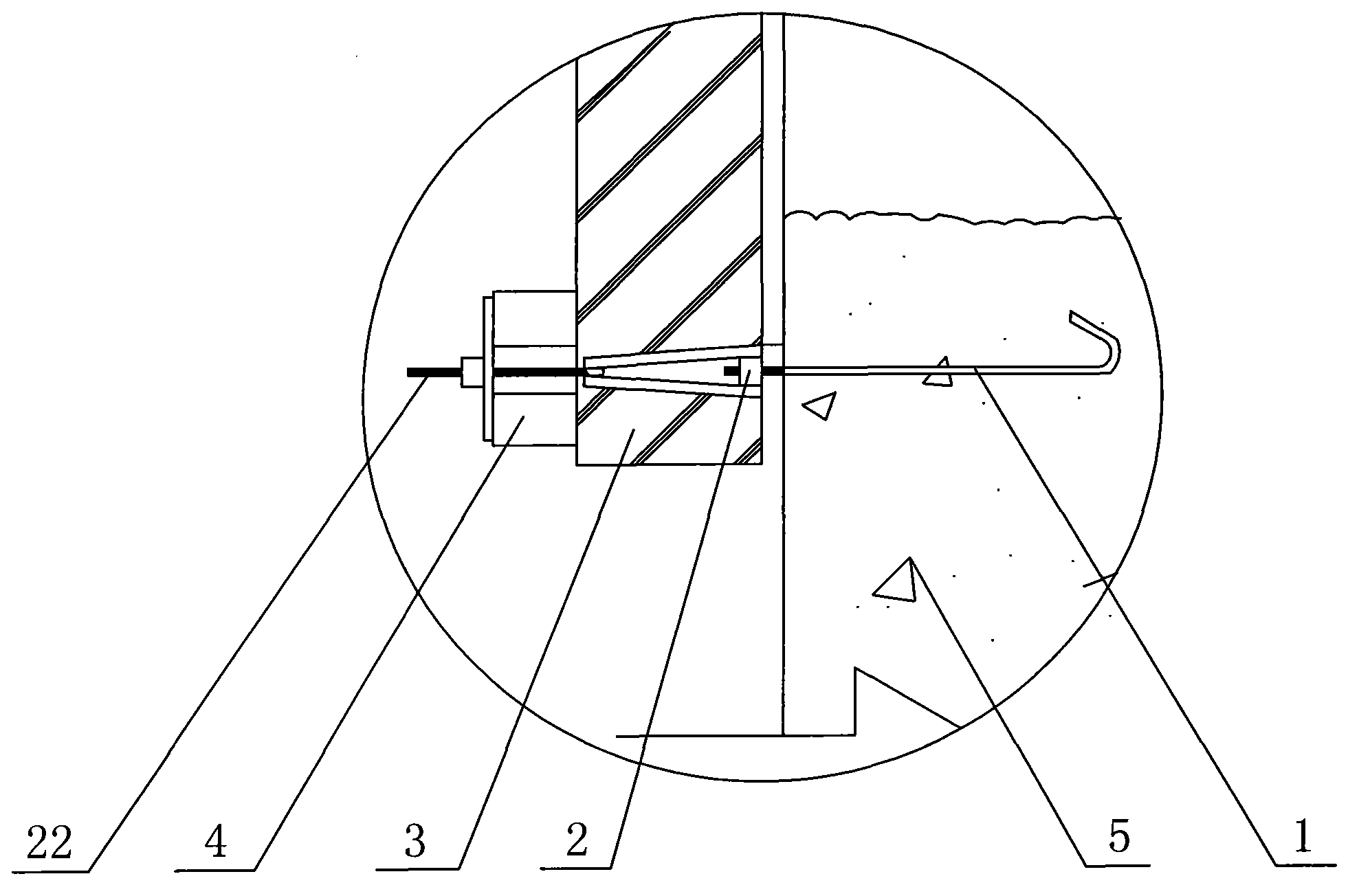

[0019] Such as figure 1 , 2 , shown in 3, a kind of reinforcement bolt of stubble formwork for shear wall, comprises the embedded component 1 with straight rod 11, is provided with reinforcement mechanism 13 at the embedded end 12 of embedded component 1, and reinforcement mechanism 13 is arranged as straight rod 11 The end is a crotch bent at an acute angle with the straight rod 11 . The connecting end 14 of the embedded component 1 is detachably connected to the reinforcing component 2 arranged outside the shear wall, and the connecting end 14 of the embedded component 1 is provided with a threaded rod 15 screwed to the reinforcing component 2 . Reinforcement member 2 is made up of the frame body 21 that is screwed with the connecting end 14 of embedded component 1 and the threaded connecting column 22 that is used to connect back corrugated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com