High-speed ultra-wide roller oil supply bearing

An ultra-wide roller, oil supply technology, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of poor chip removal, incomplete, uneven oil supply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further illustrate the features and advantages of this patent, the following description will be made in conjunction with the accompanying drawings.

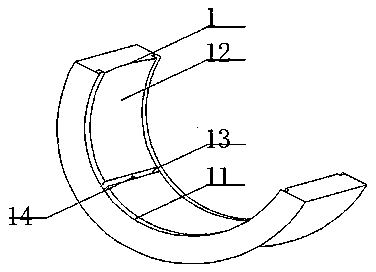

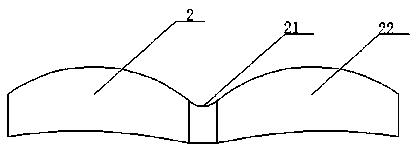

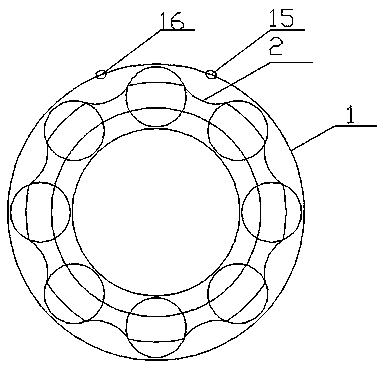

[0012] As shown in the figure: a high-speed ultra-wide roller oil supply bearing, including: an inner ring, an outer ring 1, a roller, and a roller support 2; the outer ring 1 is set on the inner ring, and the rollers are mounted on Between the two rings; the rollers are multiple rows of rollers; the inner wall of the outer ring 1 is provided with a flow groove 11 for oil to pass through; a bulging flow groove 12 is provided directly above each row of rollers ; A communication groove 13 is provided at the position corresponding to the bottom of the outer ring 1 corresponding to the chip outlet. The roller bracket 2 is in the shape of symmetrical wings; a diversion groove is arranged at the root where the two wings are connected. The inner wall of the inner ring is provided with a bulge flow groove 12 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com