Patents

Literature

70 results about "Needle adapter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

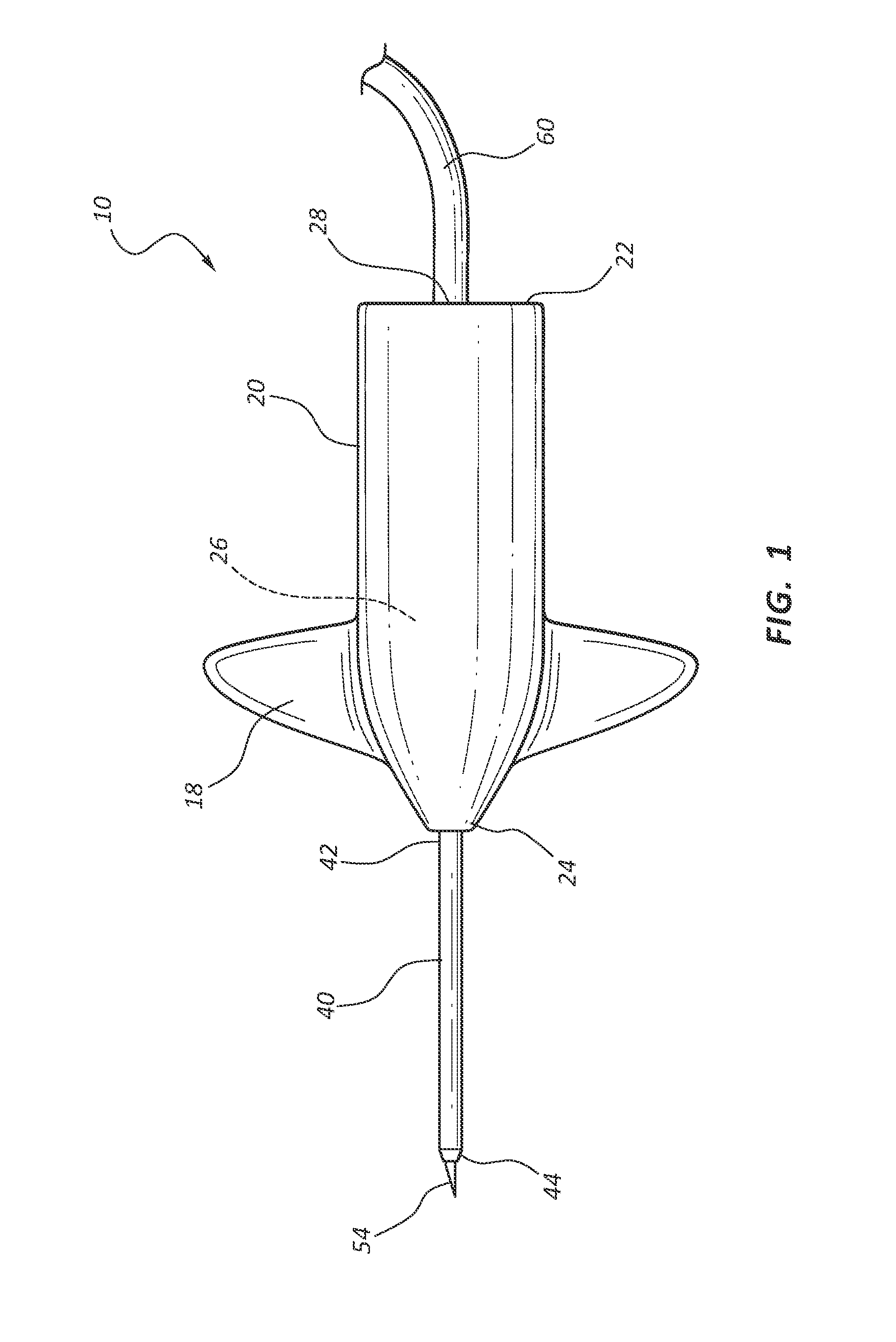

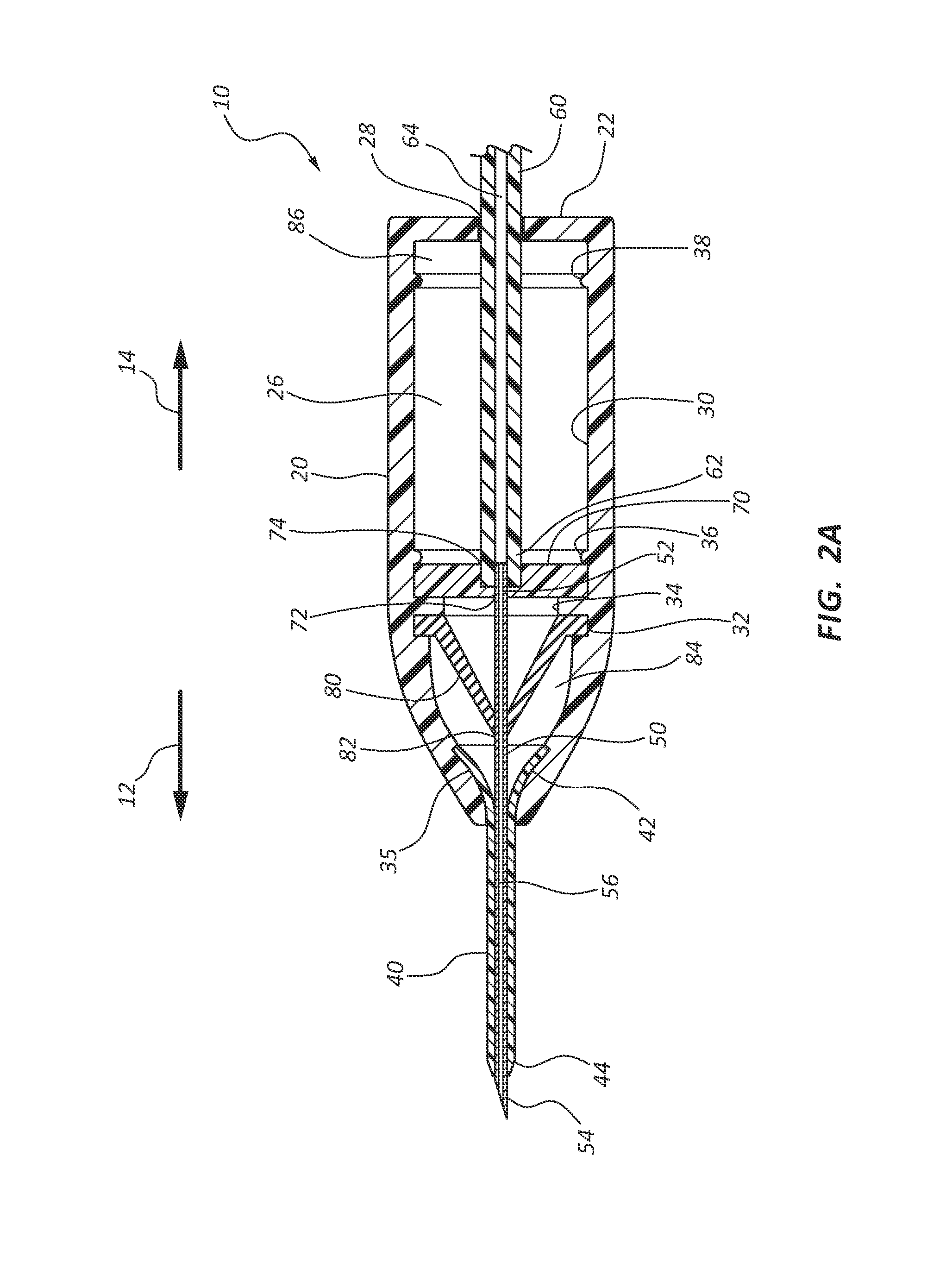

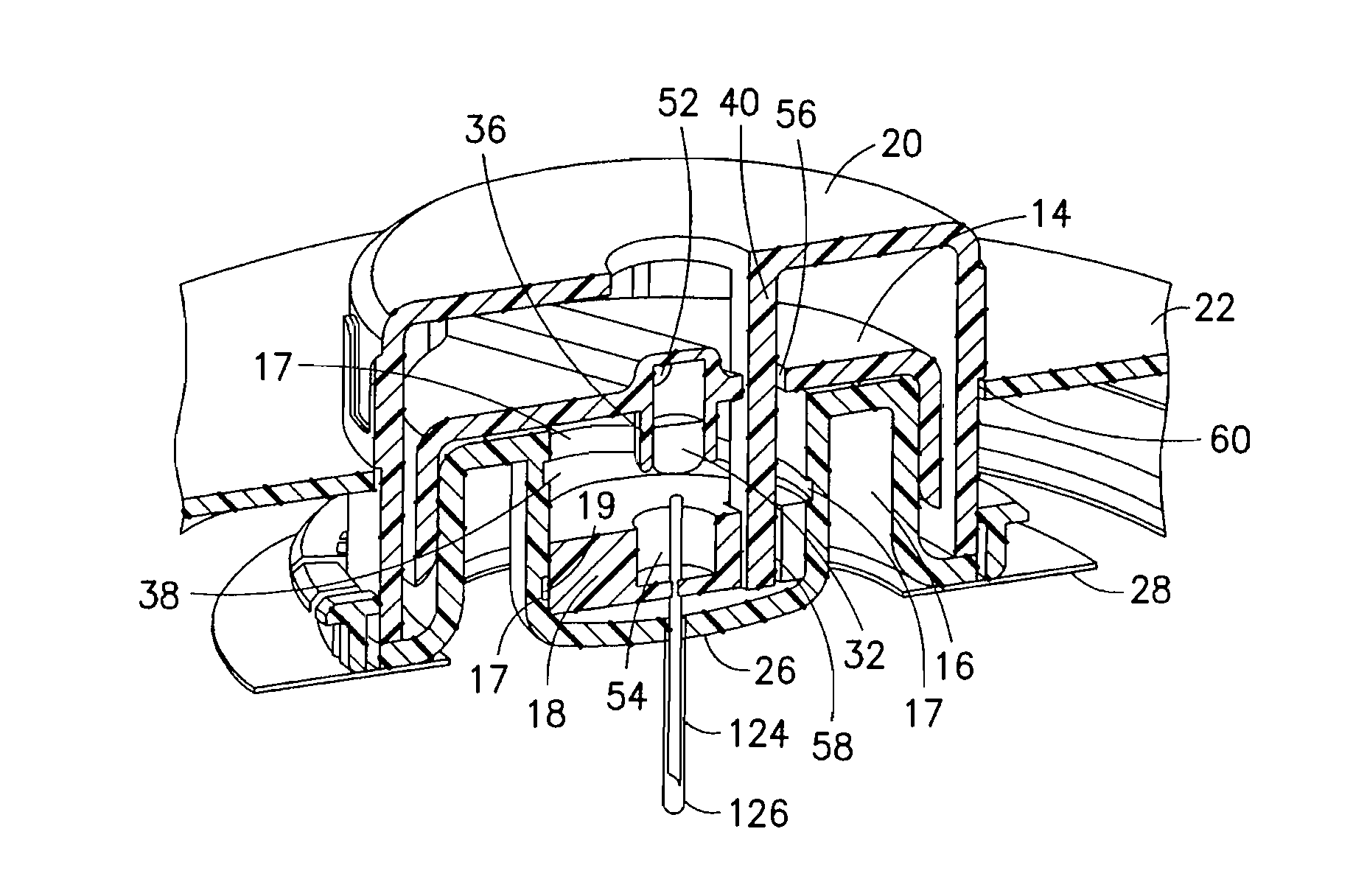

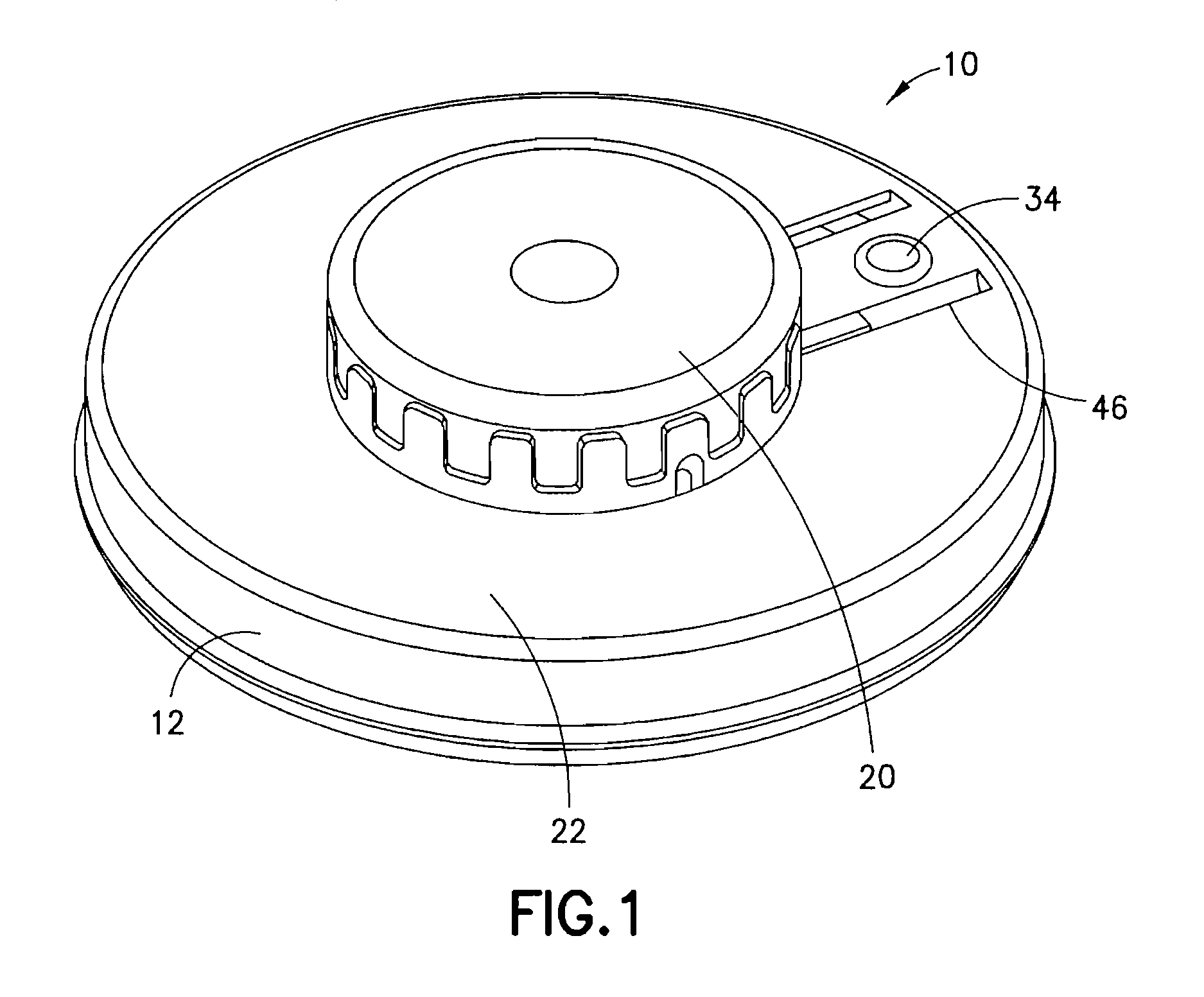

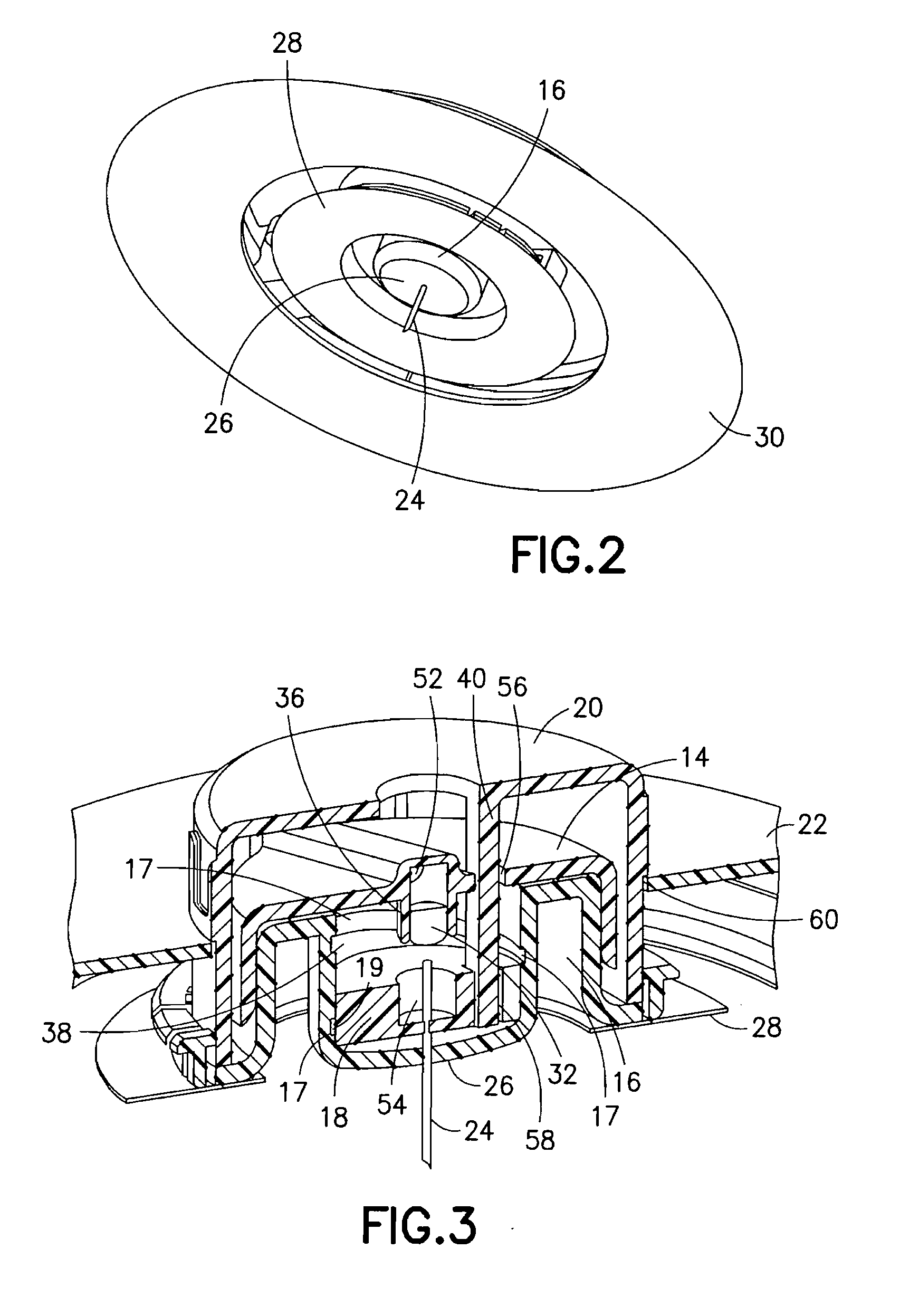

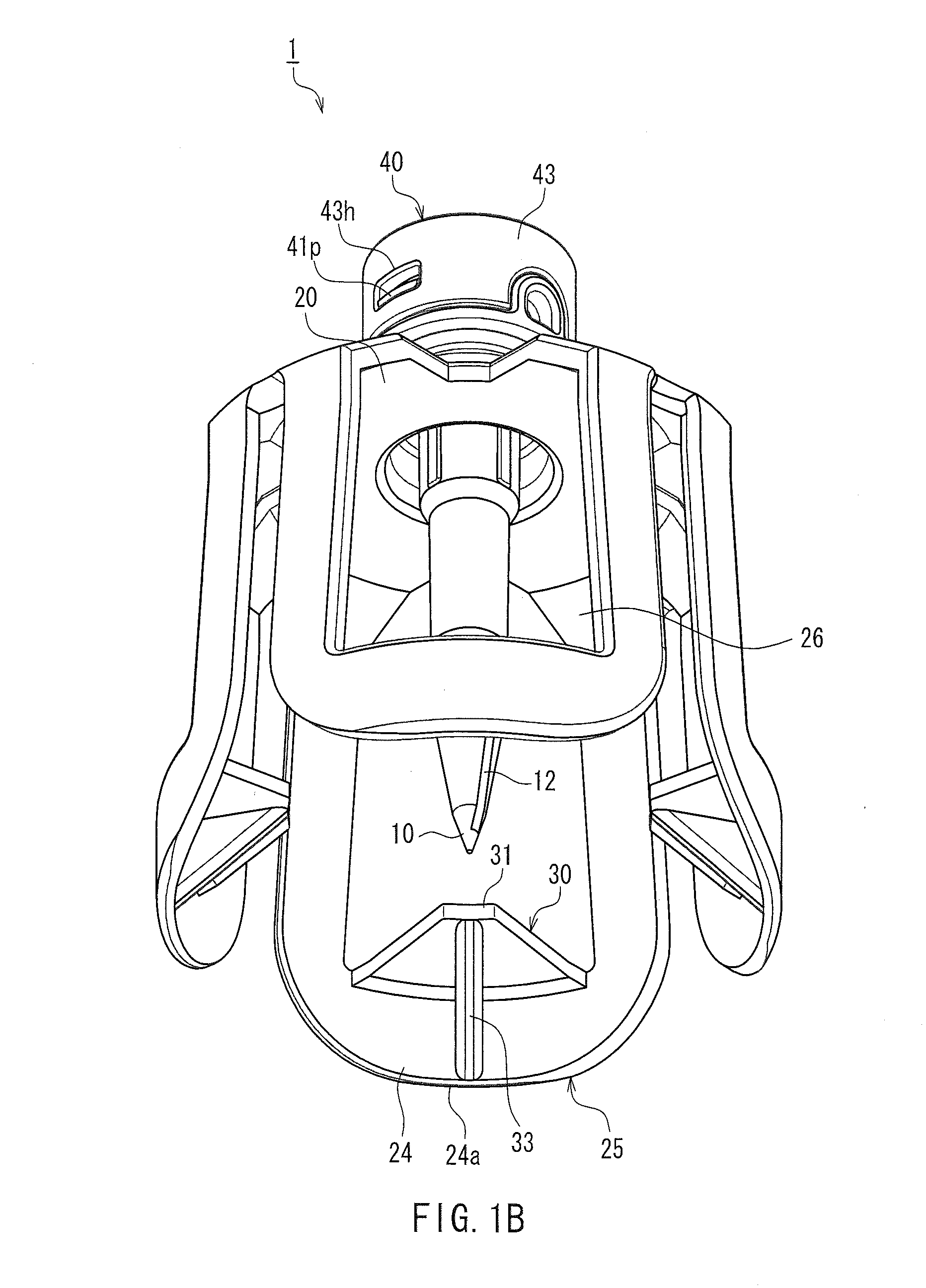

Disposable needle and hub assembly

ActiveUS20070149924A1Easy injectionFacilitates stress concentration relocationMedical devicesInfusion needlesDisposable NeedleTissue skin

A needle assembly including a cover, an inner shield, a needle and a hub assembly is provided. After use, the cover is placed over the distal (patient) end of the needle and the inner shield can be used to cover the proximal (non-patient) end of the needle. The inner shield comprises flexible extensions above its open end to secure the inner shield over the proximal end of a needle in the needle assembly. A needle hub is also provided that eliminates adhesive bumps at the base of the needle and further distributes needle angular bending along an irregular surface, which facilitates proper insertion technique and effective needle length. The hub further includes stanchions or castellations on its edge such that when the patient uses proper injection techniques, the edges of the hub leave a distinctive impression in the skin of a user for a short period of time.

Owner:EMBECTA CORP

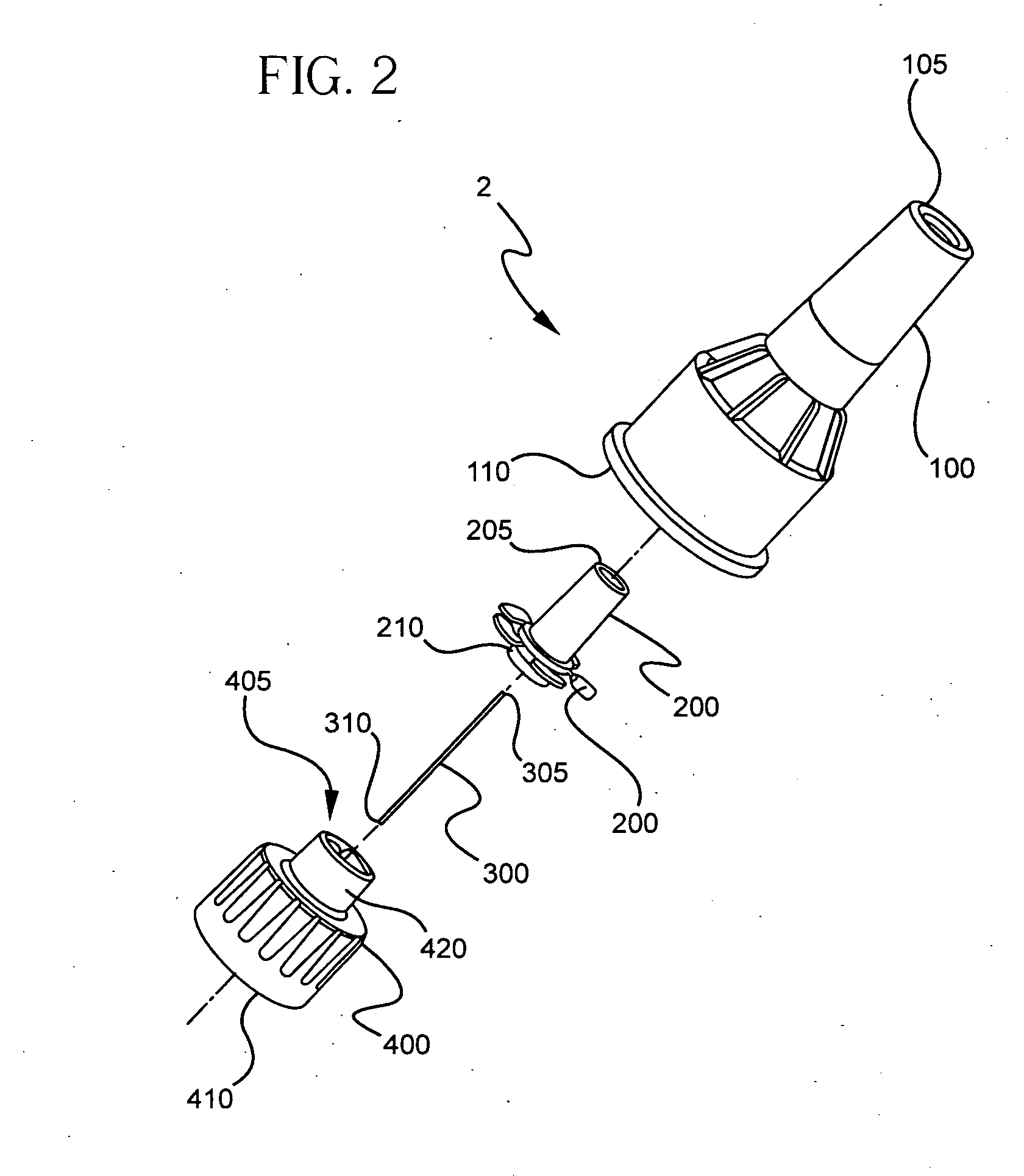

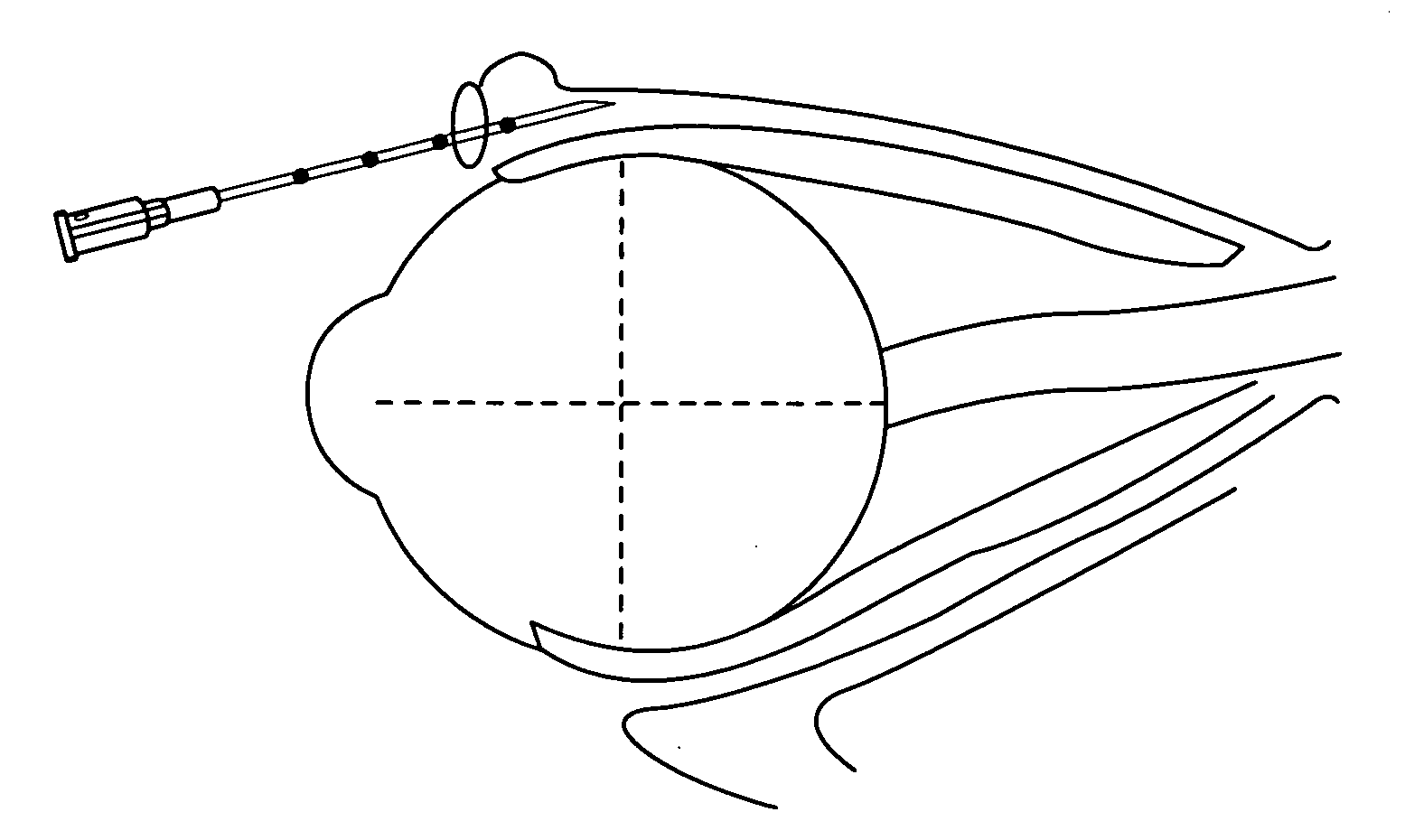

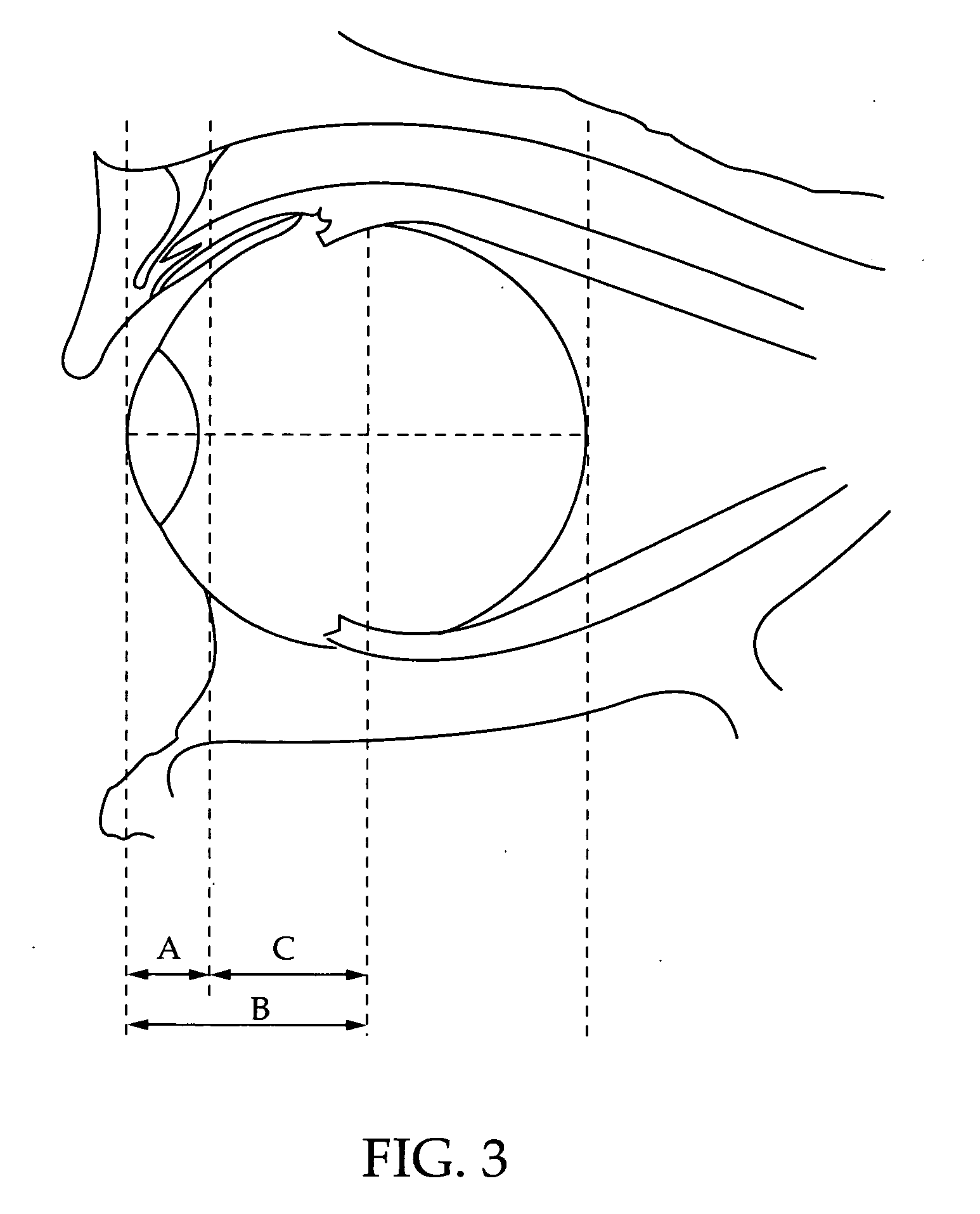

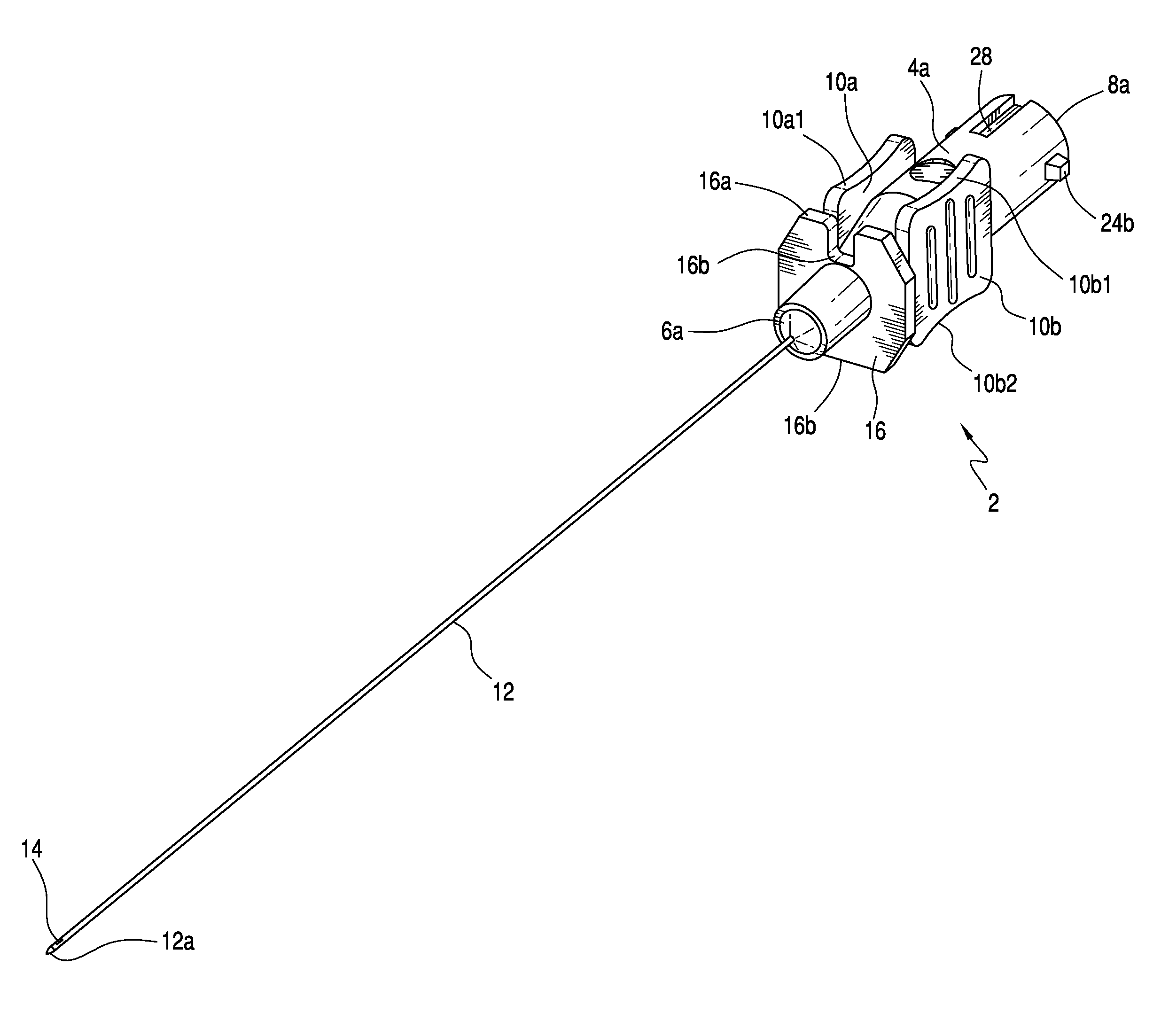

Insertion mechanism for use with a syringe

InactiveUS20090124973A1Improve securityEasy to operateIntravenous devicesEye treatmentSyringe needleMedical procedure

A needle preferably for the delivery of ophthalmic regional anesthesia, wherein the needle includes a hub and a shaft having a plurality of markings to indicate the depth of the needle after insertion into an individual during a medical procedure, thereby enabling a practitioner to gauge the exact measurement of the needle at all times during the operation.

Owner:DAGOSTINO EDUARDO +1

Disposable needle and hub assembly

ActiveUS8133202B2Exact lengthEasy injectionMedical devicesInfusion needlesEngineeringDisposable Needle

A needle assembly including a cover, an inner shield, a needle and a hub assembly is provided. After use, the cover is placed over the distal (patient) end of the needle and the inner shield can be used to cover the proximal (non-patient) end of the needle. The inner shield comprises flexible extensions above its open end to secure the inner shield over the proximal end of a needle in the needle assembly. A needle hub is also provided that eliminates adhesive bumps at the base of the needle and further distributes needle angular bending along an irregular surface, which facilitates proper insertion technique and effective needle length. The hub further includes stanchions or castellations on its edge such that when the patient uses proper injection techniques, the edges of the hub leave a distinctive impression in the skin of a user for a short period of time.

Owner:EMBECTA CORP

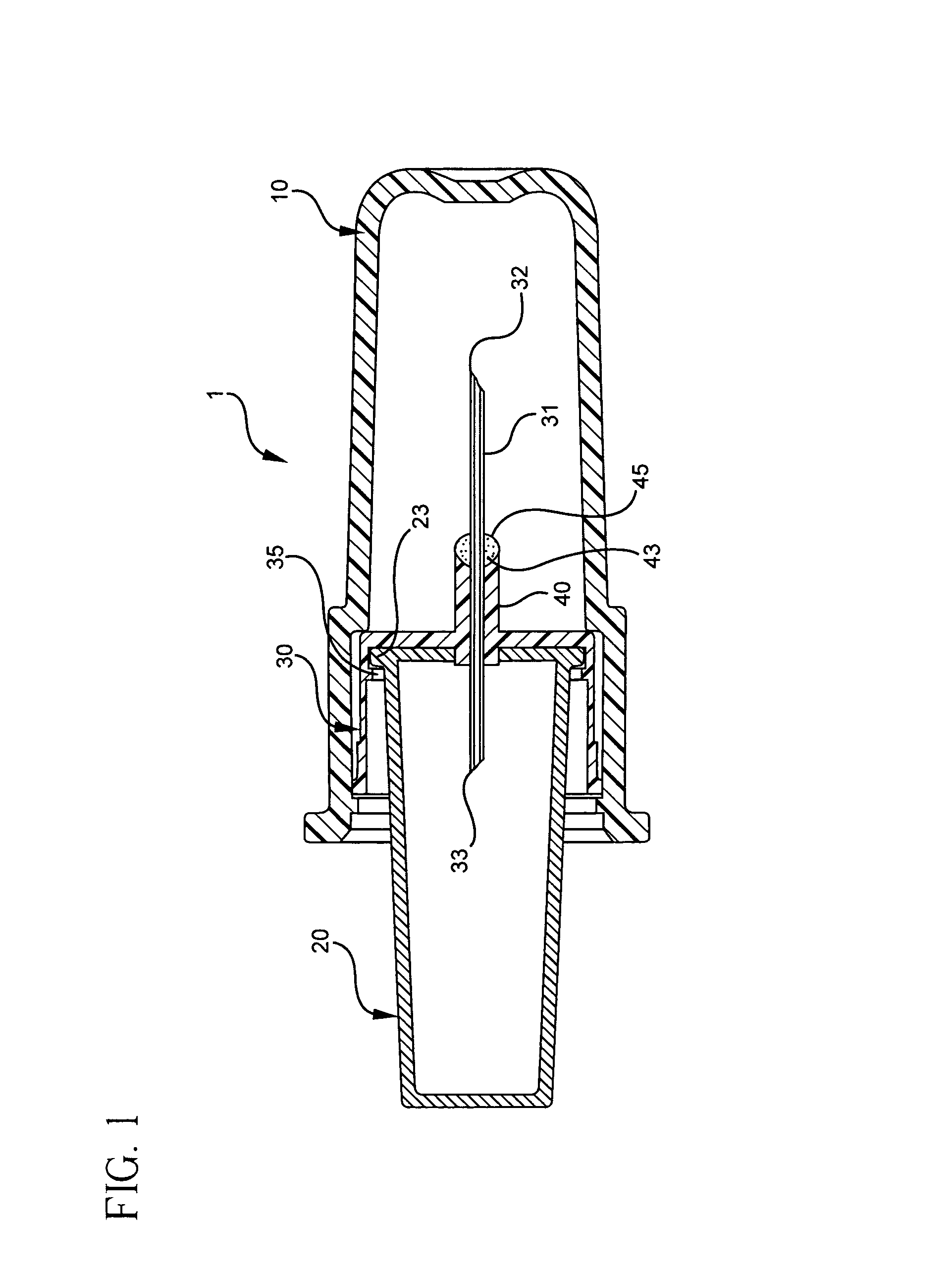

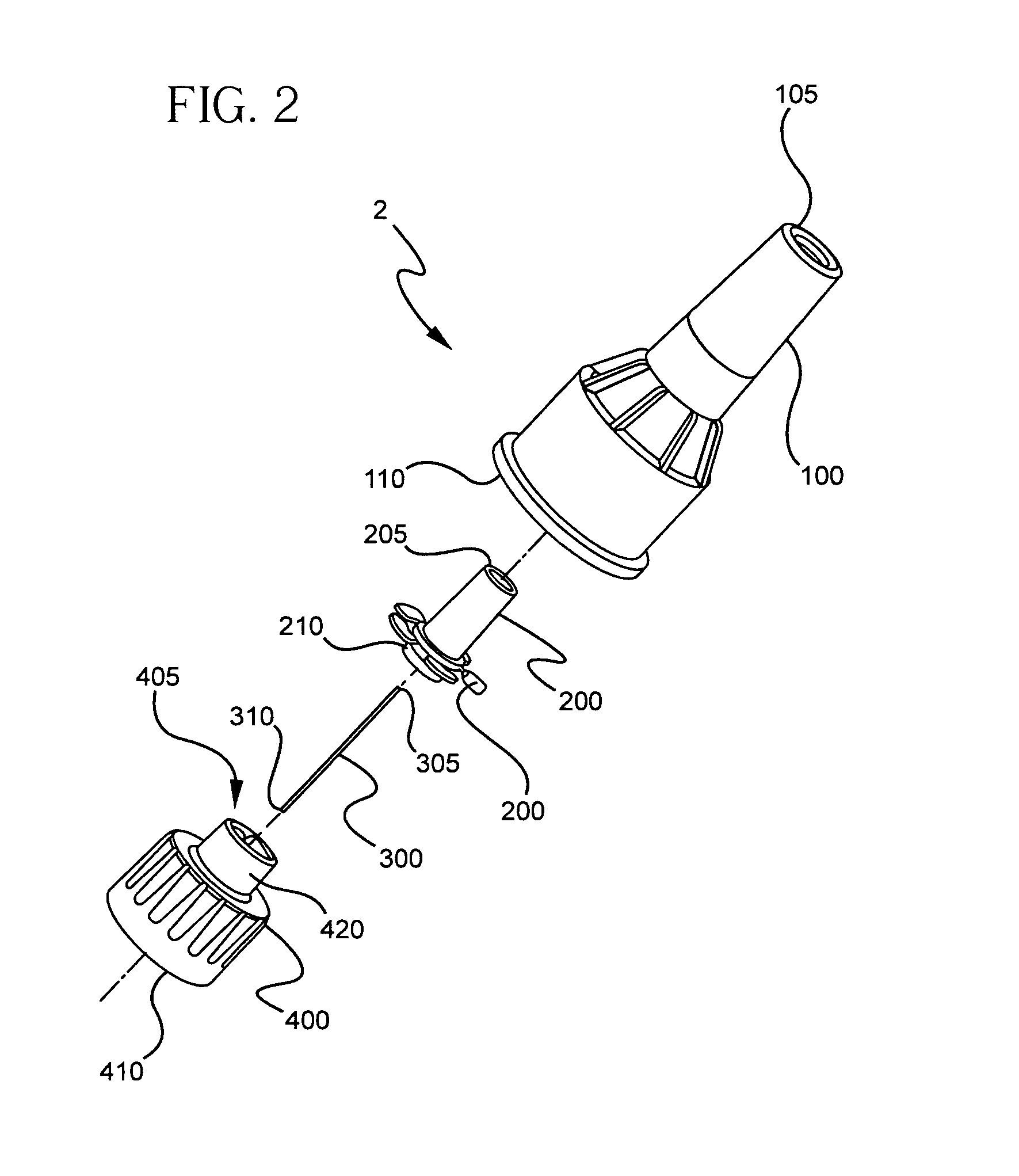

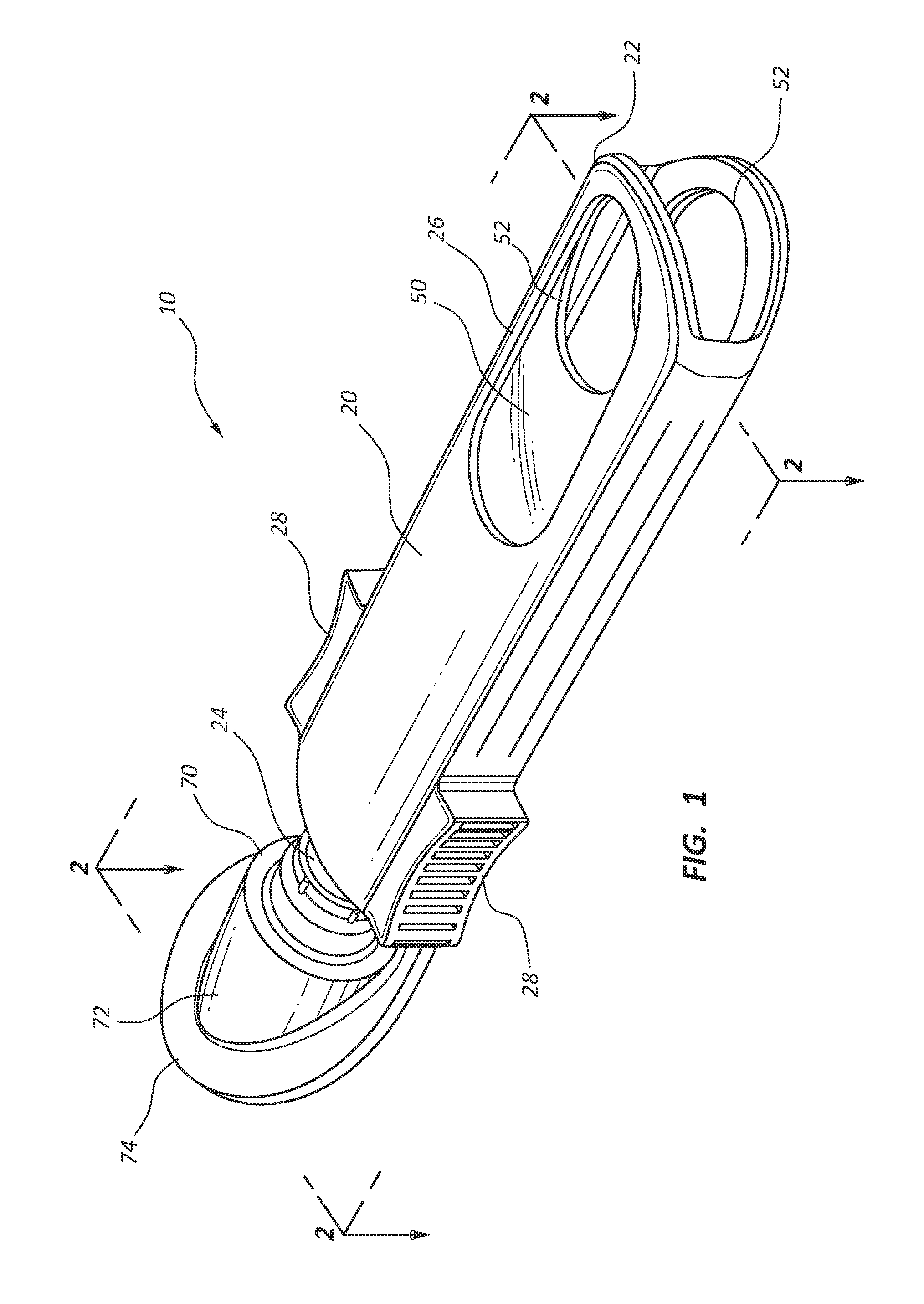

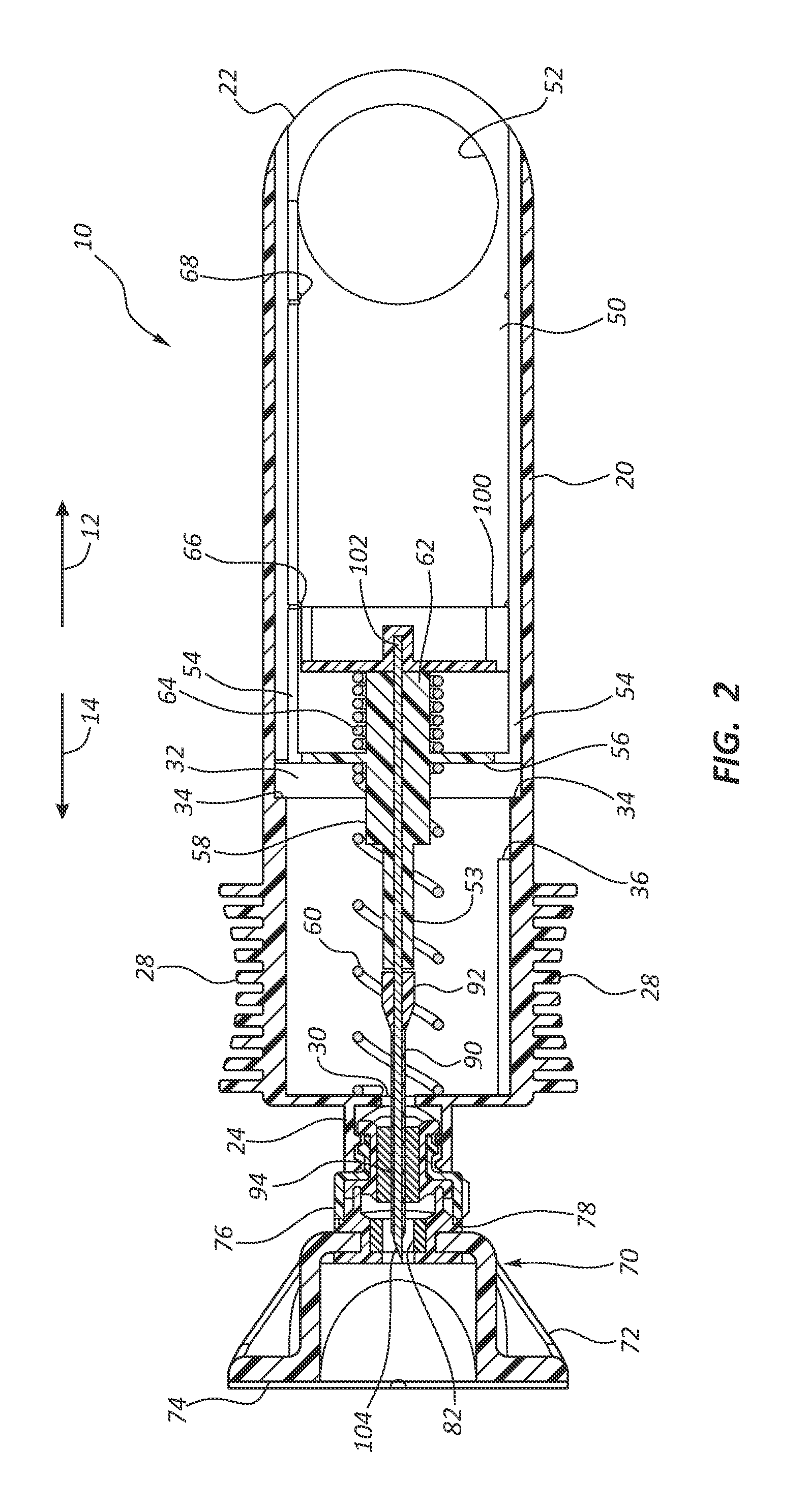

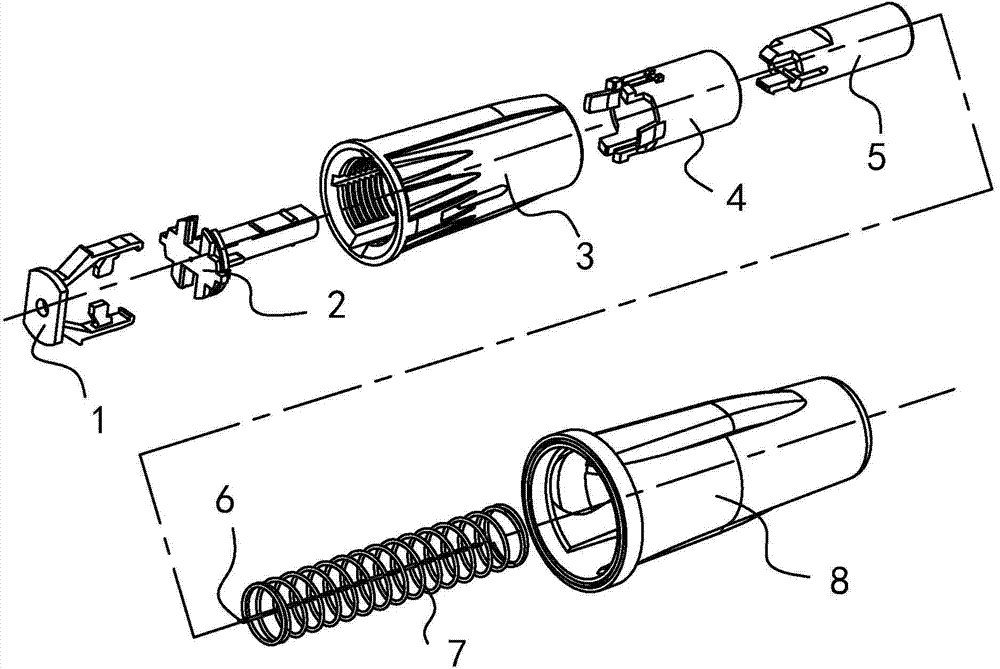

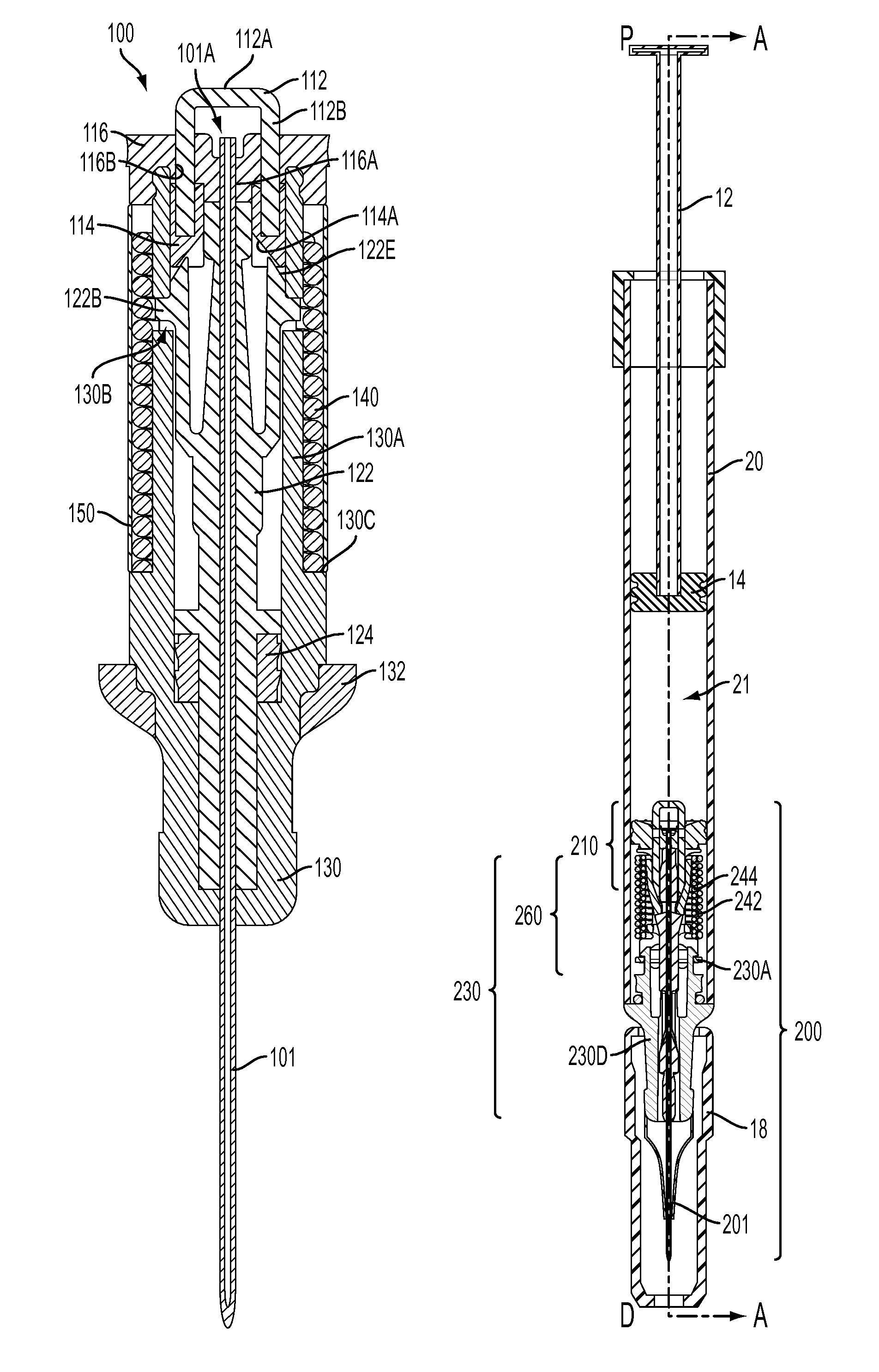

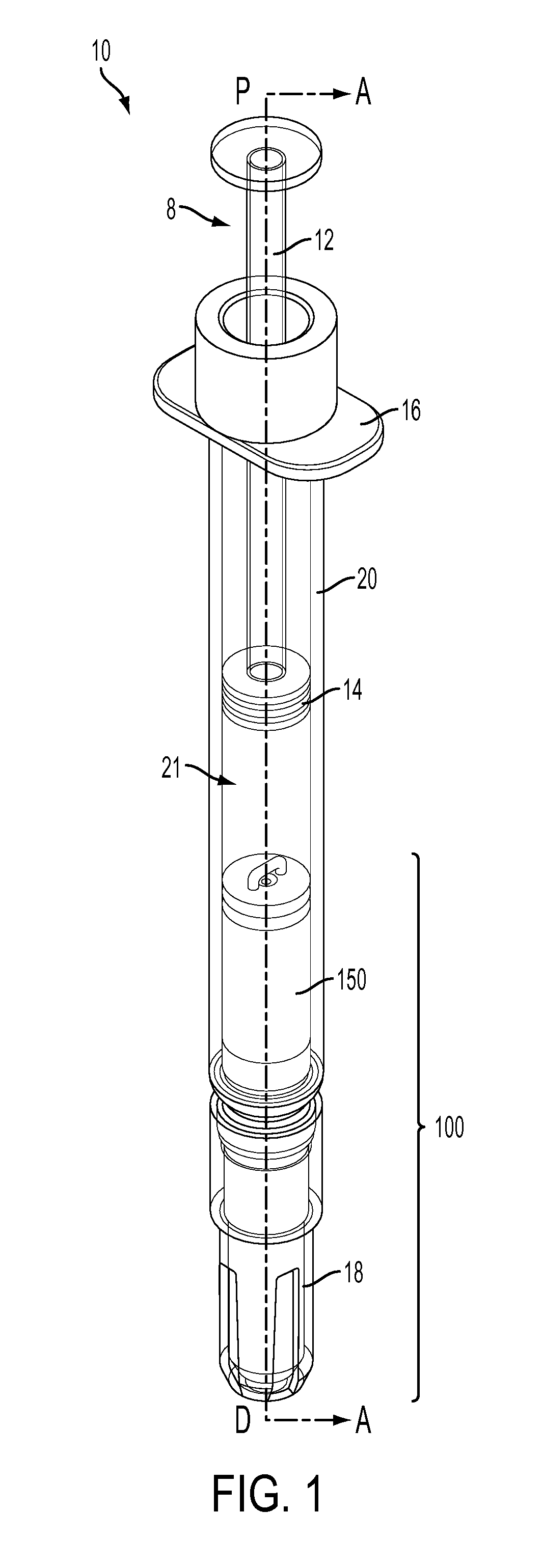

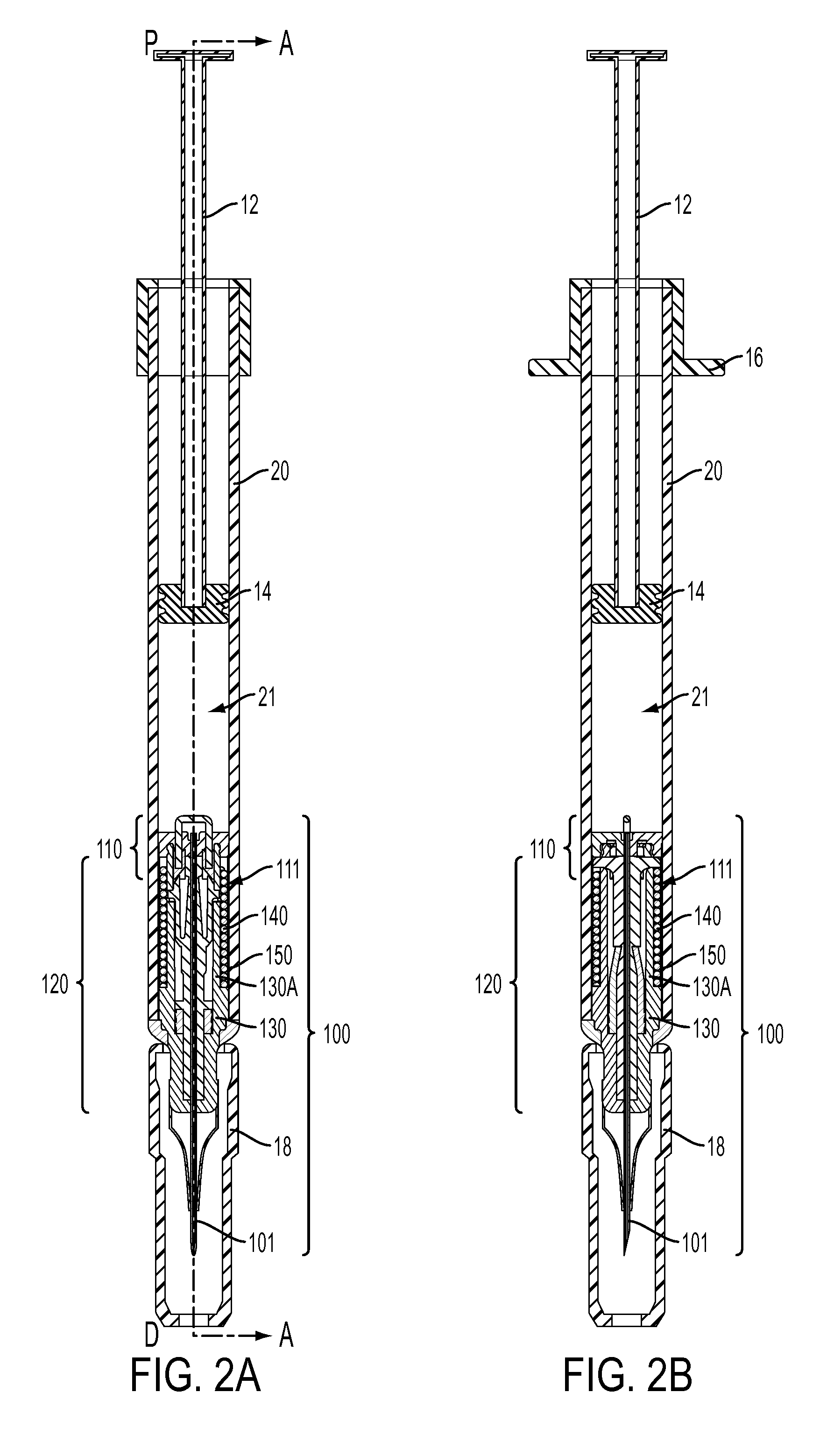

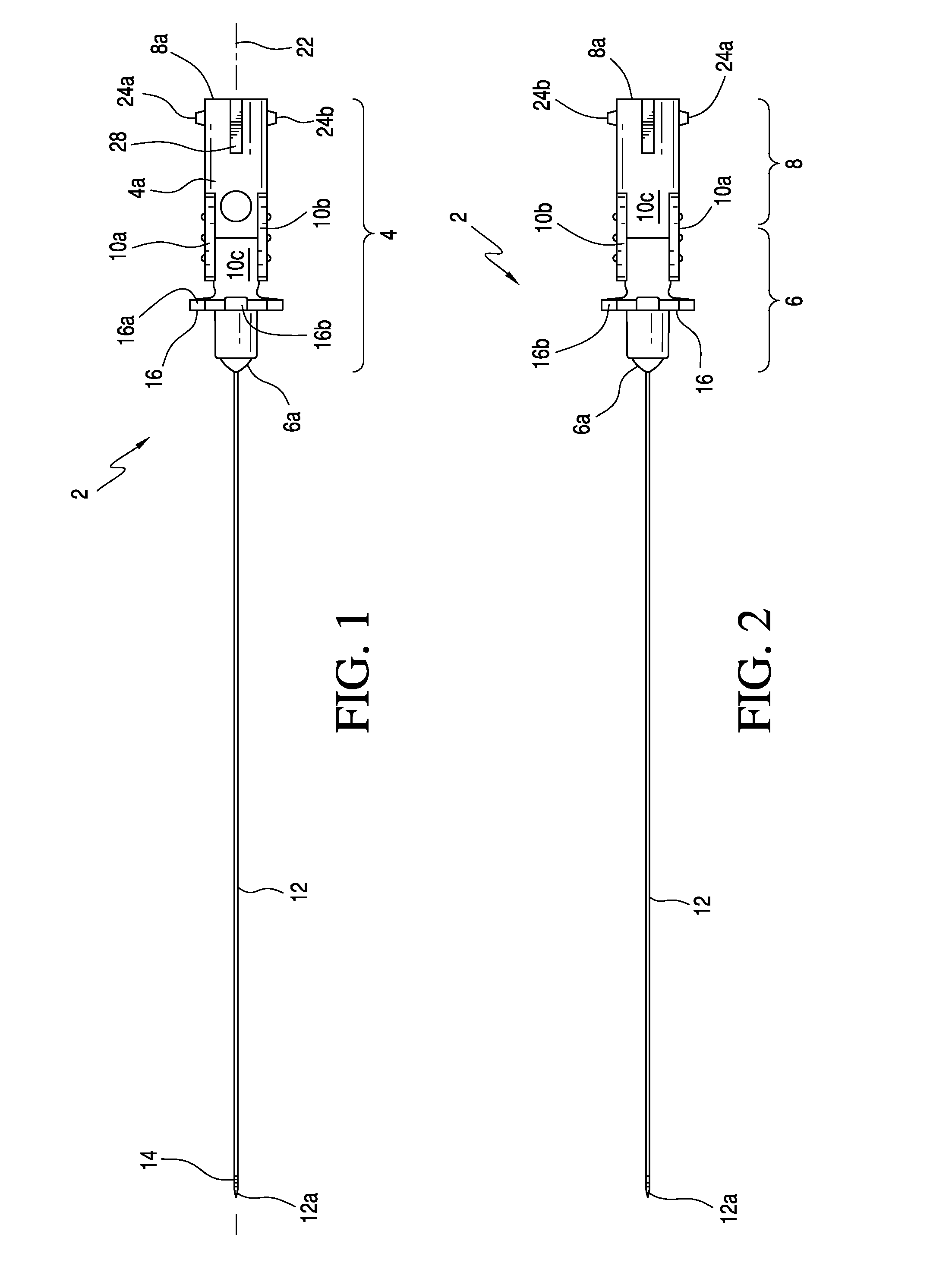

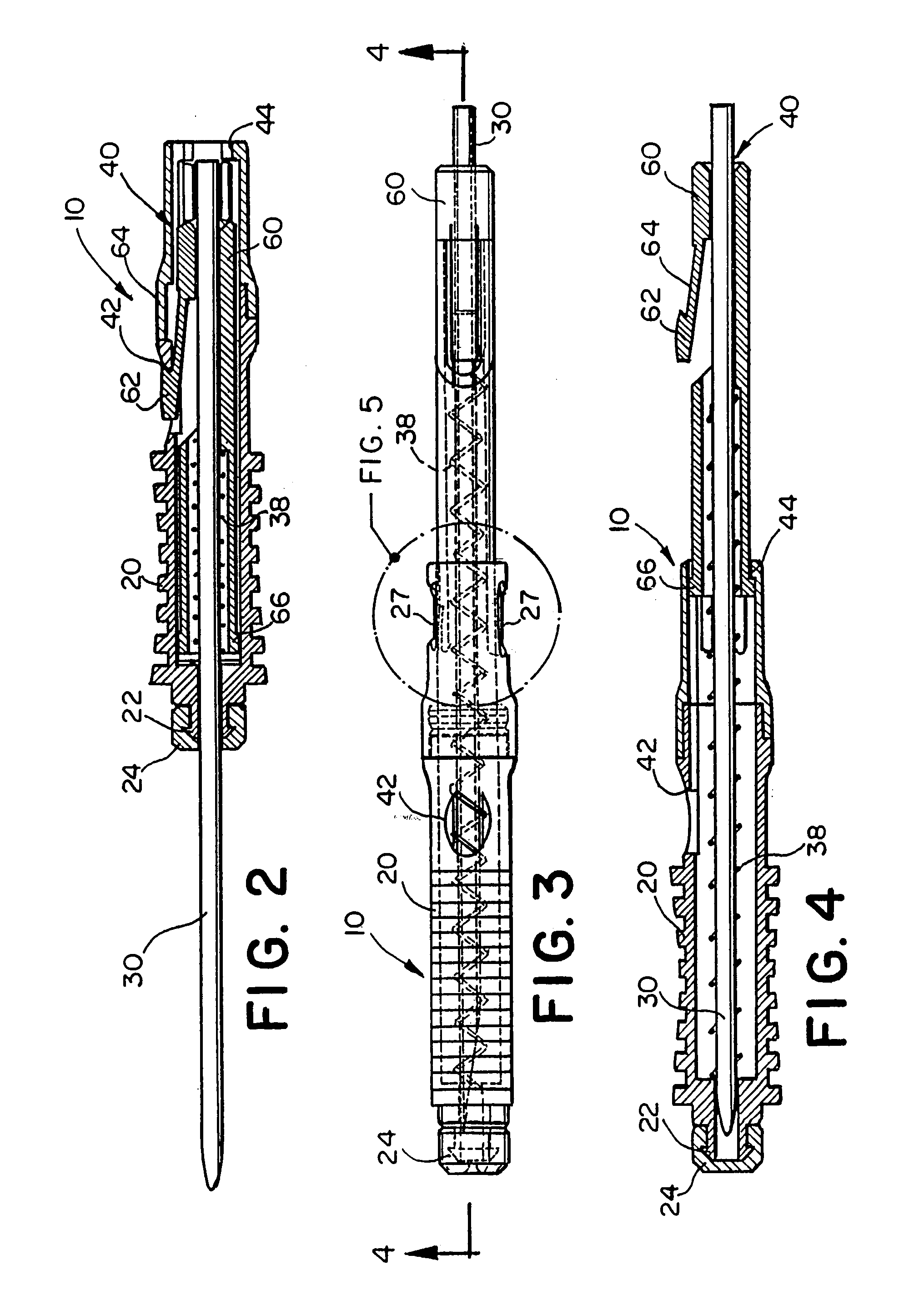

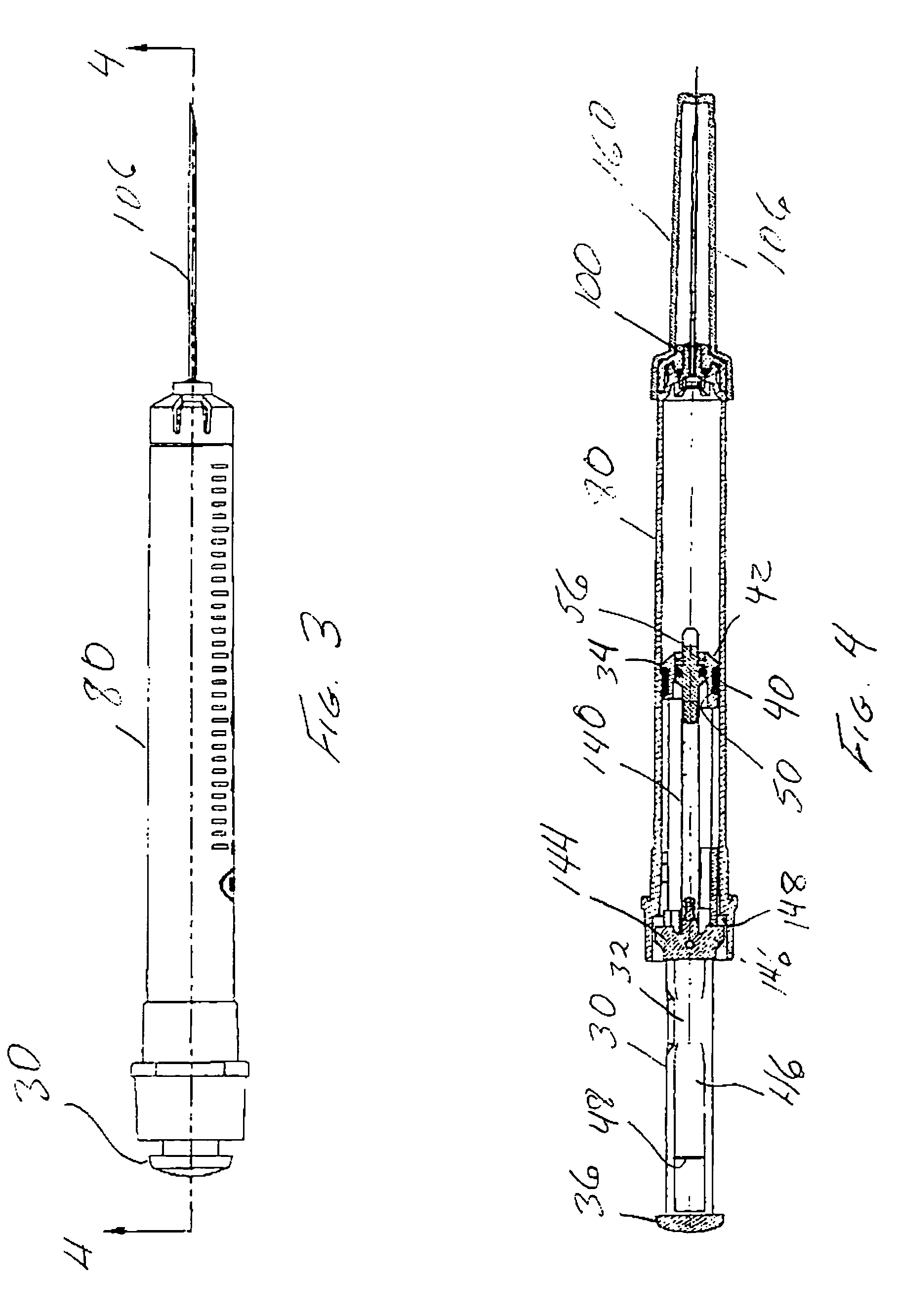

Retractable needle adapters and safety syringes

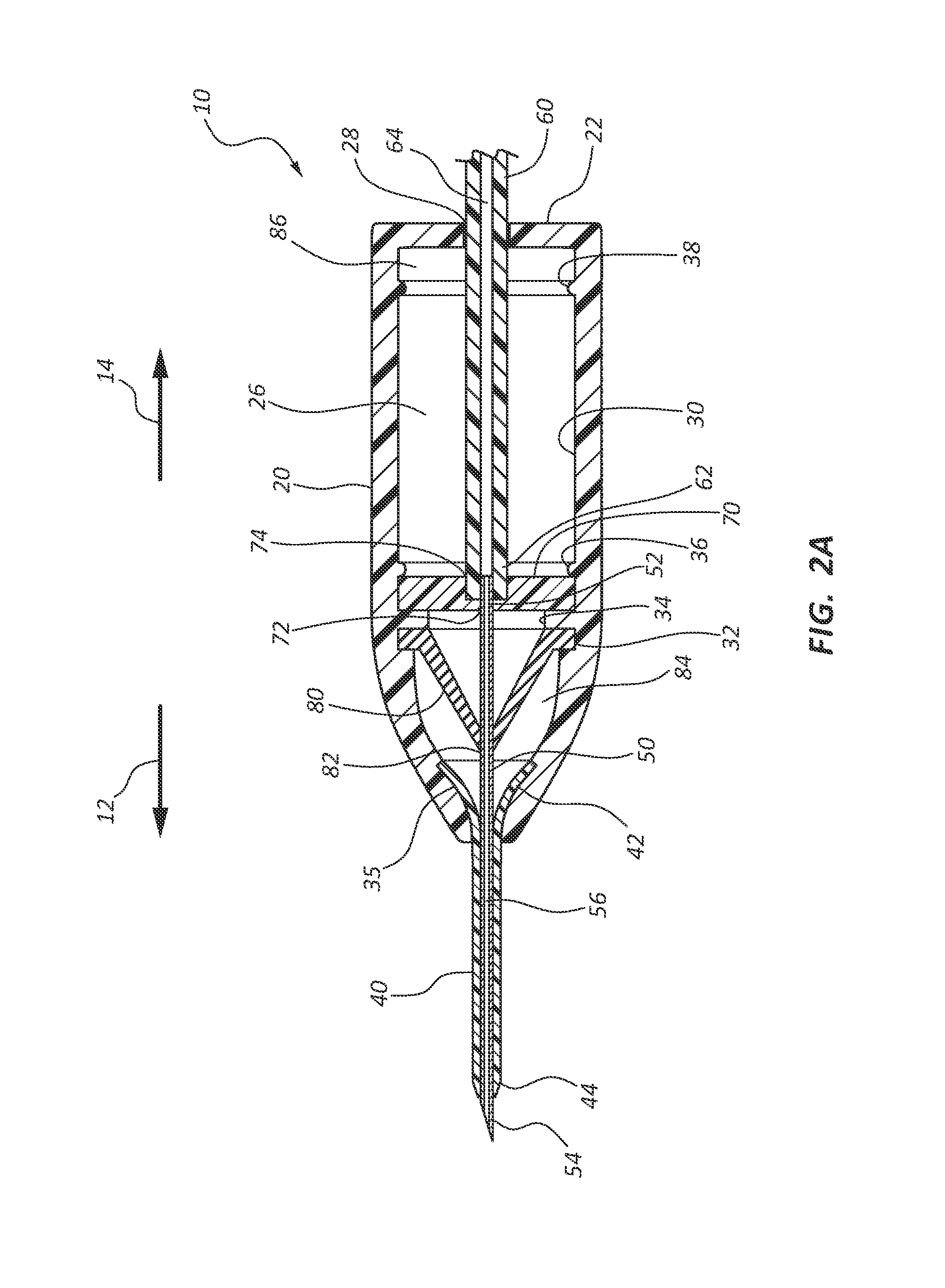

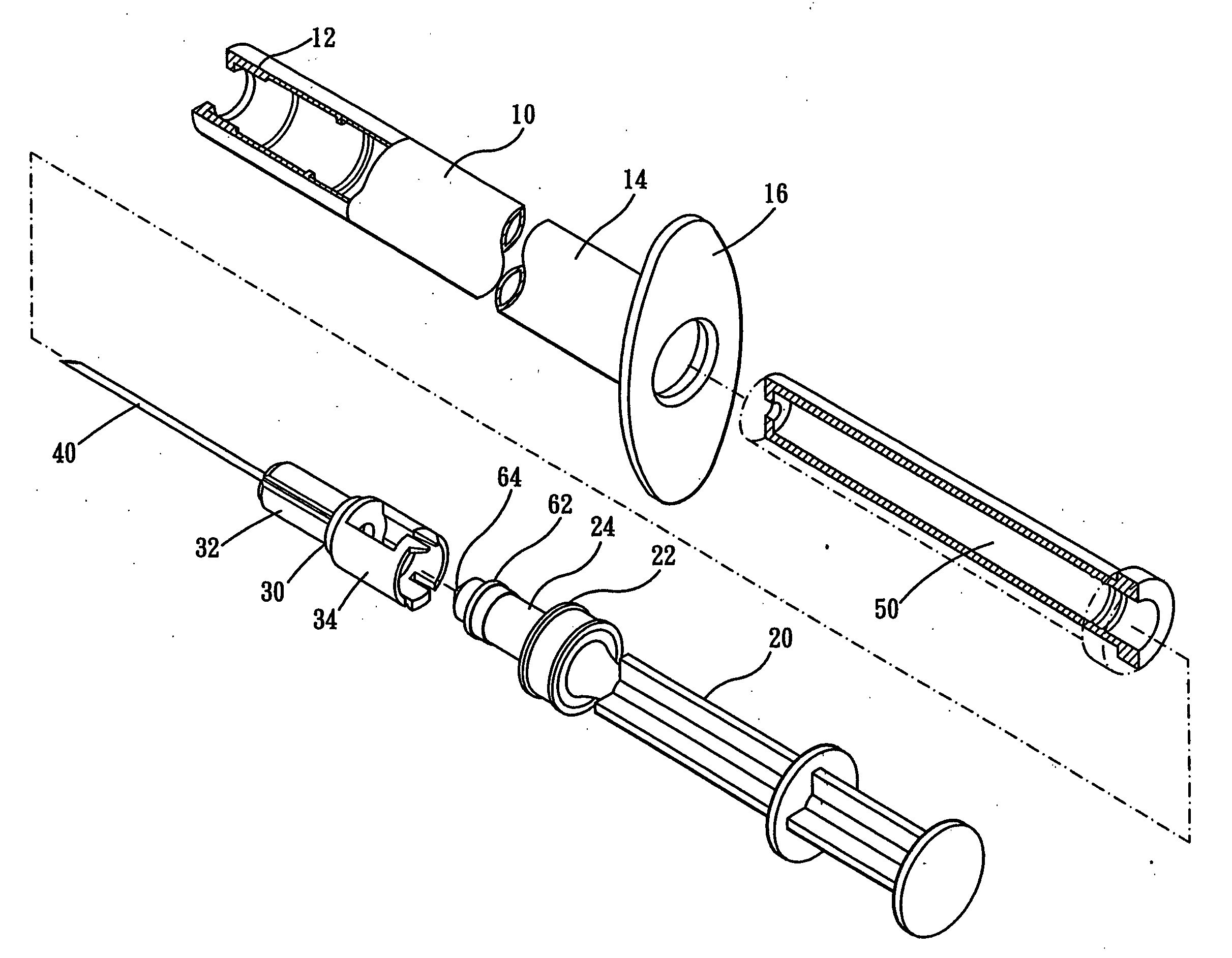

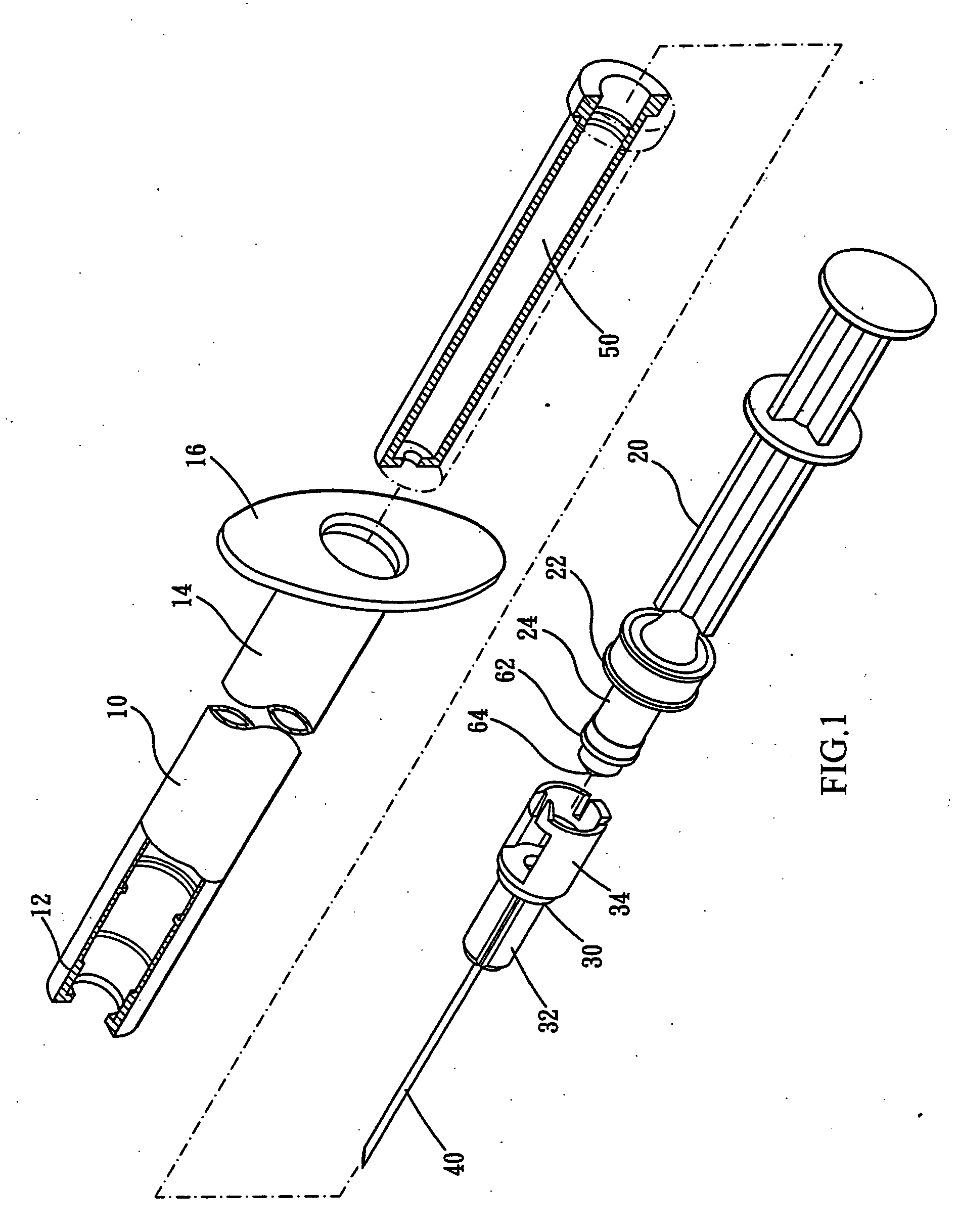

ActiveUS20150174339A1Readily integrated into drug filling processReliable retractionMedical devicesInfusion needlesBarrel ShapedEngineering

Barrel adapters for safety syringes include a barrel and a plunger assembly adapted to move within the barrel, a barrel tip adapted to be sealingly engaged with a distal end of the barrel and a needle retraction mechanism barrel having a needle subassembly and an actuator subassembly. The needle subassembly includes a needle, and a needle-over-mold (NOM) through which the needle extends. The needle subassembly is disposed at least partially within the barrel tip, and adapted to move from an injection position in which the needle extends from a distal end of the barrel tip to a retracted position in which the needle is disposed within at least one of the barrel tip or the barrel. The actuator subassembly includes a needle seal, a push-bar, and an actuator surface. The needle retraction mechanism barrel includes a biasing member and an actuable locking arrangement. A syringe includes such barrel adapters.

Owner:UN HOLDINGS LLC

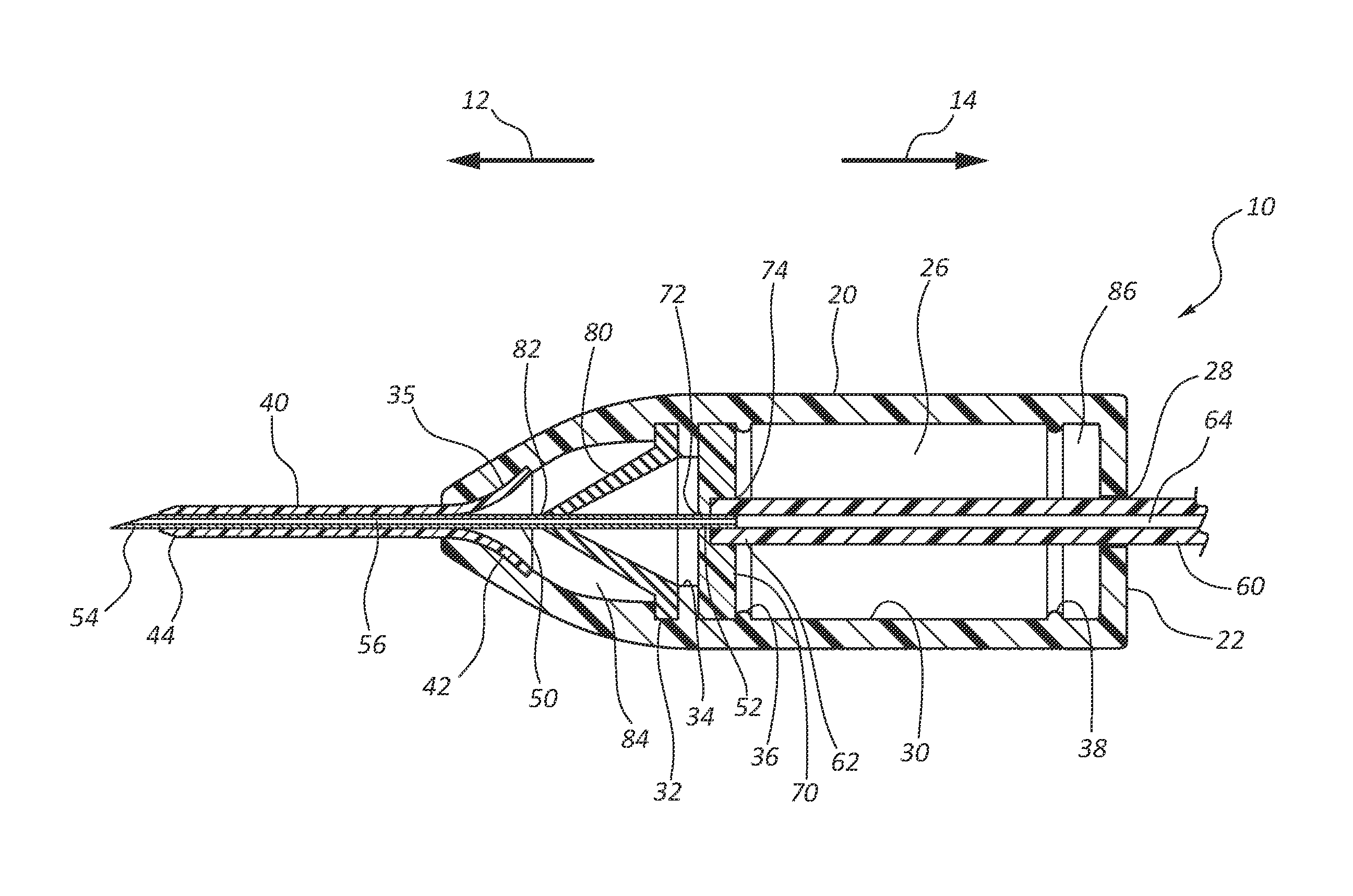

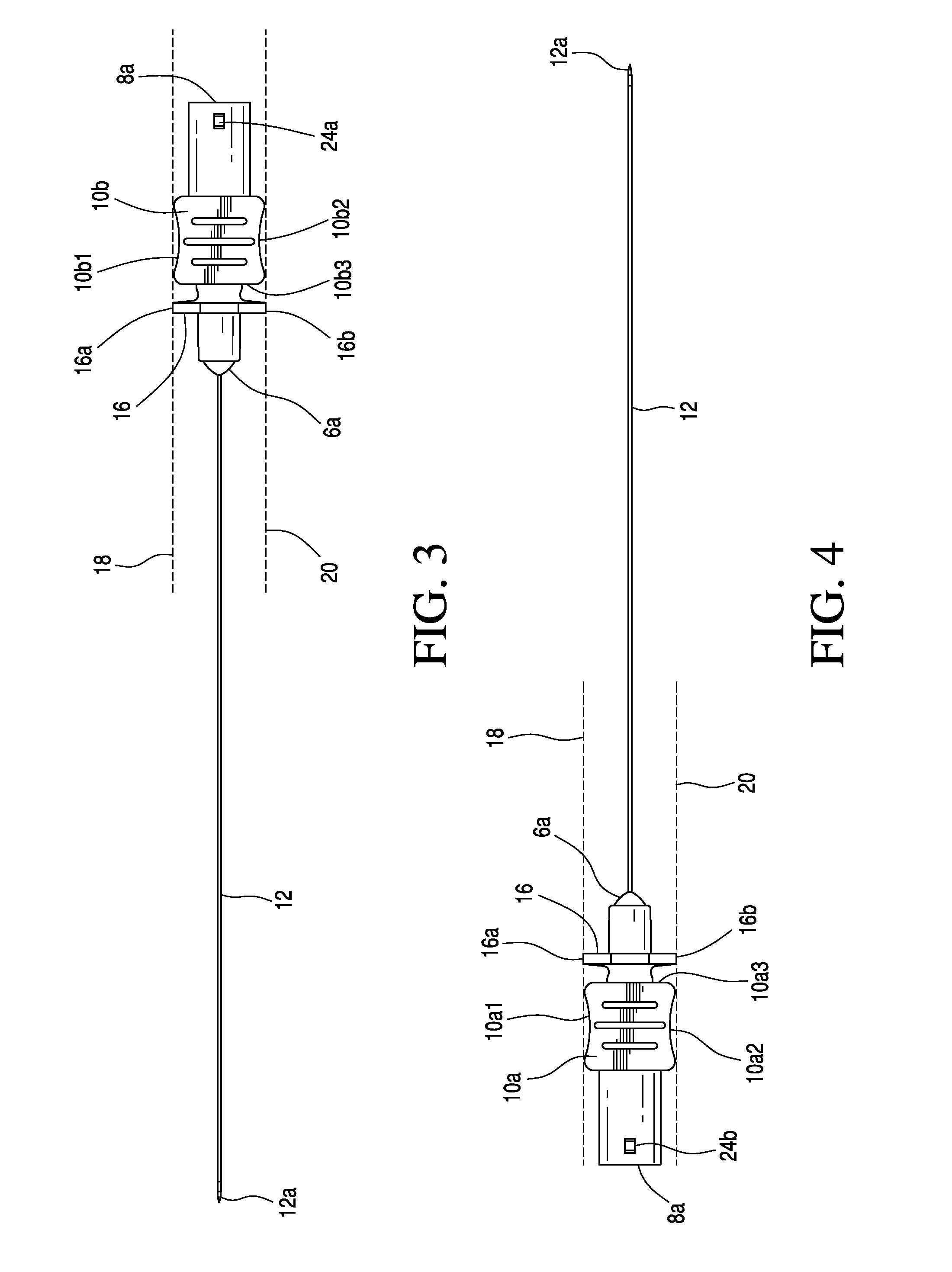

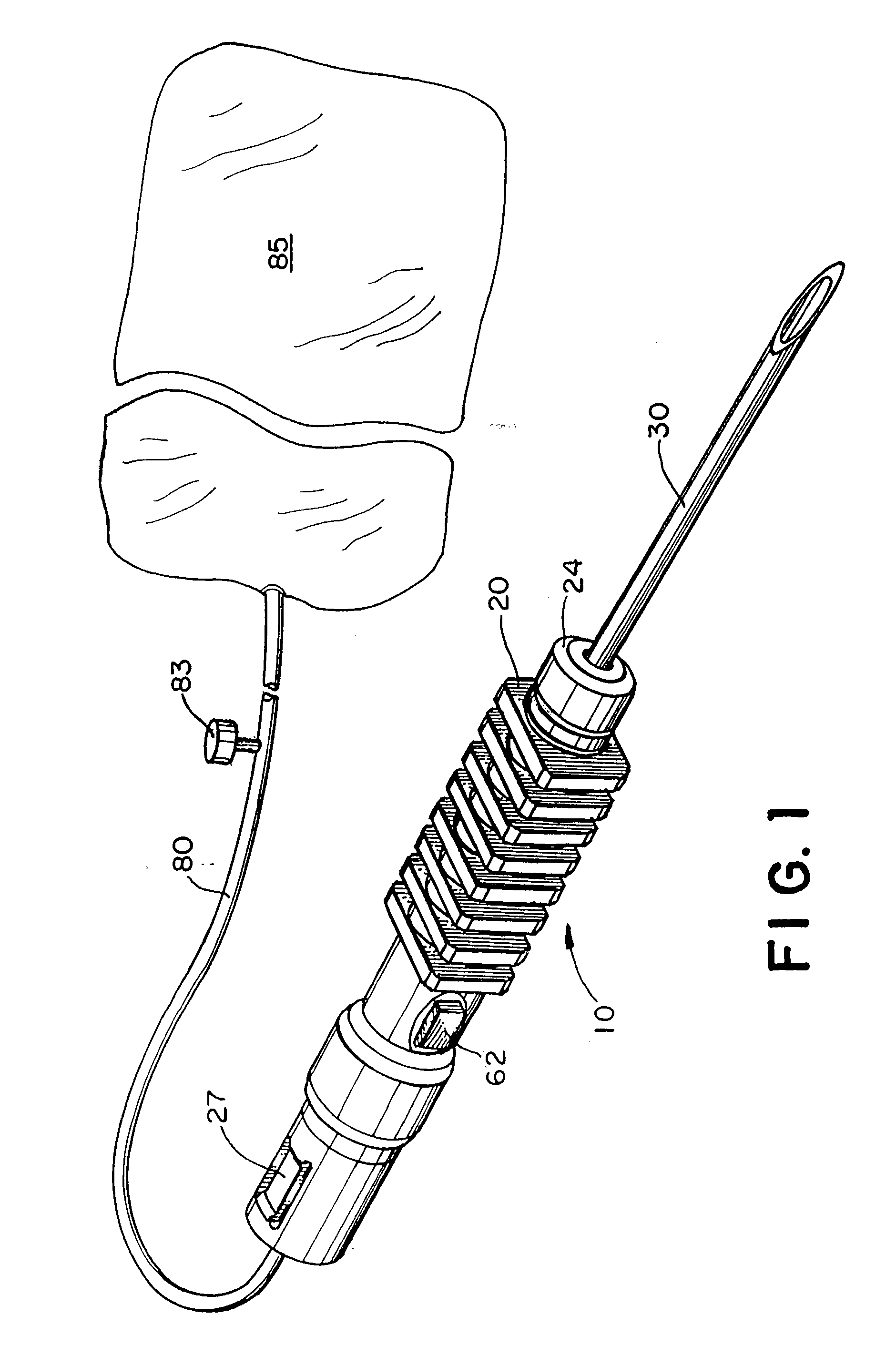

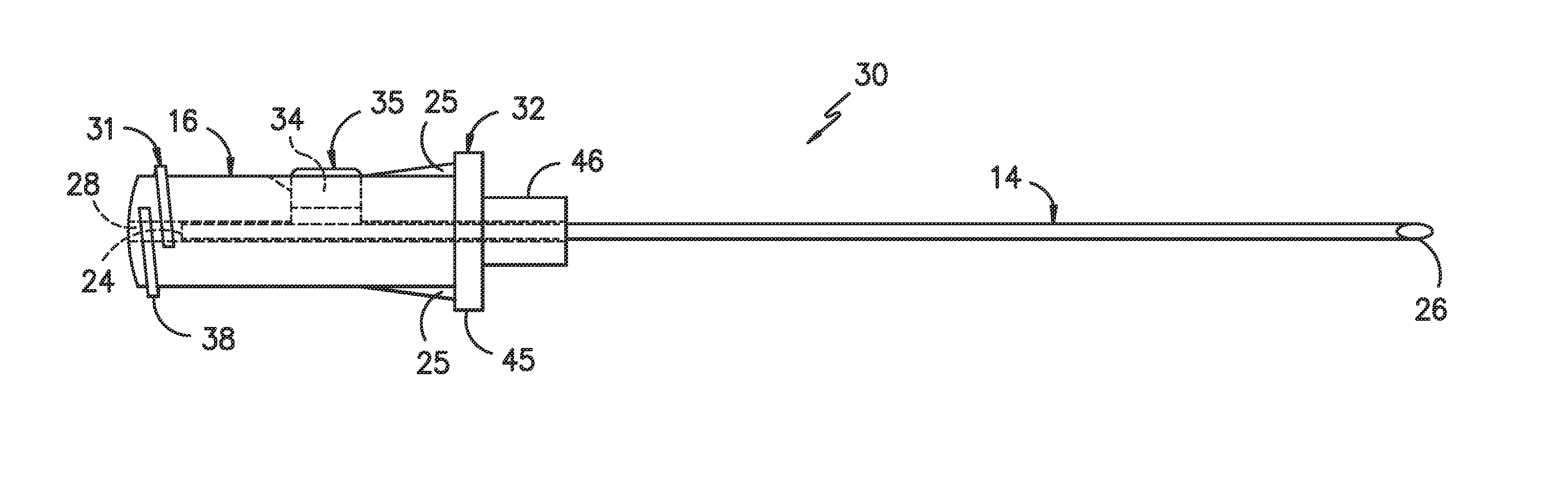

Over-the-needle intravenous catheter assembly with integrated intravenous tubing

ActiveUS20130310751A1Easy accessAvoid communicationInfusion syringesSurgical needlesCATHETER ADAPTERIntravenous tubing

An intravenous catheter device is provided which includes a catheter adapter having a fluid chamber, a needle adapter being slidably positioned within the fluid chamber, the needle adapter supporting a base of an introducer needle and a terminal end of a section of intravenous tubing such that a fluid pathway of the introducer needle is in fluid communication with a fluid pathway of the section of intravenous tubing. Following catheterization, the needle adapter is slid to a preferred proximal position whereby a sharpened tip of the introducer needle is shielded within a catheter of the intravenous catheter device, or a portion of the fluid chamber of the catheter adapter. When in the preferred proximal position, fluid communication between the catheter and a section of intravenous tubing is facilitated via the hollow body of the introducer needle.

Owner:BECTON DICKINSON & CO

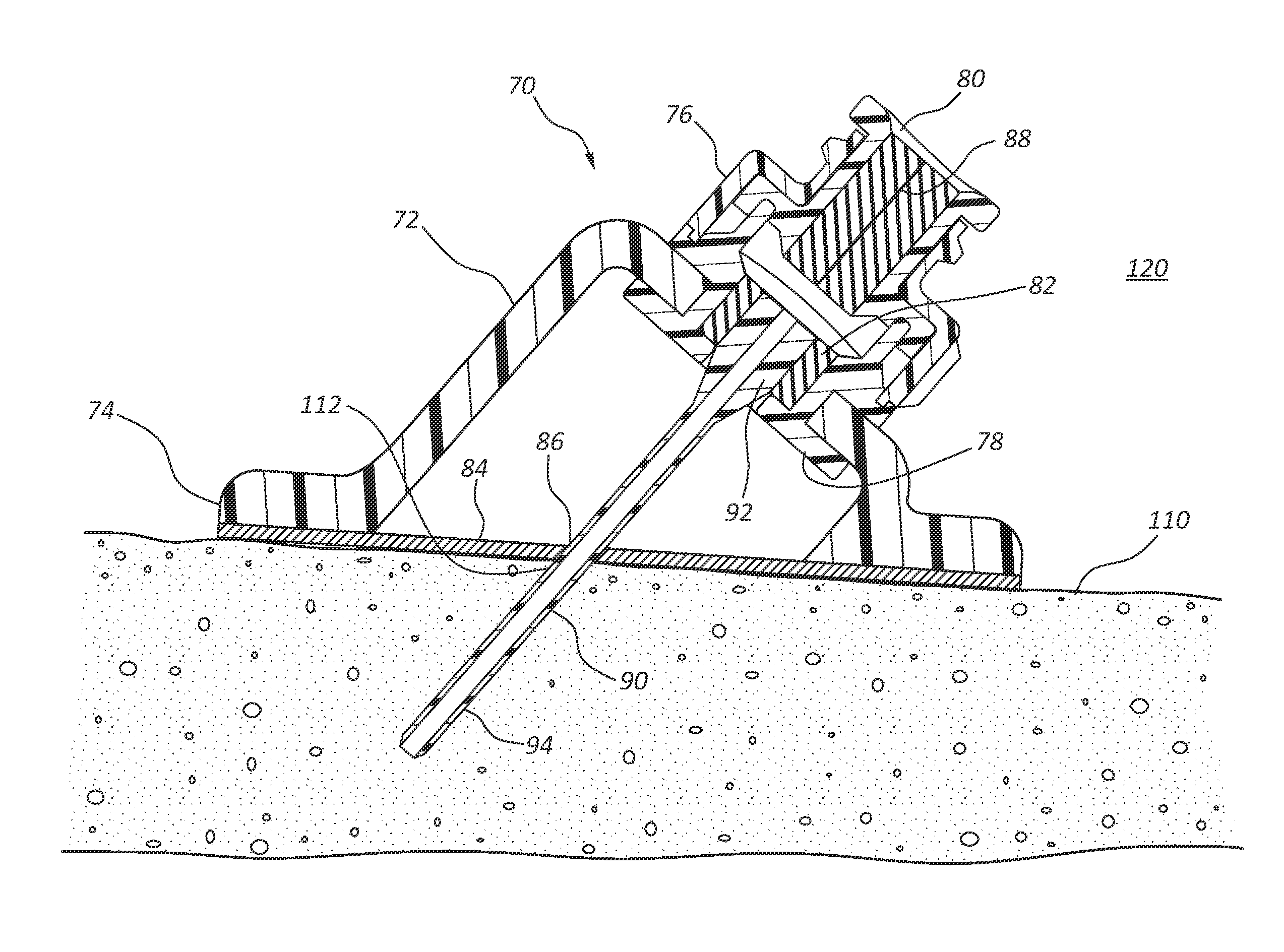

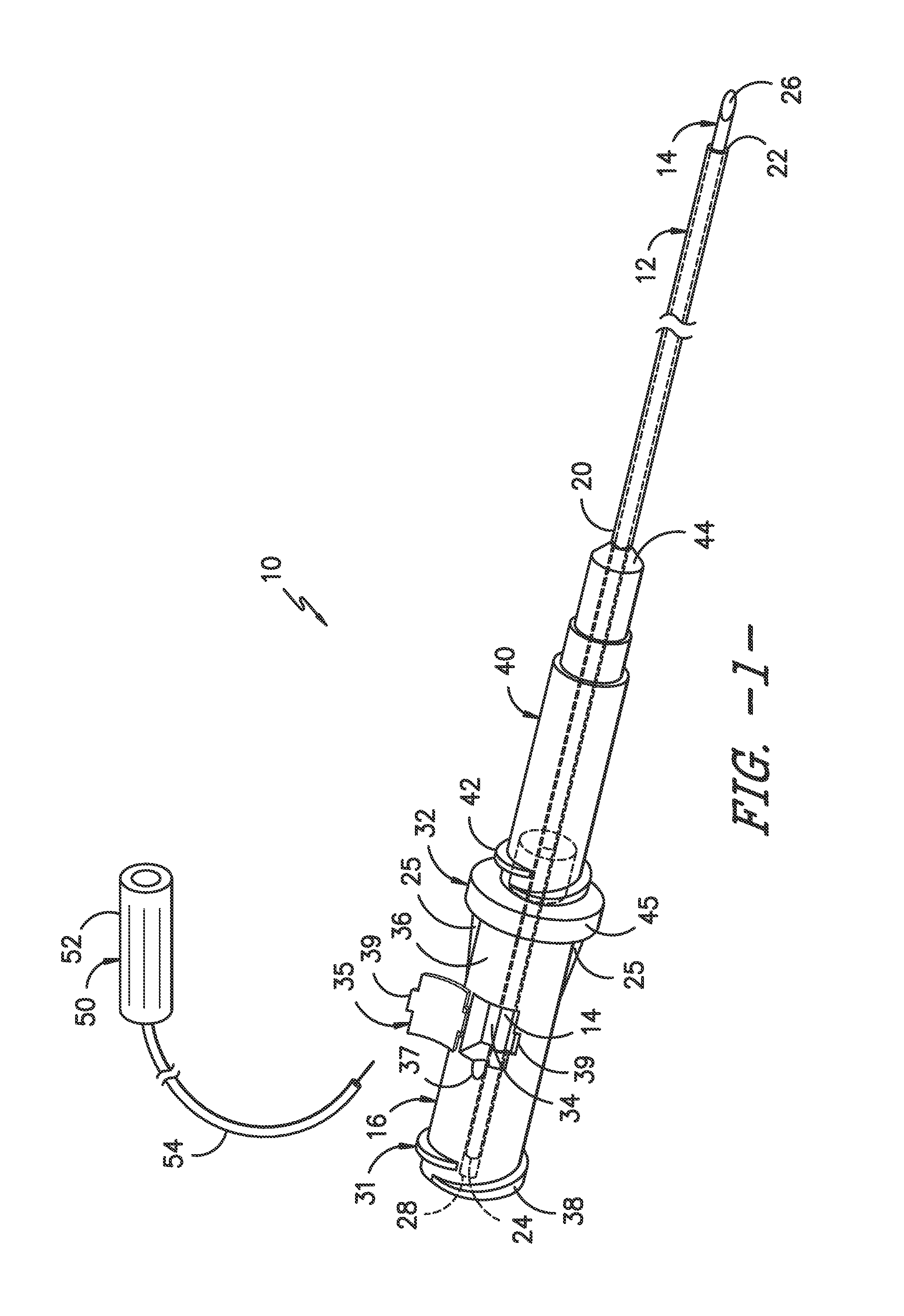

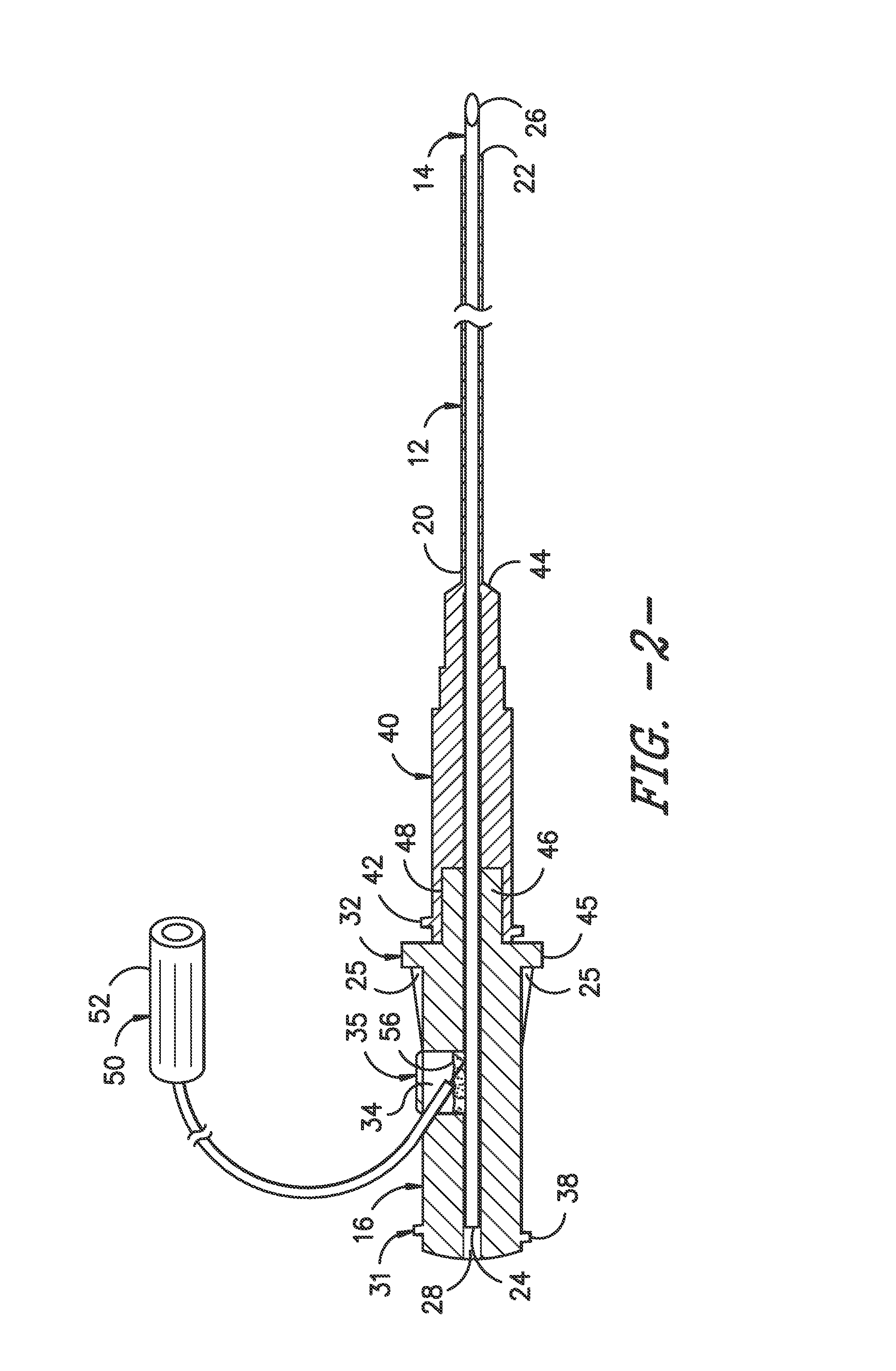

Integrated catheter securement and luer access device

ActiveUS20140074031A1Maintain positionGuide needlesInfusion syringesCatheter insertionNeedle adapter

A Luer securement device comprising a Luer adapter having a septum and a catheter hood, the Luer adapter further having a wedge seal for receiving a base portion of a catheter. The Luer securement device further includes an inserter body in which is slidably housed a catheter threader having a probe which is configured to advance a base portion of a catheter through the septum thereby seating the base portion of the catheter into the wedge seal of the Luer adapter as a tip portion of the catheter is inserted into a patient. The catheter threader further includes a needle adapter having a needle which is threaded through the probe and the catheter to assist in inserting the catheter into the patient. Following insertion of the catheter, the catheter threader is retracted within the inserter body thereby withdrawing the needle from the catheter and shielding a sharpened tip of the needle within at least one of the inserter body and the catheter threader. The inserter body is then detached from the Luer adapter and discarded.

Owner:BECTON DICKINSON & CO

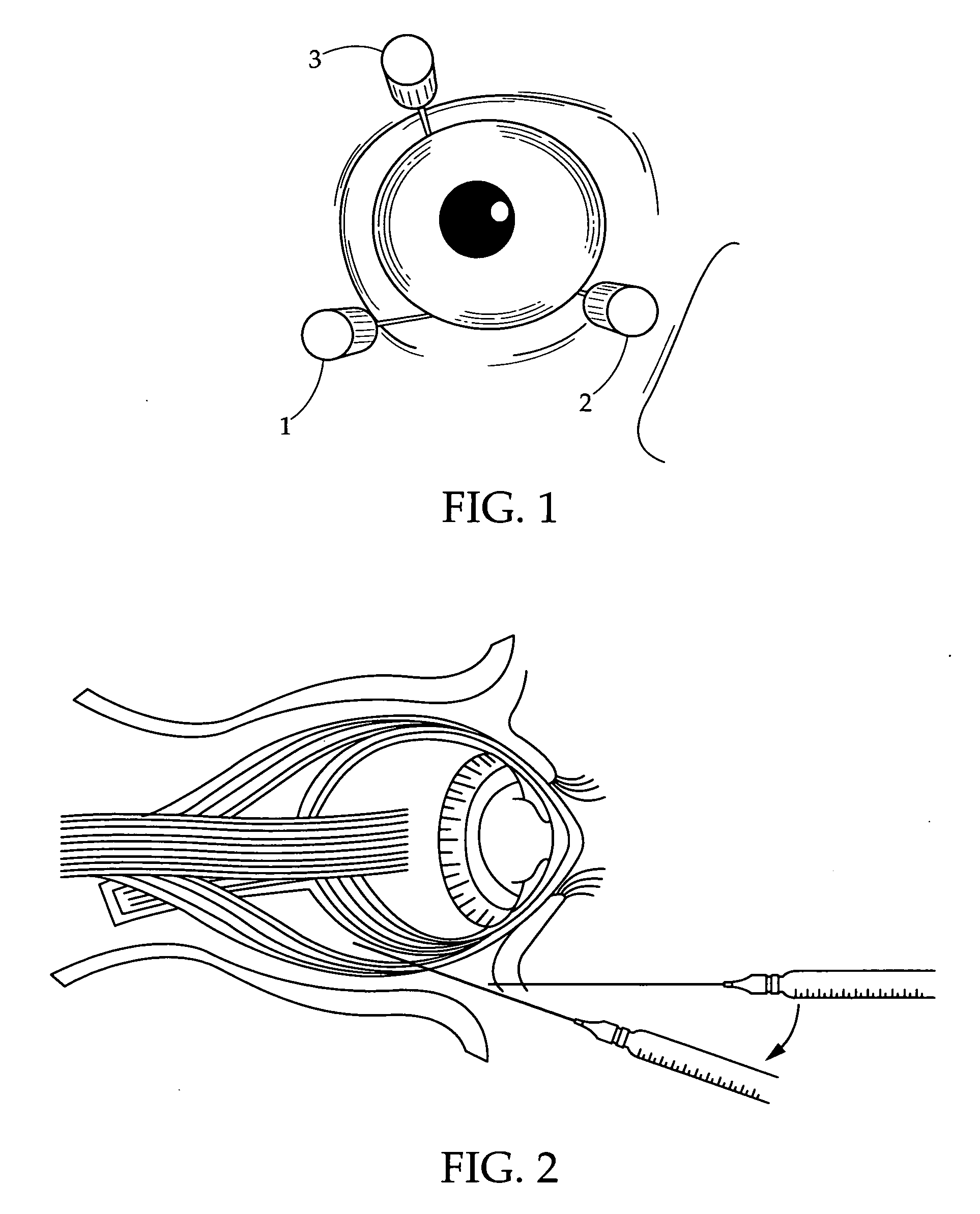

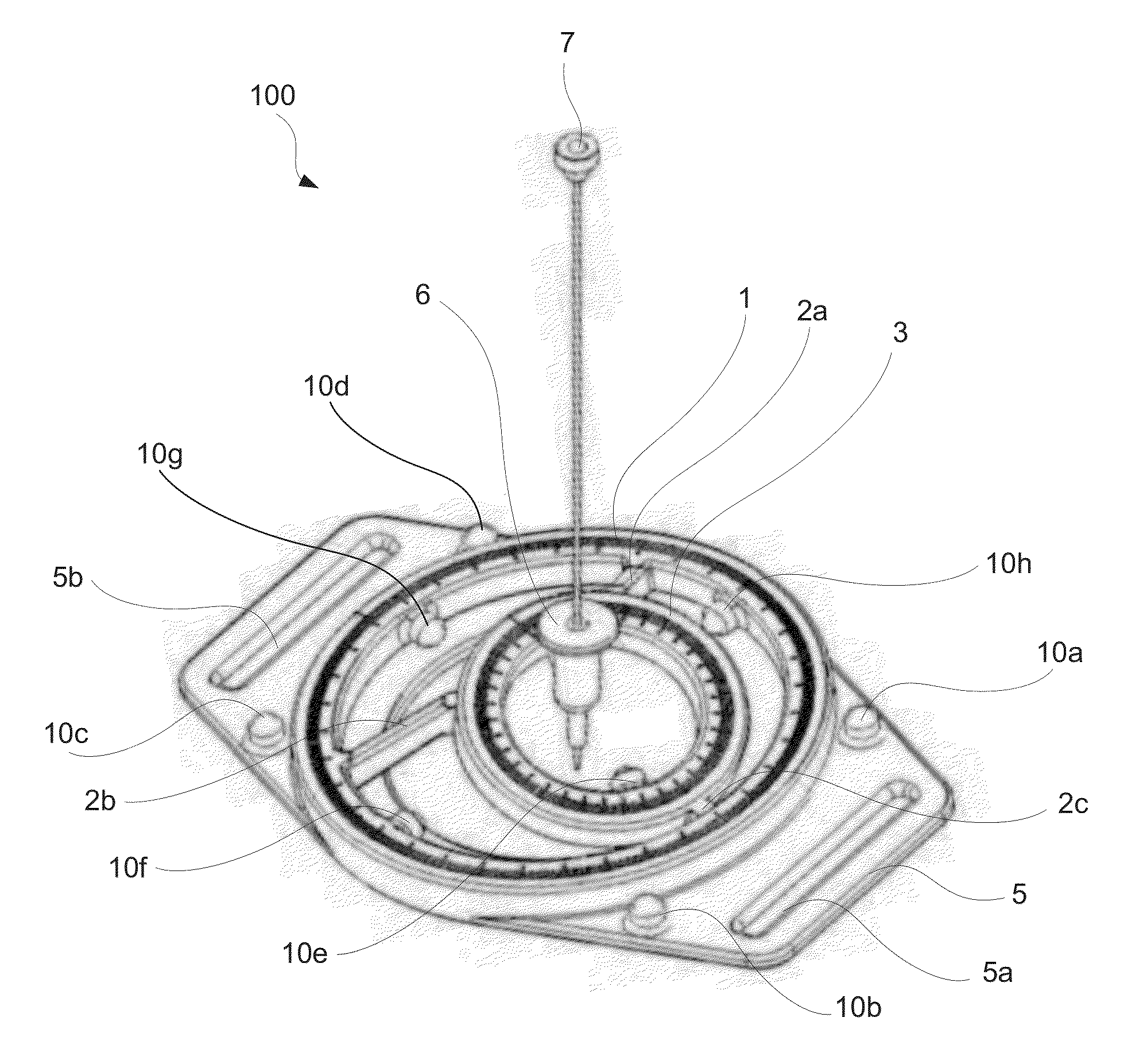

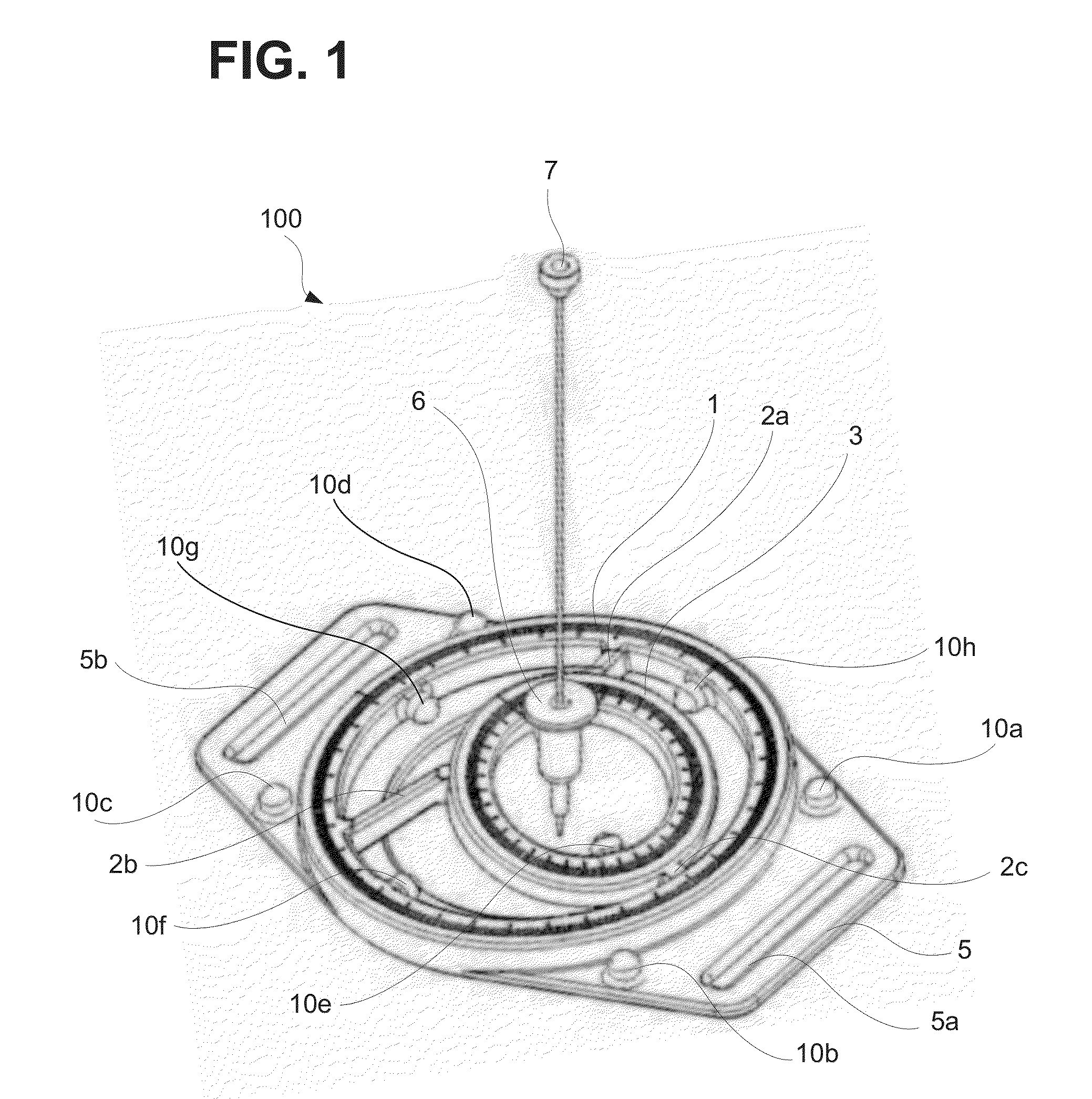

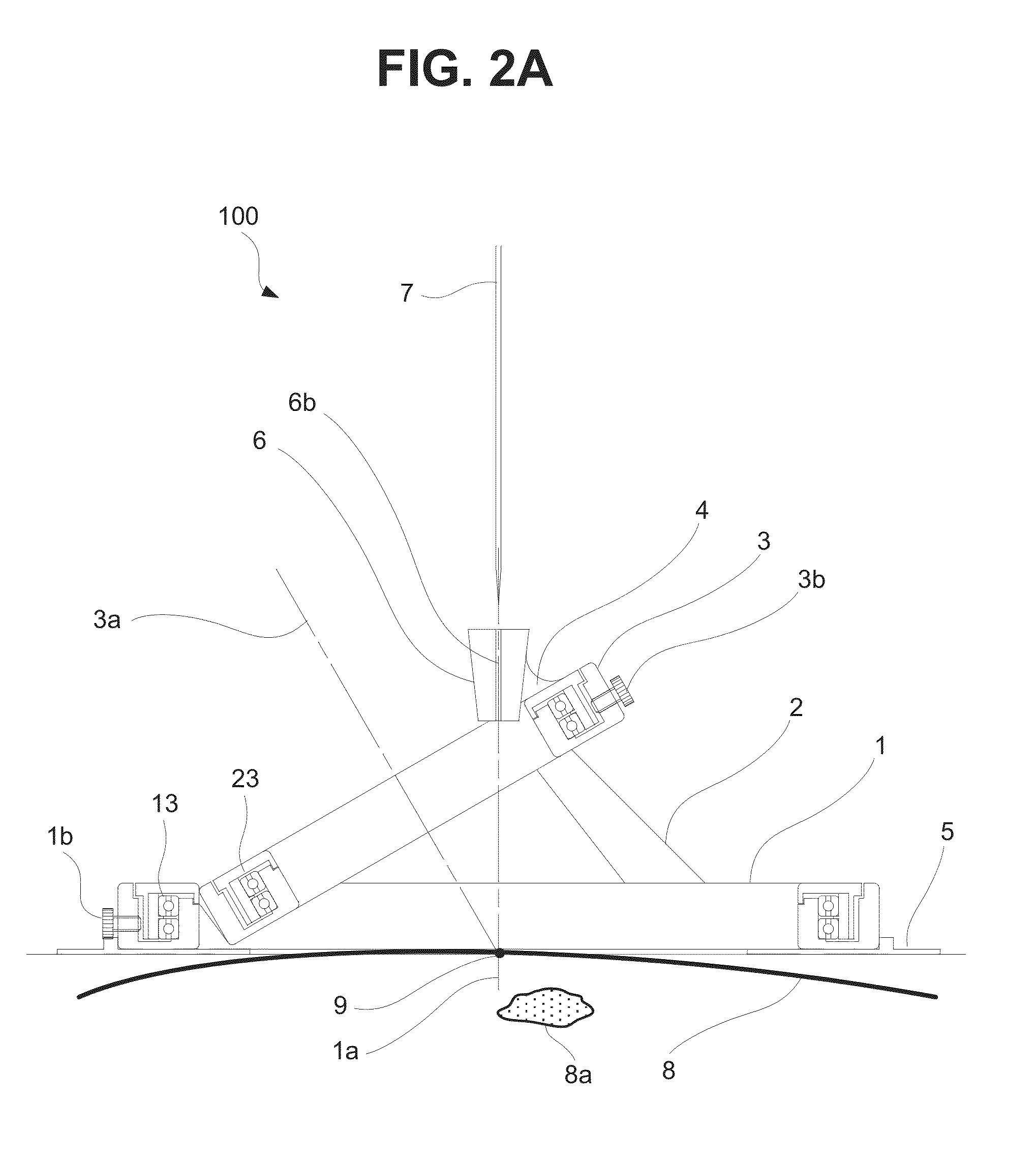

Needle placement manipulator with two rotary guides

A needle placement manipulator includes, a pair of rotary guides arranged at a slanted angle with respect to each other, a needle holder which holds a needle along a needle holder axis, and a base body on which the guides are supported. The needle holder axis and each axis of the rotary guides cross at a single point located at or below the base body. The base body is configured to be attached to a patient or to an RF-coil.

Owner:CANON USA +1

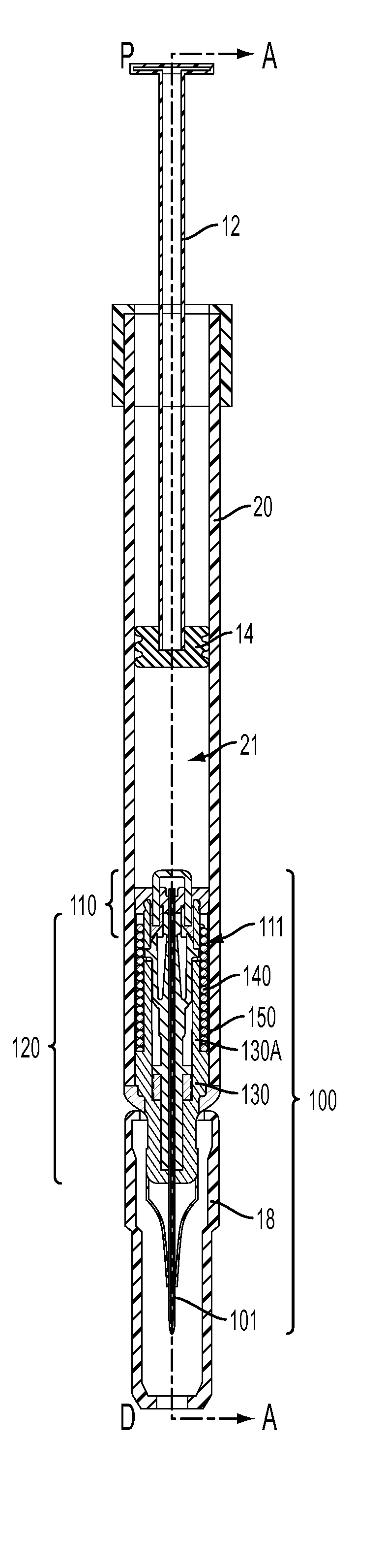

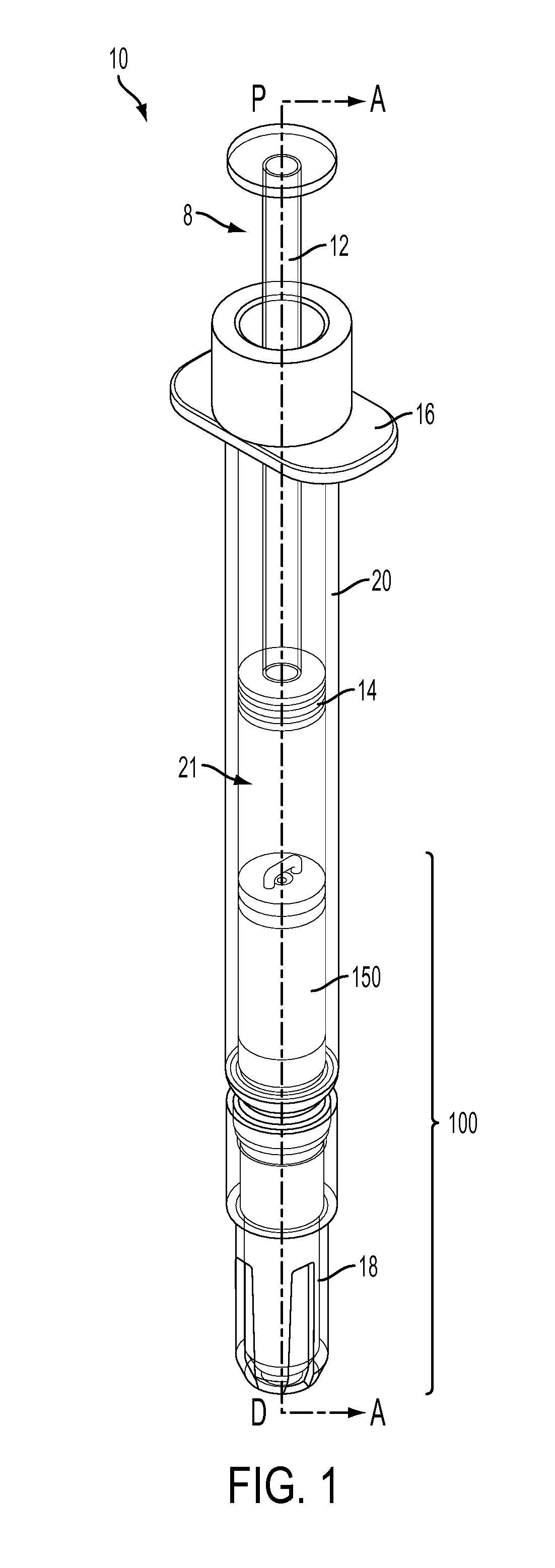

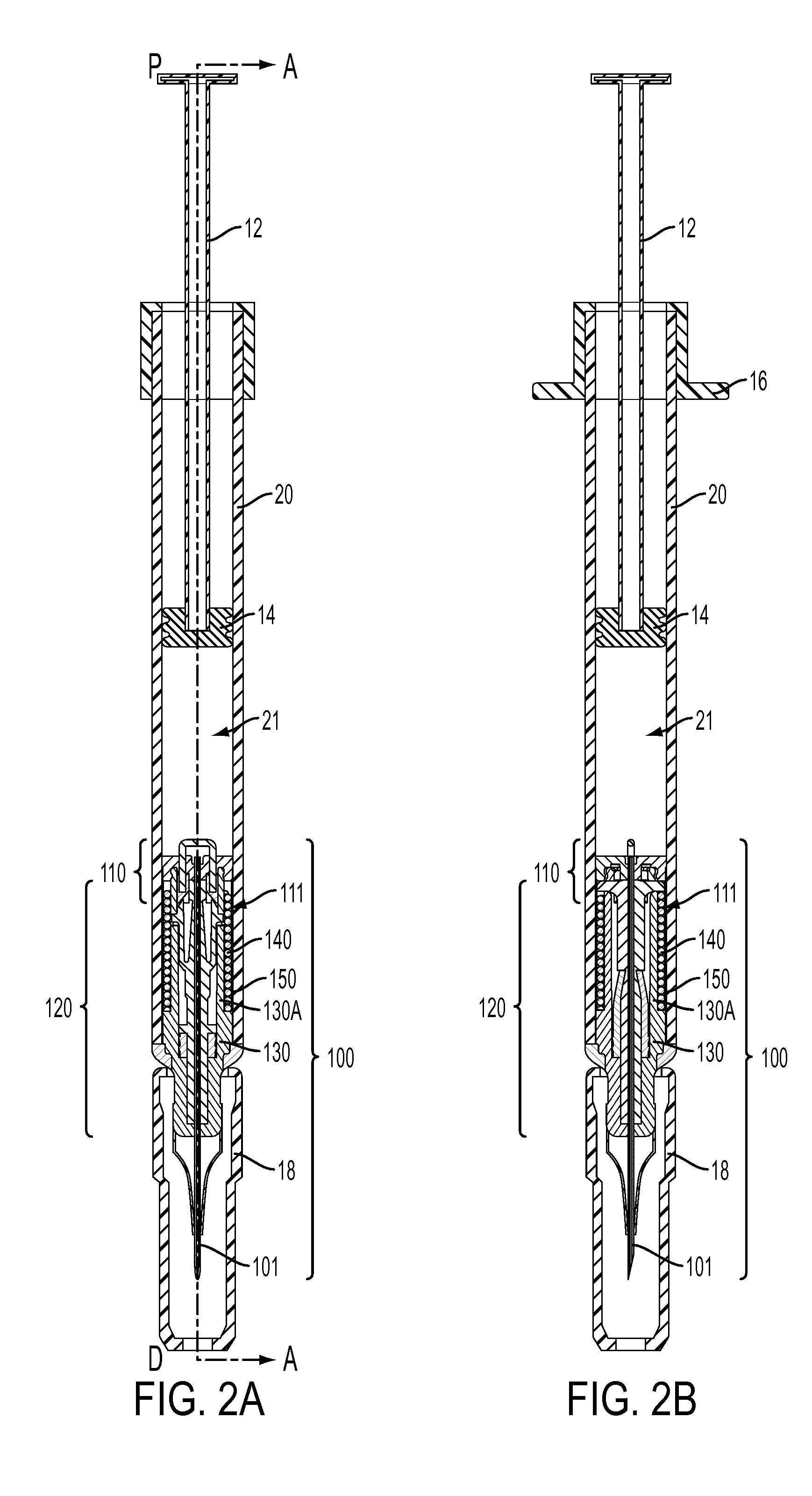

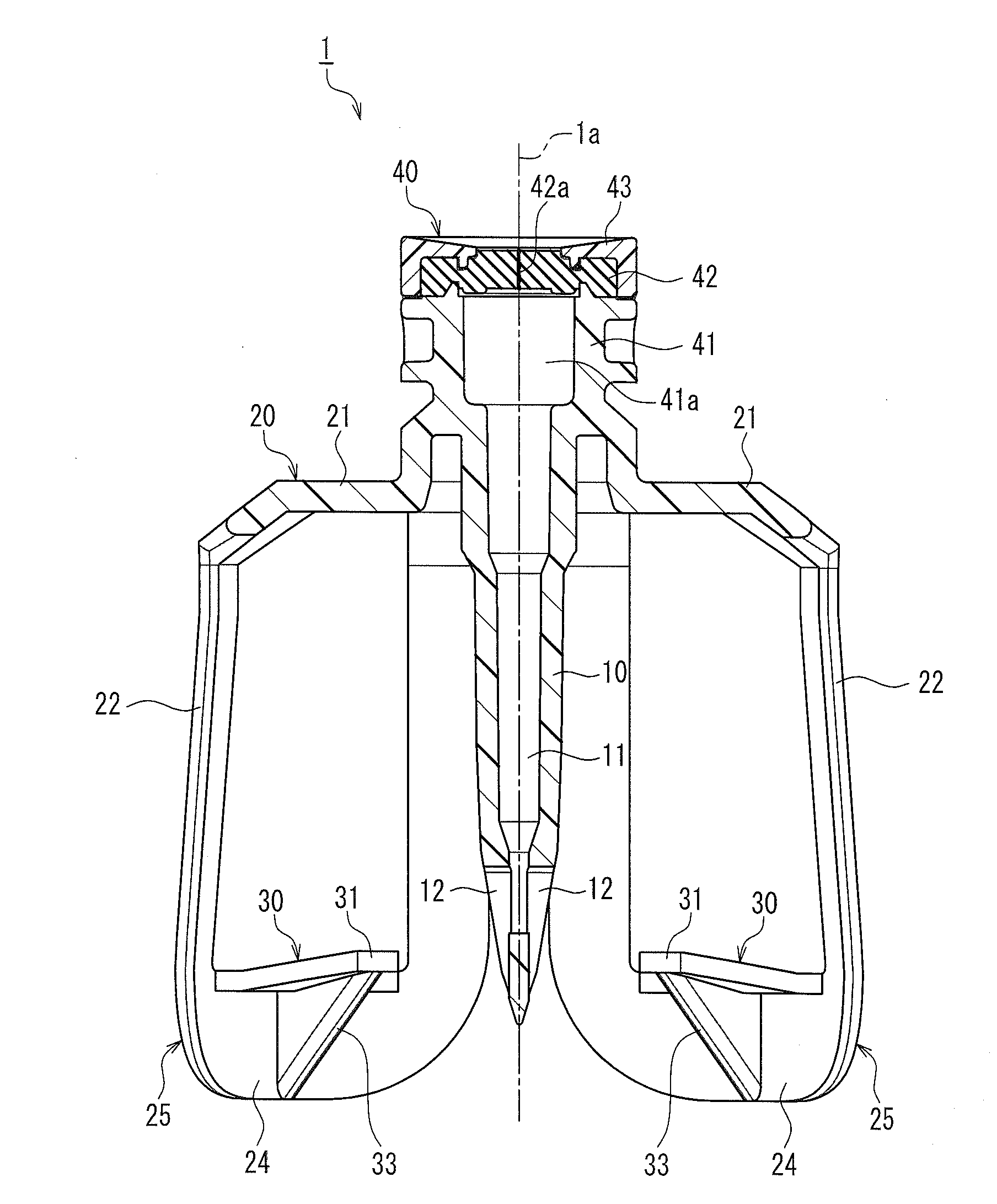

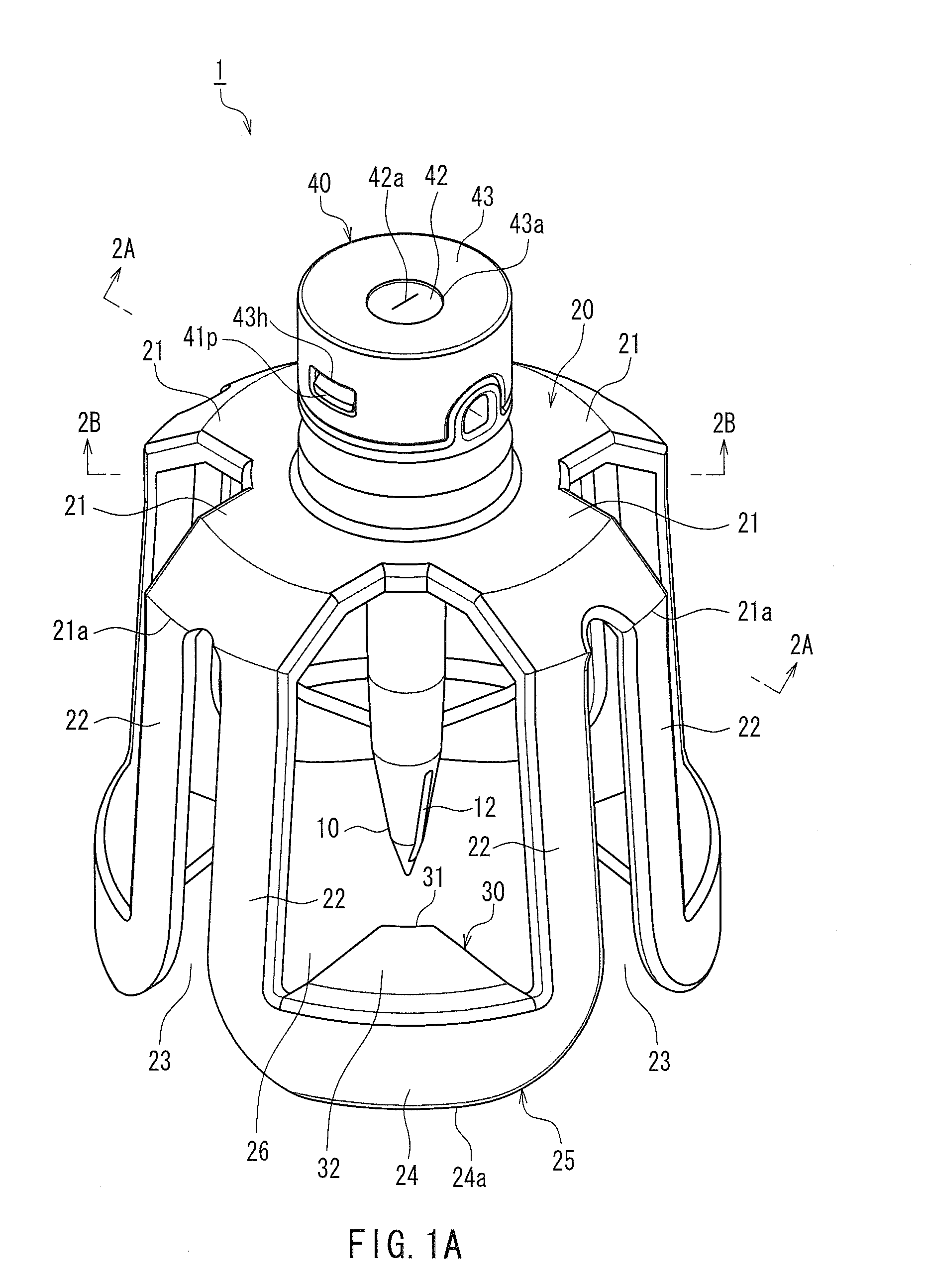

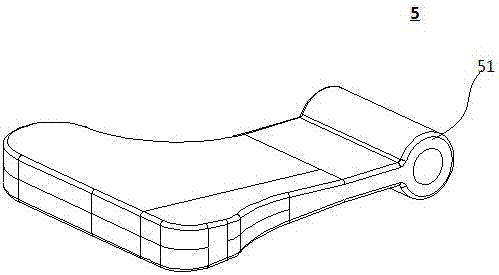

Adjustable Height Needle Infusion Device

ActiveUS20120136300A1Precise retractionMaintain depthInfusion syringesSurgical needlesSkin surfaceInsertion depth

An infusion set has a retraction dial that can be removably assembled with the infusion set and access a threaded needle hub contained therein such that the dial can be used to advance or retract a needle hub and an inserted needle to a more precisely controlled insertion depth to deliver insulin or other medicament intradermally (i.e. to the upper 3 mm of skin surface). Position of the inserted needle can be maintained by providing a separated and isolated needle hub, main base and main hub of the infusion set that can isolate the inserted needle from external forces such that the needle can be maintained at a depth to deliver content to the upper 3 mm of skin surface during normal use.

Owner:BECTON DICKINSON & CO

Integrated catheter securement and luer access device

A Luer securement device comprising a Luer adapter having a septum and a catheter hood, the Luer adapter further having a wedge seal for receiving a base portion of a catheter. The Luer securement device further includes an inserter body in which is slidably housed a catheter threader having a probe which is configured to advance a base portion of a catheter through the septum thereby seating the base portion of the catheter into the wedge seal of the Luer adapter as a tip portion of the catheter is inserted into a patient. The catheter threader further includes a needle adapter having a needle which is threaded through the probe and the catheter to assist in inserting the catheter into the patient. Following insertion of the catheter, the catheter threader is retracted within the inserter body thereby withdrawing the needle from the catheter and shielding a sharpened tip of the needle within at least one of the inserter body and the catheter threader. The inserter body is then detached from the Luer adapter and discarded.

Owner:BECTON DICKINSON & CO

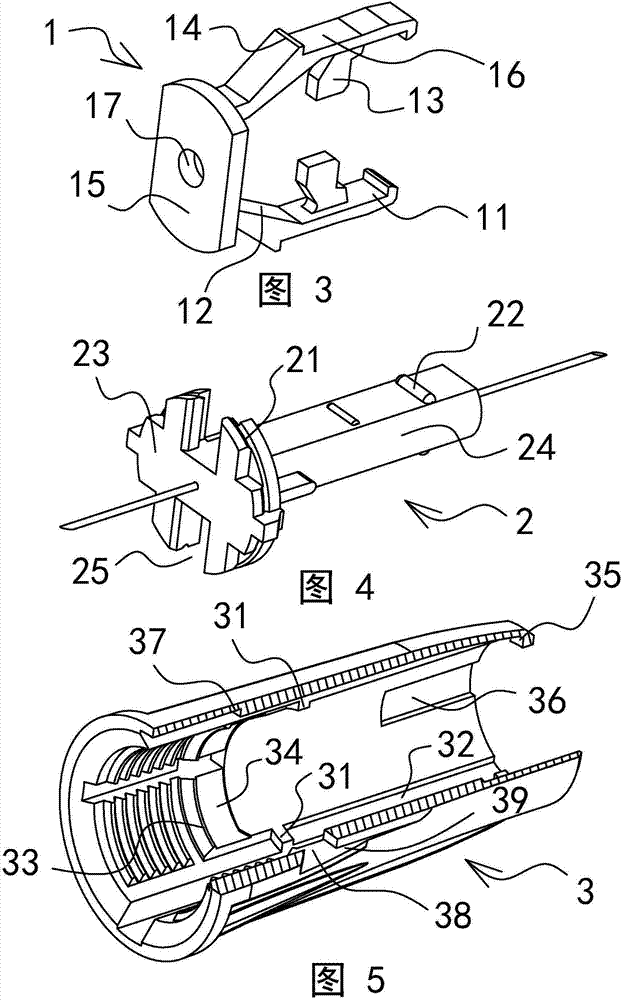

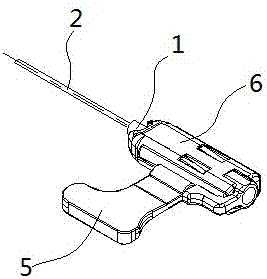

Insulin syringe needle with needle tip protection function

ActiveCN104771815AProtection securityAddress reliabilityOther printing matterMedical devicesInsulin injectionSyringe needle

The invention relates to an insulin syringe needle with a needle tip protection function. The insulin syringe needle comprises a needle body, a needle seat, a main shell and an outer jacket, and is characterized in that a trigger pipe, a front casing pipe and a spring are arranged in the main shell, the trigger pipe is used for protecting an injection section of the needle body before the application, and the front casing pipe is used for protecting the injection section of the needle body after the application. Before the application, the trigger pipe stretches out of the main shell and stays at a needle body protection stage, and the front casing pipe is arranged in the main shell; after the application, the trigger pipe is arranged in the main shell, the front casing pipe stretches out of the main shell and stays at a needle body protection state. The unlocking of the trigger pipe and the front casing pipe is correlated to the state whether the syringe needle is prepared for injection or not, and the unlocking of the trigger pipe and the front casing pipe is triggered by utilizing a tail cover and the needle seat when in installation, and safety and convenience in use can be improved.

Owner:SANDSTONE MEDICAL SUZHOU INC

Puncture needle adapter

Owner:JMS CO LTD

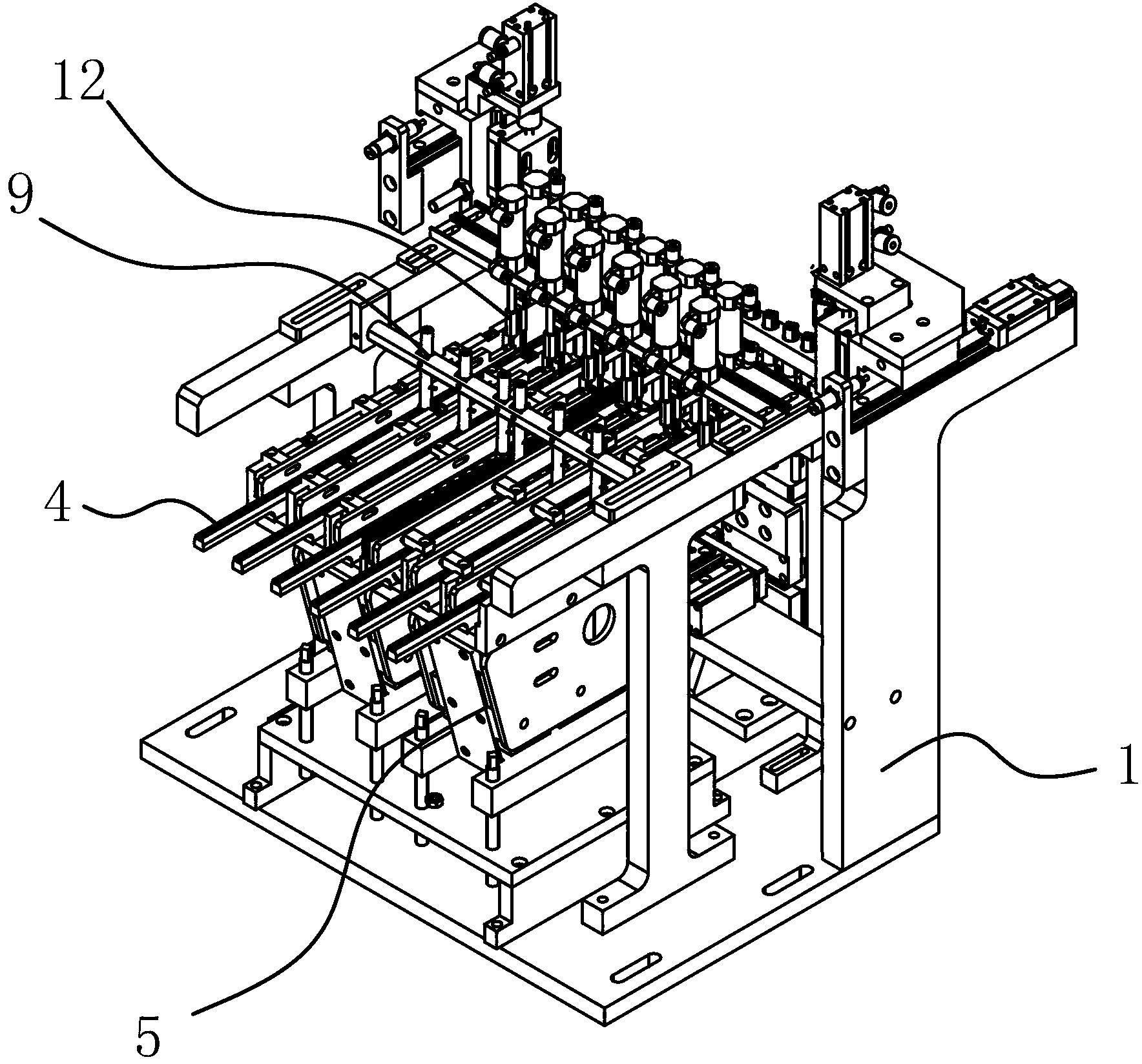

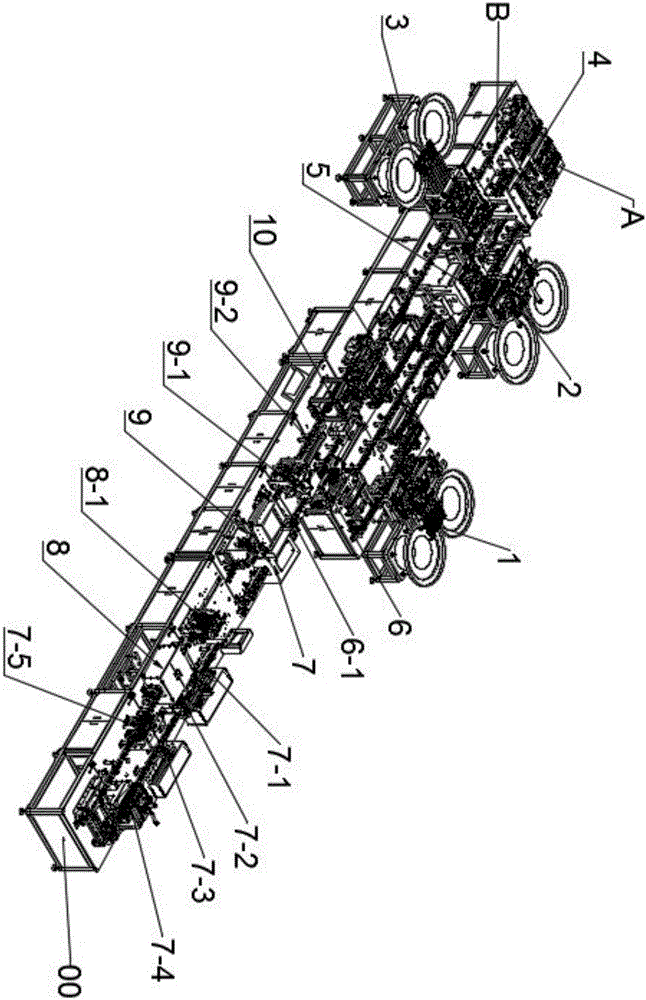

Separation method and separation device for needle seat assemblies of double-needle-handle medical vein needle

ActiveCN103241540ARealize automatic feeding processBarriers preventing subsequent assemblyConveyor partsVeinMedical device

The invention provides a separation method and a separation device for needle seat assemblies of a double-needle-handle medical vein needle, and belongs to the technical field of medical equipment. The method and the device solve the technical problems that the needle seat assemblies are low in assembling speed and low in efficiency in the prior art. The separation method comprises the following steps of a, discharge, b, feeding, c, intermittent output, and d, reversing adjustment. The separation device comprises a base, wherein strip-shaped feeding groove bodies used for supporting the needle seat assemblies are fixed on the base; vibrators capable of allowing the feeding groove bodies to generate vibration are arranged between the feeding groove bodies and the base; the needle seat assemblies on the feeding groove bodies can be conveyed forward by the vibration of the feeding groove bodies; strip-shaped pressing strips are fixed on the base, parallel to the feeding groove bodies, and located right above the feeding groove bodies; and gaps capable of allowing the needle seat assemblies to pass through are formed between the pressing strips and the feeding groove bodies. The method and the device have the advantages of high assembling speed, high efficiency and the like.

Owner:MAIDER MEDICAL IND EQUIP

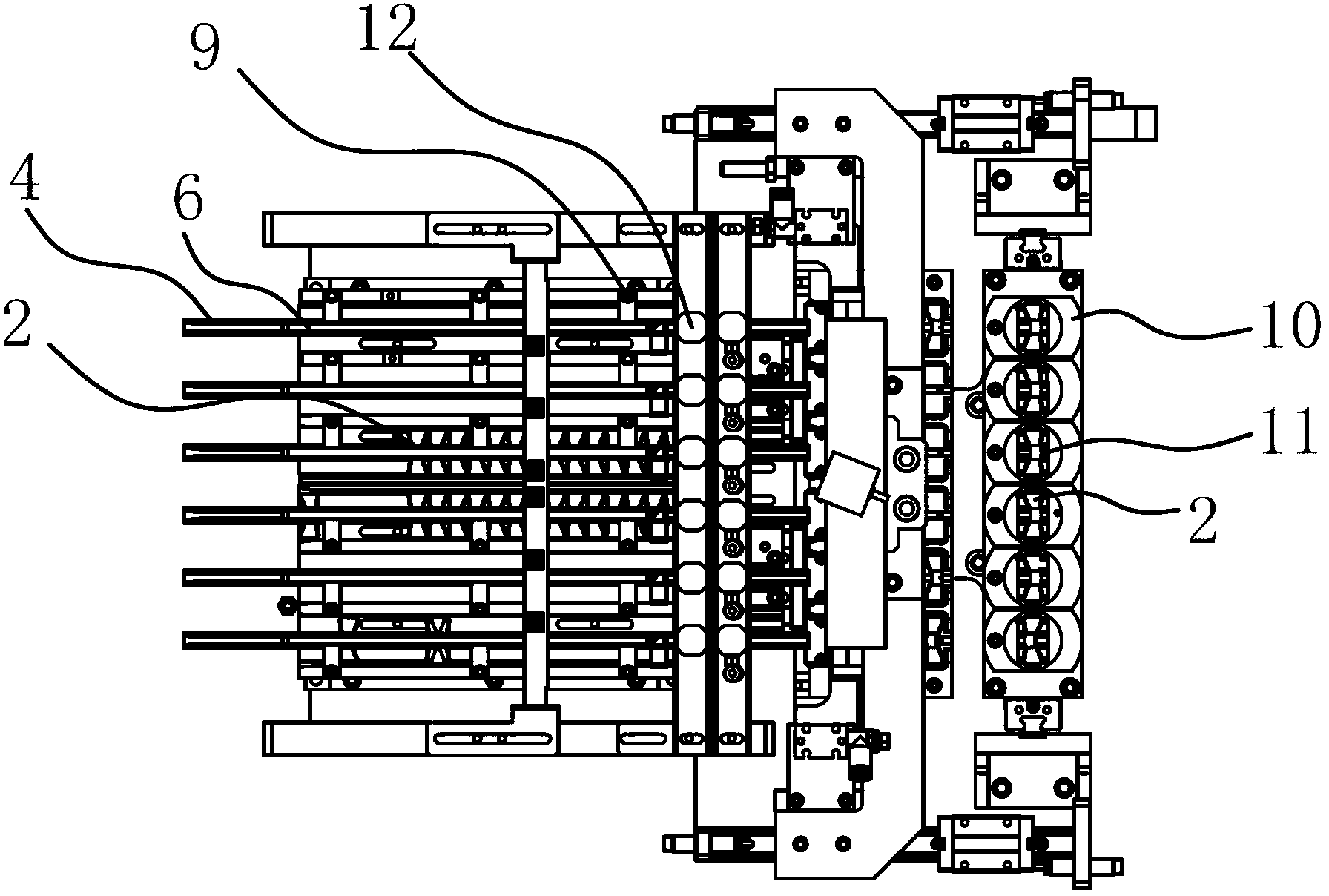

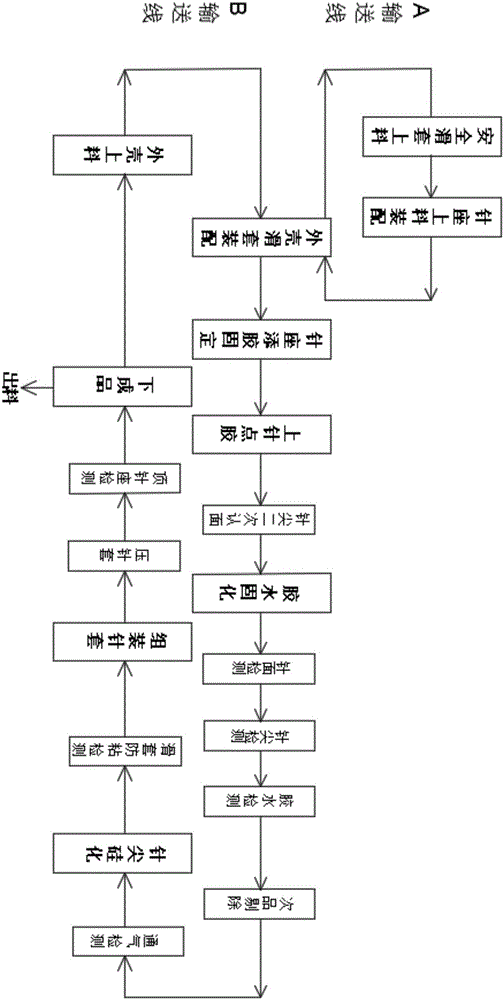

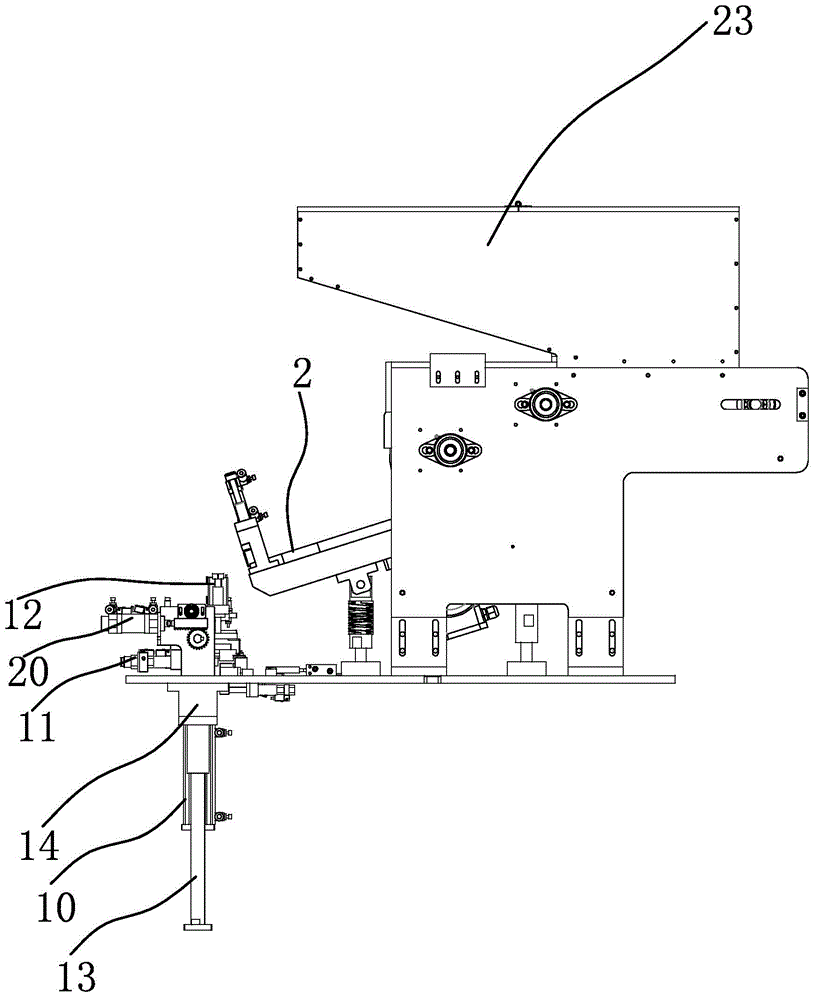

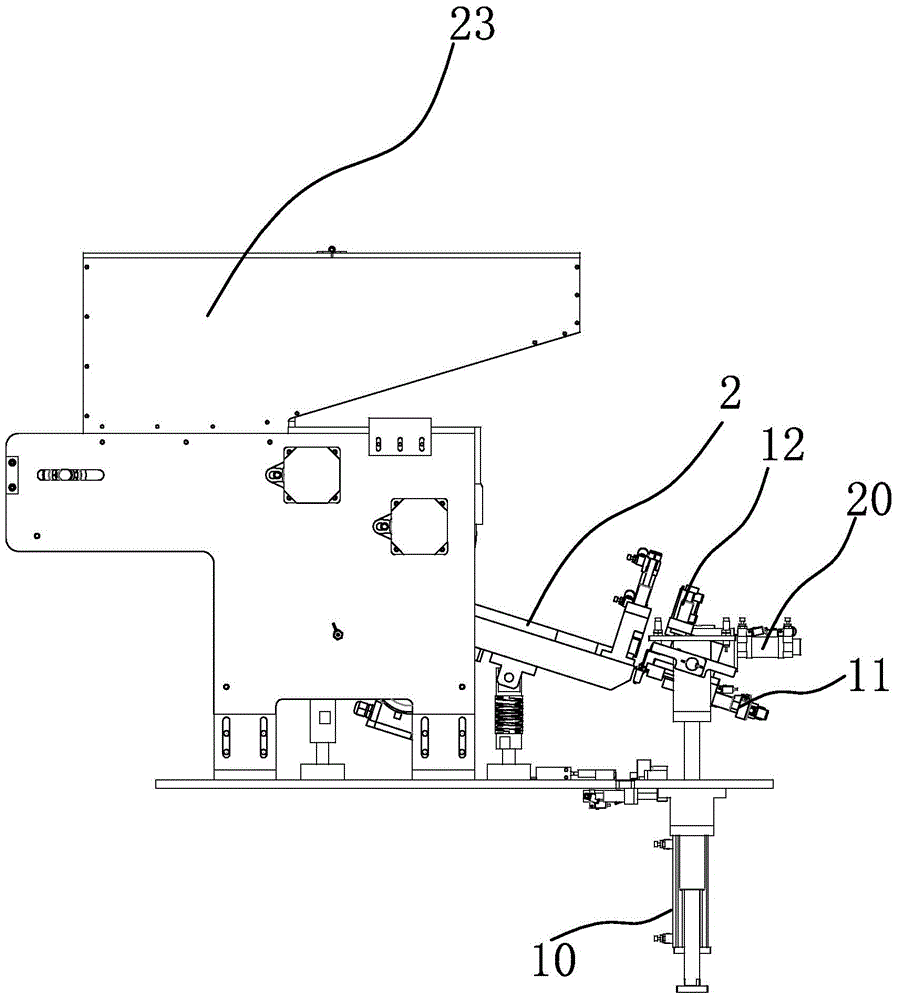

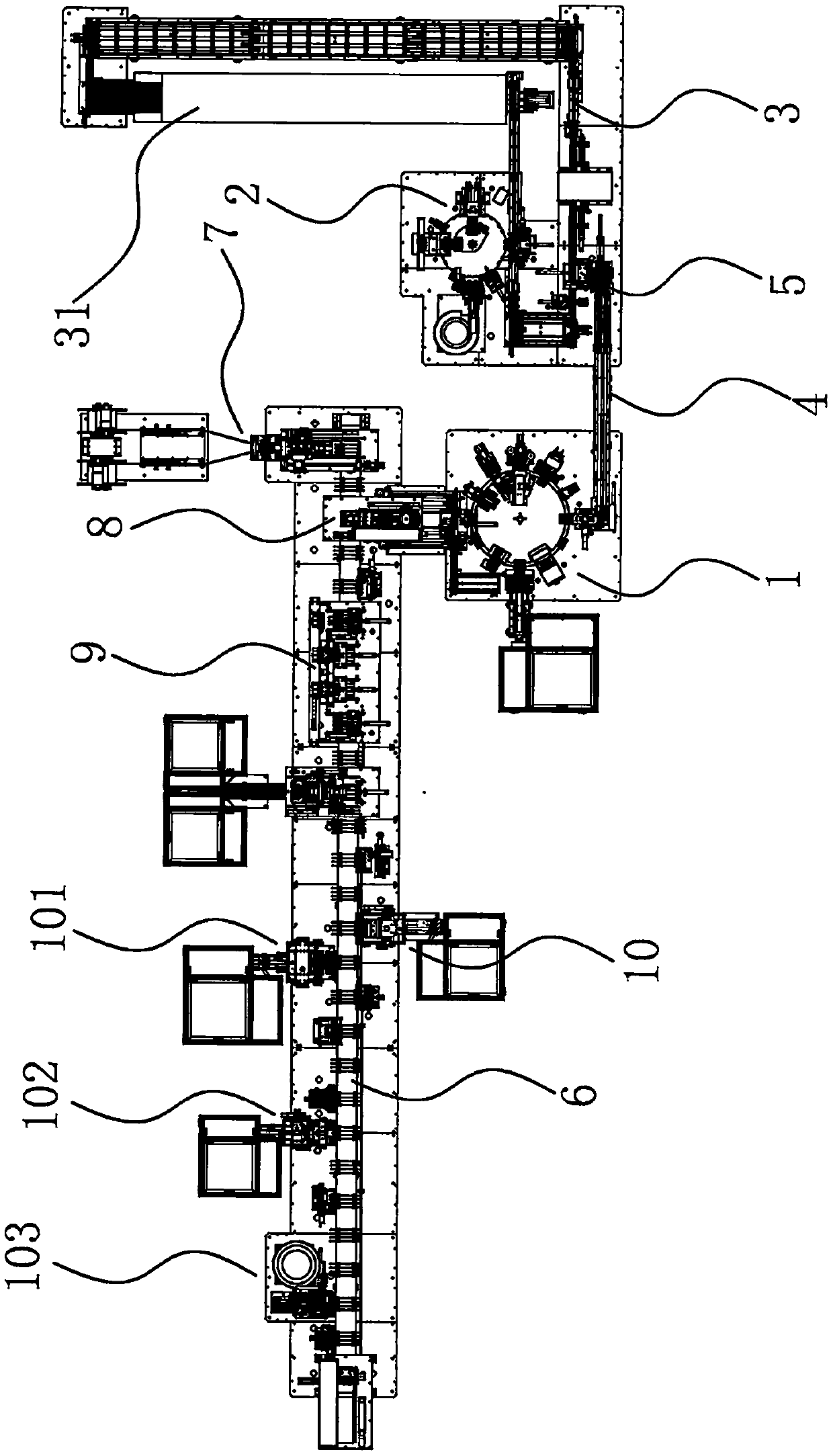

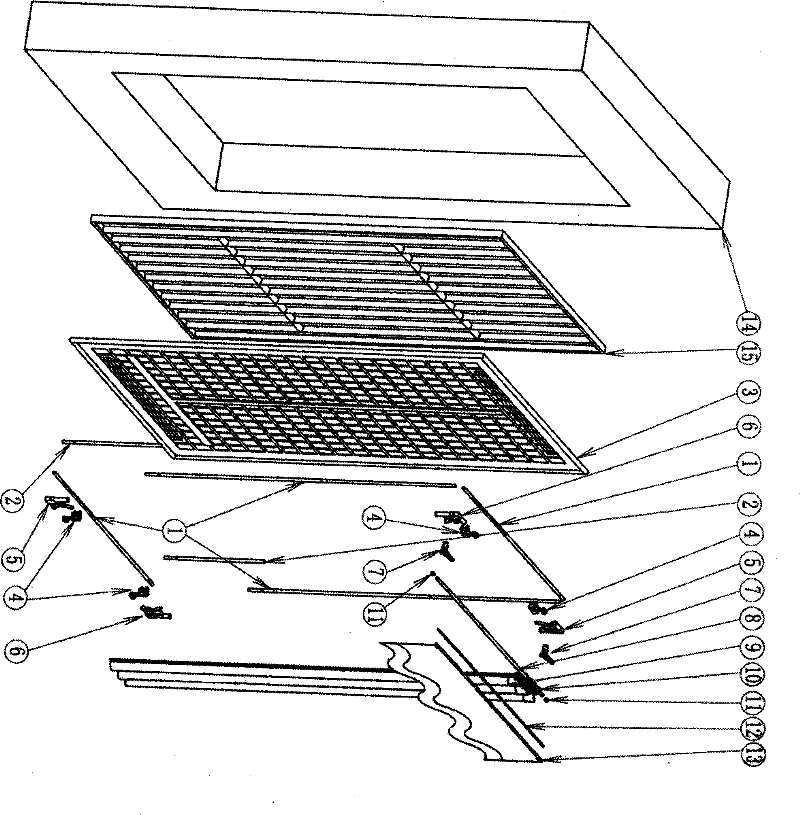

Safe intravenous needle assembling machine

PendingCN106041523ARealize the assemblyImprove yield rateAssembly machinesFinal product manufactureIntravenous needlesEngineering

The invention provides a safe intravenous needle assembling machine, and belongs to the technical field of medical apparatuses and instruments. The safe intravenous needle assembling machine solves the problems that an existing assembling machine is incomplete in assembling and not high in yield of finished products. The assembling machine comprises a machine frame, and is characterized in that two carrier circulation conveying lines are arranged on the machine frame in parallel and include the sliding sleeve carrier conveying line and the outer shell carrier conveying line; the sliding sleeve carrier conveying line is sequentially provided with a safe sliding sleeve feeding mechanism for feeding corresponding assemblies to an assembling station and a needle base feeding and assembling mechanism in the conveying direction; the outer shell carrier conveying line is sequentially provided with an outer shell feeding mechanism, an outer shell and sliding sleeve assembling mechanism, a needle base glue adding fixing mechanism, a needle feeding and dispensing mechanism, a glue curing device, a needle tip silicification mechanism, a needle sleeve assembling mechanism and a finished product discharging mechanism in the conveying direction; and the outer shell and sliding sleeve assembling mechanism is located between the sliding sleeve carrier conveying line and the outer shell carrier conveying line and located behind the needle base feeding and assembling mechanism of the sliding sleeve carrier conveying line in the conveying direction. According to the safe intravenous needle assembling machine, assembling of the accessories in a safe intravenous needle can be successfully achieved; the accessories are subject to staggered and repeated receiving, so that the production efficiency can be greatly improved; and a plurality of inspection items are additionally carried out in the assembling process, and inferior-quality product screening is carried out on the accessories and middle assemblies in an all-around manner, so that discharging of inferior-quality products is reduced, and the yield of the finished products is improved.

Owner:梁启明

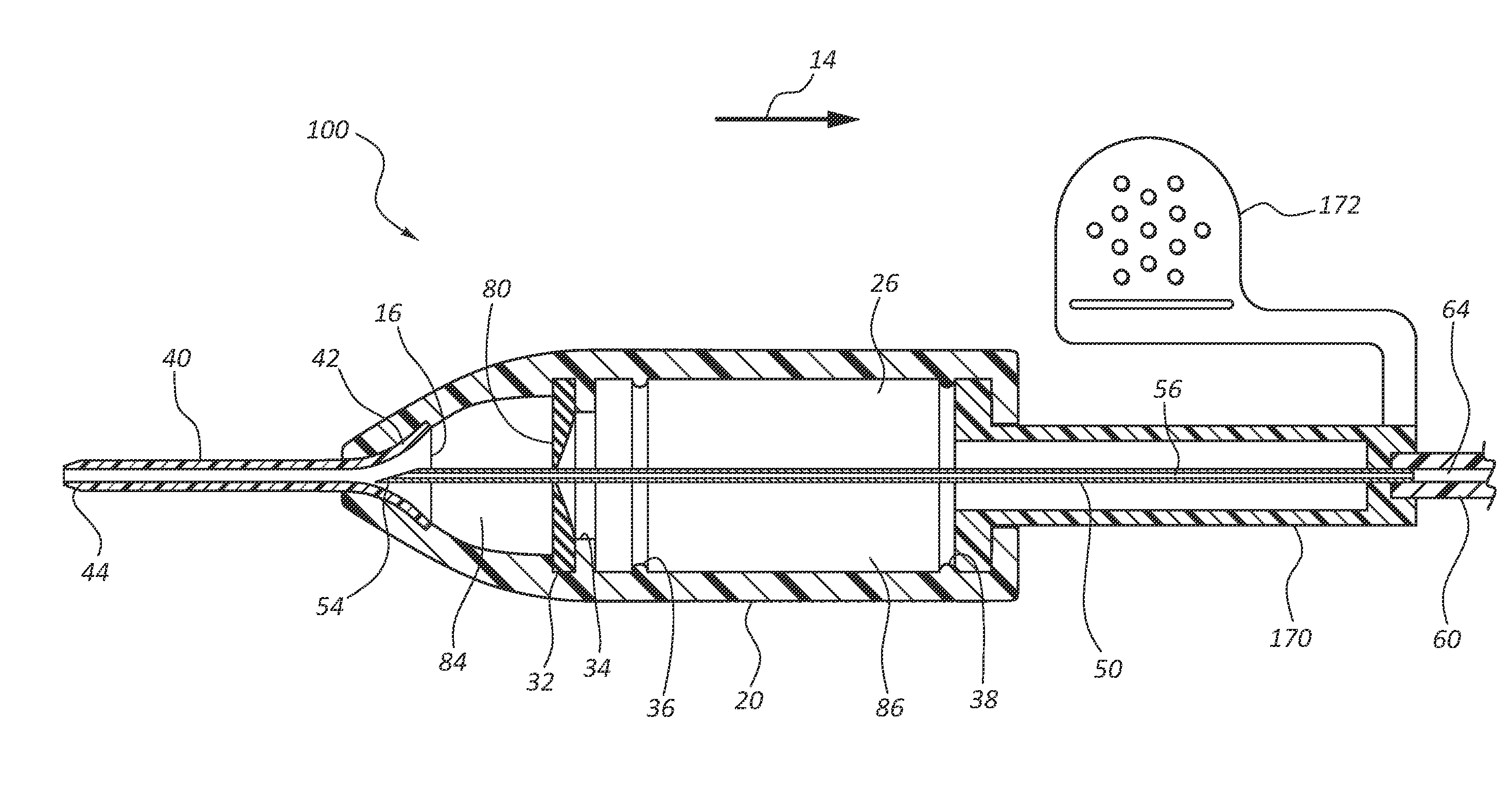

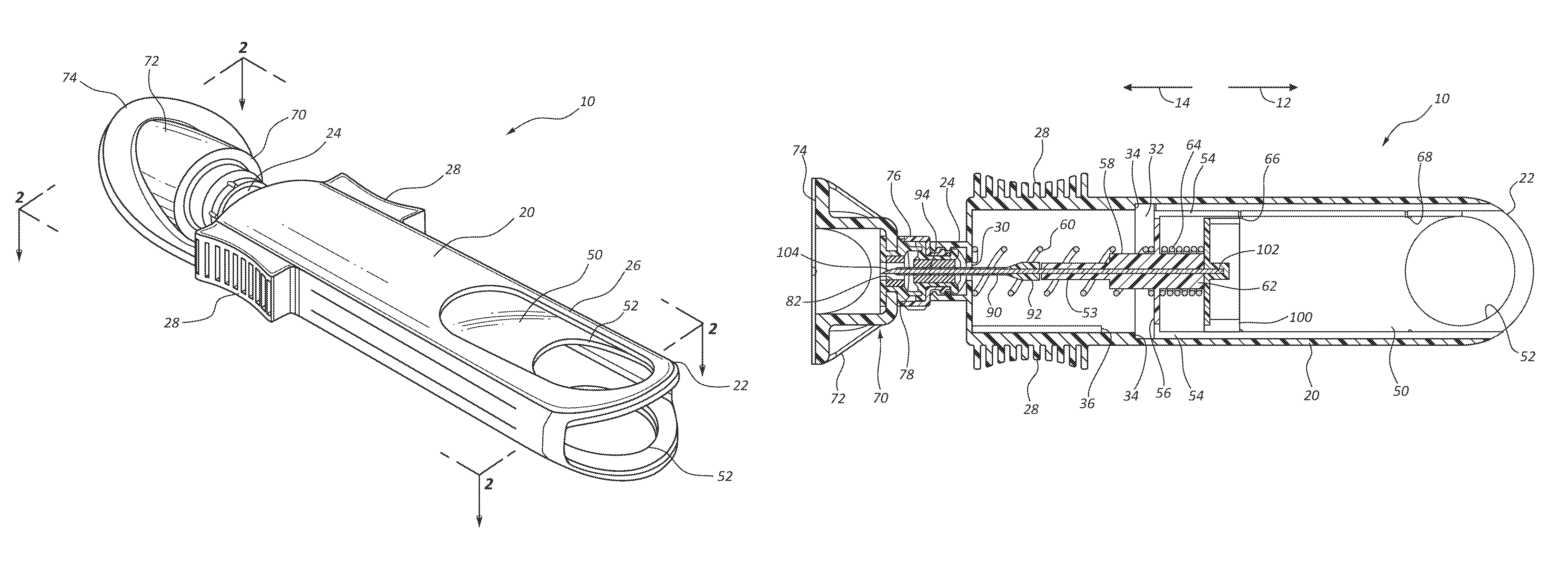

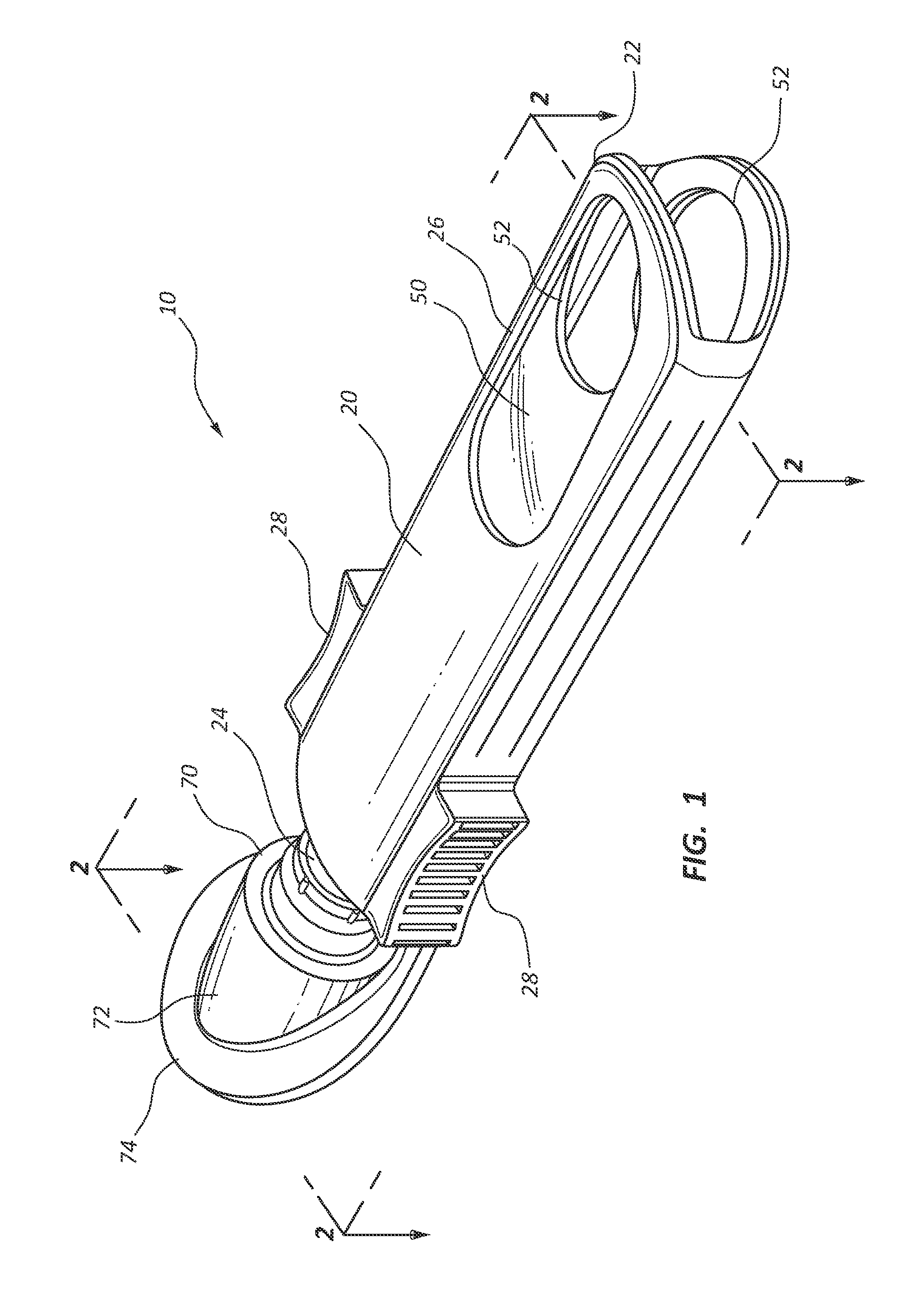

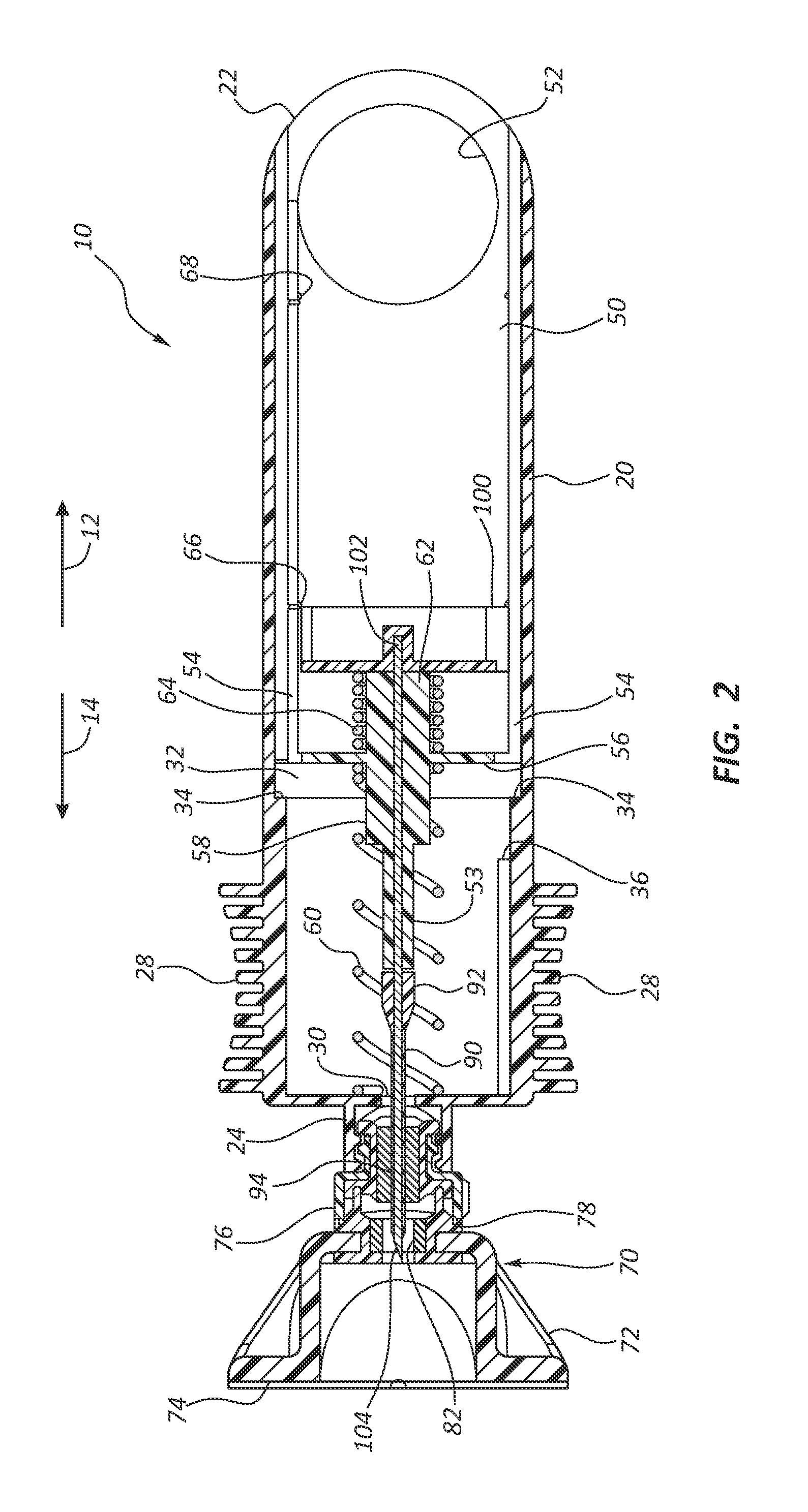

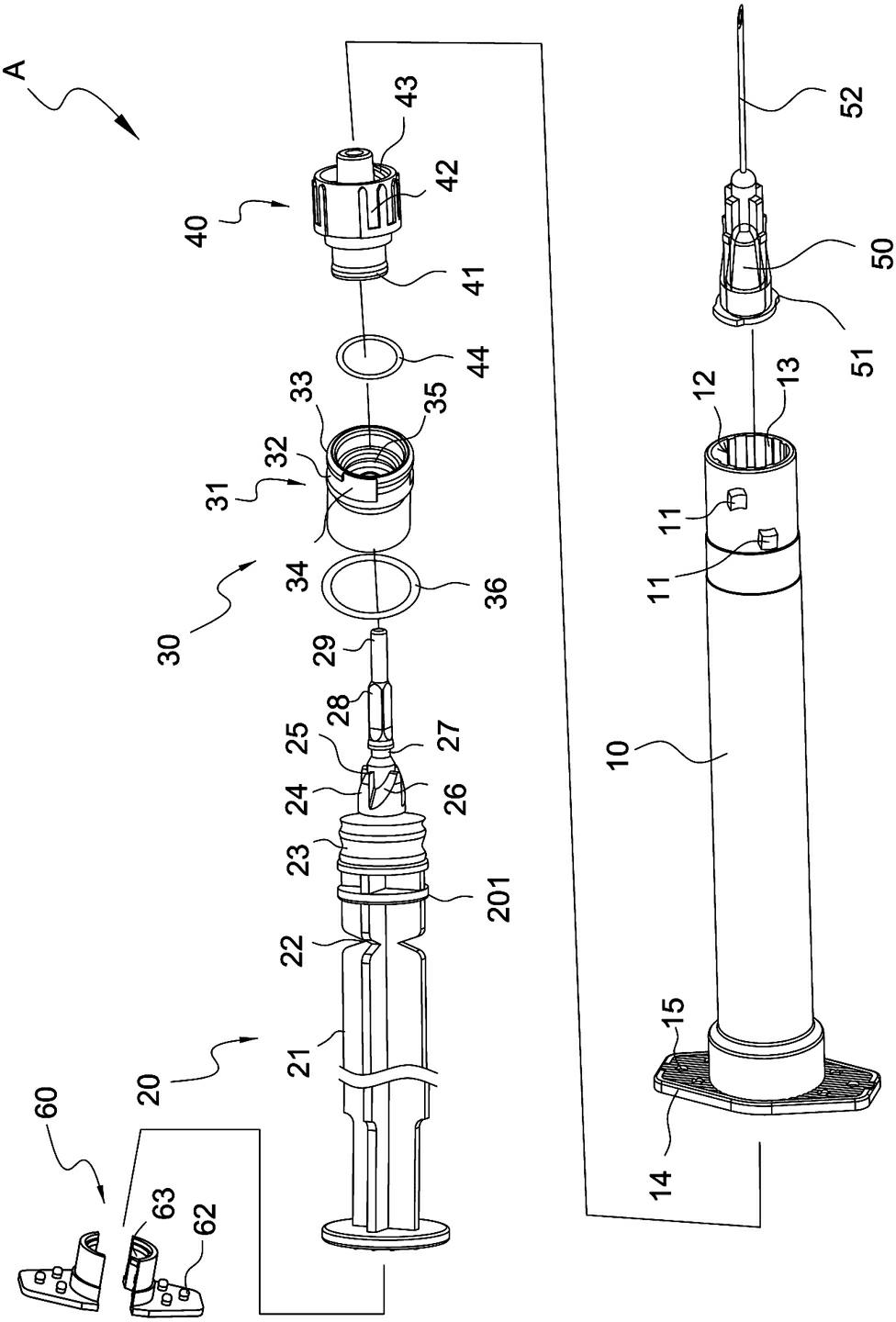

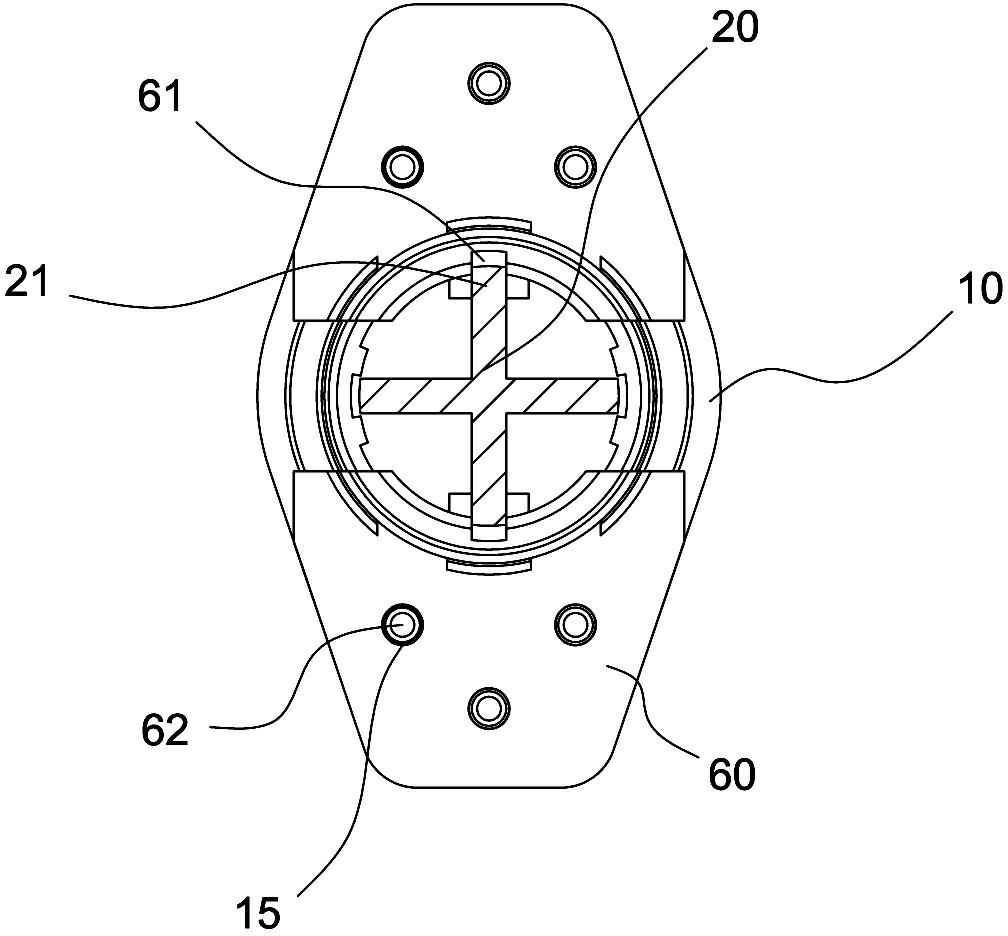

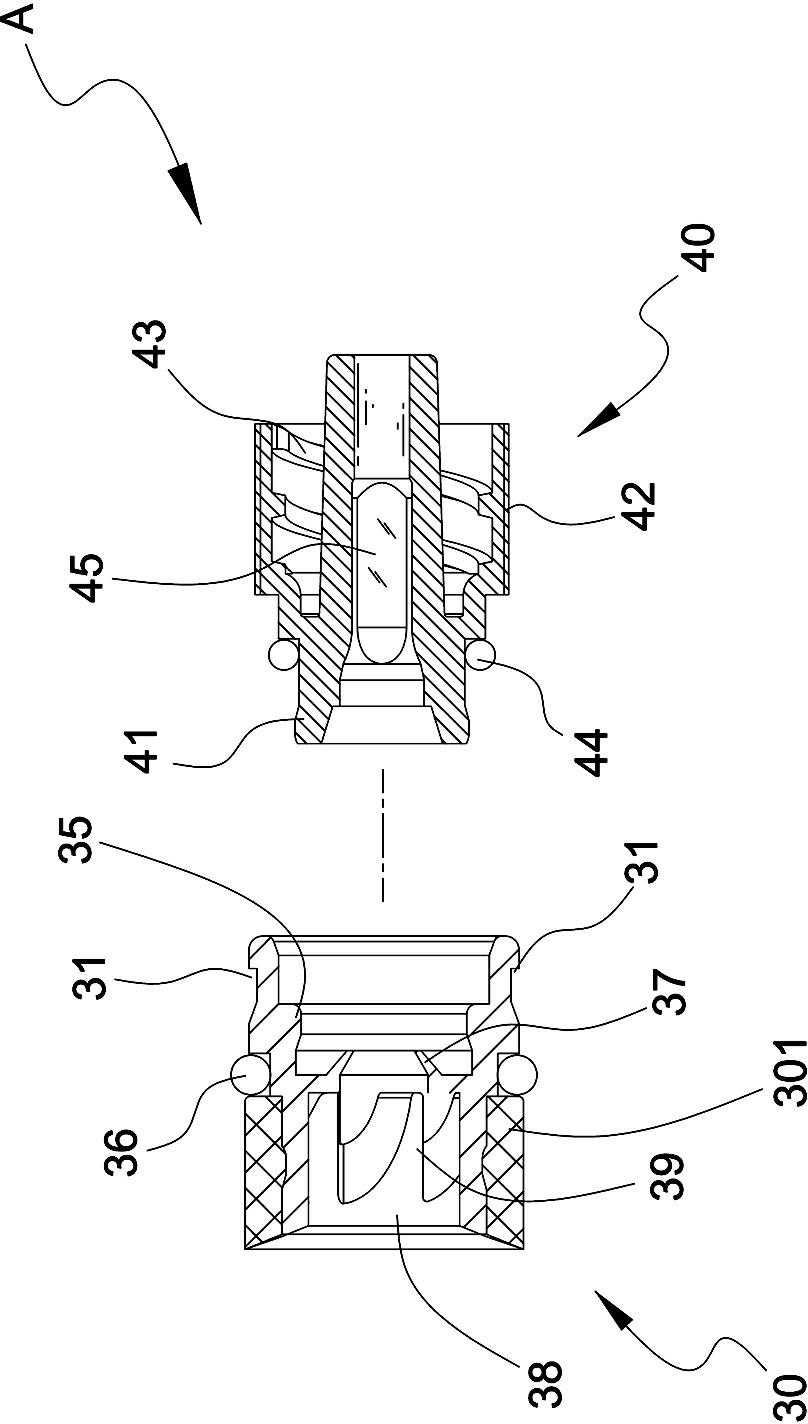

Retractable needle adapters and safety syringes

ActiveUS8979795B2Readily integrated into drug filling processReliable retractionMedical devicesInfusion needlesBarrel ShapedEngineering

Barrel adapters for safety syringes include a barrel and a plunger assembly adapted to move within the barrel, a barrel tip adapted to be sealingly engaged with a distal end of the barrel and a needle retraction mechanism having a needle subassembly and an actuator subassembly. The needle subassembly includes a needle, and a needle-over-mold (NOM) through which the needle extends. The needle subassembly is disposed at least partially within the barrel tip, and adapted to move from an injection position in which the needle extends from a distal end of the barrel tip to a retracted position in which the needle is disposed within at least one of the barrel tip or the barrel. The actuator subassembly includes a needle seal, a push-bar, and an actuator surface. The needle retraction mechanism includes a biasing member and an actuable locking arrangement. A syringe includes such barrel adapters.

Owner:UN HOLDINGS LLC

Over-the-needle intravenous catheter assembly with integrated intravenous tubing

An intravenous catheter device is provided which includes a catheter adapter having a fluid chamber, a needle adapter being slidably positioned within the fluid chamber, the needle adapter supporting a base of an introducer needle and a terminal end of a section of intravenous tubing such that a fluid pathway of the introducer needle is in fluid communication with a fluid pathway of the section of intravenous tubing. Following catheterization, the needle adapter is slid to a preferred proximal position whereby a sharpened tip of the introducer needle is shielded within a catheter of the intravenous catheter device, or a portion of the fluid chamber of the catheter adapter. When in the preferred proximal position, fluid communication between the catheter and a section of intravenous tubing is facilitated via the hollow body of the introducer needle.

Owner:BECTON DICKINSON & CO

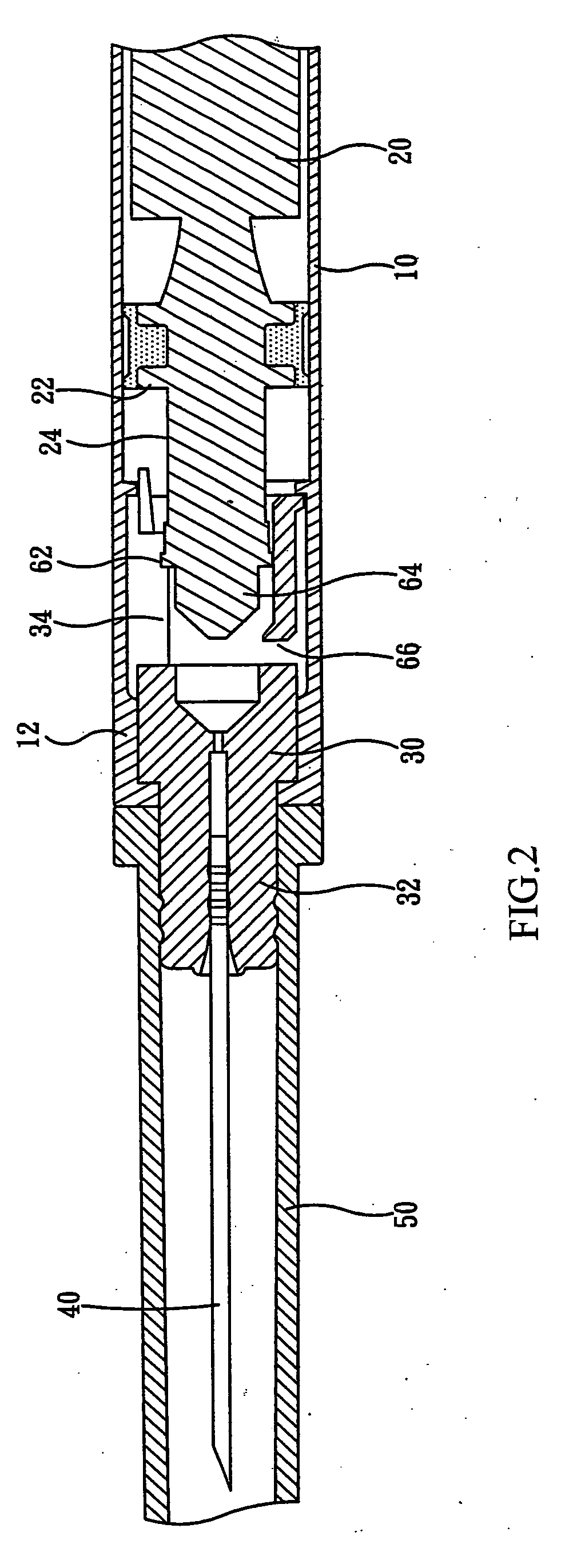

Mechanism for tilting retractable needle

The present invention discloses a mechanism for tilting a retractable needle, in which a needle adapter housed within a barrel comprises a connecting tube with a receiving groove on inner wall. The connecting tube forms a rectangle hole on the wall, and a cantilever with at least one tongue is formed between the rectangle hole and the rear portion of the connecting tube. The plunger fitted in the barrel comprises an extruding ring at a front end thereof. When the plunger is pushed forwardly into the connecting tube of the needle-adapter, an exterior ring of the plunger connected to with a piston will force the tongue to bend the cantilever toward the center of the open area, and engage the extruding ring into the receiving groove. When the plunger is pulled backward, the needle-adapter and the needle will be retracted into the barrel. Meanwhile, the needle will tilt as the tongue is forced against exterior ring by the cantilever, and the needle point is therefore close to the inner wall of the barrel. Accordingly, exposure of the needle point due to carelessly pushing the plunger can be prevented.

Owner:INTAI TECH CORP

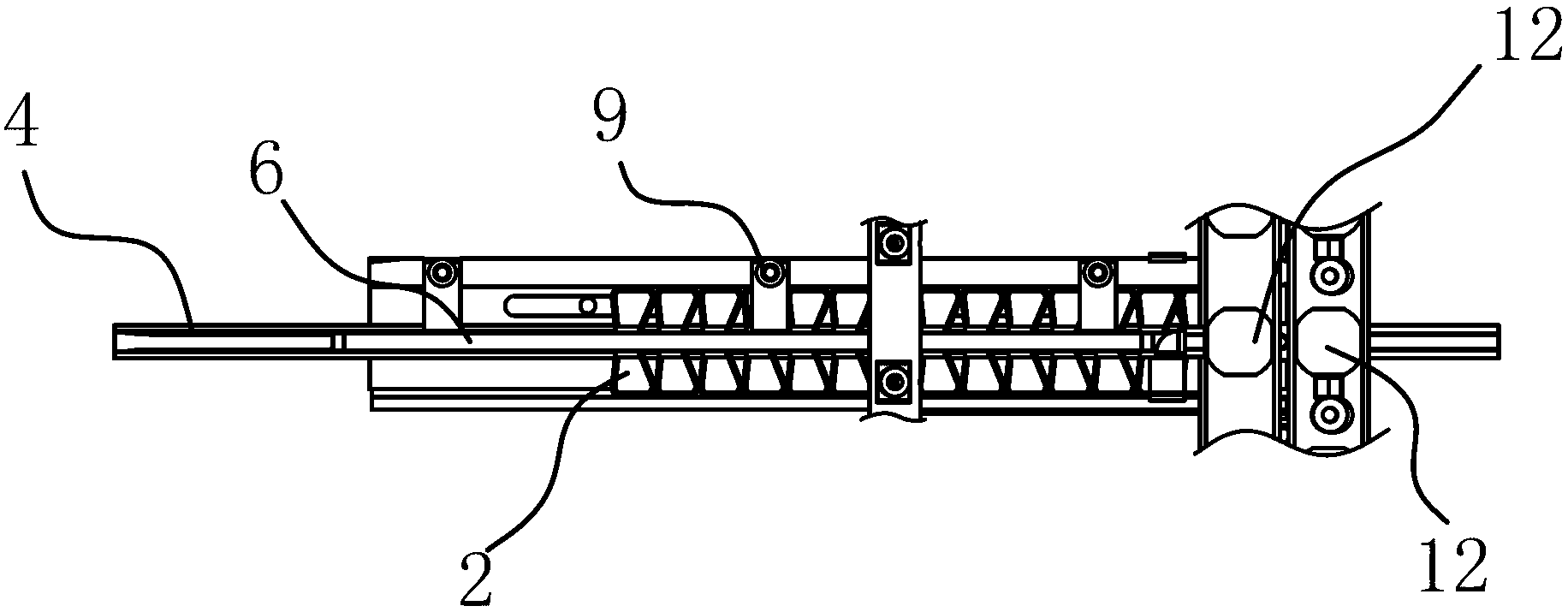

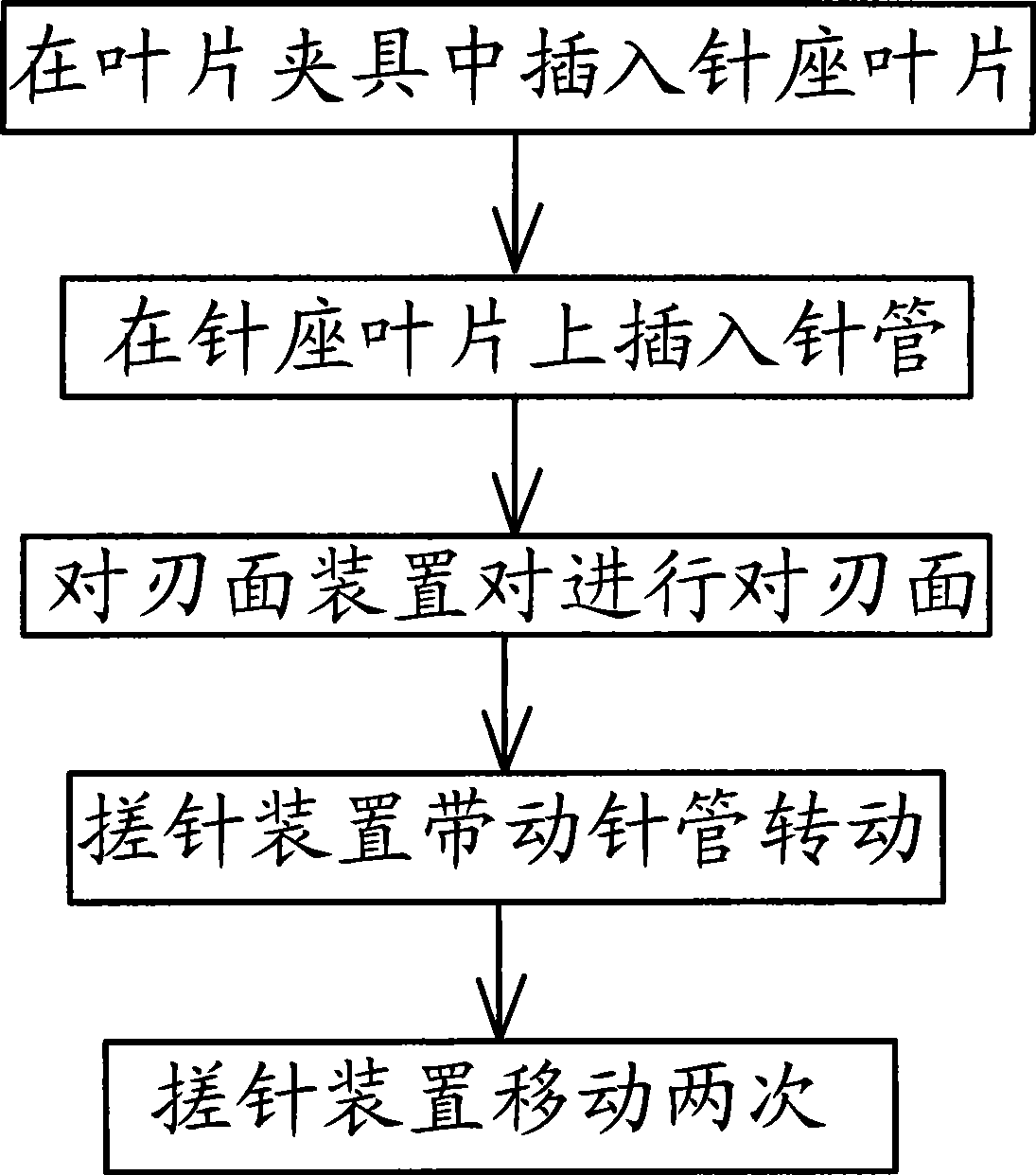

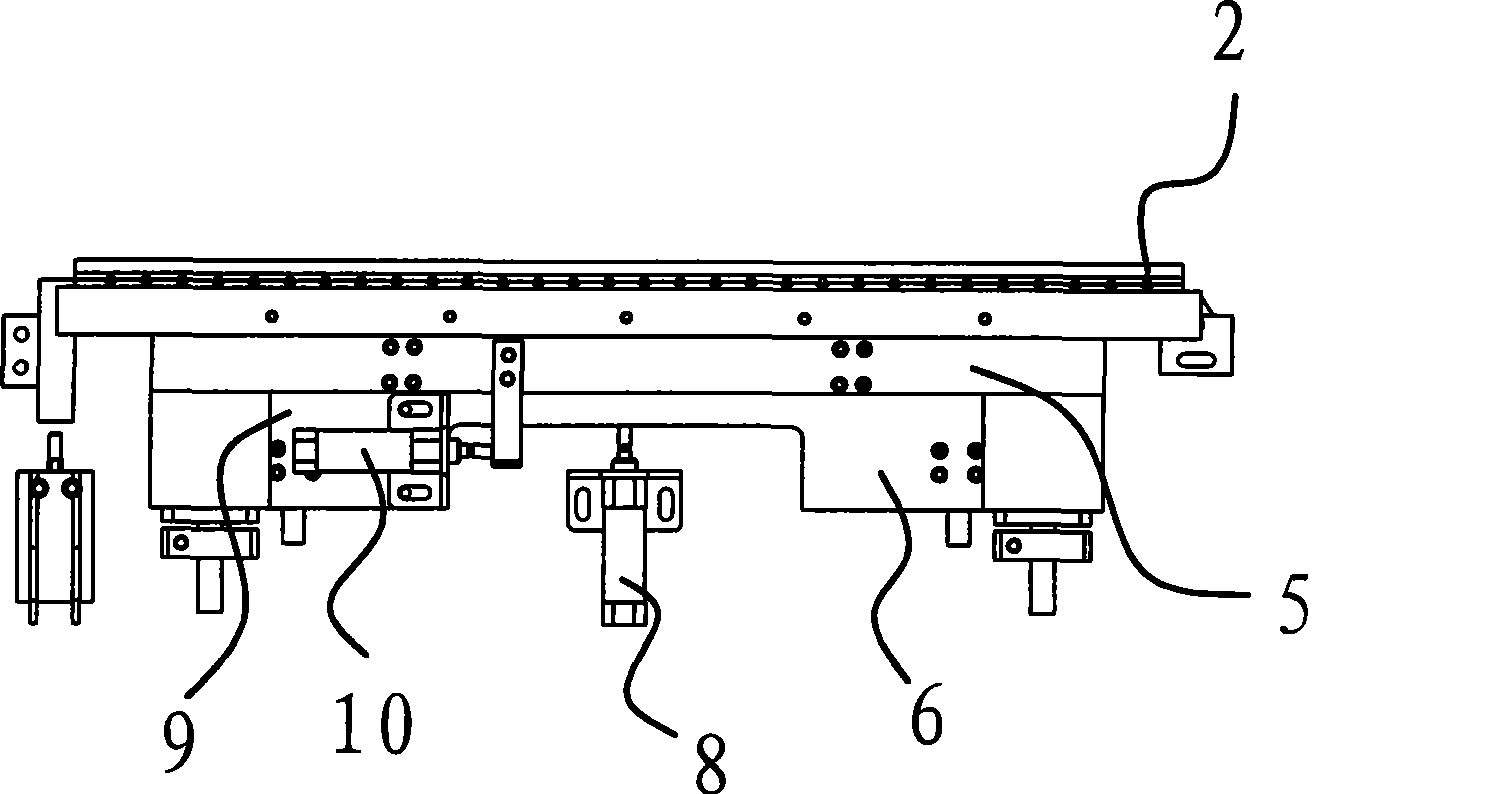

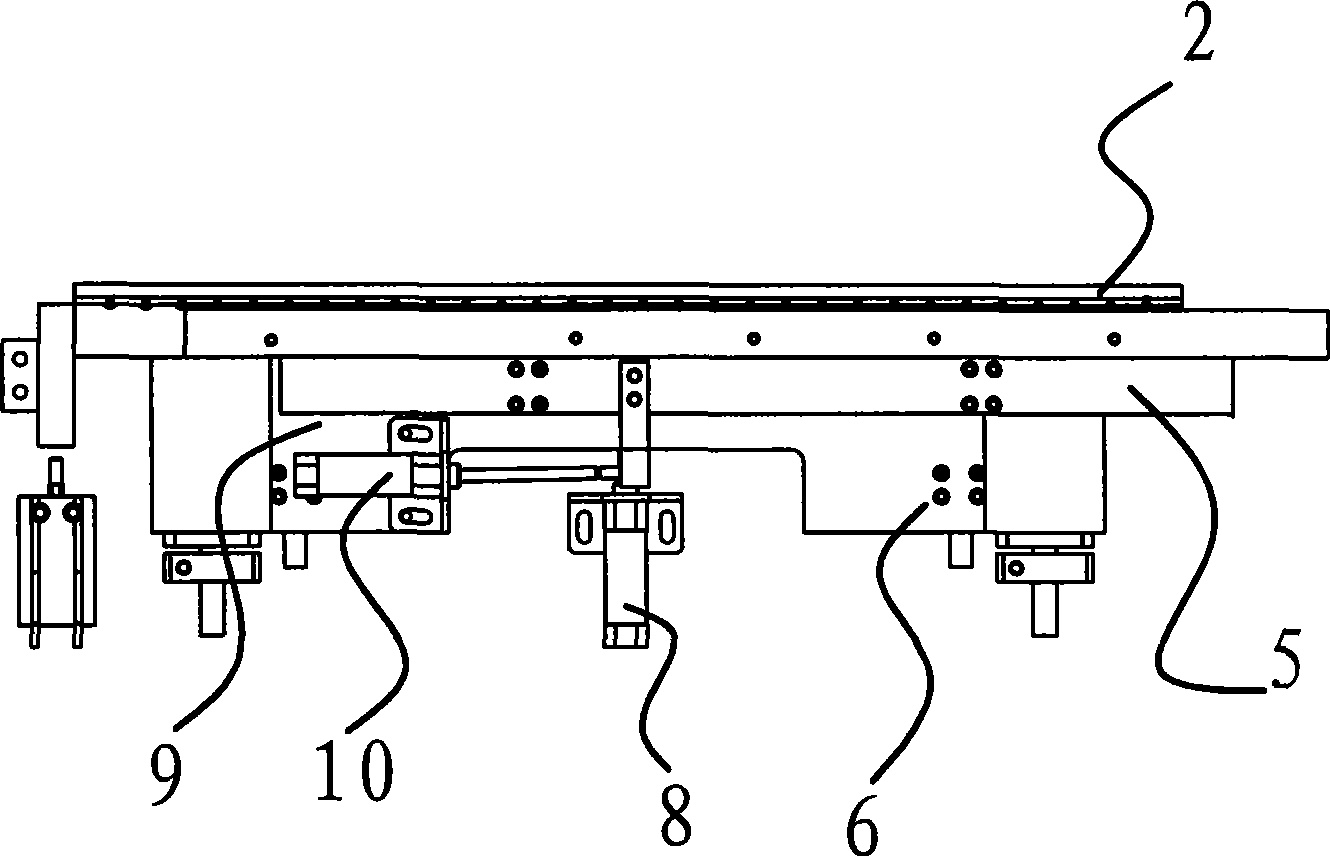

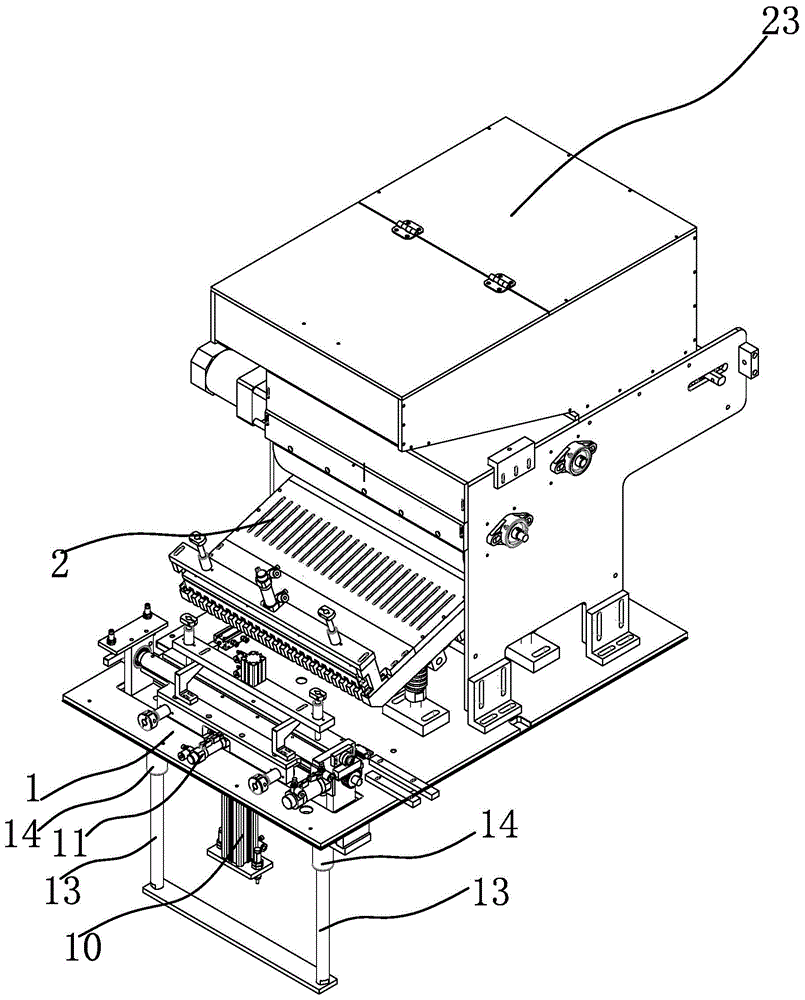

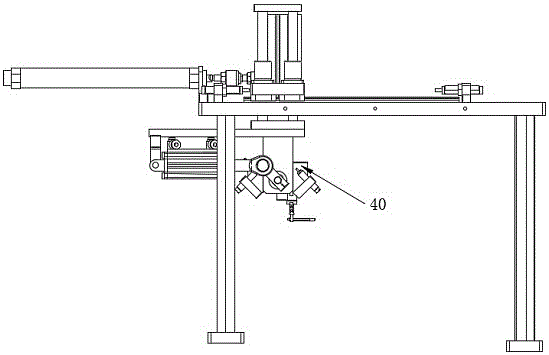

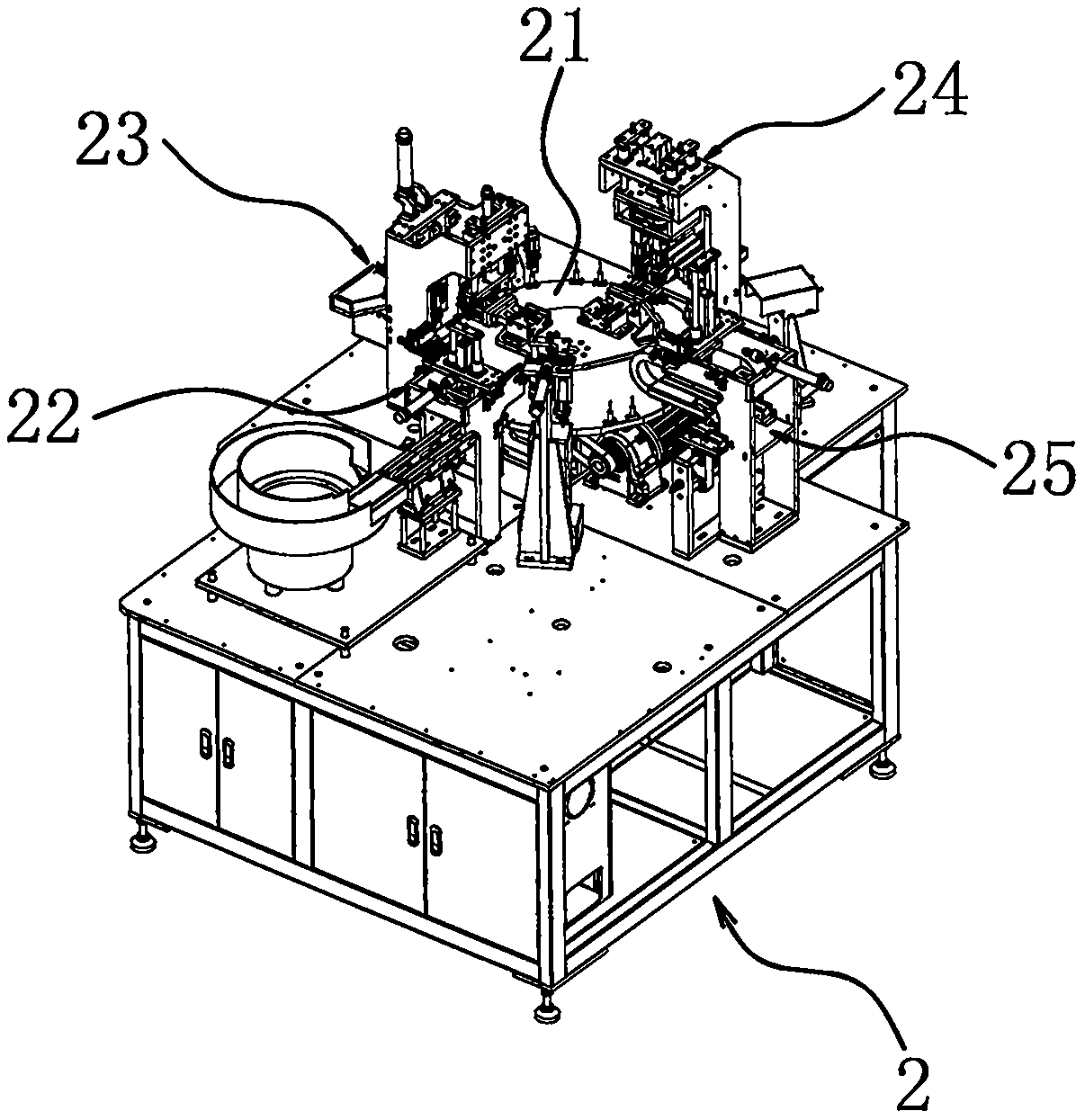

Correction method of needle tube of medical needle and needle-stand blade and needle twisting device

ActiveCN101456127AIncrease productivityAccurate correctionInfusion needlesMetal working apparatusCorrection methodBiomedical engineering

The invention provides a method for correcting a needle tube and a needle stand vane of a medical needle, and a needle twisting device, which belongs to the technical field of medical instrument. The method and the device solve the technical problems that the prior method for correcting the needle tube and the needle stand vane of the medical needle and the prior needle twisting device can only perform the correction singly, and manual operations are easy to cause pollution, and the like. The method for correcting the needle tube and the needle stand vane of the medical needle comprises the following steps: loading materials, facing the needle tube to an active face, and twisting the needle. The needle twisting device is arranged below a needle tube opposite active face device and comprises a stand and a longitudinal cylinder fixed on the stand, wherein the stand is provided with a longitudinal bearing plate, a piston rod of the longitudinal cylinder is fixedly connected with the longitudinal bearing plate, and the longitudinal bearing plate is provided with a transverse cylinder and a bar twisting plate connected with the piston rod of the transverse cylinder. The correction method can perform batch corrections which are quick and accurate, and the needle twisting device has the advantages of automatic batch adjustments, high efficiency, and the like.

Owner:MAIDER MEDICAL IND EQUIP

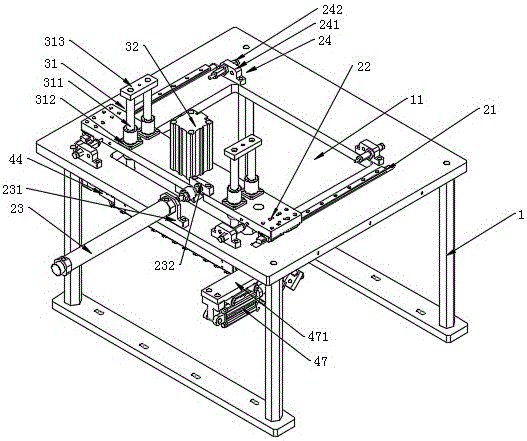

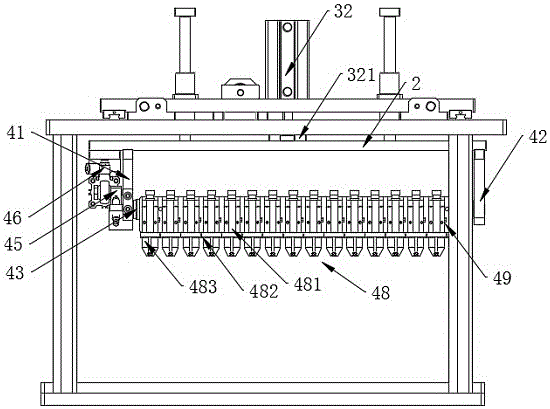

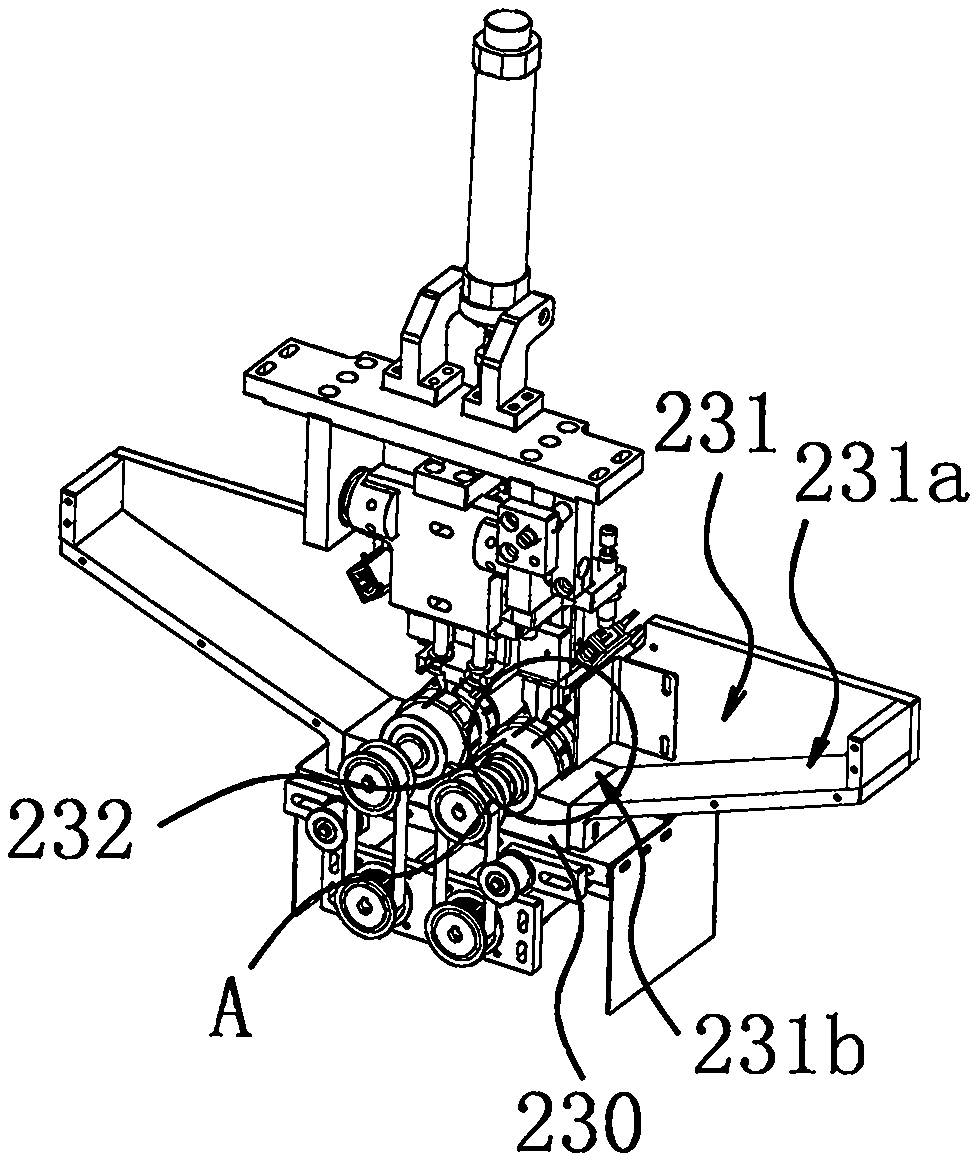

Feed mechanism of needle base of assembling machine for medical accessories

The invention provides a feed mechanism of a needle base of an assembling machine for medical accessories and belongs to the assembling device technical field for medical accessories. The feed mechanism of the needle base of the assembling machine for medical accessories solves the technical problem of the existing feed mechanism that the degree of automation is low. The feed mechanism comprises an installing shelf and a feeding orbit capable of transporting the needle base, the installing shelf is provided with a lifting base and a drive piece 1 capable of driving the lifting base for moving up and down, the lifting base is provided with a long strip-shaped installing base, a through hole is formed in the installing base, a material hanging plate is inserted in the through hole, a drive piece 2 capable of driving the material hanging plate for moving in the through hole in a reciprocating motion mode is fixedly arranged on the installing base, a material hanging notch capable of hanging the needle base is formed on the material hanging plate; the material hanging notch is connected with the outlet end of the feeding orbit in a butt joint mode; the installing base is provided with a material pressing plate located just above the material hanging notch. The column-shaped needle base is transported to the assembling carrier for executing the next process by material receiving, returning, dropping, material falling and material pressing steps, the operation is convenient and fast and the degree of automation is high.

Owner:MAIDER MEDICAL IND EQUIP

Rotary shifting device of safe intravenous needle base

InactiveCN106064741ASame distanceFirmly connectedConveyorsConveyor partsIntravenous needlesSlide plate

The invention discloses a rotary shifting device of a safe intravenous needle base. The rotary shifting device comprises a frame bracket, a translation unit including two translation modules symmetrically arranged on the left and right two sides of the upper end surface of the frame bracket, a lifting unit including two sets of lifting modules symmetrically arranged on the left and right two sides of the frame bracket and mounted on translation slide plates fixed on the translation modules, a turnover fixed plate connected with the lifting modules by one end, and a rotating unit including a rotating module, wherein the two ends of the rotating module are respectively connected with the other end of the turnover fixed plate through a left support plate and a right support plate. The rotary shifting device, provided by the invention, synchronously clamps medical fittings in discharge ports through clamping modules, synchronously feeds the medical fittings into next stations through lifting units and through synchronous turnover of rotating modules, guarantees the same direction of all medical fittings in each shifting, saves the subsequent assembly time, and improves the productivity.

Owner:梁启明

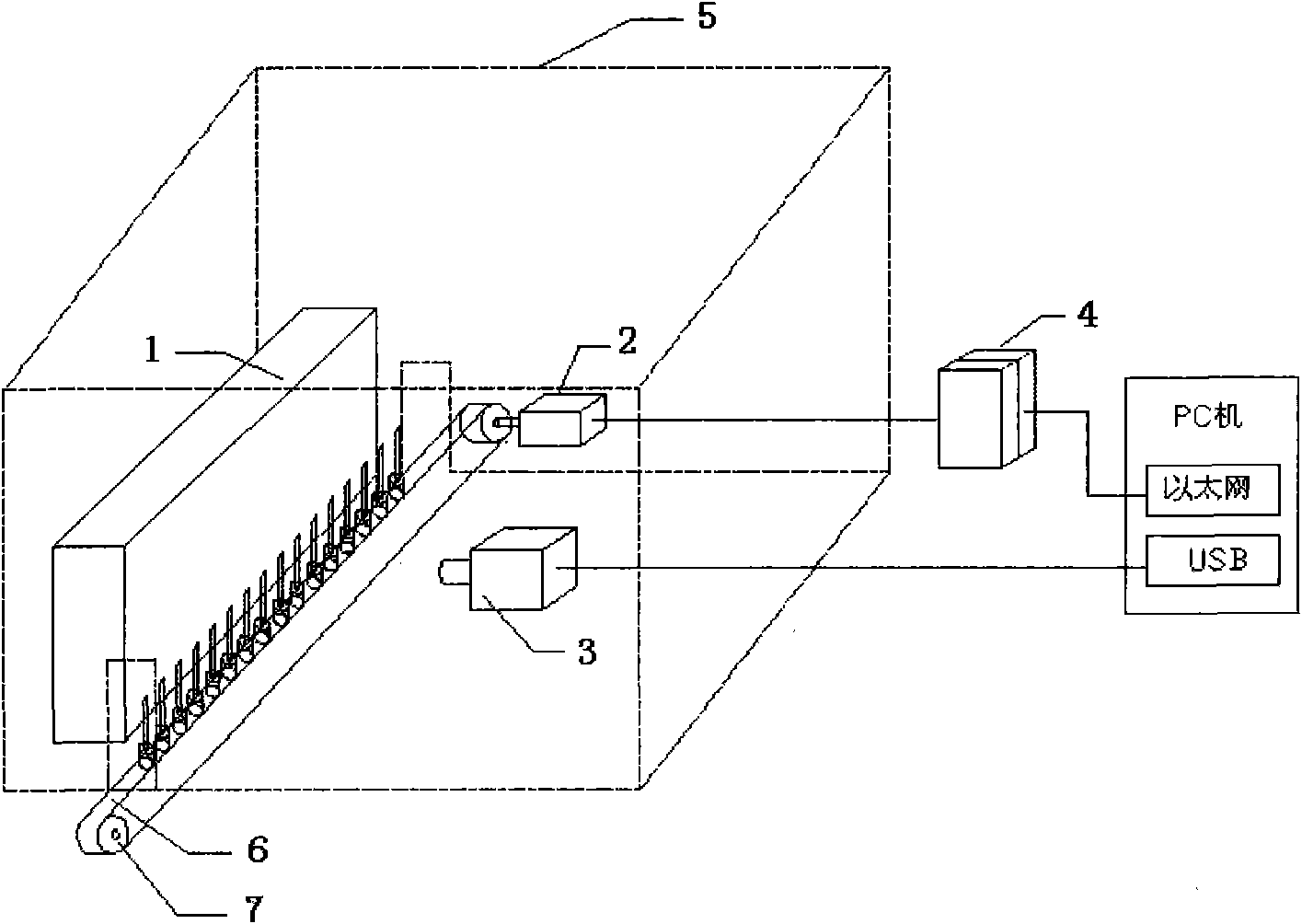

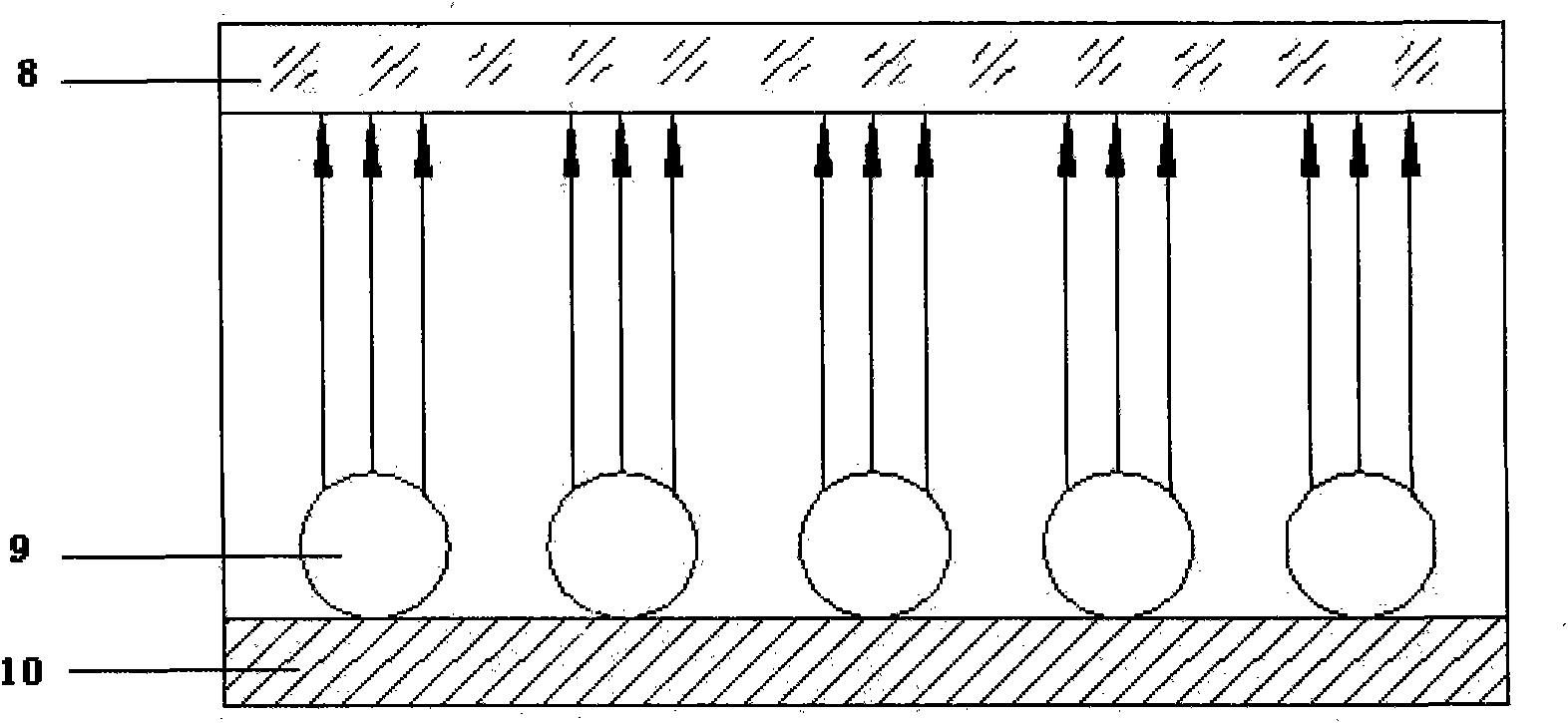

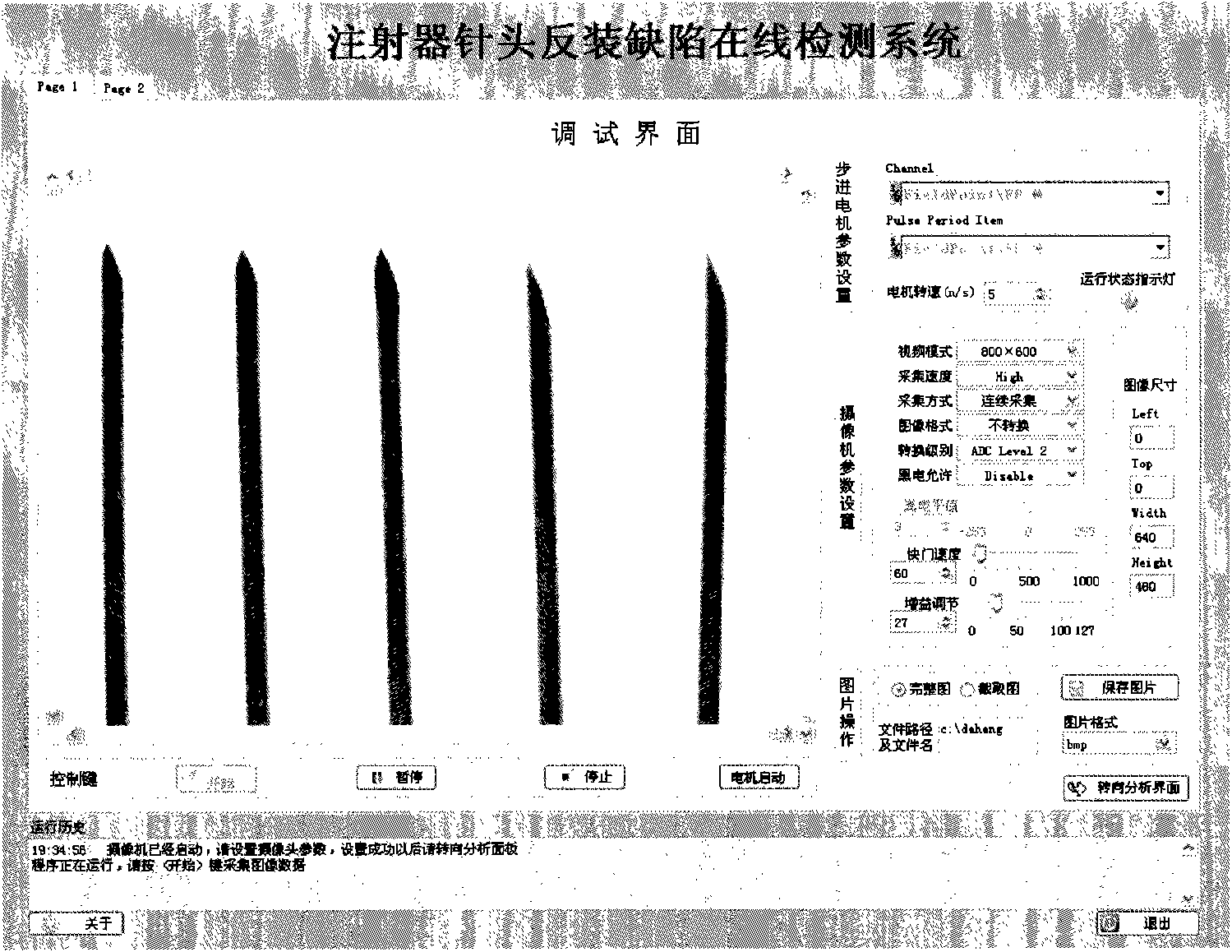

On-line detection technology of reversion defect of disposable injection needle

InactiveCN101832944ARapid anti-assembly defect detectionAccurate reverse assembly defect detectionOptically investigating flaws/contaminationElectric machineryCcd camera

The invention discloses an on-line detection technology of the reversion defect of a disposable injection needle. A detection device comprises a lighting device and a CCD industrial digital camera used for acquiring an image; a conveying device comprises a [c] FP controller, a step motor, a belt wheel, a conveying belt and the like; and a virtual apparatus LabVIEW is used for constructing a software platform to realize automatic detection and alarming of the reversion defect of the injection needle. In a process of producing and assembling the disposable injection head, the needle is easy to produce the reversion defect (a needle point is inserted into a needle stand); and because shapes of the needle point and the bottom are different, the shape of the needle point after the reversion changes, which is the detection basis. The designed lighting device provides uniform stable shadowless lighting, under the action of the lighting device, the CCD camera obtains a sharp image of the needle point, and the reversion or not of the needle can be detected accurately by using the LabVIEW virtual software platform. A detection result is directly displayed by computer software and alarmed.

Owner:EAST CHINA JIAOTONG UNIVERSITY

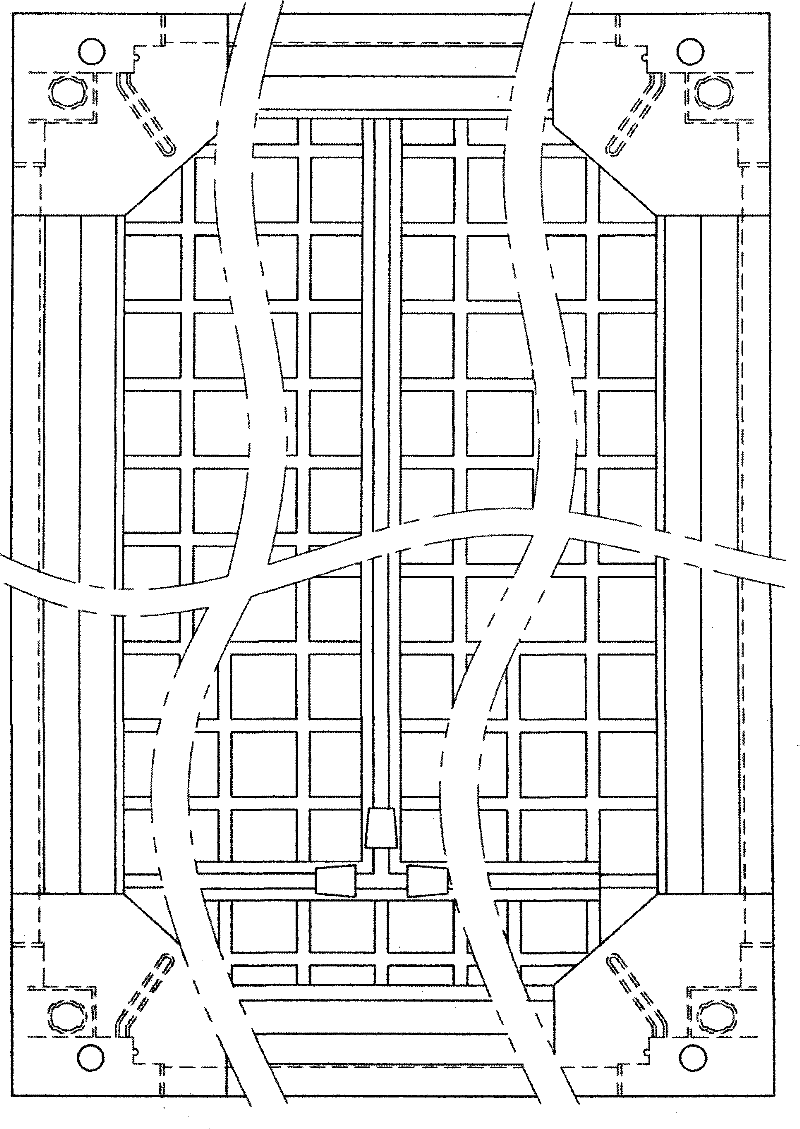

Puncture needle assembly machine

PendingCN109514251AImprove separation efficiencyStable and continuous feedingAssembly machinesMetal working apparatusEpoxyAssembly line

The invention provides a puncture needle assembly machine and belongs to the technical field of medical equipment. The puncture needle assembly machine solves the problem that the degree of automationof an existing puncture needle assembly machine is low. The puncture needle assembly machine comprises a circulation conveying line I, a circulation conveying line II and a needle tube component transfer mechanism, wherein a needle tube component assembly mechanism is located on one side of the circulation conveying line I and comprises a turntable I, a needle seat feeding component, an upper epoxy resin component and a blanking component; and a butterfly wing assembly mechanism comprises a turntable II, a surrounding butterfly wing feeding component, a butterfly wing surface fixing component, an assembly component, a needle surface positioning component, a spraying point component and a glue dispensing component. With adoption of the puncture needle assembly machine, the butterfly wing and the needle tube component are assembled together through the butterfly wing assembly mechanism, the needle tube, the needle seat and the butterfly wing realize assembly line type full automatic assembly and the assembling efficiency of the puncture needle is greatly improved.

Owner:昕迪智能装备(东莞)有限公司

Needle assembly

InactiveUS20130053791A1Prevent coringAnaesthesiaSurgical needlesParallel plateBiomedical engineering

A needle assembly has a needle hub that has a body to which are formed two plates at opposite sides thereof in a parallel relationship. The plates have respective upper edges and lower edges that lie substantially along respective planes, so that the needle hub may be stably placed onto a surface by means of the respective edges. The plates also prevent the rolling of the needle between the fingers of the clinician when the clinician holds the needle assembly by means of the plates. A partition is formed orthogonally proximate to the front ends of the parallel plates. The connector at the proximal portion of the needle hub is configured to have a non-conventional configuration that allows it to mate only with a counterpart connector that has a complementary non-conventional configuration.

Owner:SMITHS MEDICAL ASD INC

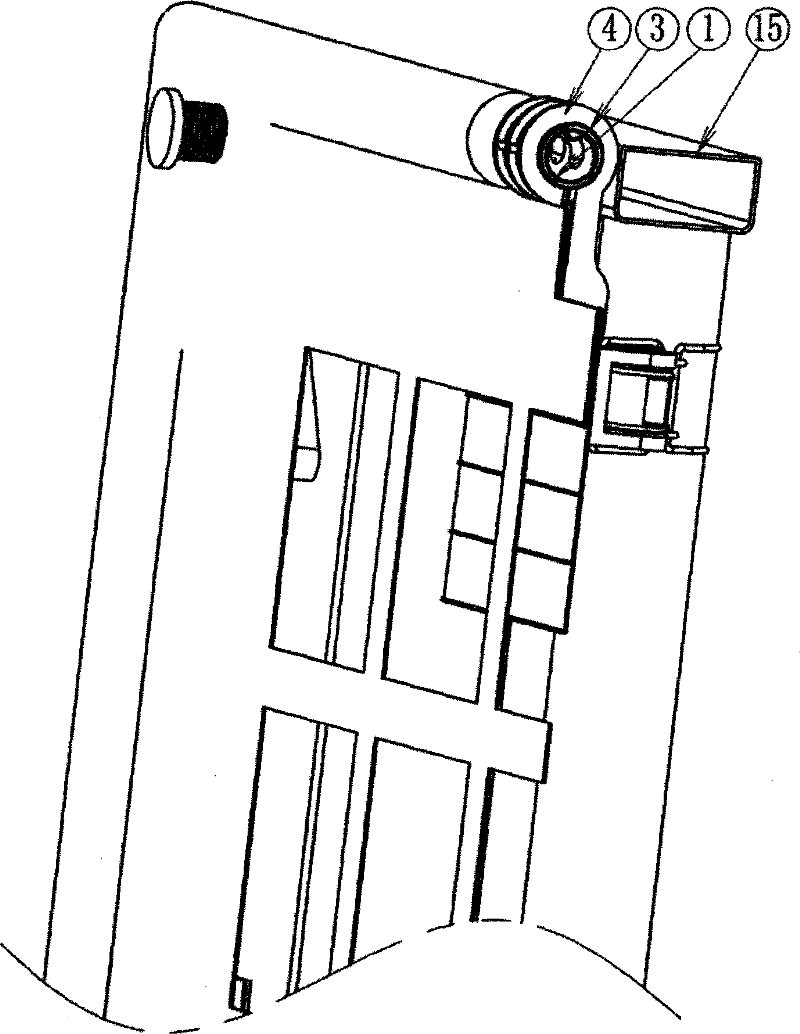

Easy to install and disassemble telescopic combination curtain

InactiveCN102287130ASimple structureLow costInsect protectionLight protection screensClip deviceNeedle adapter

The invention discloses an easy-to-attach telescopic combination curtain that can be installed and disassembled on windows of different sizes, and can be washed, folded and carried without professionals and professional tools. The easy-to-load telescopic combination curtain of the present invention is mainly composed of a mosquito-proof curtain and a light-shielding curtain. Among them, the anti-mosquito curtain is composed of four sets of telescopic rods, extension rods, a frame composed of adapters with pins, support clips, and mosquito nets with multiple sets of rod holes on the four sides. The connector can be used in conjunction with windows with anti-theft nets to increase the installation reliability of the curtains); the blackout curtain is composed of a guide rail bracket, a guide rail for the telescopic rod, several buckles, and a blackout cloth. The blackout curtain is assembled on the inner side of the window through the assembly of the rail bracket and the anti-mosquito curtain frame. The anti-mosquito curtain, the blackout curtain and the anti-mosquito blackout curtain can be combined by adding or subtracting the curtain components. The present invention is particularly suitable for rental houses in modern cities. Mass production can be realized, and the cost can be greatly reduced.

Owner:朱赛胜

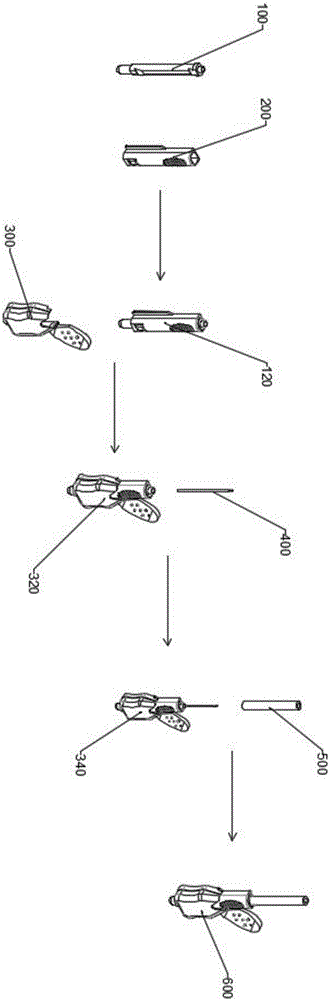

Needle base assembly rotating and retracting structure of safety injector

ActiveCN102652849AEasy to retractEasy retraction actionInfusion syringesInfusion needlesBiomedical engineeringSafety syringe

The invention provides a needle base assembly rotating and retracting structure of a safety injector. The structure has the following beneficial effects: fastening grooves of the needle base assembly and fastening stops corresponding to a drum body to rotate from the limit and lock state to the non-limit and open state by virtue of automatic deflectors of a needle base assembly, so that a push rod can be rapidly embedded in the needle base assembly and positioned and presents the mode of retracting an injection needle so that the user can carry out the next retraction action, and the needle base assembly can be stably assembled and positioned at the opening end of the drum body and hardly causes the following unexpected phenomena due to the external temperature: the fastening degree between a needle base and the drum body is reduced due to temperature surge, thus causing inward retraction or leakage of the needle base in the injection process, or the needle base and the drum body are excessively fastened due to sudden temperature drop and the injection needle and the needle base can not be retracted into the drum body after injection; therefore the structure can be safely operated by the operator with one hand, improves the environment quality and achieves convenience in retraction use of the injection needle.

Owner:张淑茗

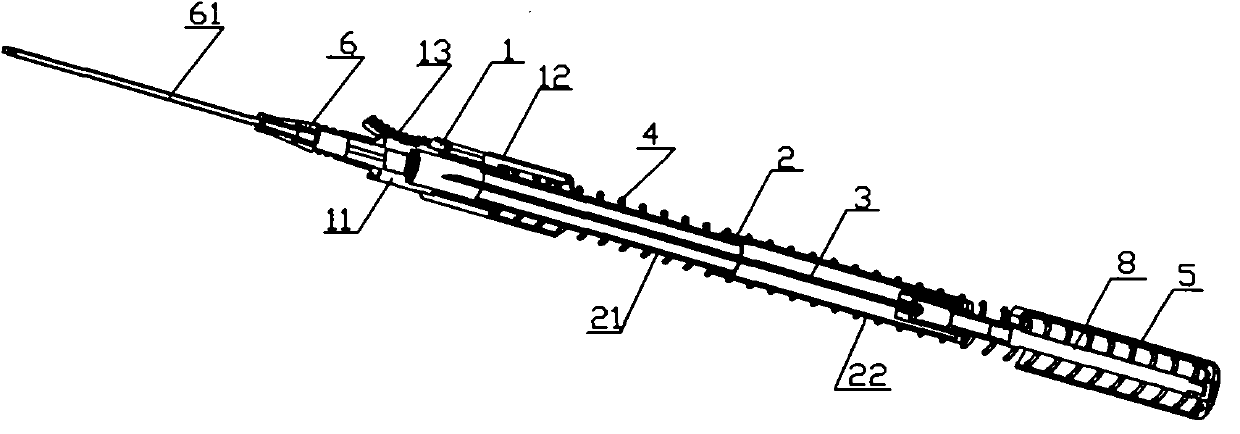

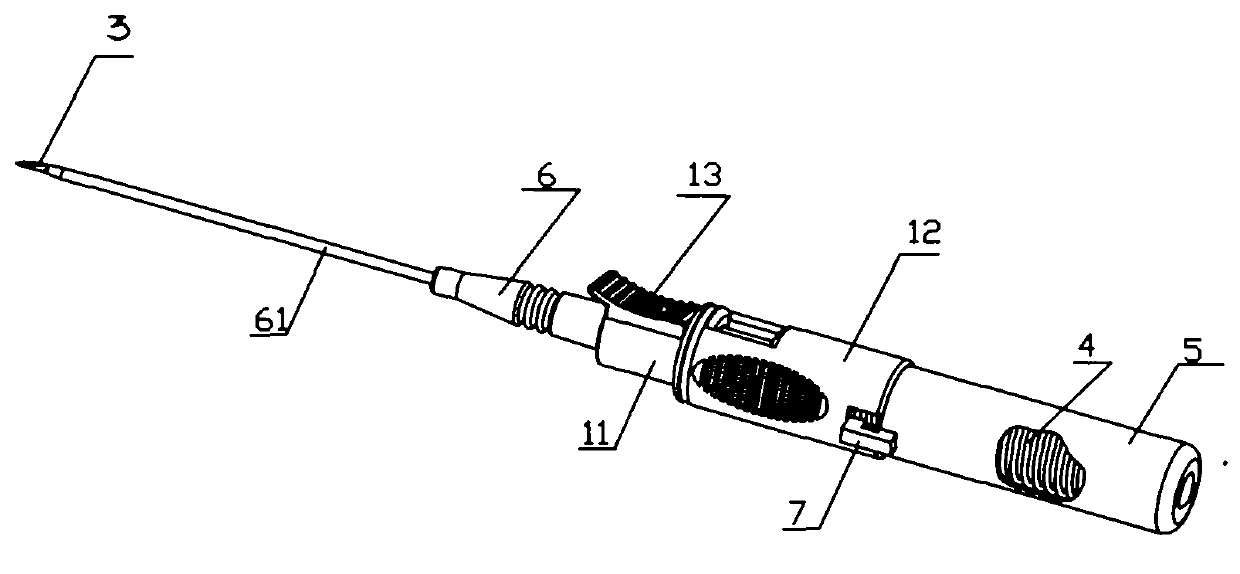

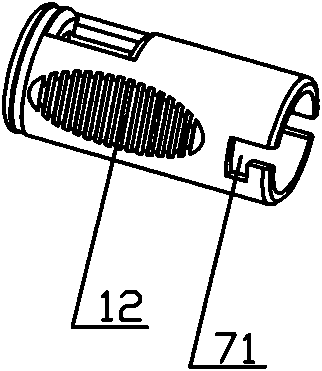

Syringe needle manual retracting type intravenous infusion needle

InactiveCN107281586AAvoid damageMeet comfortMedical devicesCatheterIntravenous InfusionsSyringe needle

The invention provides a syringe needle manual retracting type intravenous infusion needle, which comprises a needle base, a built-in slide sleeve, and a protecting shell body; the needle base is a hollow cylinder, wherein one end of the needle base is used for mounting the syringe needle while the other end is used for connecting a conveying pipe; the needle base is detachably mounted in the built-in slide sleeve, and freely glided in the built-in slide sleeve; the protecting shell body is formed by buckling upper and lower protecting shell bodies together; the built-in slide sleeve is installed in the protecting shell bod y and freely glided in the protecting shell body; when the needle base is pulled from the built-in slide sleeve out of the limited place, and the built-in slide sleeve is pulled from the protecting shell body out of the limited place, the needle pipe is completely covered and thus the syringe needle cannot be exposed. The syringe needle manual retracting type intravenous infusion needle has the advantages of preventing pricking wound and crossing infection; the product design is minimized, the production technique is simple, and the cost is low.

Owner:王祖扬

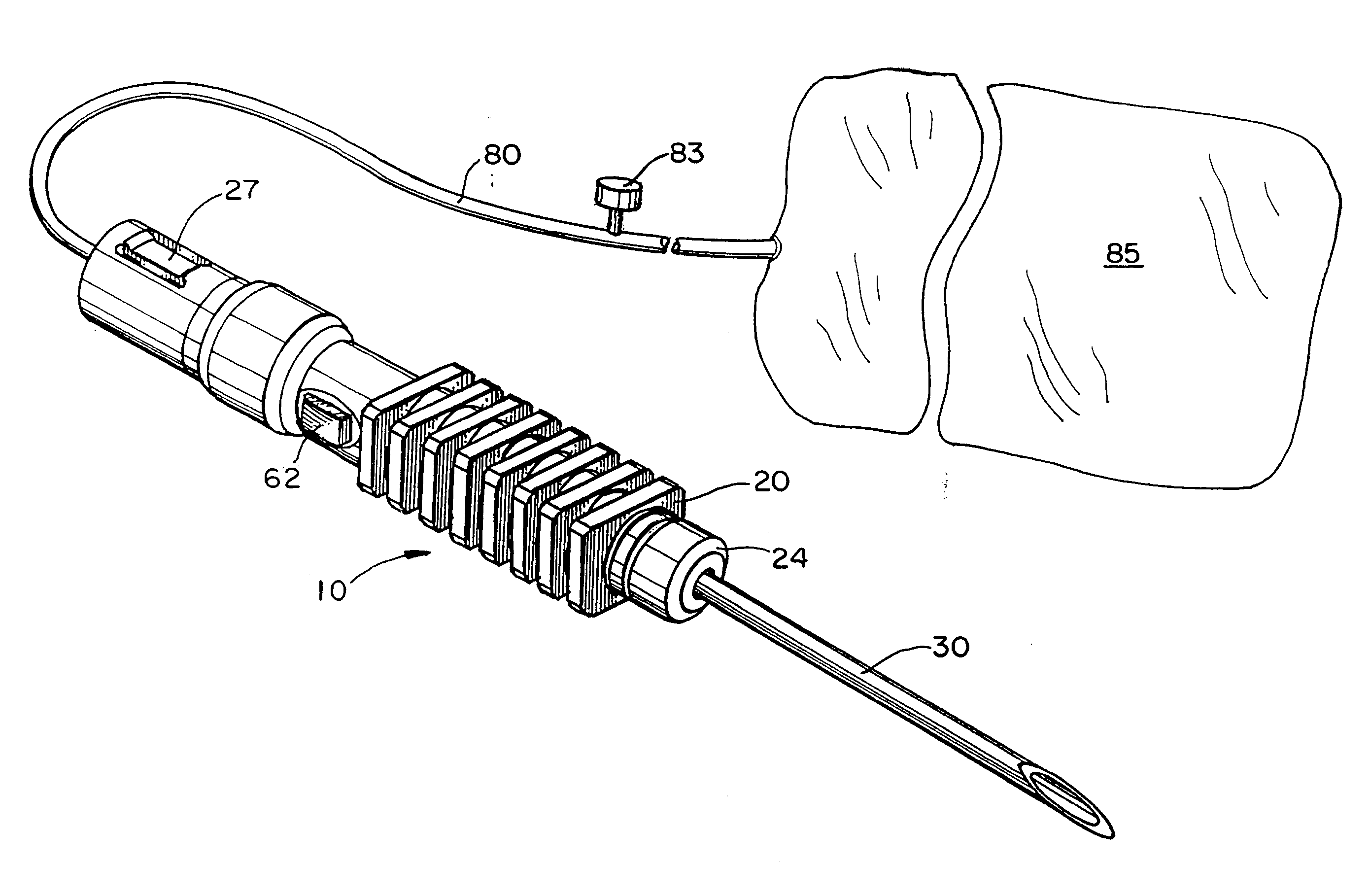

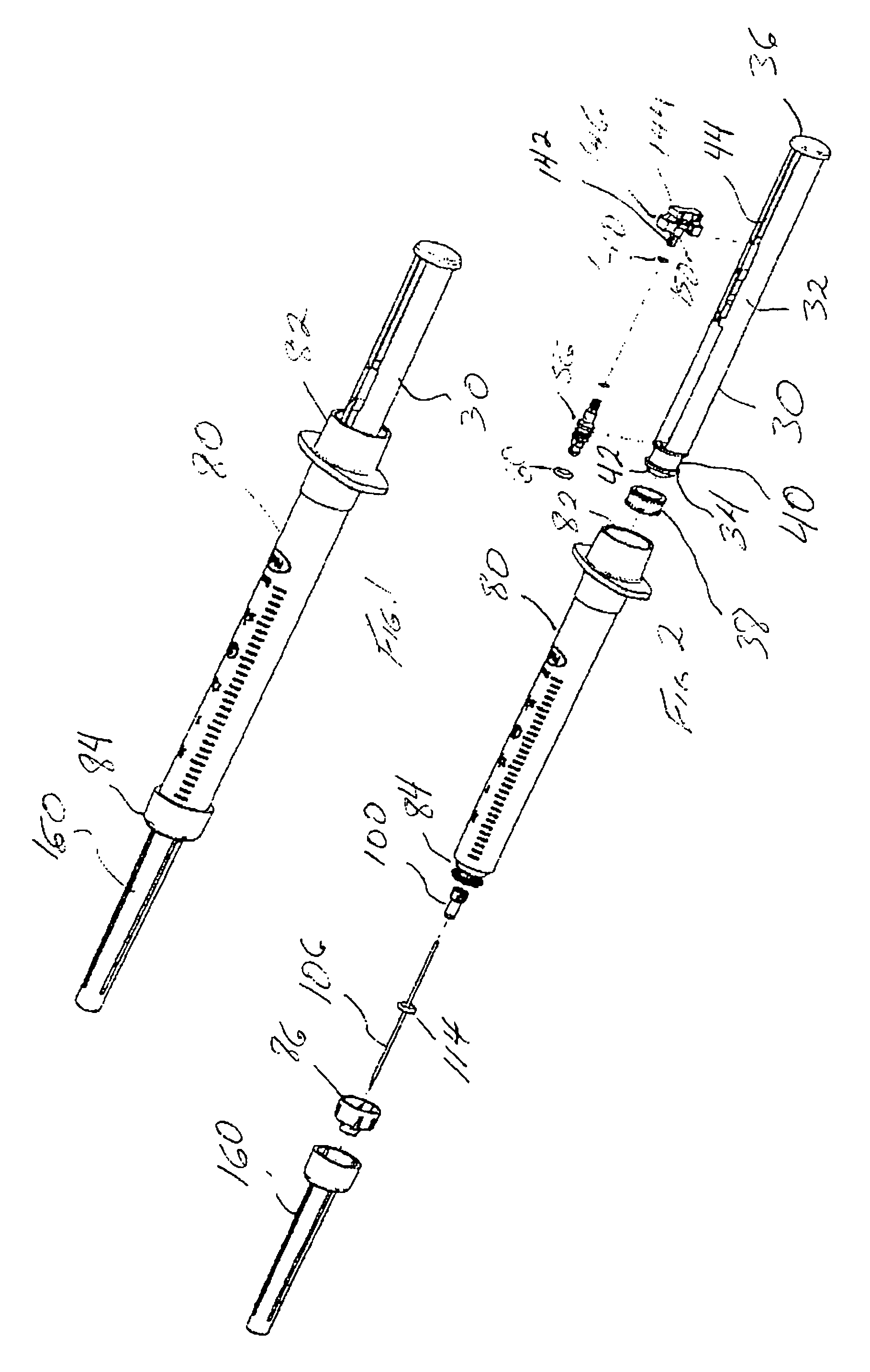

Fluid Collection Device with Retractable Needle and Safety Sampling Access Needle Adapter

InactiveUS20070083166A1Surgical needlesVaccination/ovulation diagnosticsActuatorBiomedical engineering

A retractable needle fluid transfer device is provided. The device includes a manually operable actuator for affecting retraction. Upon depressing the actuator, a spring displaces the needle rearwardly so that the contaminated needle is enclosed, thereby preventing inadvertent needle sticks. The device includes forward and rearward stops for impeding displacement of the needle after the needle is retracted. A seal prevents contaminants from entering the device after the needle is retracted. A safety sampling access port adapter for obtaining fluid samples from a fluid line is also provided. The sampling adapter includes a first end configured to cooperate with an access port attached to the fluid line. The sampling adapter further includes a collapsible socket configured to cooperate with a fluid container such as a vacuum tube. A needle assembly disposed within the housing of the sampling adapter is operable to pierce the seal on the fluid container. After use, the socket is collapsed to prevent contact with the contaminated needle.

Owner:MDC INVESTMENT HLDG

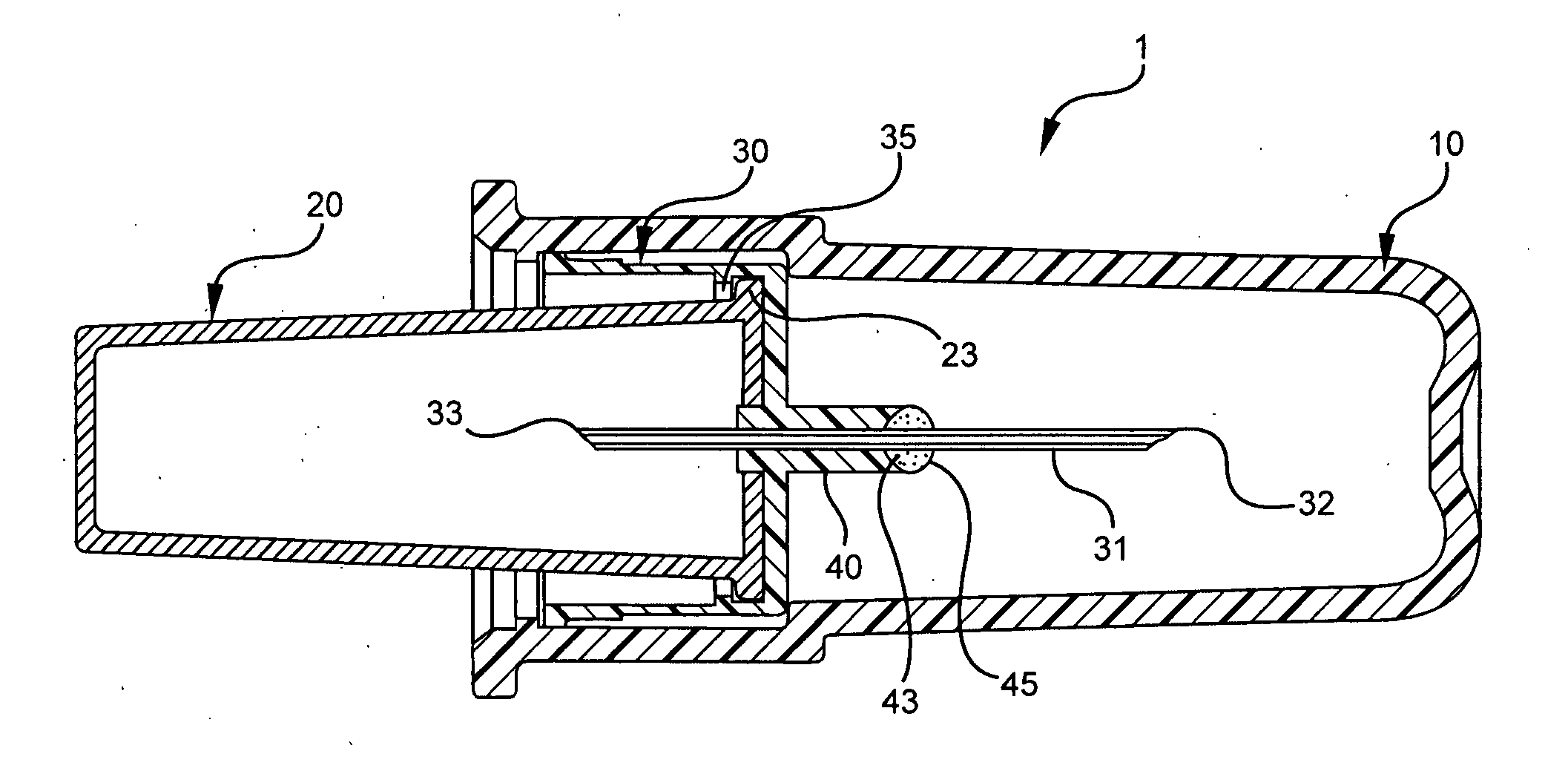

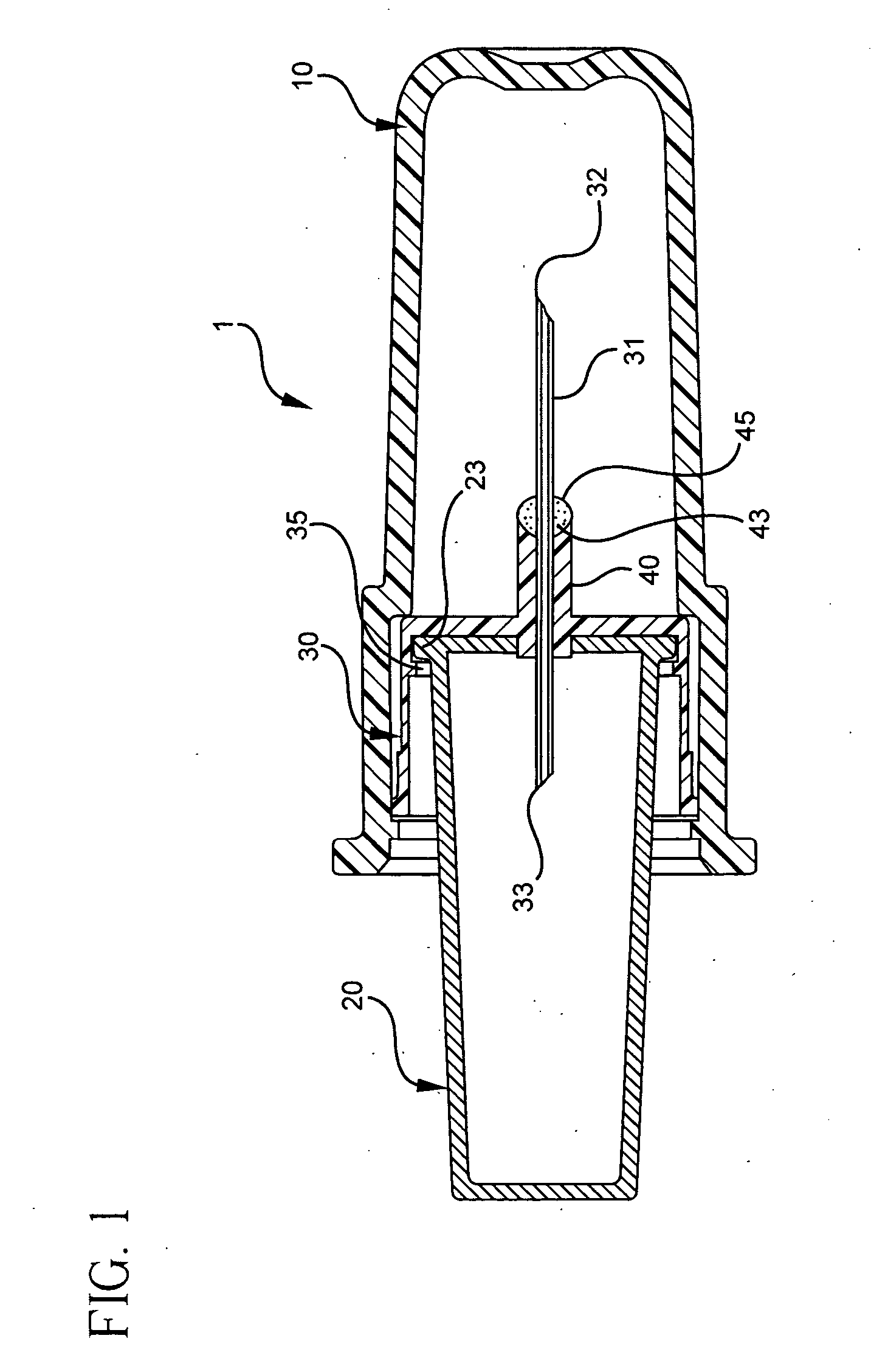

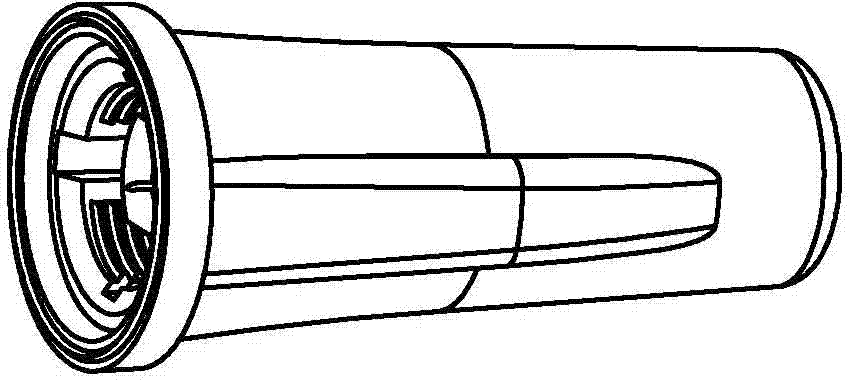

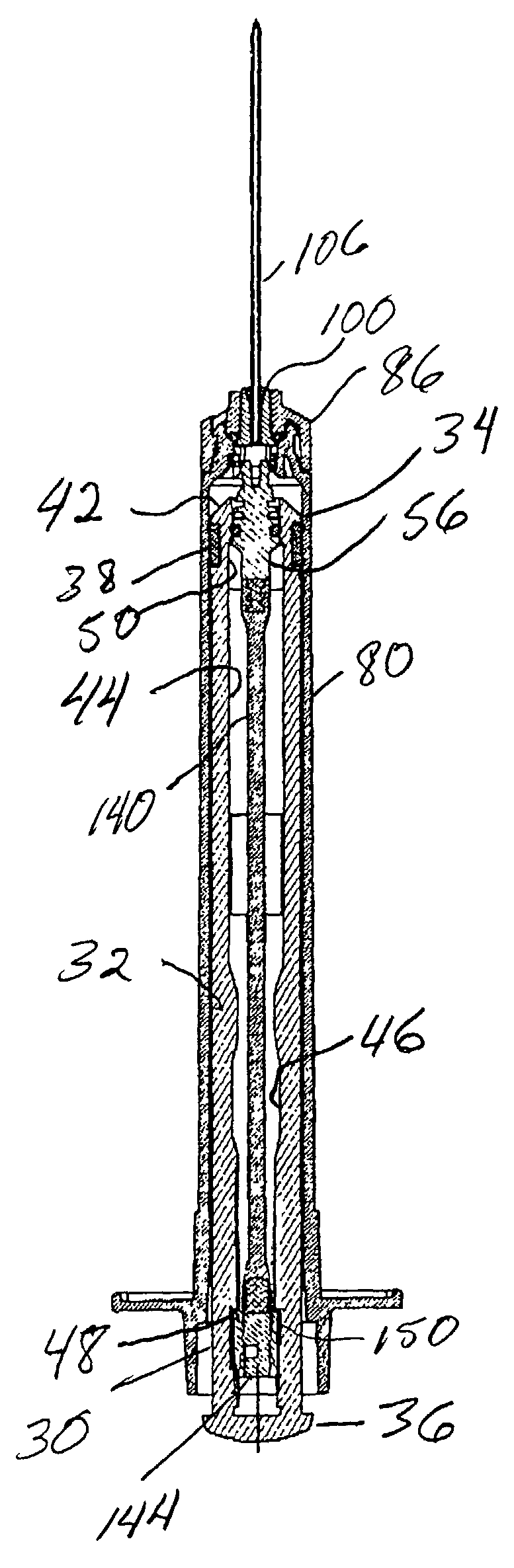

Syringe with retractable needle assembly

InactiveUS7494479B2Enhance syringe operationEasy to operateInfusion syringesInfusion needlesSyringe needleGun barrel

A hypodermic syringe employing a plunger slidably disposed within a barrel. The plunger has a mounting hole extending through the seal end thereof to receive a mandrel. The mandrel has a flexible flange to be releasably engaged with the plunger. A spring element withdraws the mandrel into a cavity within the plunger upon full extension of the plunger within the barrel. The barrel includes a hub retainer at the forward end thereof and a needle hub retained therein the mandrel includes barbed tines with surfaces having axes of the conical surfaces that are displaced from one another such that movement of the tines toward one another also brings the axes closer. A catch associated with the back end of the spring element coupled with the mandrel at the other end cooperates with shoulders on smooth surfaces within the cavities to retain tension within the bungee. The hub retainer and the needle hub cooperate to insure that the needle hub is constrained to limited motion such that the mandrel will fully engage the needle hub.

Owner:HYPOGUARD USA

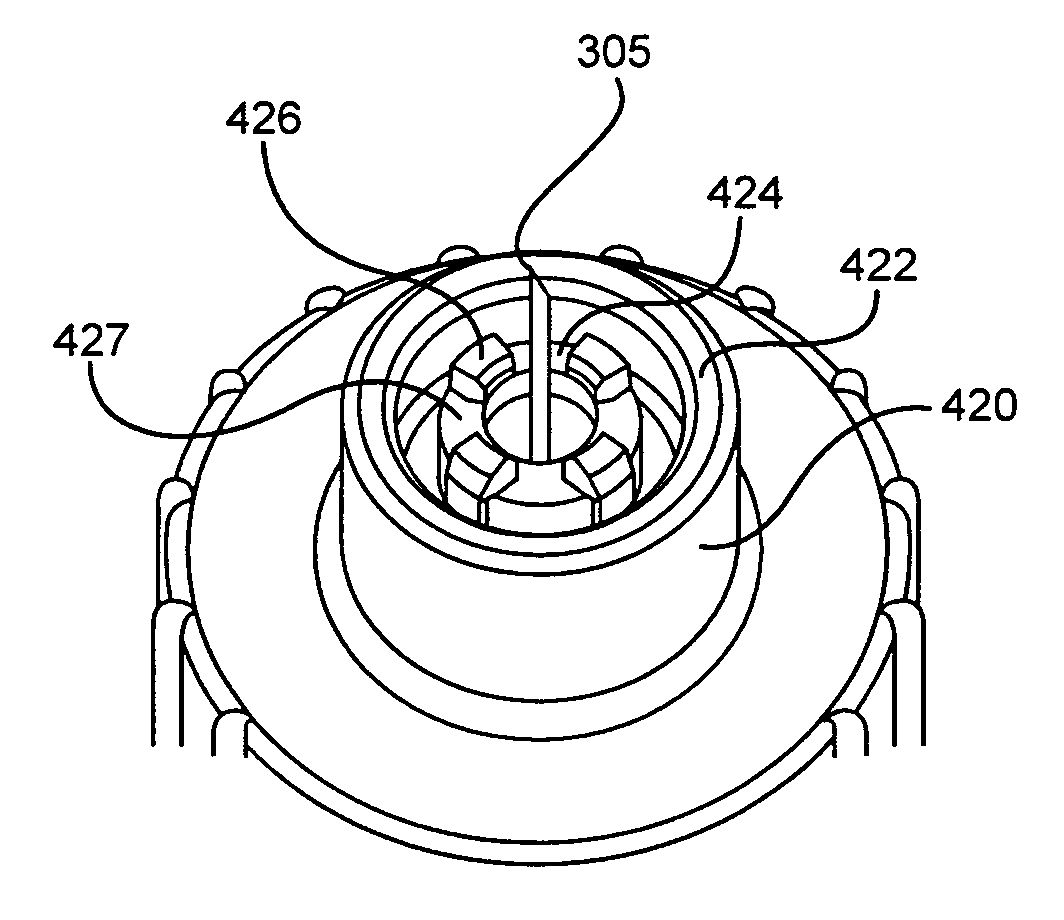

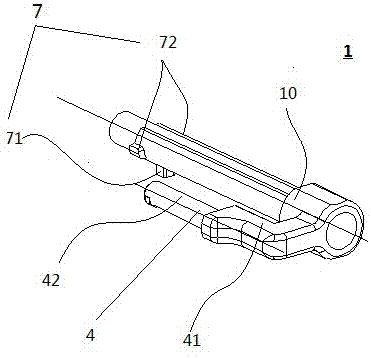

Placement manipulator and attachment for positioning a puncture instrument

ActiveUS20180103979A1Expand coverageAdjustable coverageSurgical needlesVaccination/ovulation diagnosticsManipulatorNeedle holder

An apparatus (51) includes a needle placement manipulator (1) and an attachment (52) for the manipulator. The manipulator includes a needle holder and a rotary mechanism. The rotary mechanism (3, 4) has a remote center of motion (RCM: 11) and is configured to position a needle holder (5) such that the axis of the needle holder traces a conical region of coverage (108), the conical region of coverage having the apex thereof at the RCM and the base thereof in a direction towards a subject of needle placement (14). The attachment supports the guide mechanism and is configured to be mounted onto the subject of needle placement. The attachment includes a guide portion (183c) configured to change an inclination of the rotary mechanism with respect to the subject of needle placement such that the axis of the needle holder intersects an insertion target (14) located outside of the conical region of coverage.

Owner:CANON USA +1

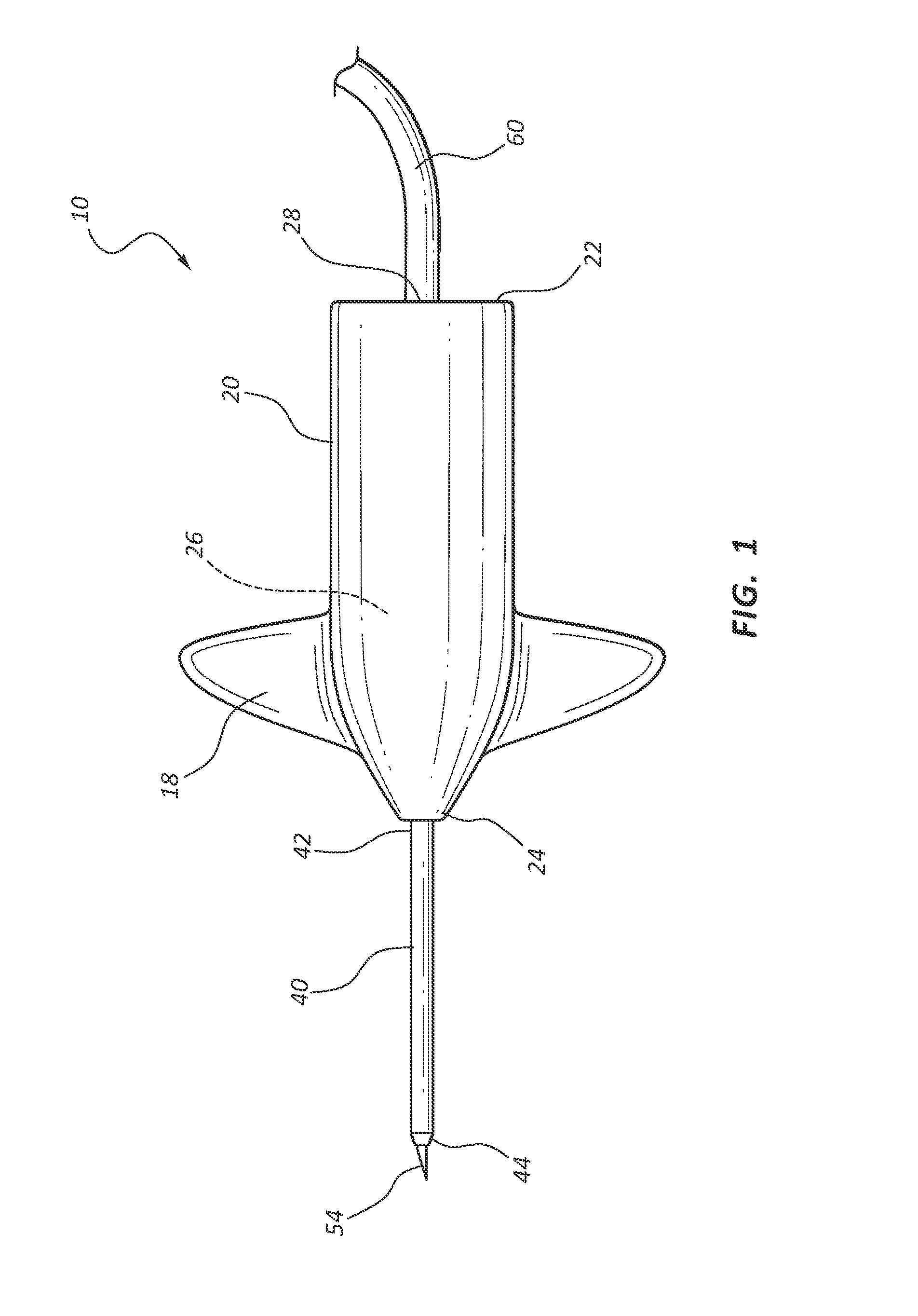

Needle Hub for Over-the-Needle Catheter

The present disclosure is directed to an over-the-needle (OTN) catheter assembly having an improved needle hub. The OTN catheter assembly includes a catheter defining a lumen extending from a proximal end to a distal end. A needle having a proximal end and a distal end is configured within the lumen of the catheter. The needle hub is configured with the proximal end of the needle and includes a bore defined therethrough. The needle hub also includes at least one cavity extending from the bore to an exterior surface of the needle hub. Thus, the needle extends at least partially through the bore of the needle hub such that the needle is exposed via the cavity from the exterior surface of the needle hub so as to engage a nerve stimulator apparatus.

Owner:AVENT INC

Retention needle tube assembly

ActiveCN102000370ARealize inclusionAvoiding medical issues such as stab woundsGuide needlesInfusion needlesEngineeringCatheter

The invention relates to an instrument for introducing medium into bodies, particularly a retention needle tube assembly which comprises a connecting component, a retractable protective sleeve, a needle stand and a needle tube. The retention needle tube assembly is structurally characterized by also comprising an extension spring, wherein the retractable protective sleeve is enclosed in the innercavity of the needle stand after being compressed; and the connecting component, is connected with the needle stand through a buckling device. The invention has the technical characteristics that theextension spring is arranged in the retention pin with the retractable protective sleeve; and in the piercing process, the needle stand and the retractable protective sleeve are unfolded under the action of the spring, the needle tube retreats from the guide tube along with the needle stand and finally leaves the guide tube assembly to enter the retractable protective sleeve, and meanwhile, the connecting component, is held by a hand so as to feed the guide tube into deep inside vessels. In the piercing process, the needle point is no longer exposed outside the port of the guide tube, so thatthe needle point can not hurt the vessel when feeding the tube, thereby preventing angitis from generation. As for the medical care operators, the operation success rate is high; and as for the patients, injury and pain from piercing again can be prevented.

Owner:FUJIAN BESTWAY MEDICAL POLYMER CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com