On-line detection technology of reversion defect of disposable injection needle

A technology for injection needles and detection technology, which is applied in the field of online detection technology for reverse-installation defect detection of disposable injection needles. It can solve problems such as heavy workload, inability to adapt to large-scale production, and large human eye damage, and meet the needs of industrial online production. , Accurate needle anti-installation defect detection, avoiding difficult effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

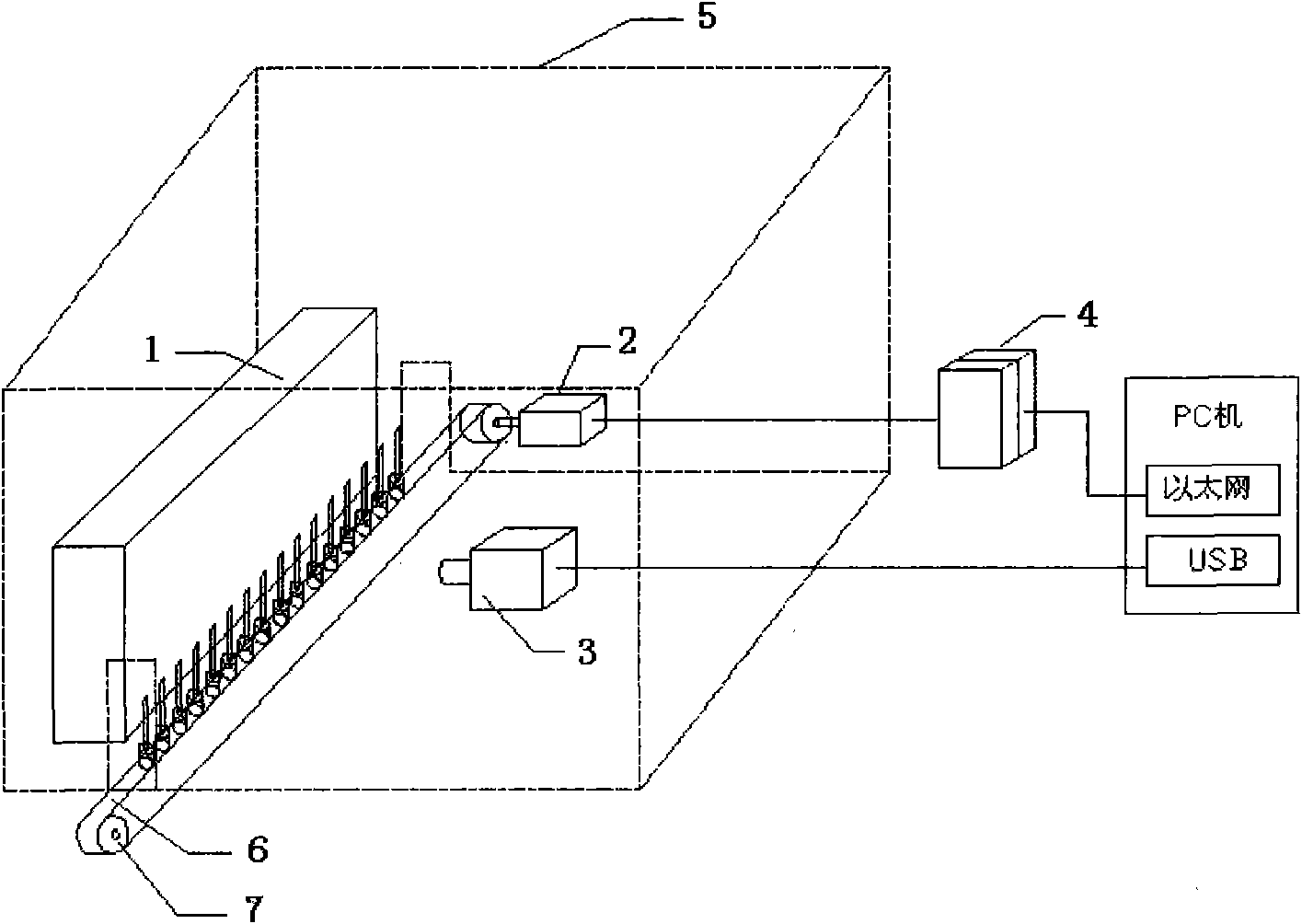

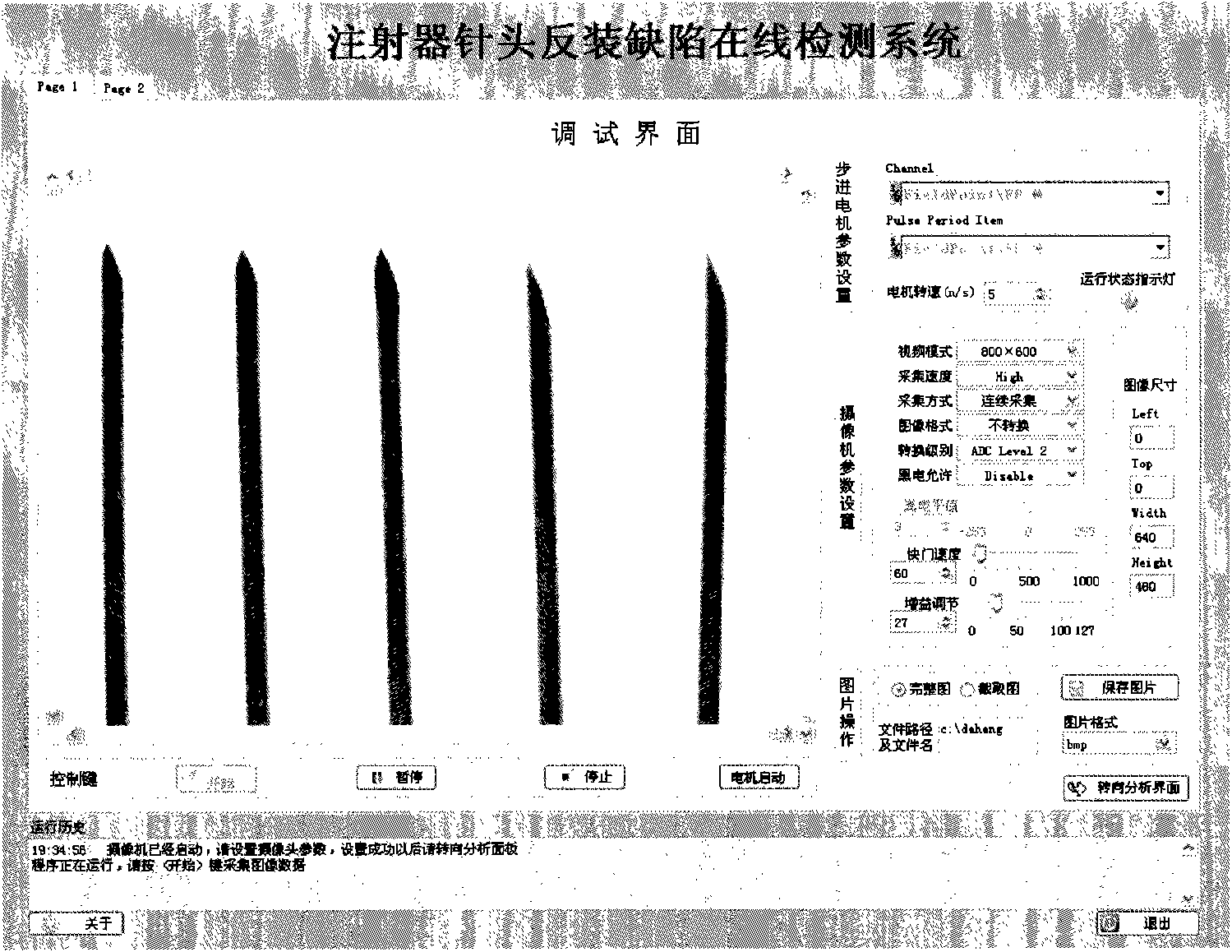

[0016] The device of the present invention includes: lighting device, stepping motor and driver, motor control module [c] FP-PWM-520, CCD camera, lens, PC, conveyor belt and pulley, etc.

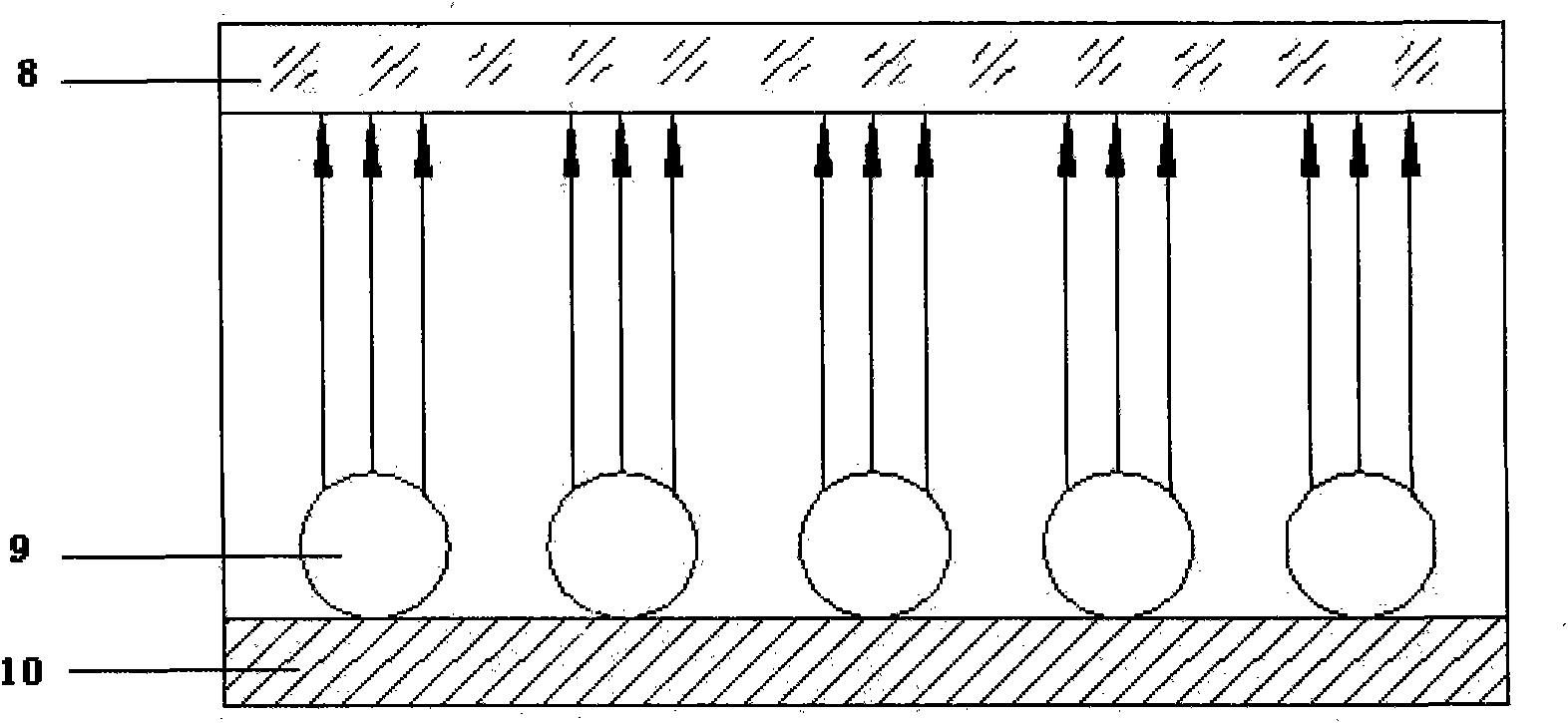

[0017] The existing production process of injection needles is as follows: firstly, the injection needle base is installed on the needle row, and then the injection needle is inserted into the injection needle base by the automatic installation device, and the entire needle is discharged to the automatic conveyor belt on the needle production line, and finally brushed. glue, drying and other processes. In the process of automatic installation of the injection needle to the injection needle base, the phenomenon that the needle tip is partially inserted into the base often occurs, that is, the reverse installation phenomenon mentioned in the present invention. Existing production enterprises arrange a full-time person for manual visual inspection at this station, which is time-consuming and la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com