Needle base assembly rotating and retracting structure of safety injector

一种安全注射器、针座的技术,应用在针座组件自转回缩结构领域,能够解决注射器质量管制失败、医护人员及清洁人员刺伤、针座内缩或漏液等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

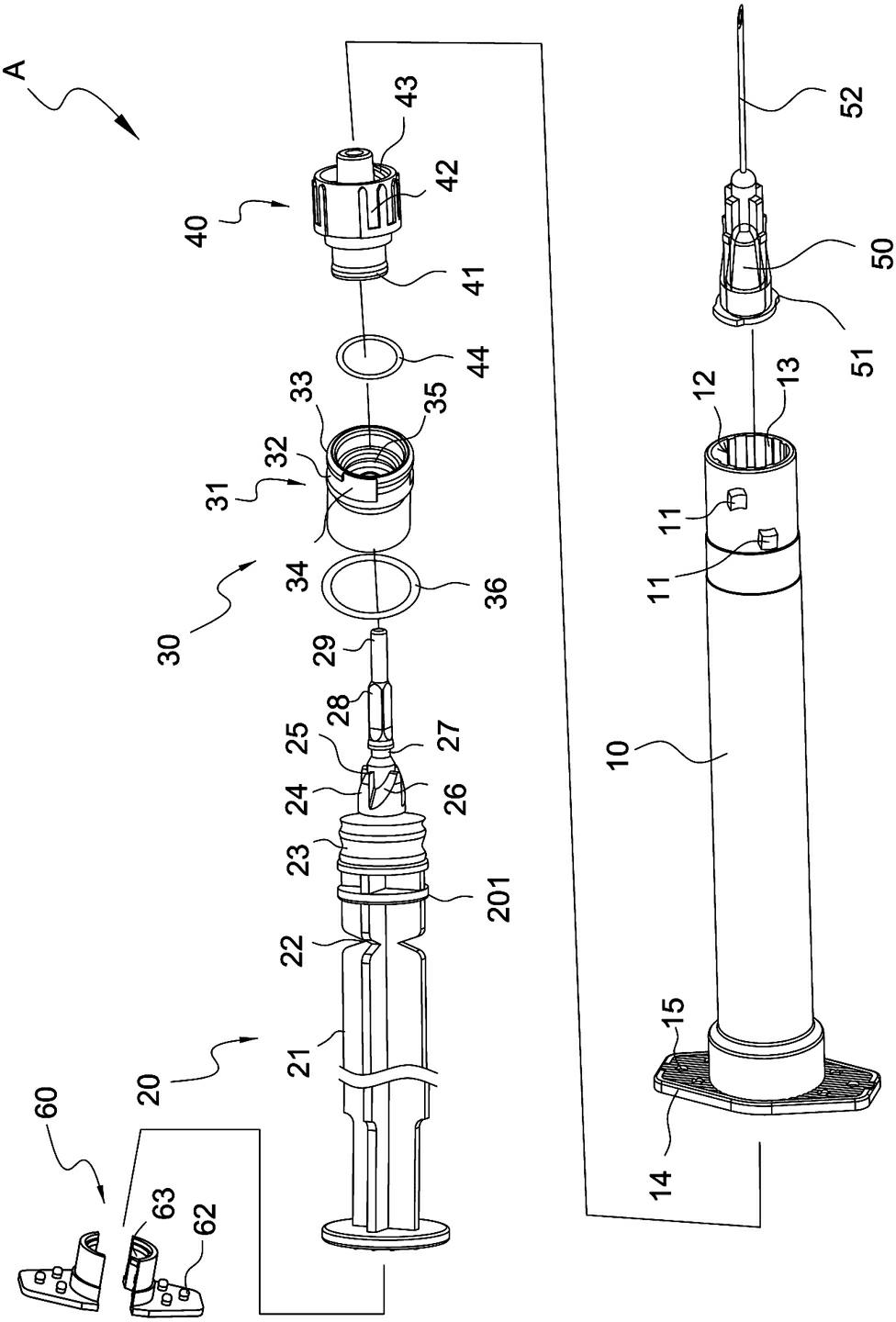

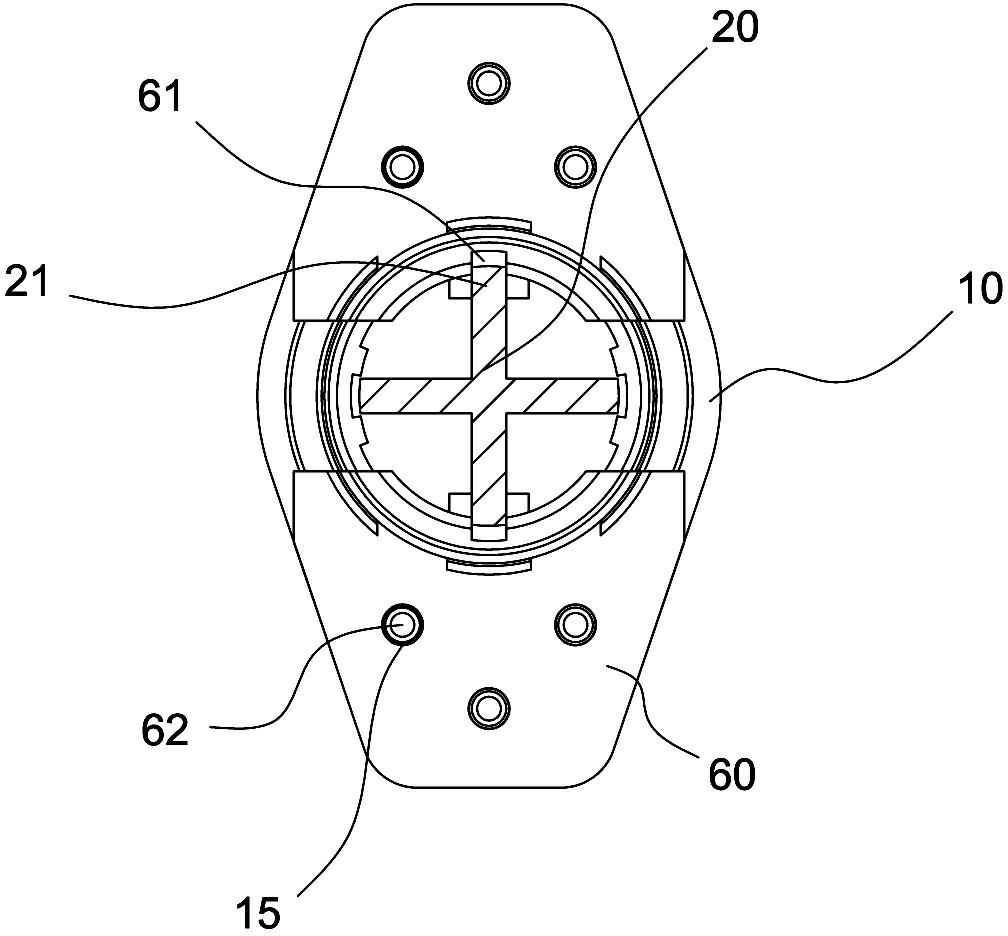

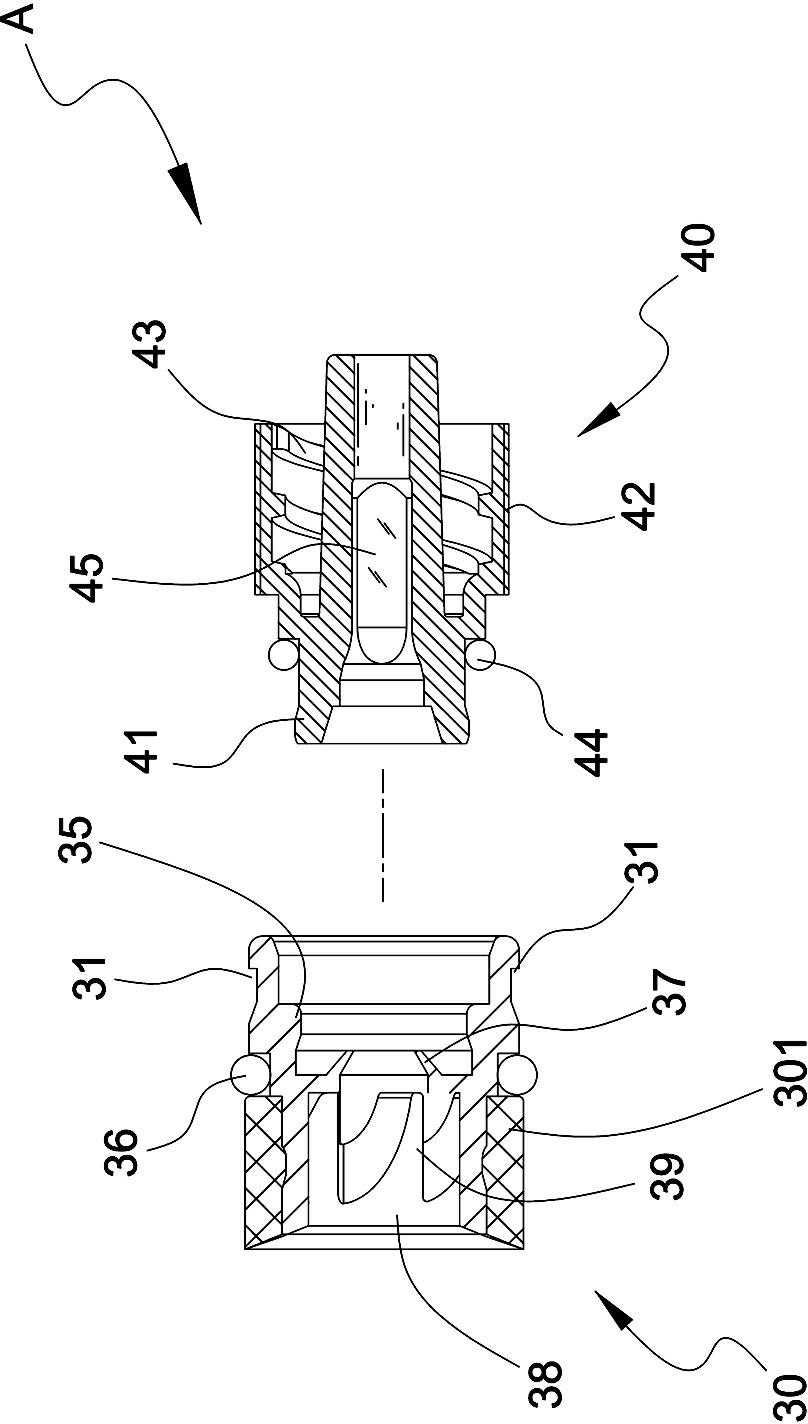

[0026] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

[0027] Description of main component symbols:

[0028] Needle seat group (A), cylinder body (10), stopper (11), chamber (12), rotation limiting piece (13), terminal end (14), group hole (15), push rod (20) , ribs (21), breaks (22), rubber plugs (23), dialing parts (24), dialing ends (25), letting grooves (26), buckle parts (27), non-circular Section (28), leading post (29), ring retaining edge (201), ring rotating piece (30), L groove (31), closed end (32), stopper (33), open end (34), Pivot part (35), sealing ring (36), embedded buckle part (37), rotation receiving part (38), guide inclined surface (39), assembly part (301), rotation limiting part (40), pivot part (41), limited rotation seat (42), assembly part (43), sealing ring (44), non-circular groove (45), injection piece (50), final assembly end (51), injection needle (52) , track clamping plate (60), limited turn g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com