Puncture needle assembly machine

A technology of assembling machine and puncture needle, which is applied in the direction of assembling machine, metal processing, metal processing equipment, etc., can solve the problem of not being able to fully realize fully automatic assembly, and achieve the effect of stable placement and improved separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

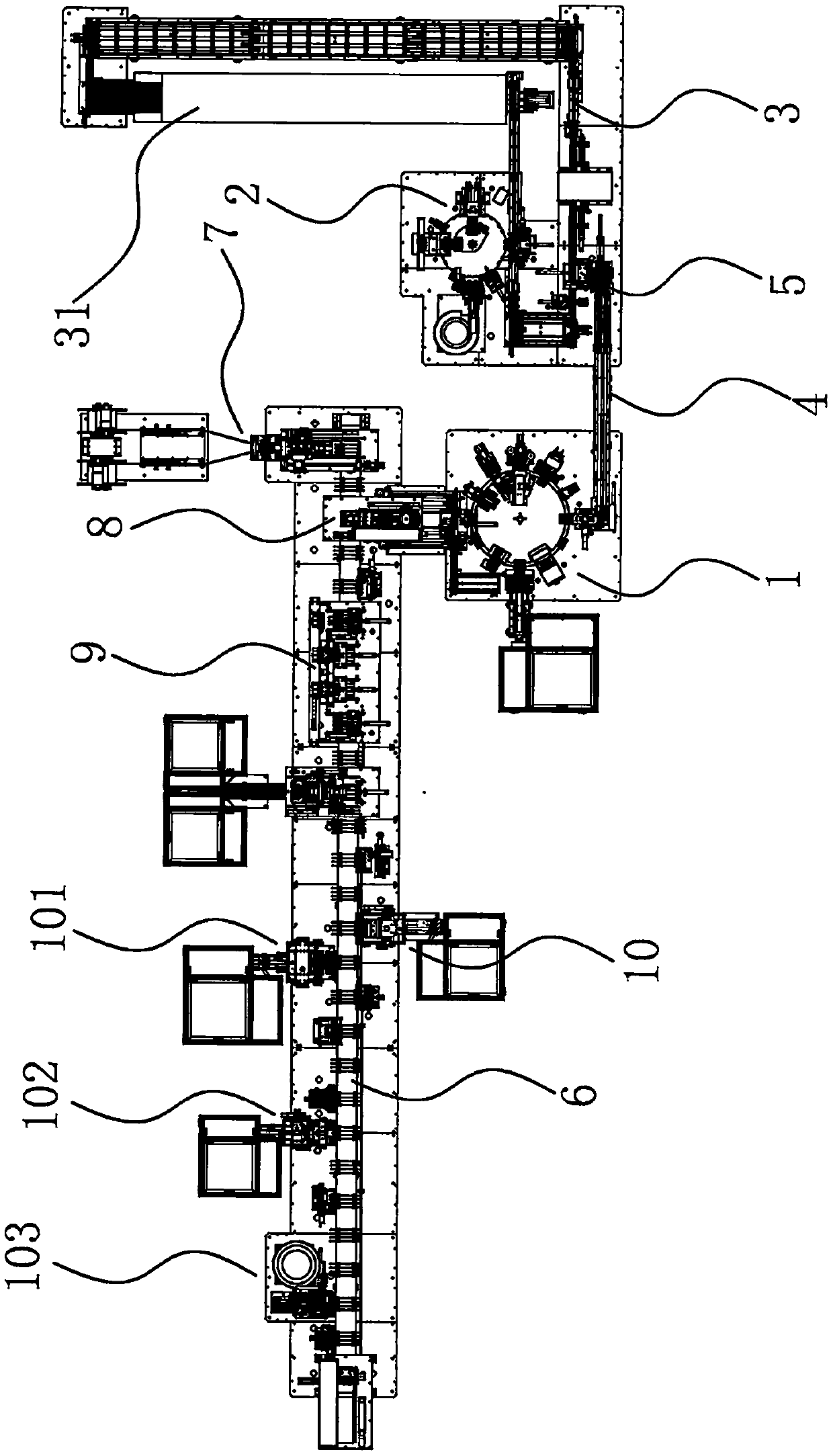

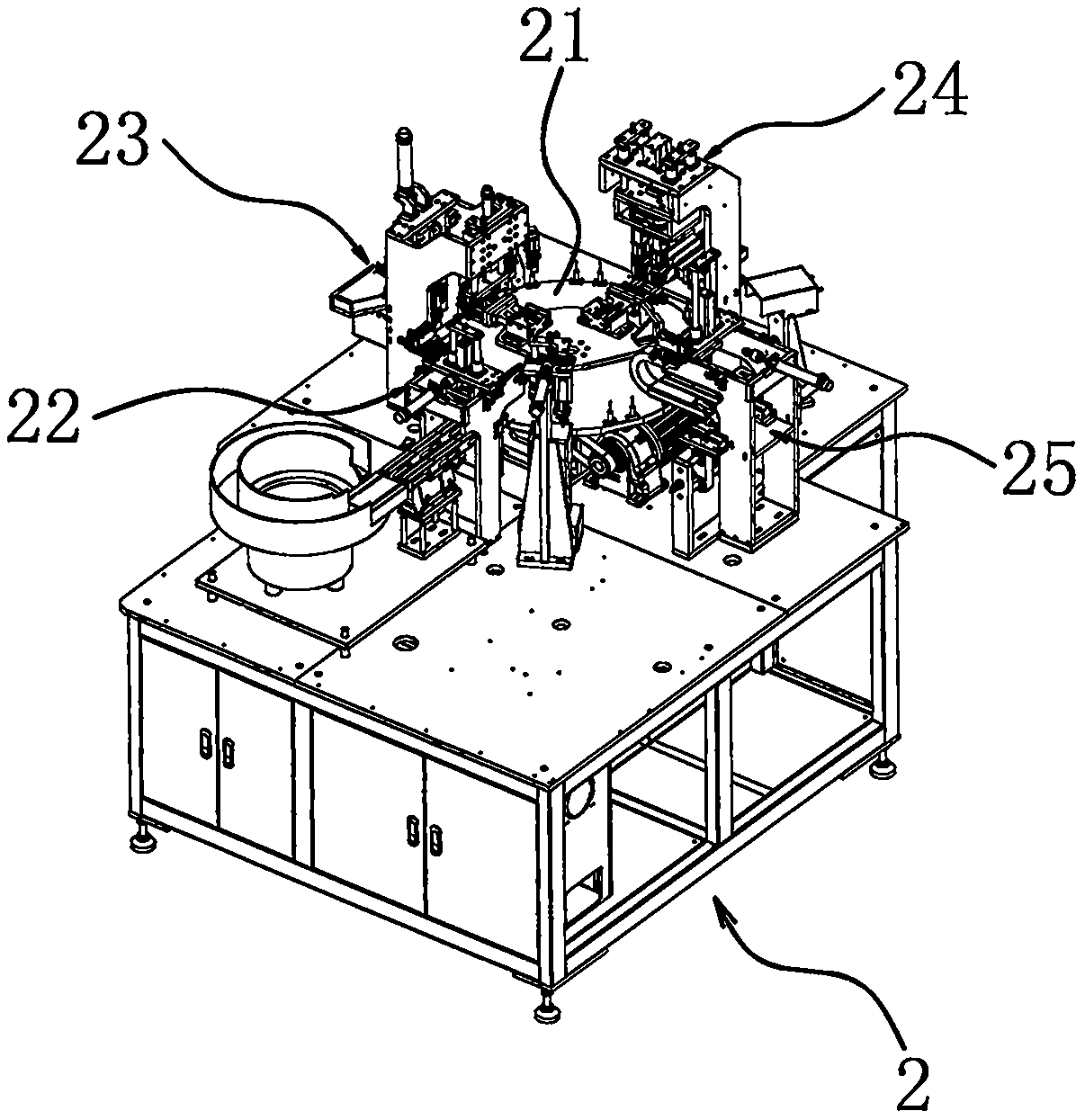

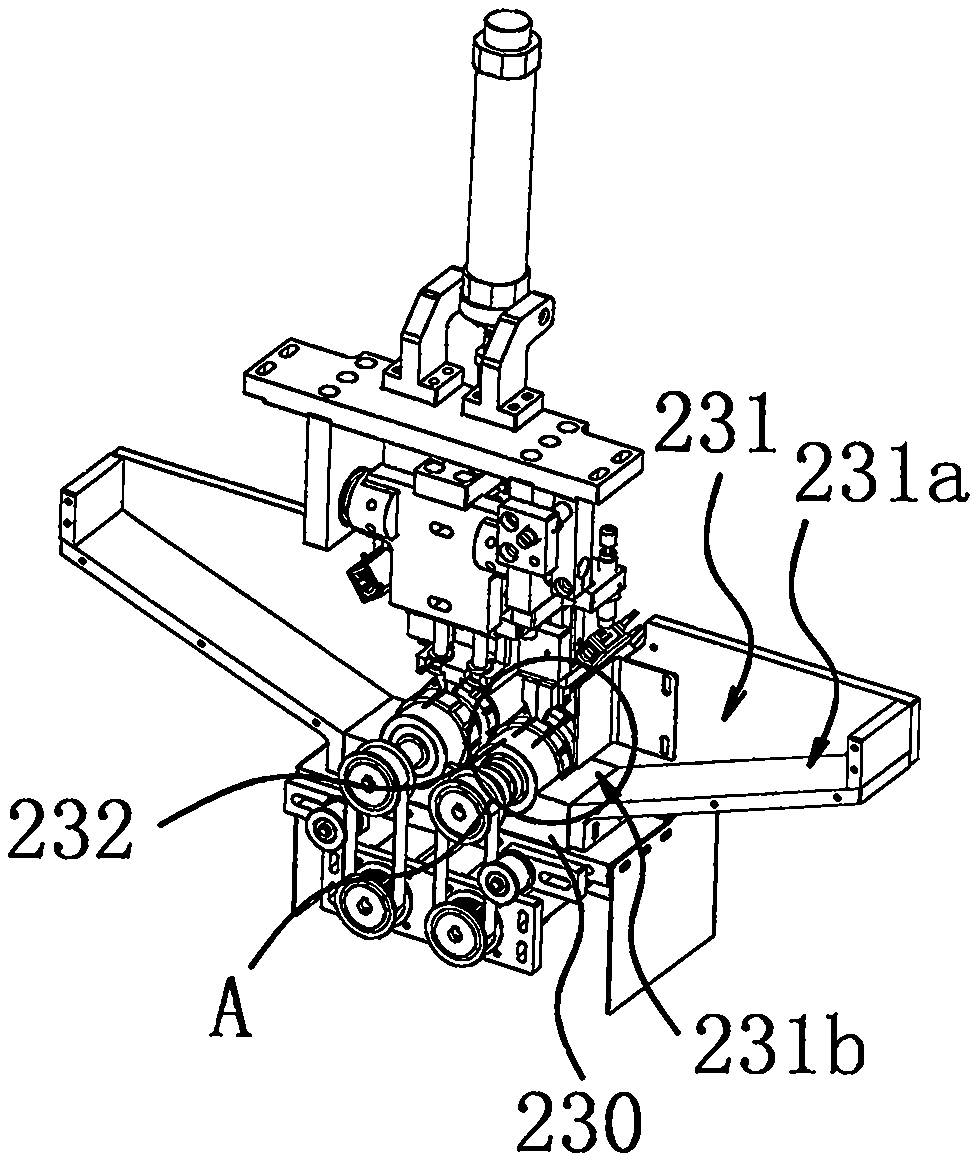

[0039] Such as figure 1 , figure 2 with Figure 7As shown, the puncture needle assembly machine includes a butterfly wing assembly mechanism 1, a needle tube assembly assembly mechanism 2, a circular conveying line 3, a circular conveying line 2 4, a needle tube assembly transfer mechanism 5, a catheter conveying line 6, and a catheter conveying line 6 Conduit feeding mechanism 7, butterfly wing connecting mechanism 8, siliconization and blowing mechanism 9, sliding sleeve feeding mechanism 10, hemostatic clip feeding mechanism 101, female needle base feeding mechanism 102 and female Needle base cover feeding mechanism 103, butterfly wing assembly mechanism 1 includes turntable 2 11, butterfly wing feeding component 12, butte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com