Novel piston rod mechanism of forging and pressing machinery

A piston rod and forging technology, which is applied in the field of forging machinery, can solve the problems of difficult oil supply and short service life of the piston rod, and achieve the effects of smooth oil supply, long service life of the piston rod and less wear of the piston rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

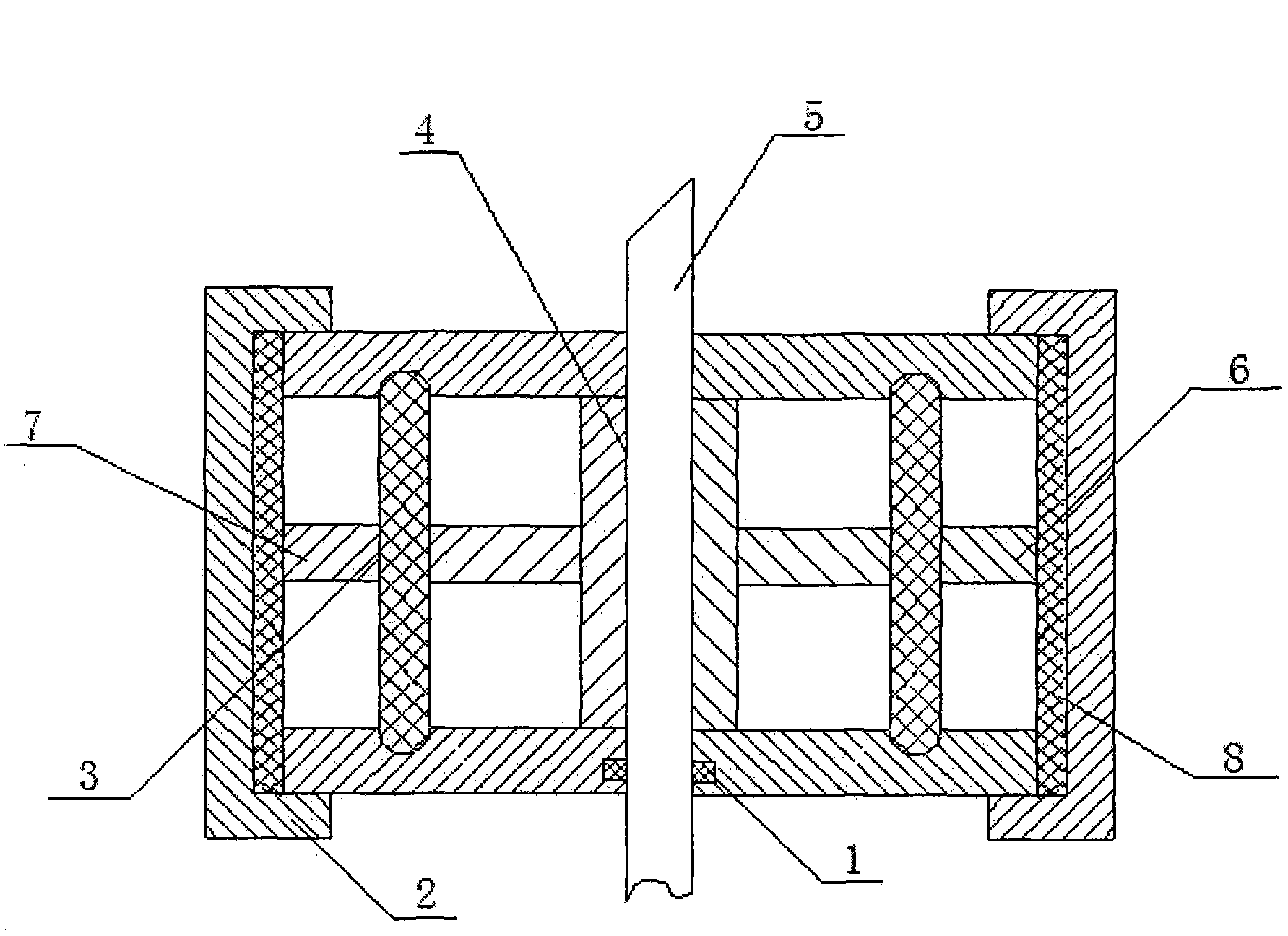

[0009] The piston rod mechanism has a bearing seat (2), and a sealing ring (8) is installed on both sides of the bearing seat (2), and a piston rod (5) is installed in the middle of the bearing seat (2), and the left and right sides of the piston rod (5) An oil supply tank (4) is installed on both sides, an oil seal (1) is arranged on the oil supply tank (4), and a double solid copper sleeve (3) is installed on the outside of the oil supply tank (4) and the inside of the sealing ring (8), The double-solid copper sleeve (3) is installed on the top of the bearing seat (2) through its own hole, and an oil inlet (6) and an oil return port (7) are arranged on the bearing seat (2) and the double-solid copper sleeve (3). ), so that the lubricating oil enters the double-solid copper sleeve (3) from the oil inlet (6) and is stored in the oil supply tank (4). The oil port (7) flows out to form a good circulation lubrication.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com