Oil or grease coating machine

A coating machine and grease technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of the thickness of the grease, the influence of the oil output, and the large volume change, so as to improve the mobility and accuracy, Control the oil output time to ensure the effect of the oil output area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

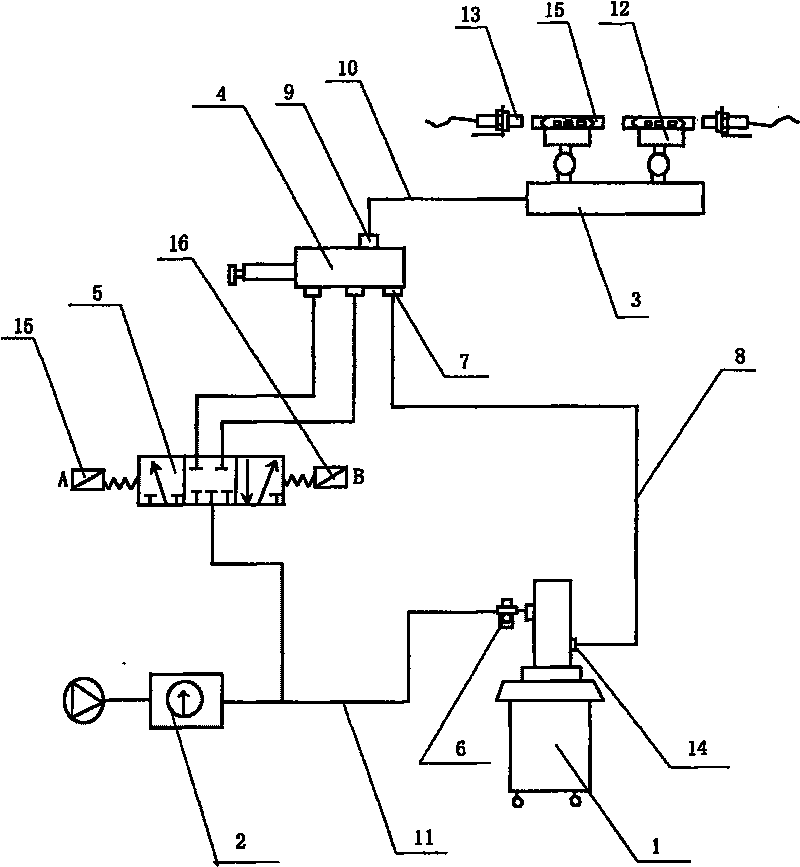

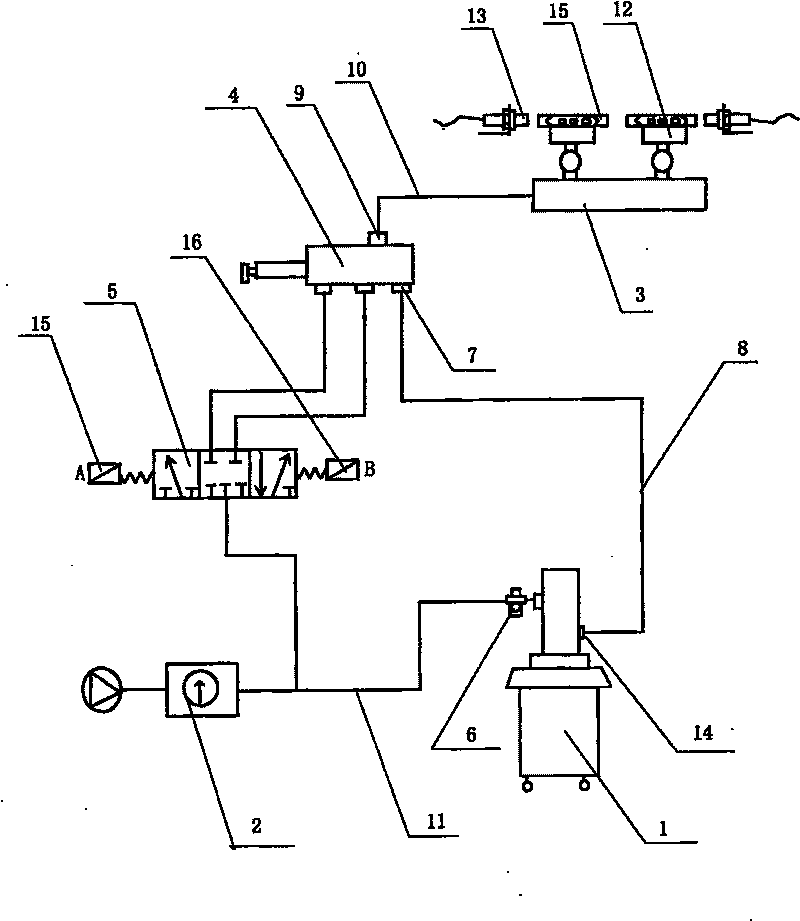

[0010] exist figure 1 Among them, the present invention is a kind of grease spreader, and it comprises butter filling machine 1, oil-water separator 2, grease spreader fixture 3, quantitative valve 4, electromagnetic valve 5 and monitoring device, quantitative valve 4 is FA101 quantitative valve 4, Its oil output is 0.1ml-1ml, the solenoid valve 5 is a three-position five-way solenoid valve, the butter filling machine 1 is a high-pressure pneumatic butter filling machine 1, and the output end of the oil-water separator 2 is connected to the butter filling machine 1. The decompression valve 6 is connected, the oil outlet 14 of the butter filling machine 1 is connected with the oil inlet 7 of the quantitative valve 4 through the high-pressure oil pipe I 8, and the oil outlet 1 9 of the quantitative valve 4 is connected with the grease fixture 3 through a high-pressure The oil pipe II 10 is connected, and a pipeline 11 is connected between the oil-water separator 2 and the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com