Intelligent hydraulic station

A hydraulic station, intelligent technology, applied in the direction of engine components, engine lubrication, lubricating parts, etc., can solve the problems of high pressure lubricating oil temperature rise, untimely lubricating oil return, large inertial force of lubricating oil, etc., to achieve oil supply Unobstructed, reliable, and loss-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

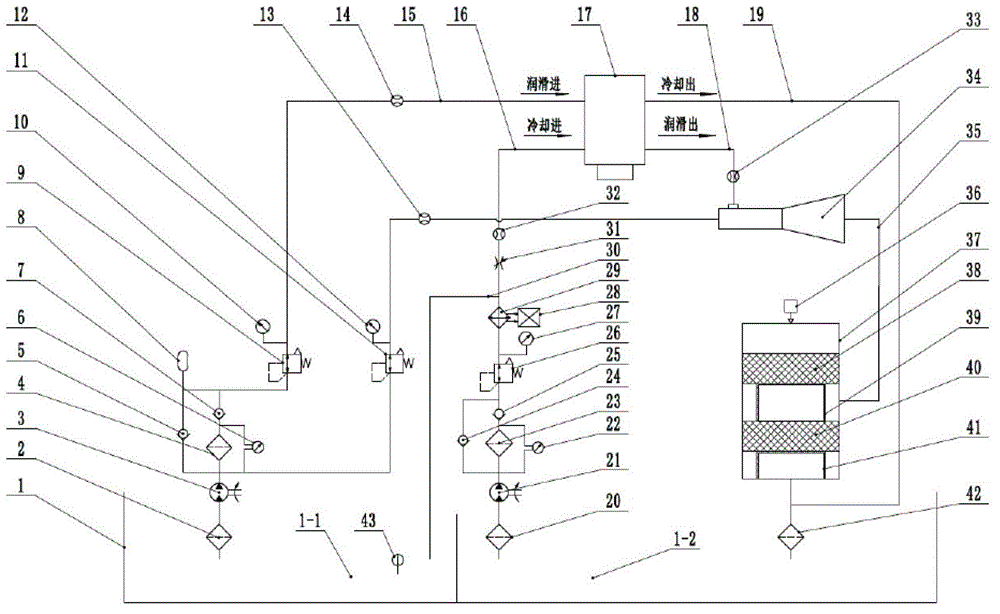

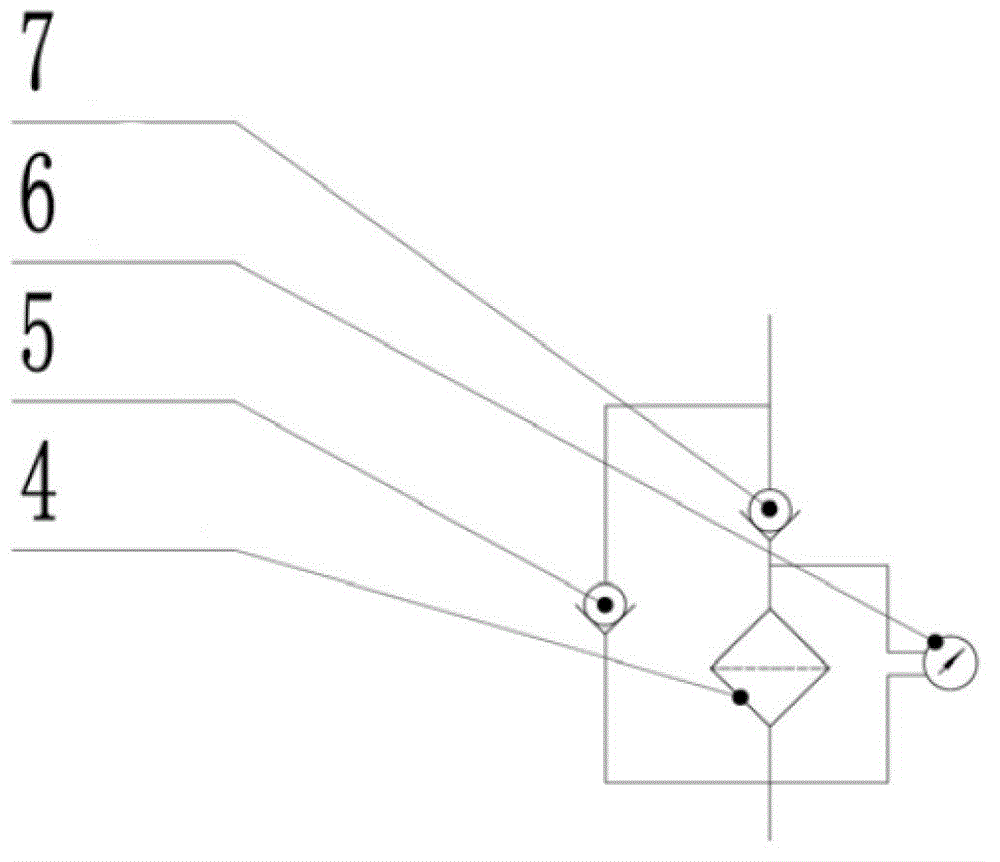

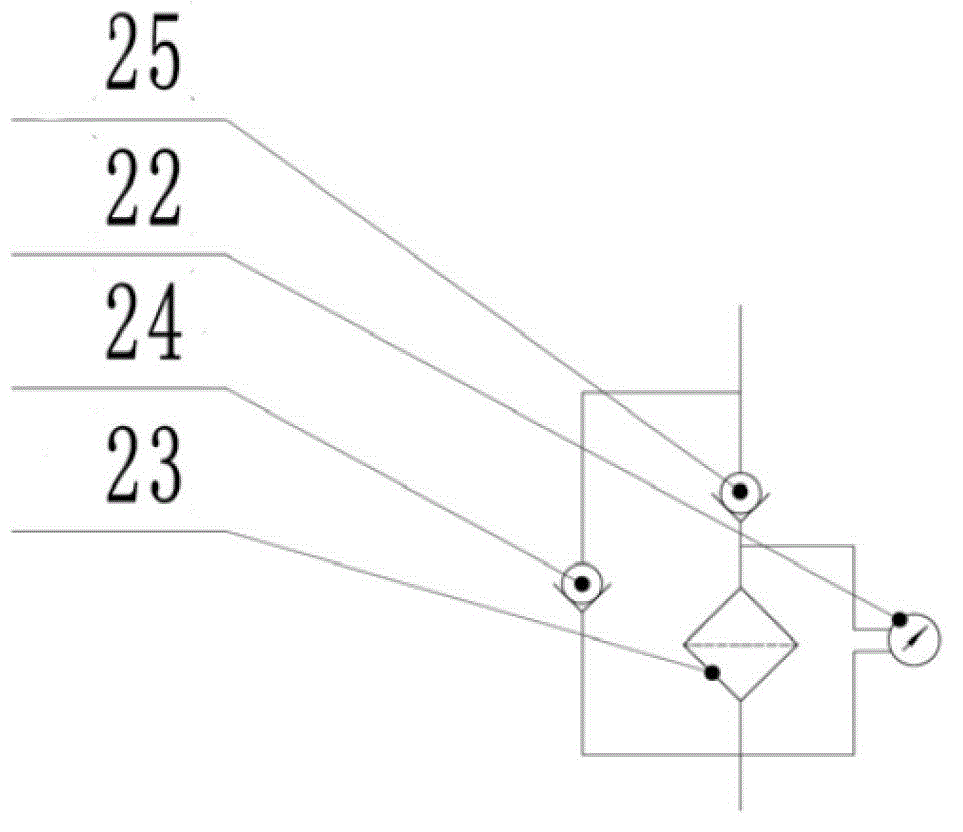

[0022] Example: such as figure 1 As shown, the lubricating oil inlet subsystem consists of constant temperature oil zone 1-1, oil suction filter 1-2, hydraulic pump 3, precision filter assembly 1, accumulator 8, overflow pressure reducing valve 9, pressure gauge 10 , flow meter one 14 and lubricating oil inlet pipeline 15, wherein precision filter assembly one includes precision filter one 4, one-way valve one 5, differential pressure sensor one 6, one-way valve two 7; cooling oil inlet subsystem Including hot oil zone 1-2, oil suction filter 220, hydraulic pump 21, precision filter assembly 2, overflow pressure reducing valve 26, pressure gauge 27, chiller 28, heat exchanger 29, pipeline 1 30. An adjustable throttle valve 31, a flow meter 2 32 and a cooling oil inlet pipeline 16, wherein the precision filter component 2 includes a differential pressure sensor 22, a precision filter 23, a one-way valve three 24 and a one-way valve four 25. The lubricating oil return subsys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com