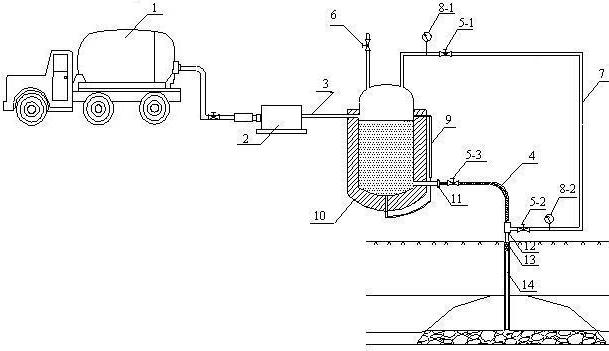

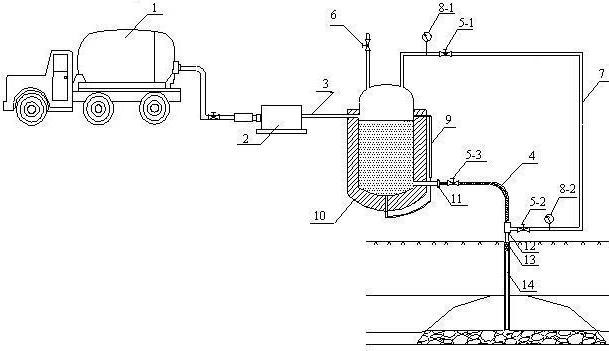

Ground direct injection type liquid nitrogen fire preventing and extinguishing system

A fire prevention and ground technology, applied in fire prevention, dust prevention, fire rescue, etc., can solve the problems of poor cooling effect, long fire extinguishing cycle, small coverage, etc., and achieve high perfusion efficiency, high fire extinguishing efficiency, and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] exist figure 1 Among them, the outlet of the liquid nitrogen tank truck 1 is connected to the inlet of the reciprocating cryogenic liquid pump 2 through the cryogenic liquid delivery hose 3, and the outlet of the reciprocating cryogenic liquid pump 2 is connected to the liquid inlet on the upper part of the buffer tank 10 through the cryogenic liquid delivery hose 3 The liquid outlet at the lower part of the buffer tank 10 is connected to the vacuum cryogenic insulation pipe 4 through the vacuum flange 11, and the vacuum cryogenic insulation pipe 4 is connected to the nitrogen injection pipe 14 and the nitrogen delivery pipe 7 through the three-way valve 12. The upper end of the buffer tank 10 An exhaust port is provided, and the exhaust port is connected with a nitrogen delivery pipe 7, and the nitrogen delivery pipe 7 is sequentially connected with a front pressure gauge 8-1, a nitrogen outlet pressure reducing valve 5-1, a rear pressure gauge 8-2 and a terminal decomp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com