A kind of degassing method of diesel engine cooling system

A cooling system, diesel engine technology, applied in the direction of engine cooling, liquid cooling, mechanical equipment, etc., to achieve the effect of avoiding air resistance, meeting high emission and high strengthening intensity, and avoiding loss of coolant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

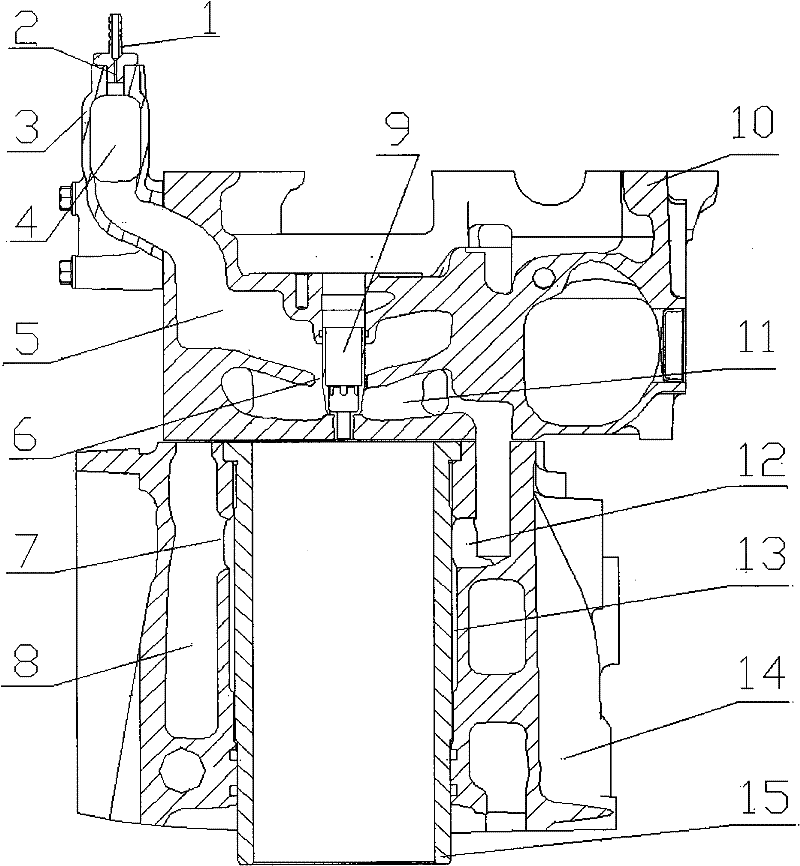

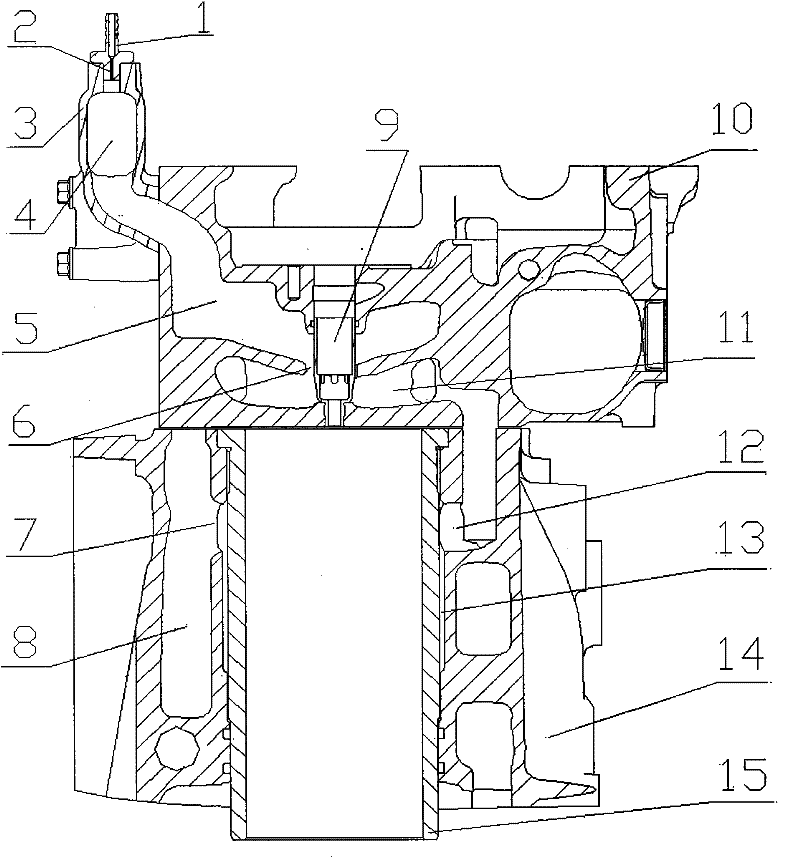

[0021] The method of the present invention is further described below in conjunction with the accompanying drawings, which are used to explain the method of the present invention together with the embodiments of the method of the present invention, and do not constitute a limitation to the method of the present invention.

[0022] Such as figure 1 As shown, the cooling system applicable to the degassing method of the diesel engine cooling system of the present invention includes a degassing joint 1, a water inlet pipe 3, a water jacket 5 on the cylinder head, a water jacket 11 under the cylinder head, a water jacket 13 for the cylinder block, and a water collection for the cylinder block Manager 8. The water inlet main pipe 3 is at the highest position of the cooling system. The degassing joint 1 is installed at the highest position above the water inlet main pipe 3 . The degassing connection 1 has an orifice 2.

[0023] Such as figure 1 As shown, when the diesel engine is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com