Oil well casing gas pressurizing and collecting device

An oil well casing and gas pressurization technology, which is applied in the fields of production fluids, wellbore/well components, and earth-moving drilling, etc., can solve problems such as productivity decline, gas lock, and safety hazards, so as to eliminate energy waste and avoid environmental pollution. , the effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the drawings and embodiments, and the content of the embodiments is not to limit the protection scope of the present invention.

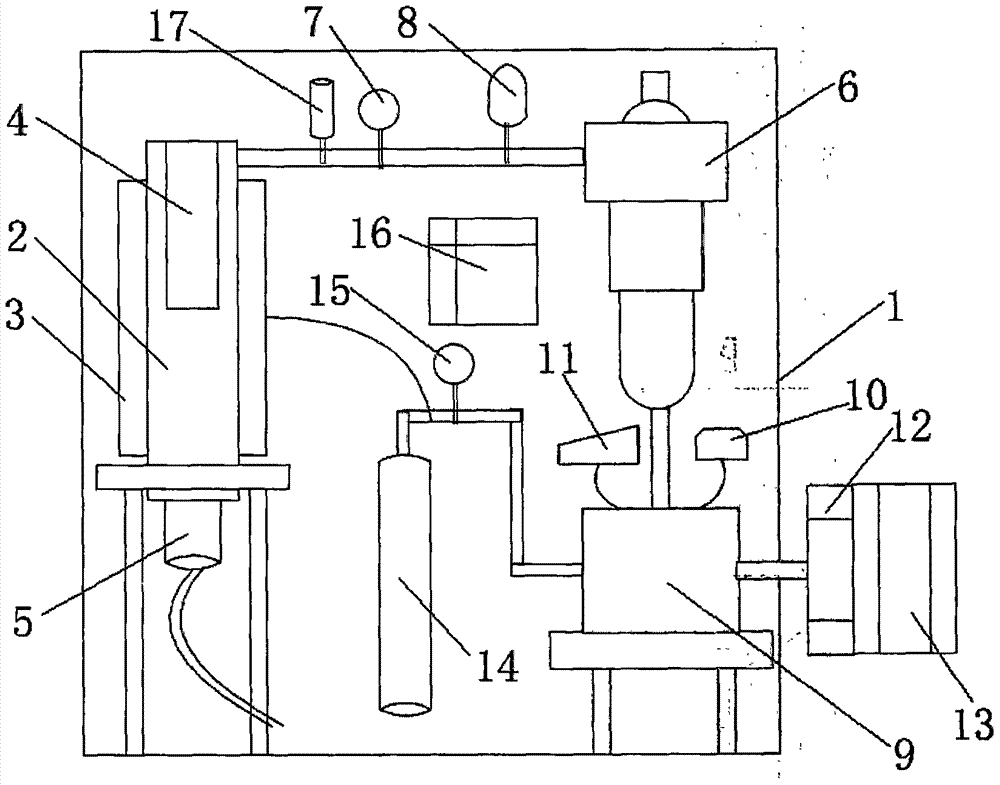

[0018] figure 1 The schematic diagram of the structure of the gas pressurized collection device for oil well casing of the present invention is shown. See figure 1 , The oil well casing gas pressurized collection device of the present invention includes a casing 1. The casing 1 is provided with an automatic gas-liquid separation pipe 2 connected with an oil well casing. The oil and gas from the oil well casing is separated from gas and liquid in the gas-liquid automatic separation pipe 2.

[0019] In the present invention, the gas-liquid automatic separation tube 2 is sheathed with an antifreeze thermostatic diversion tube 3. The antifreeze constant temperature guide tube 3 contains gas introduced from the compressor 9 described later, with a certain temperature, which pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com