Volume pump for liquid

A volumetric and liquid technology, which is applied in the direction of liquid displacement machines, pumps, pumps with flexible working elements, etc., can solve the problem of insufficient pressure drop in the pump chamber, improper operation of the check valve on the suction side, and check valve on the discharge side. The valve is not working properly (the valve core is not displaced to the open valve position, etc., to achieve the effect of good pump function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

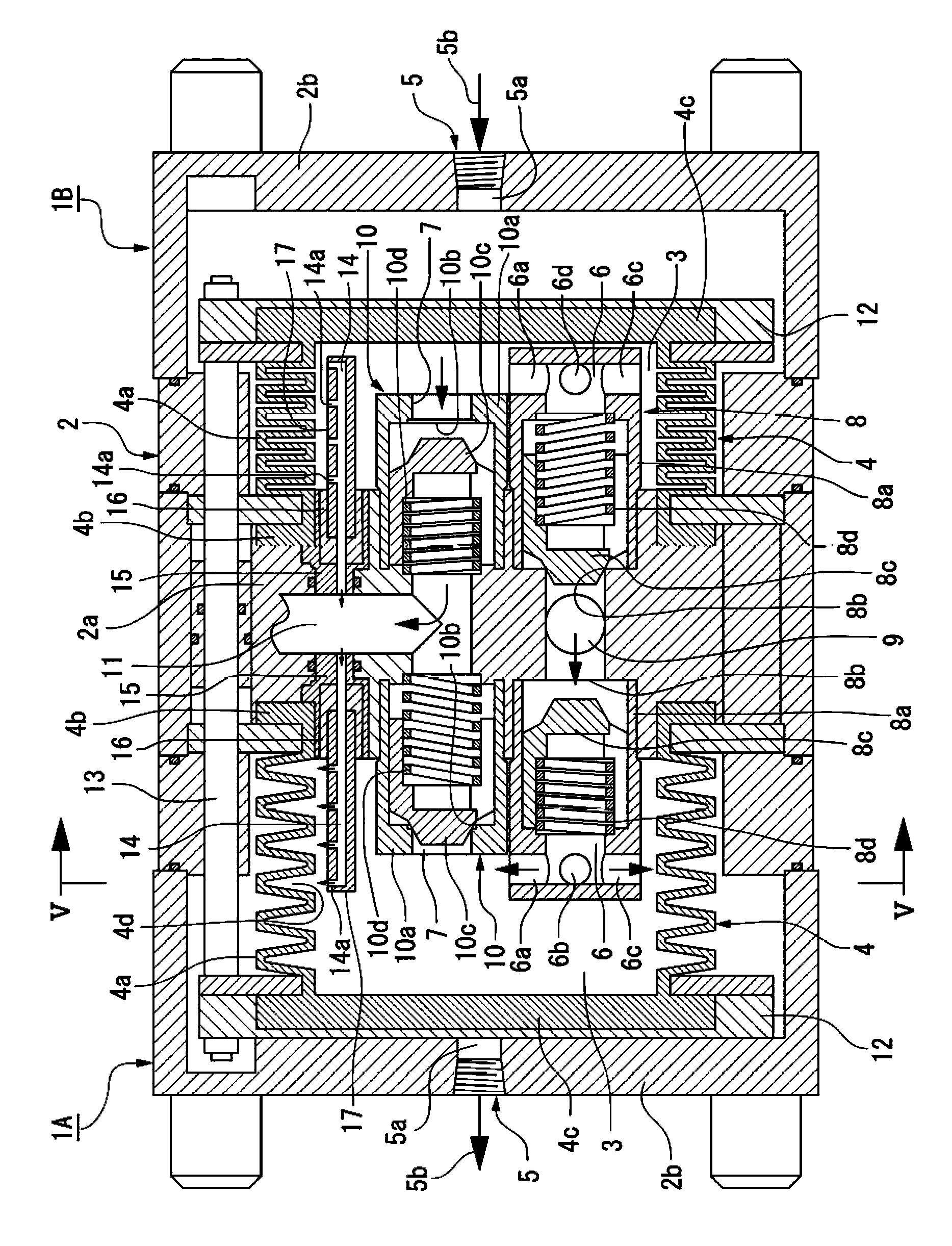

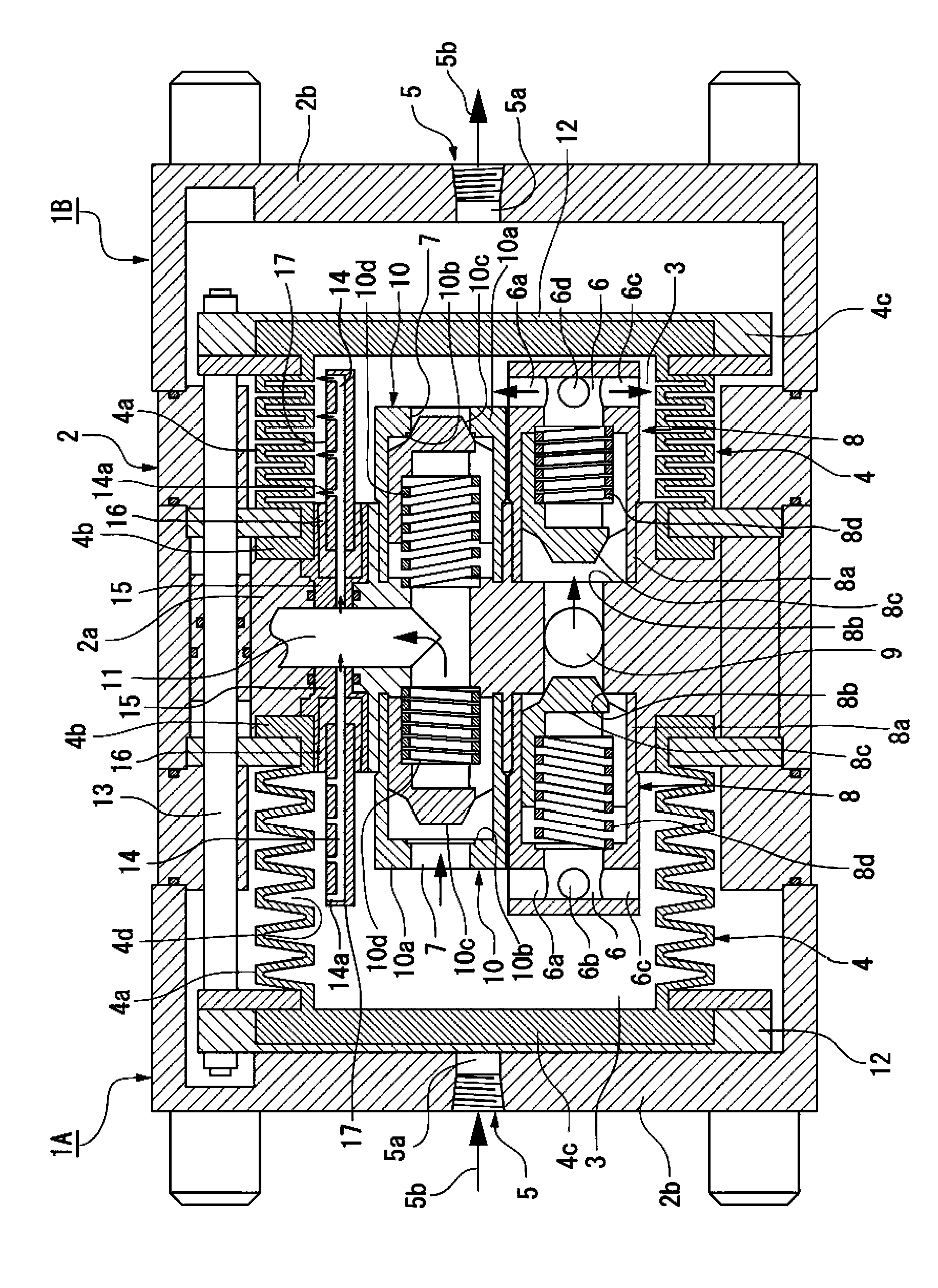

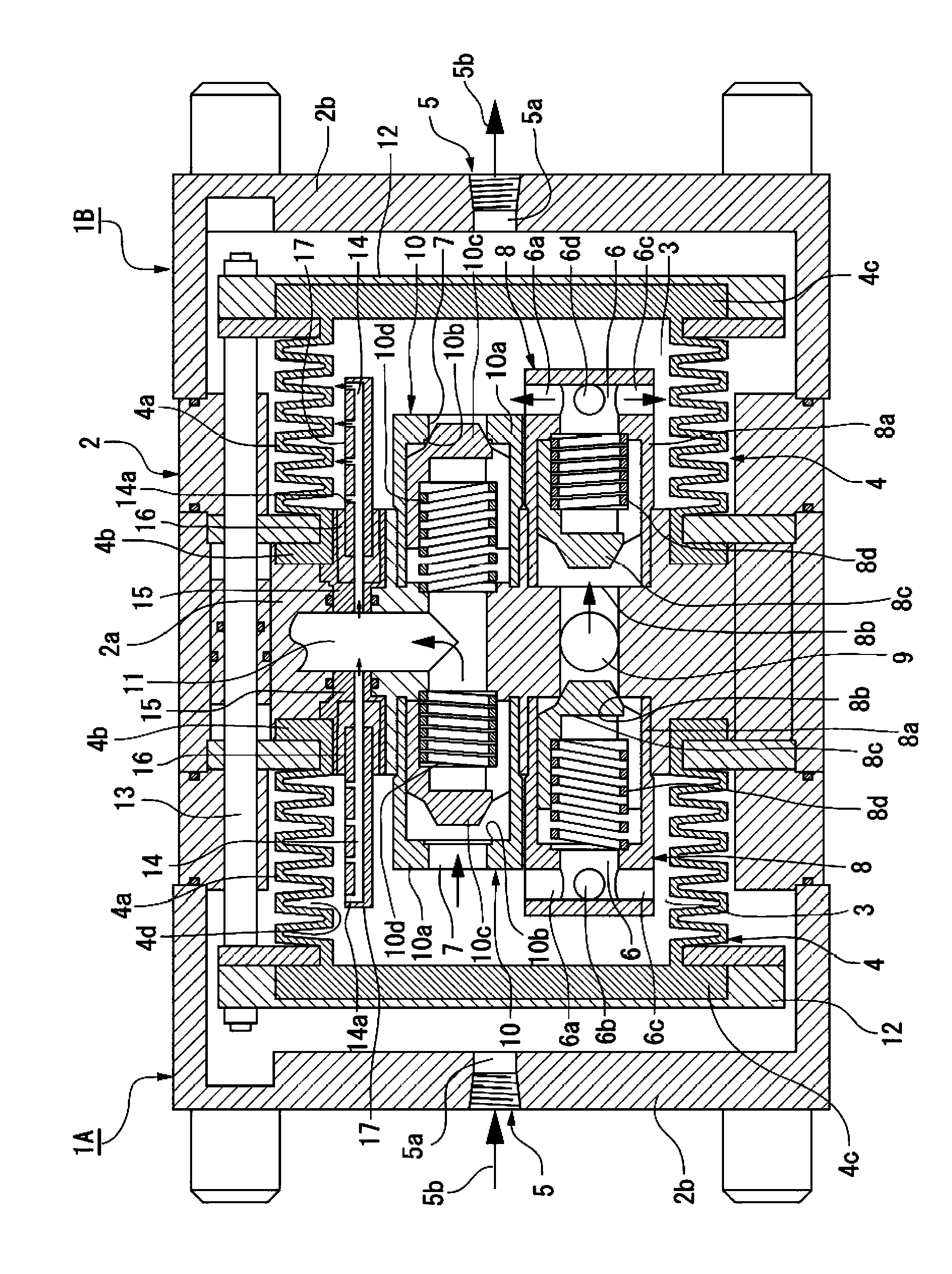

[0028] Based on the drawings, the method for implementing the present invention will be described in detail.

[0029] figure 1 It is a longitudinal sectional side view showing an example of a liquid delivery pump equipped with a positive displacement pump for liquid of the present invention, figure 2 as well as image 3 Respectively represent and figure 1 Different state of action and figure 1 Equivalent longitudinal side view, Figure 4 Is to figure 1 The main part of the zoomed in to show the details, Figure 5 Is along figure 1 A vertical sectional front view of the main part of the V-V line. In addition, in the following description, up and down, left and right refer to Figure 1 ~ Figure 3 Up and down, left and right.

[0030] figure 1 The liquid delivery pump shown is used for liquids that tend to retain bubbles in the pump (for example, foaming liquids such as ozone water, hydrogen peroxide water, etc., which contain bubbles due to high temperature, high pressure, cavitation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com