Oil pumping technique based on mechanical open-and-close valve oil well pump

A technology of oil well pumps and opening and closing valves, which is applied to mechanical equipment, parts of pumping devices for elastic fluids, and liquid displacement machinery, etc., which can solve accelerated damage, reduce the fullness of pump chambers, and shorten the period of pump inspection And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

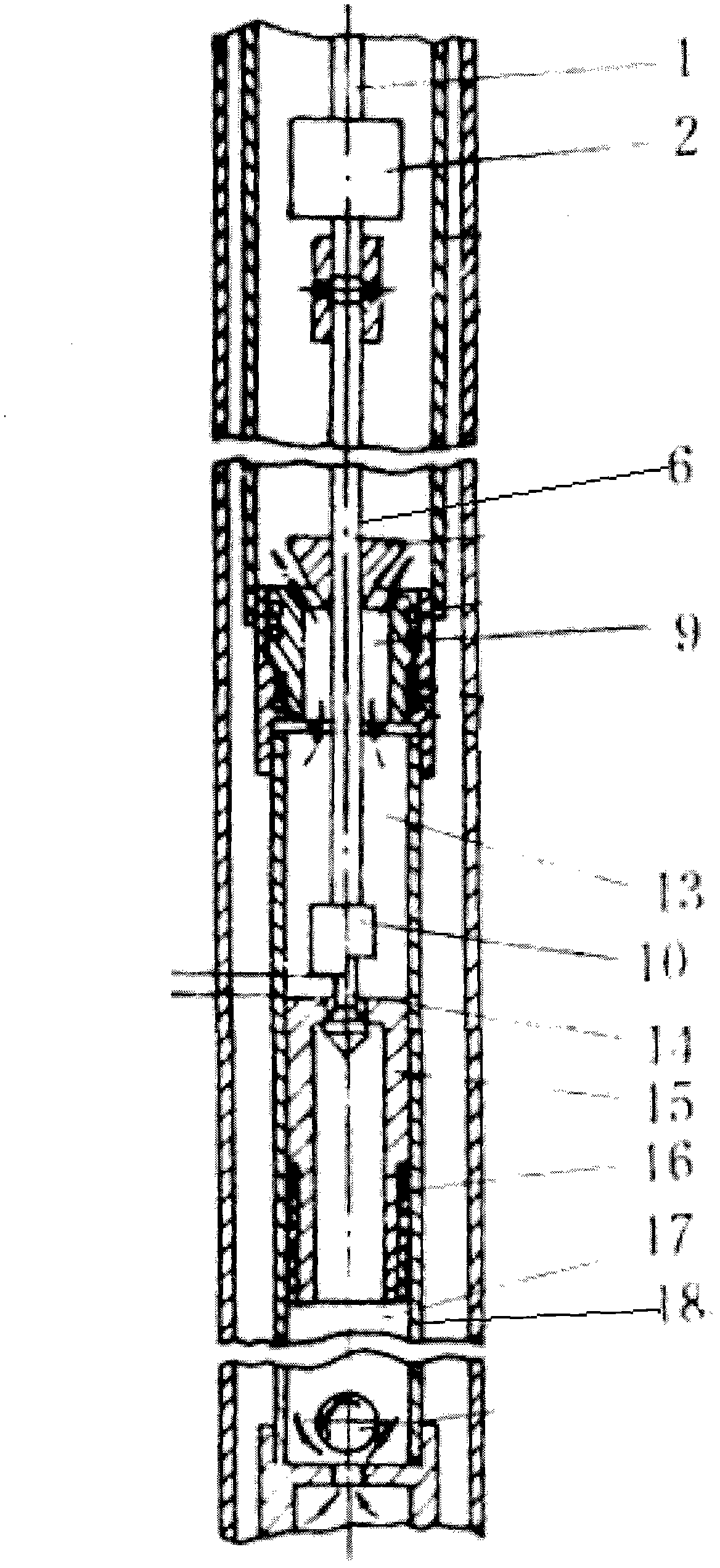

[0028] The oil pumping process based on the mechanical opening and closing valve oil pump involved in the present invention: during the upstroke, the sucker rod is lifted to close the oil outlet valve of the plunger and drive the plunger upward. At this time, the pressure in the lower chamber drops and when the pressure is lower than the inlet pressure of the pump, the oil inlet valve opens to feed oil. At the same time, the pressure in the upper chamber rises. If the oil-gas ratio of the well fluid is large, although the oil and gas are compressed, the pressure increase is small. At this time, the conventional pump often cannot open the plunger oil outlet valve and "air lock" occurs. Since this pump is designed with a push block and an air release hole on the valve stem, when the plunger is close to the bottom dead center and the direction is reversed and rises for a short distance, the upper and lower chambers of the plunger oil outlet valve can be connected to each other, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com