Composite catalyst for catalytic modification of methanol gasoline, method for preparing same and application thereof

A composite catalyst, methanol gasoline technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of catalyst deactivation, poor MTBE selectivity, etc., achieve simple preparation process, promote combustion properties, reduce The effects of air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Put the ZSM-5 carrier into a muffle furnace, bake it at 550°C for 4h, and take it out after natural cooling. Take a small amount of carrier to measure water absorption.

[0050] Take distilled water equal to the water absorption rate of 10gZSM-5, add 0.5462gCr(NO 3 ) 2 ·6H 2 O is fully dissolved, and the prepared Cr(NO 3 ) 2 The solution was slowly added dropwise to 10g of ZSM-5 carrier, stirred and placed, soaked at room temperature for 10h, placed in a drying oven, dried at 110°C, then transferred to a muffle furnace for calcination at 550°C for 4h, cooled naturally, taken out, pressed into tablets, ground, Sieve to 20-50 mesh, with H 2 Reduction catalysis for 12h.

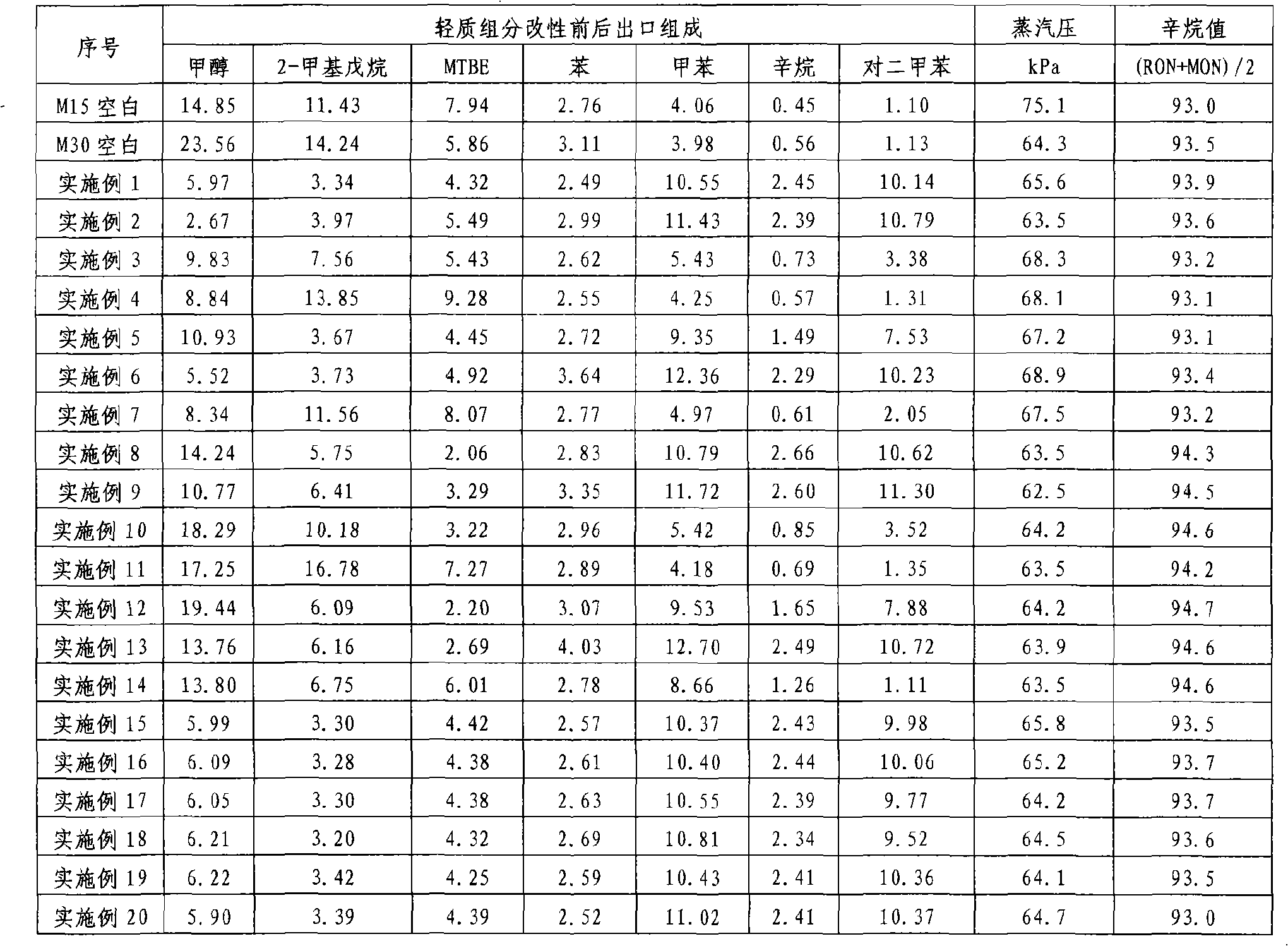

[0051] The M15 additive-free methanol gasoline was subjected to flash fractionation at 80° C., and the fractionation result was light components: heavy components=33.7:66.7 (volume ratio). The light components are catalytically modified in a continuous flow fixed-bed reactor filled with the catalys...

Embodiment 2

[0054] The carrier is 10g γ-Al 2 o 3 , 0.1353g ammonium phosphotungstate trihydrate (molecular formula (NH 4 ) 3 PO 4 ·12WO 3 ·3H 2 O) be mixed with dipping solution, make catalyst according to the method of embodiment 1, replace the catalyst of embodiment 1 and carry out the application test of embodiment 1 equally, the results are shown in table 1.

Embodiment 3

[0056] Carrier is 10g titanium oxide, and 0.0576g ammonium tetramolybdate (molecular formula (NH 4 ) 2 Mo 4 o 13 2H 2 (2) and 0.0676g ammonium phosphotungstate trihydrate (the molar ratio of the two elements is 1: 1) is prepared into an impregnation solution, and the catalyst is made according to the method in Example 1, and the application test of Example 1 is also carried out in place of the catalyst of Example 1. , see Table 1 for the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com