Electric lamp

A technology for electric lamps and lamp caps, applied in discharge lamps, circuits, incandescent lamps, etc., can solve problems such as troublesome, difficult processes, and the risk of short circuits due to high distance between current conductors, reducing the risk of electrical contact disconnection and simplifying assembly. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

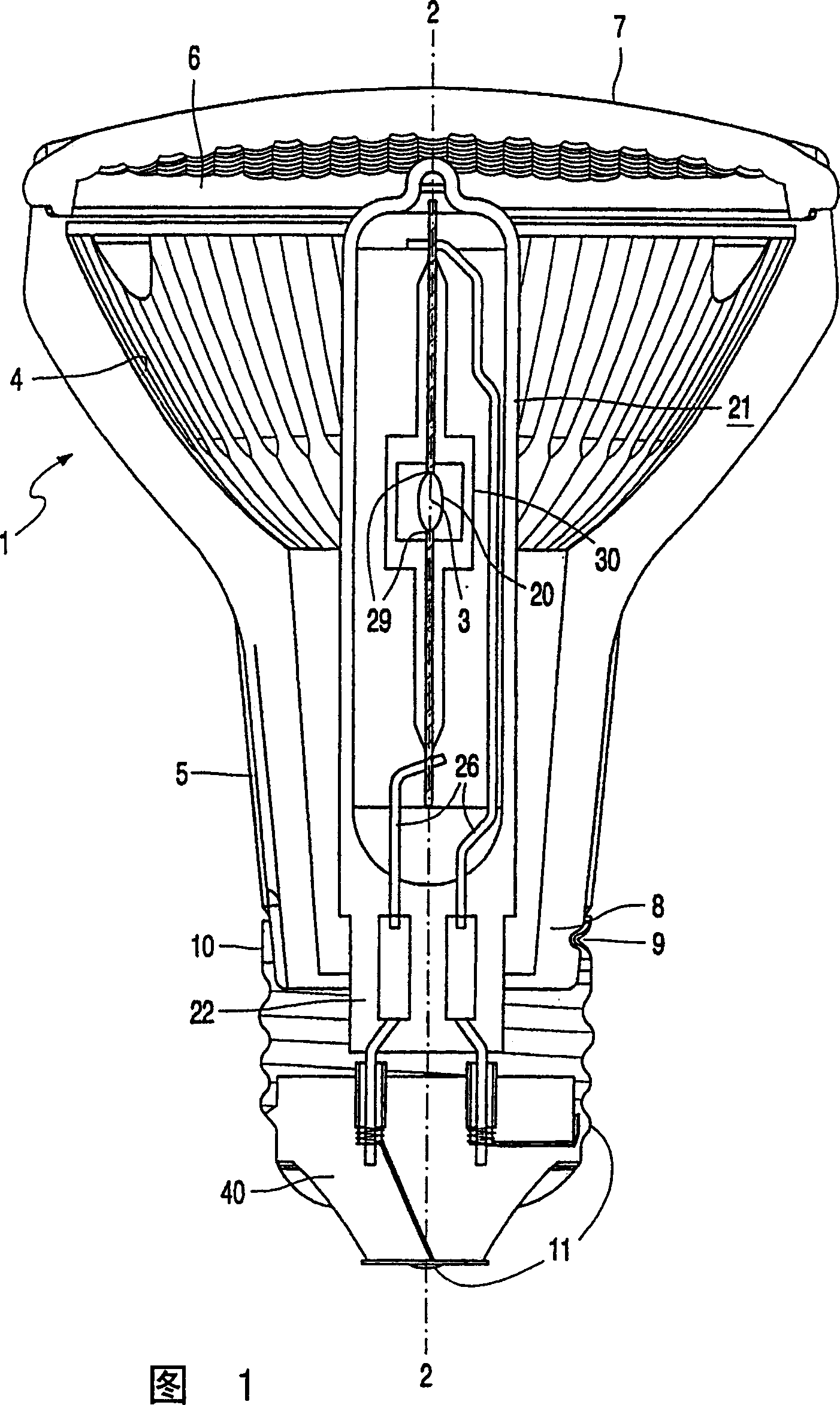

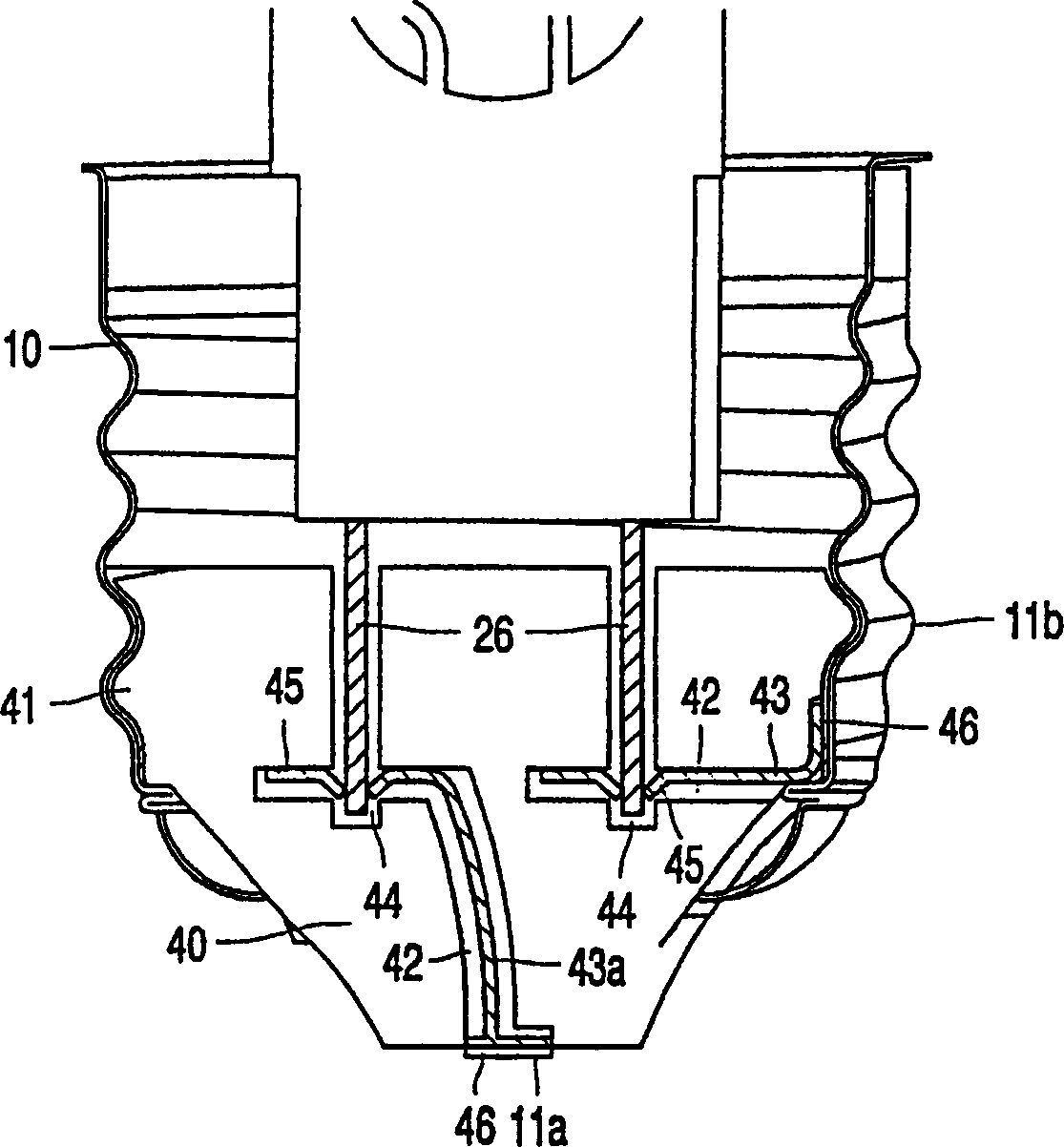

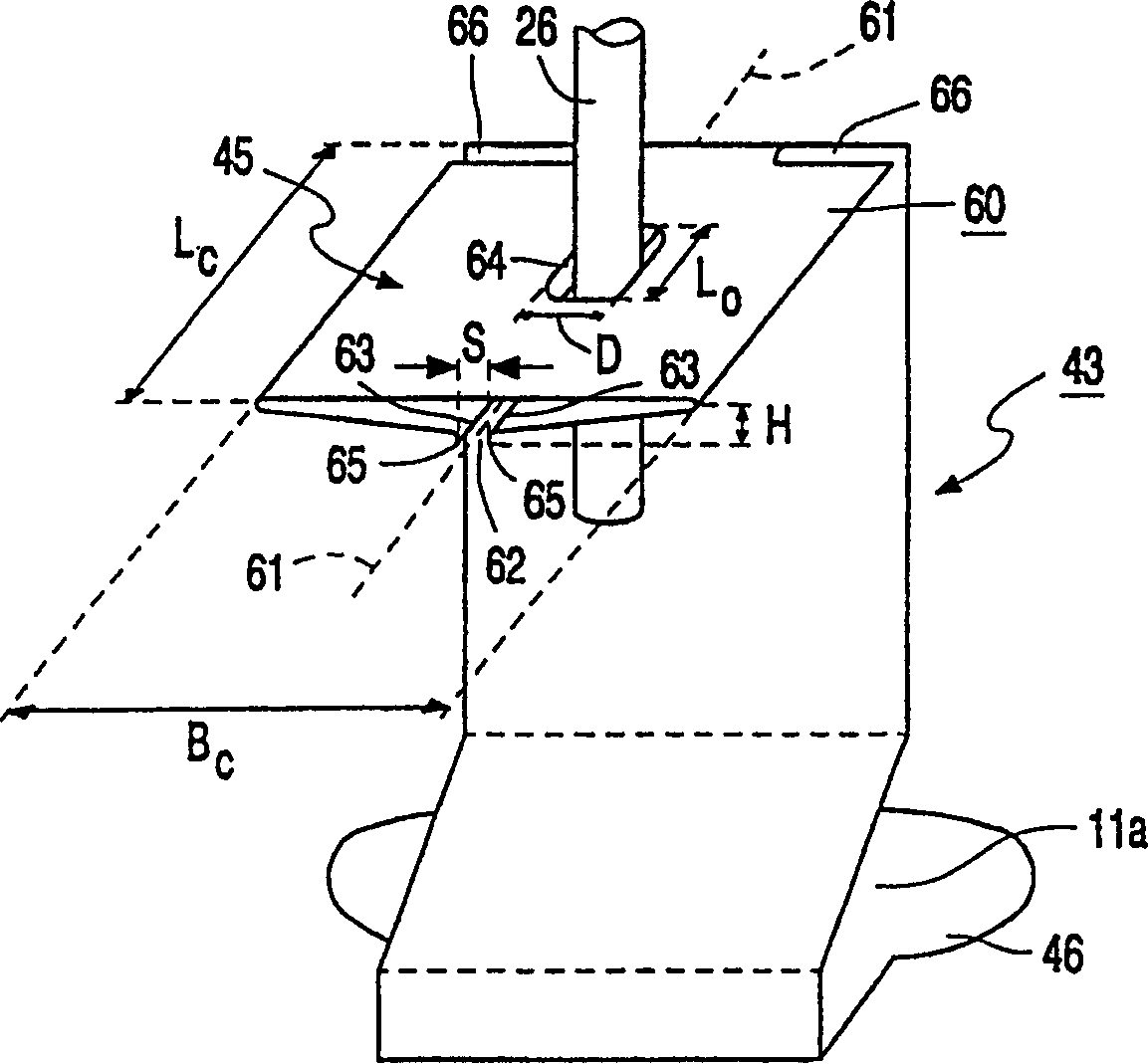

[0027] In Fig. 1 the electric lamp is a reflector lamp having a bulb 1 of light-transmitting material, in this case molded glass, which is partially reflective inside. The reflector thus obtained has a concave light focusing portion 4 , axis 2 and optical center point 3 between the neck 5 and the light emission window 6 . The reflective part of the reflector can be a metal layer, for example made of silver or aluminum, or optionally an interference filter. The light focusing part is a parabolic rotating body that rotates around the axis, and its focal point is at the optical center point. In the figure, the light-transmitting glass cover 7 is fixed to the reflector by means of epoxy resin, thus closing the light emission window 6 . A lamp cap 10 provided with contacts 11 is fixed around the free end 8 of the neck, wherein the lamp cap has been retracted into the recess 9 . Furthermore, the lamp head can also be fixed by means of an adhesive, such as glue. The light source 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com