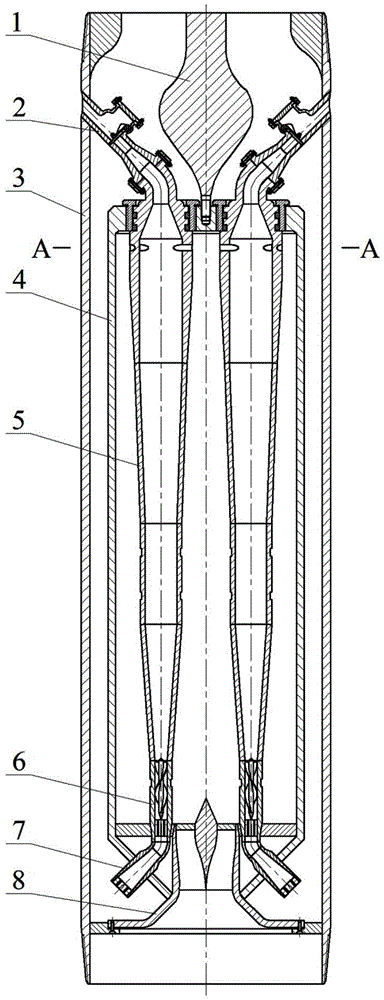

Double-tube two-stage axial flow downhole degassing device

A degassing device and double-barreled technology, which is applied in the fields of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of difficult processing and manufacturing, limited working performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the drawings, but the present invention is not limited to the following embodiments.

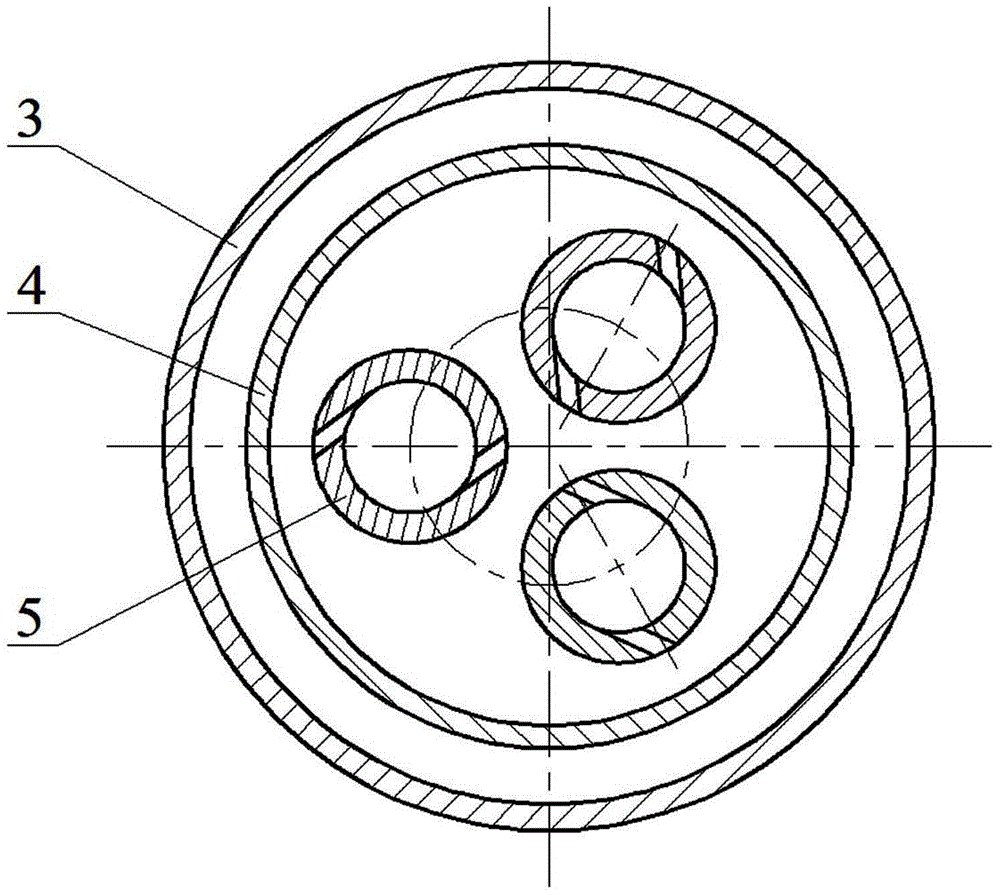

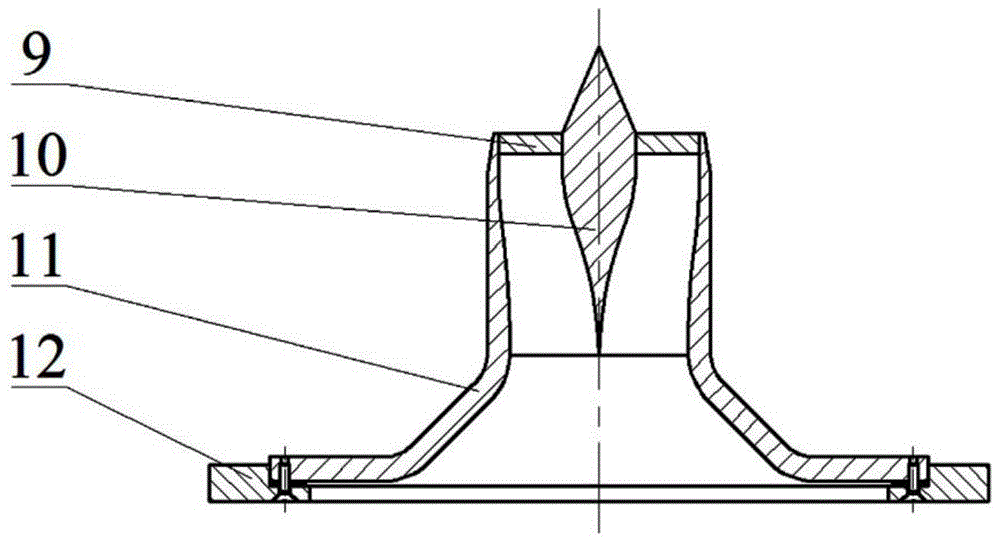

[0033] in figure 1 with figure 2 Among them, the dual-cylinder two-stage axial flow downhole degassing device consists of a deflector 1, an exhauster 2, an outer liquid cylinder 3, an inner liquid cylinder 4, an axial flow tube assembly 5, a rectifier 6, a drain 7 and During operation, the downhole degassing device is connected to the oil pump and the sand control screen through the coupling, and goes directly down the casing string along with the tubing string and auxiliary downhole tools, and is finally suspended in the well to produce liquid The upper part of the horizon. When assembling, first fix the feeder 8 to the bottom of the outer liquid cylinder 3, and then weld the axial flow tube, the rectifier 6 and the drain 7 of each axial flow tube assembly 5 into three units, and then connect them to the inner T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com