Automatic cleaning device for culture dishes

An automatic cleaning and petri dish technology, which is applied to heating devices, cleaning hollow objects, cleaning methods and utensils, etc., can solve problems such as labor and time-consuming, and achieve the effects of good cleaning effect, easy production and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] like Figure 1 to Figure 8 Shown, a petri dish automatic cleaning device, including a base and a turntable.

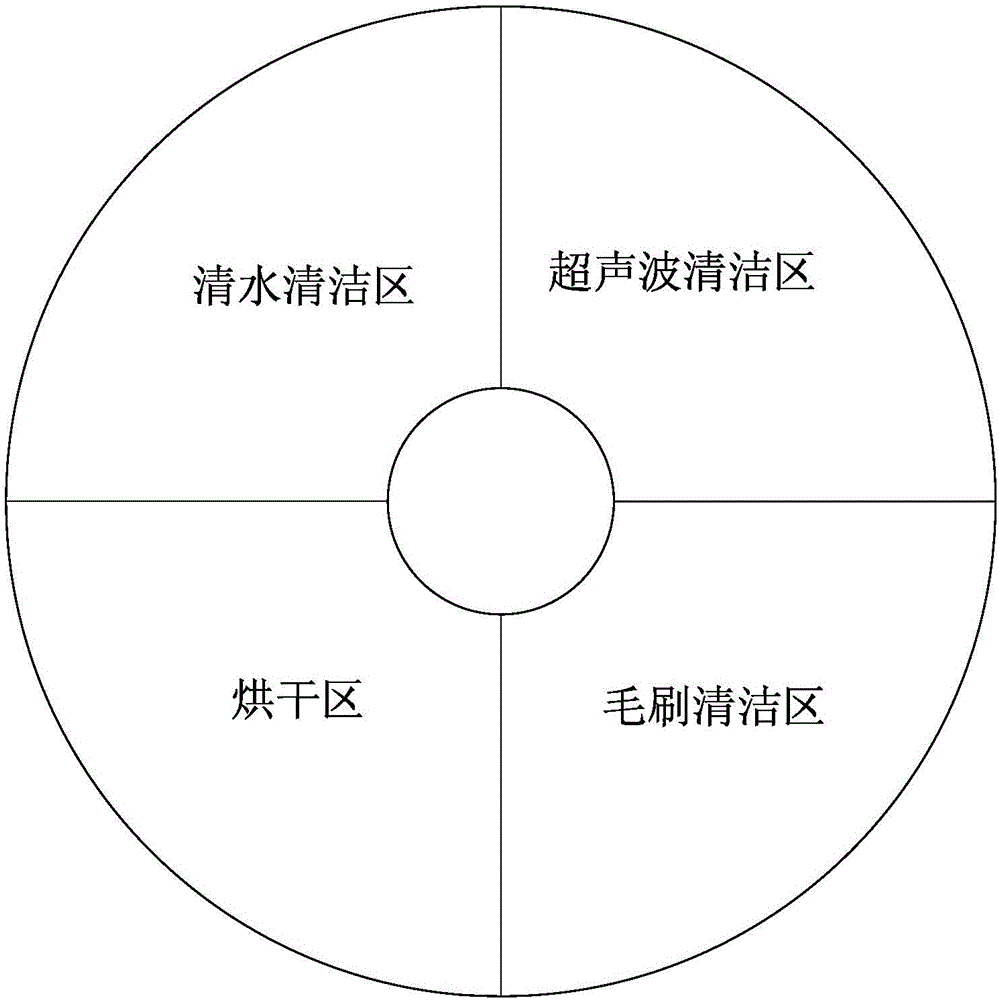

[0032] The base 1 is disc-shaped, made of stainless steel, and forms a container shape. There are four fan-shaped grooves evenly arranged in the circumferential direction of the base. Zone 11, ultrasonic cleaning zone 12, clean water cleaning zone 13 and drying zone 14, the structures of which are described in detail below.

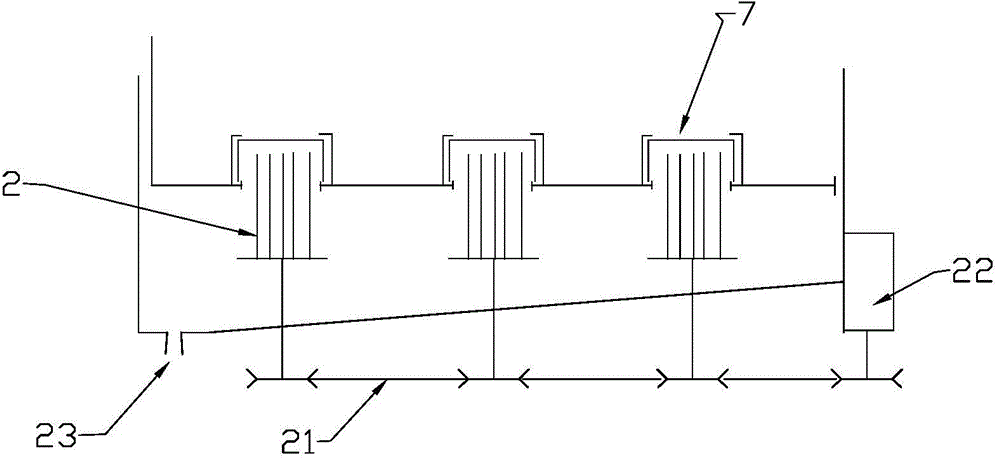

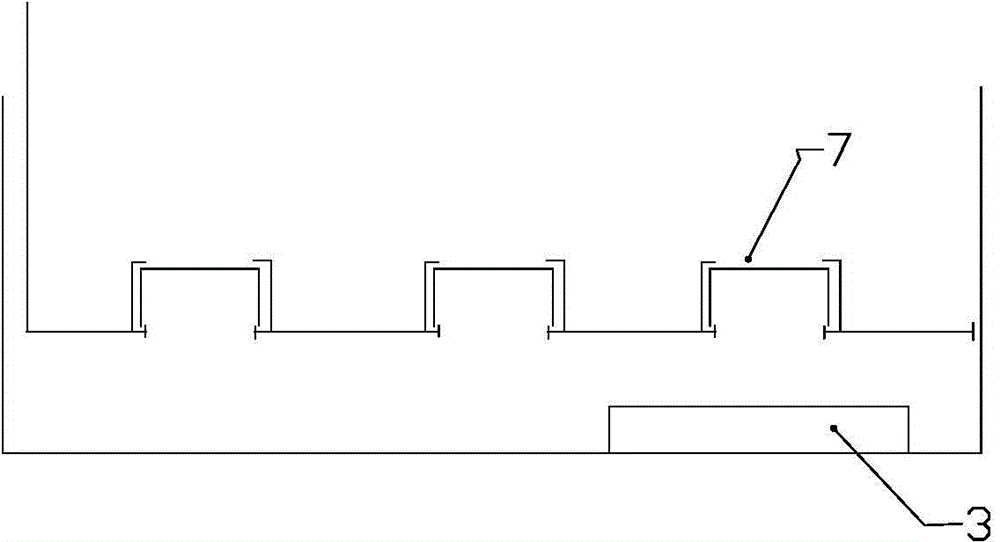

[0033] Wherein, in the brush cleaning area, several upwardly arranged rotatable hair brushes 2 are installed, the hair brushes are rod-shaped, and the low end of the hair brush shaft where the hair brushes are located is driven by a motor 22 through a synchronous belt transmission 21, so that the One motor can drive multiple brushes to rotate synchronously. After the petri dish reaches the lower position, the motor starts, and the brush rotates at a high speed to clean the inner surface of the petri dish, and most of the culture medium ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com