Liquid core-type filter

A core filter and liquid technology, which is applied to fixed filter core filters, filtration and separation, chemical instruments and methods, etc., can solve the problems of low production efficiency, complicated process of disassembling the cover, and low filtration precision, etc. The effect of production efficiency and less liquid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

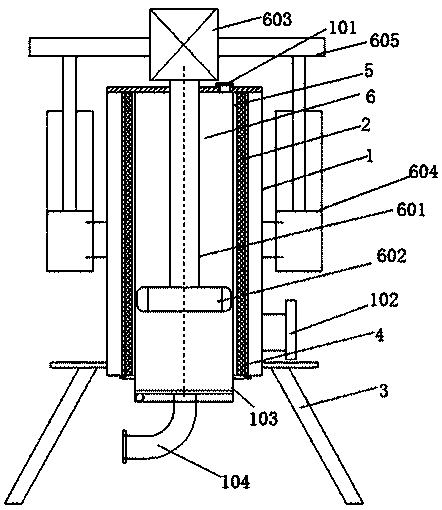

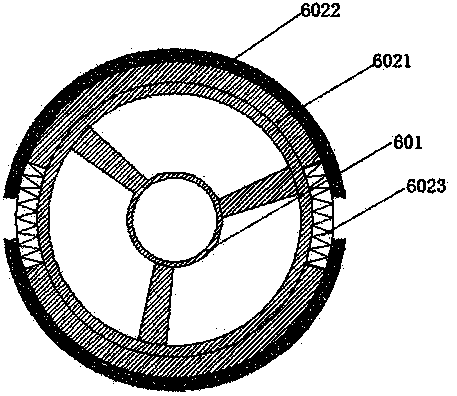

[0014] Referring to the accompanying drawings, a liquid core filter, a cylinder body 1 and a filter screen 2, the filter screen 2 is arranged in the cylinder body 1, the upper end of the cylinder body 1 is provided with a feed port 101, and the lower end is provided with a discharge port 102, the lower end of the cylinder 1 is provided with a triangular support frame 3 to support the cylinder on the ground, the outer side of the filter 2 is provided with an annular support cylinder 4, and the wall of the support cylinder 4 is provided with a plurality of evenly distributed flow holes for filtering The net 2 is close to the inner wall of the support cylinder 4, and a plurality of fixed rods 5 are arranged on the inner side of the filter net 2, and the fixed rods 5 press the filter net on the inner wall of the support cylinder, and a rotating cleaning scraper mechanism 6 is arranged inside the filter net 2 , the rotating cleaning scraping and hanging plate mechanism 6 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com