Rail cleaning device for solar cell panel

A technology for solar panels and cleaning devices, applied in the direction of electrostatic cleaning, cleaning methods and utensils, cleaning methods using tools, etc., which can solve the problems of low cleaning efficiency and cost of cleaning brushes, damage to solar panels, and damage to solar panels and other issues, to achieve the effect of low cost, guaranteed cleaning effect, and accurate transposition position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

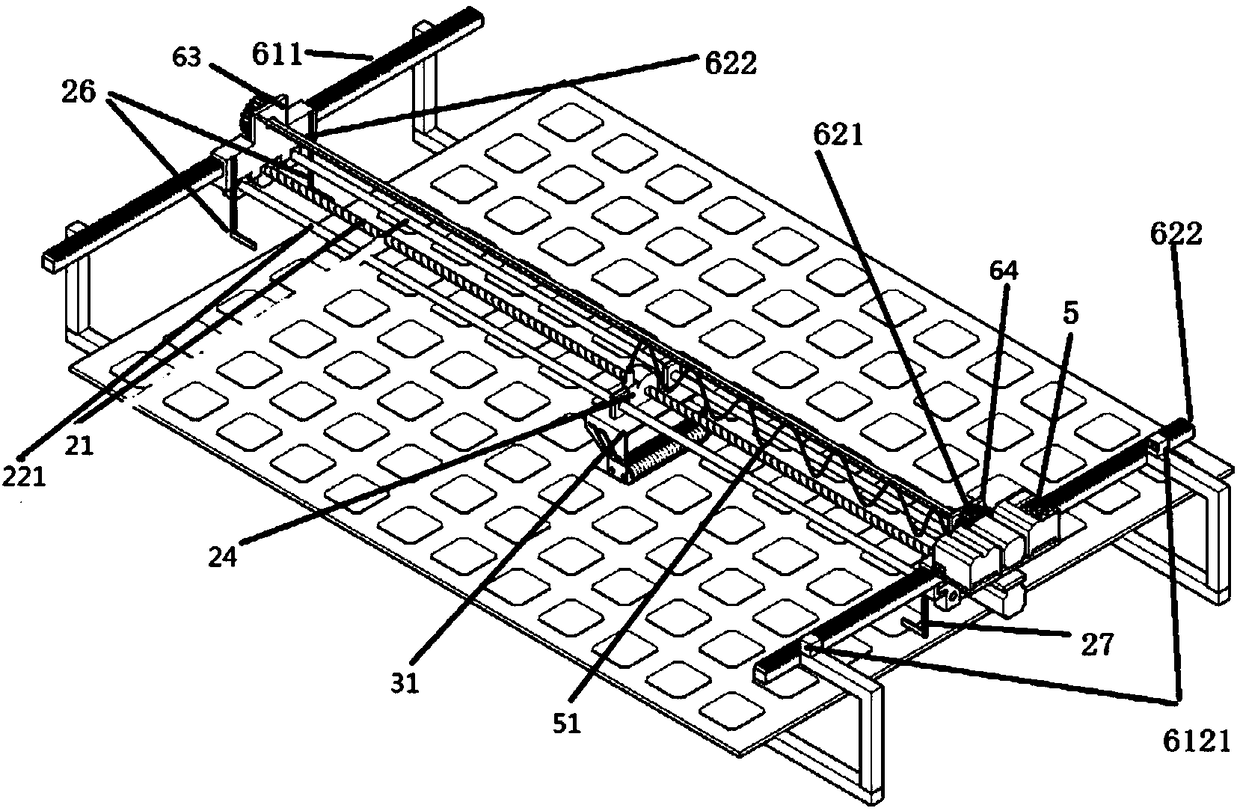

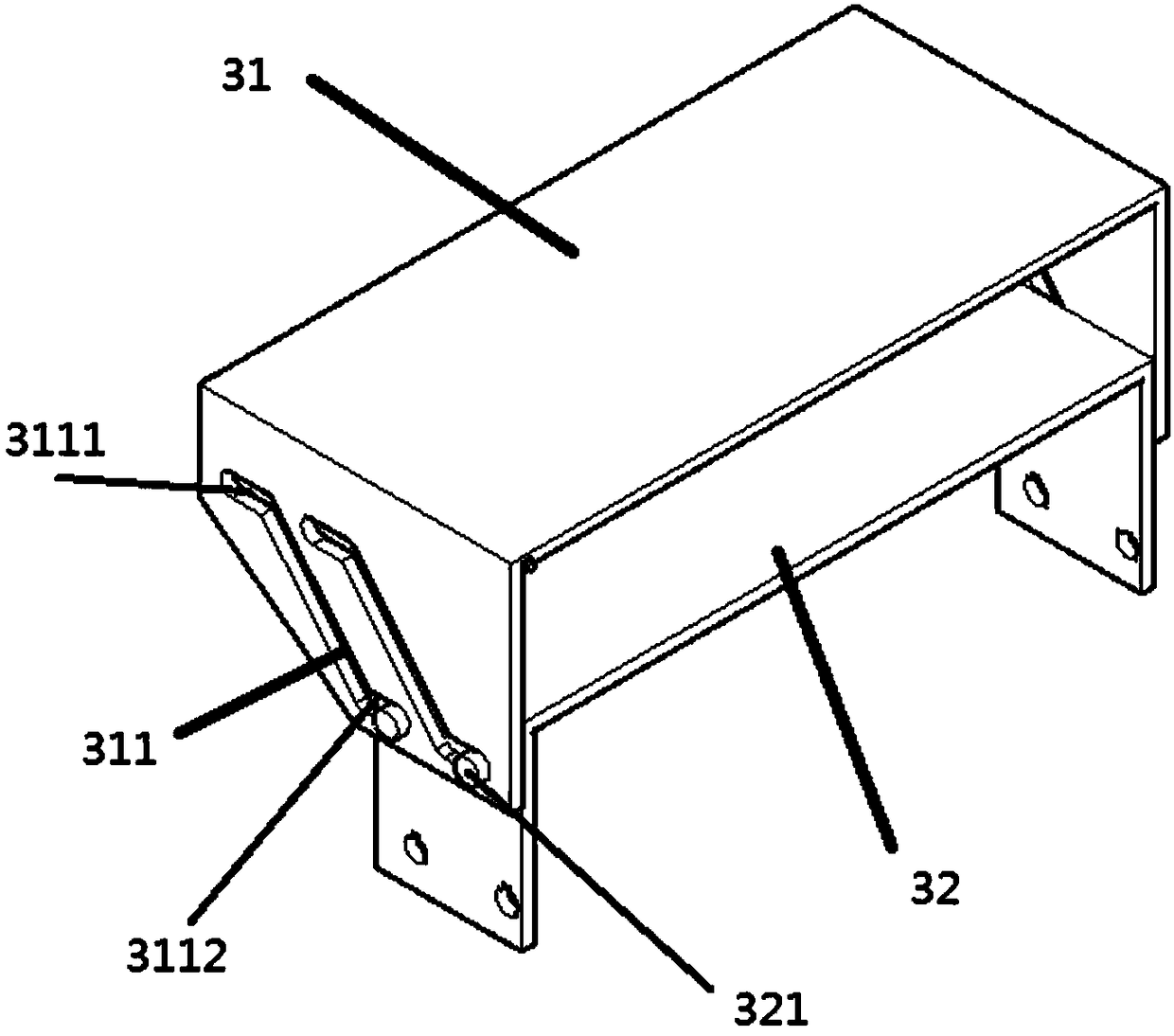

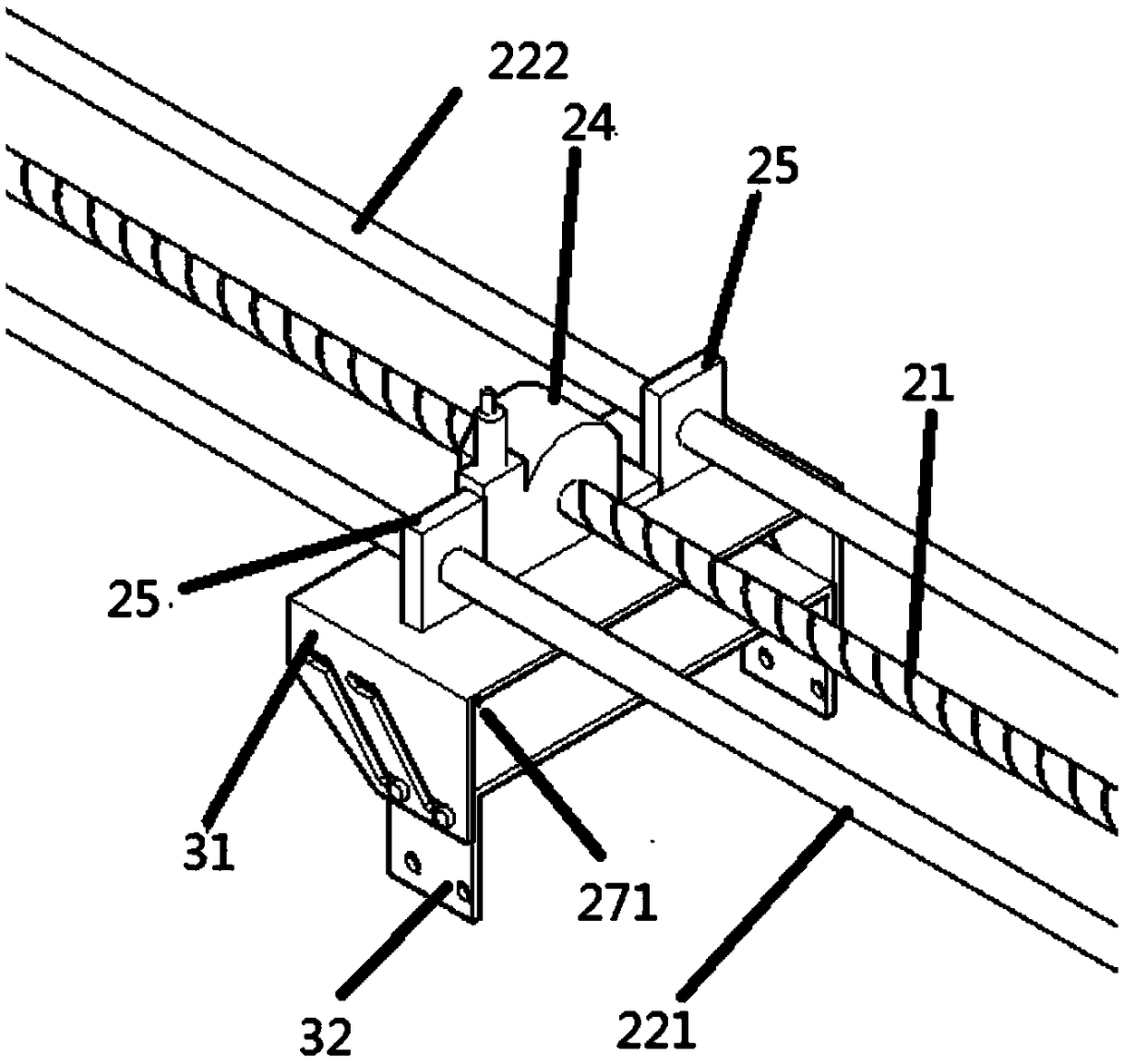

[0044] Such as Figure 1-3 As shown, a solar panel rail cleaning device, the device is erected above the solar panel, including a bracket 1, a longitudinal movement mechanism 2 erected on the bracket 1, a lifting mechanism 3 and a cleaning mechanism 4, and the longitudinal movement mechanism 2 includes Lead screw 21, and balance bar group 22, one end of lead screw 21 is directly connected with transmission DC motor 23, the other end passes through lead screw slider 24, lead screw 21 and lead screw slider 24 are meshed for transmission, and balance bar group 22 passes through Balance bar slide block group 25, leading screw 21 and balance bar set 22 are arranged in parallel; Lead screw slide block 24 is fixed with elevating mechanism 3, and elevating mechanism 3 comprises the fixed plate 31 that is connected with lead screw slide block 24, and mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com