Powder spraying curing system

A powder and spraying head technology, applied in liquid spraying equipment, coatings, spray booths, etc., can solve problems such as rusting of solder joints on barrel ears, irritating solvents in liquid coatings, difficulty in guaranteeing product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described in detail below:

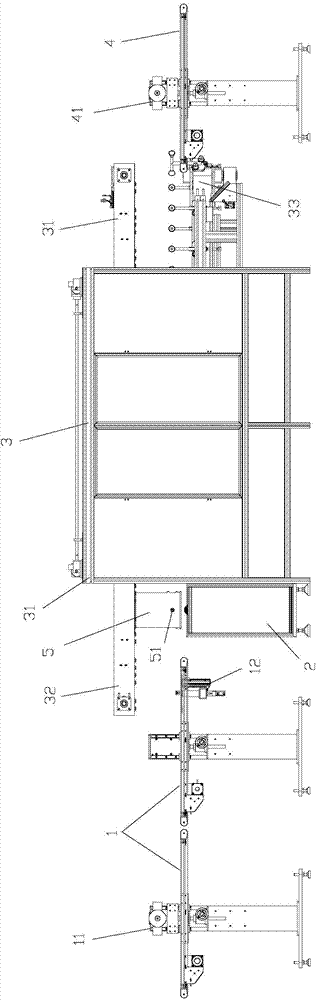

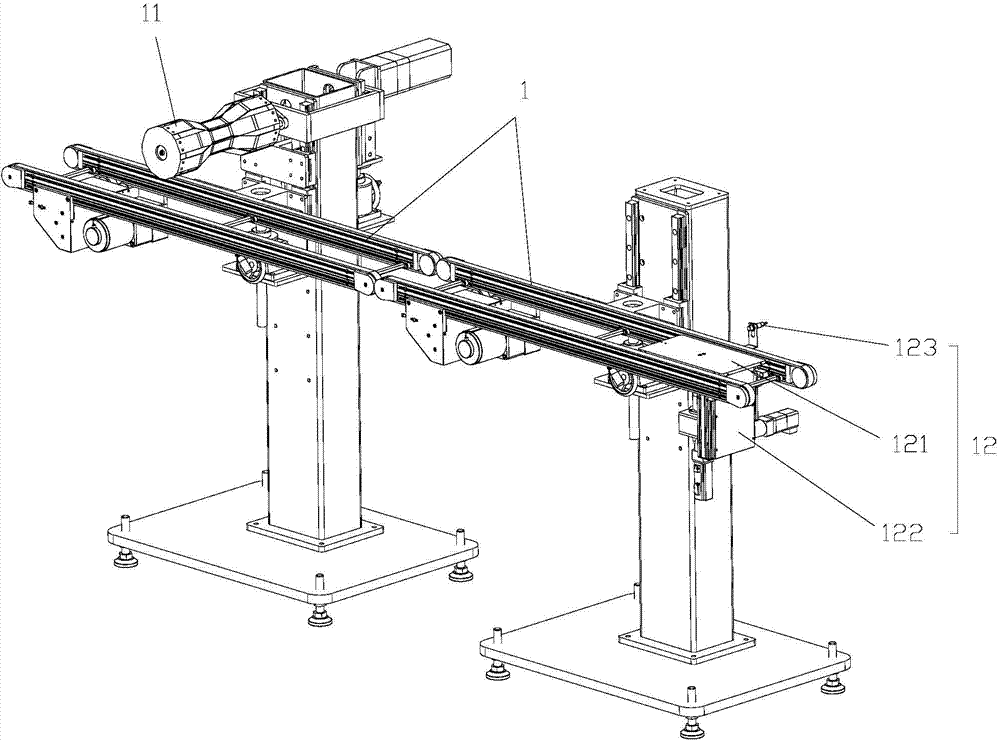

[0029] Such as Figure 1-5 As shown, it is a powder coating curing system, including:

[0030] The first conveyor belt 1 for conveying the workpiece 5 (that is, the object to be sprayed);

[0031] Powder spraying machine 2, it comprises spraying head, and this spraying head comprises spraying head main body 21 and spraying cover 22, and one end of spraying head main body 21 is the spray port that is used for powder spraying, and spraying cover 22 is arranged at the spraying port place, and spraying head main body 21 is provided with drawer. Suction channel 218, the suction channel 218 communicates with the spout;

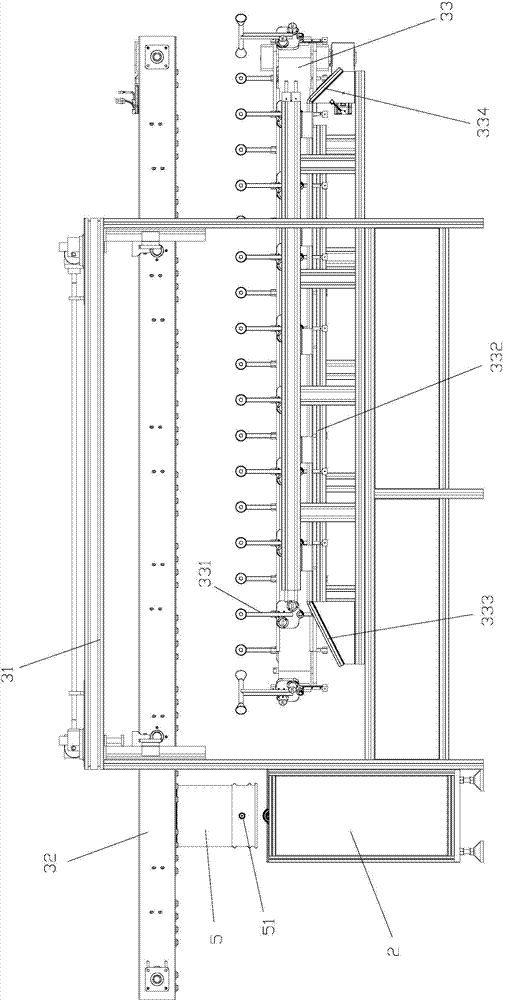

[0032] And heating oven 3, it comprises oven main body 31 and the second conveyer belt 32 that is used to convey workpiece 5, and second conveyer belt 32 runs through oven main body 31, and second conveyer belt 32 is used for accepting the workpiece 5 on the first conveyer belt 1 , the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com