Impurity removal method of oil-based neodymium iron boron oil sludge waste

An oil-based neodymium and neodymium-iron-boron technology, applied in the field of rare earth permanent magnet material recycling, can solve the problems of high carbon and hydrogen content, affecting cleaning effect, complex composition of cutting fluid, etc., and achieve the effect of low cost and short process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

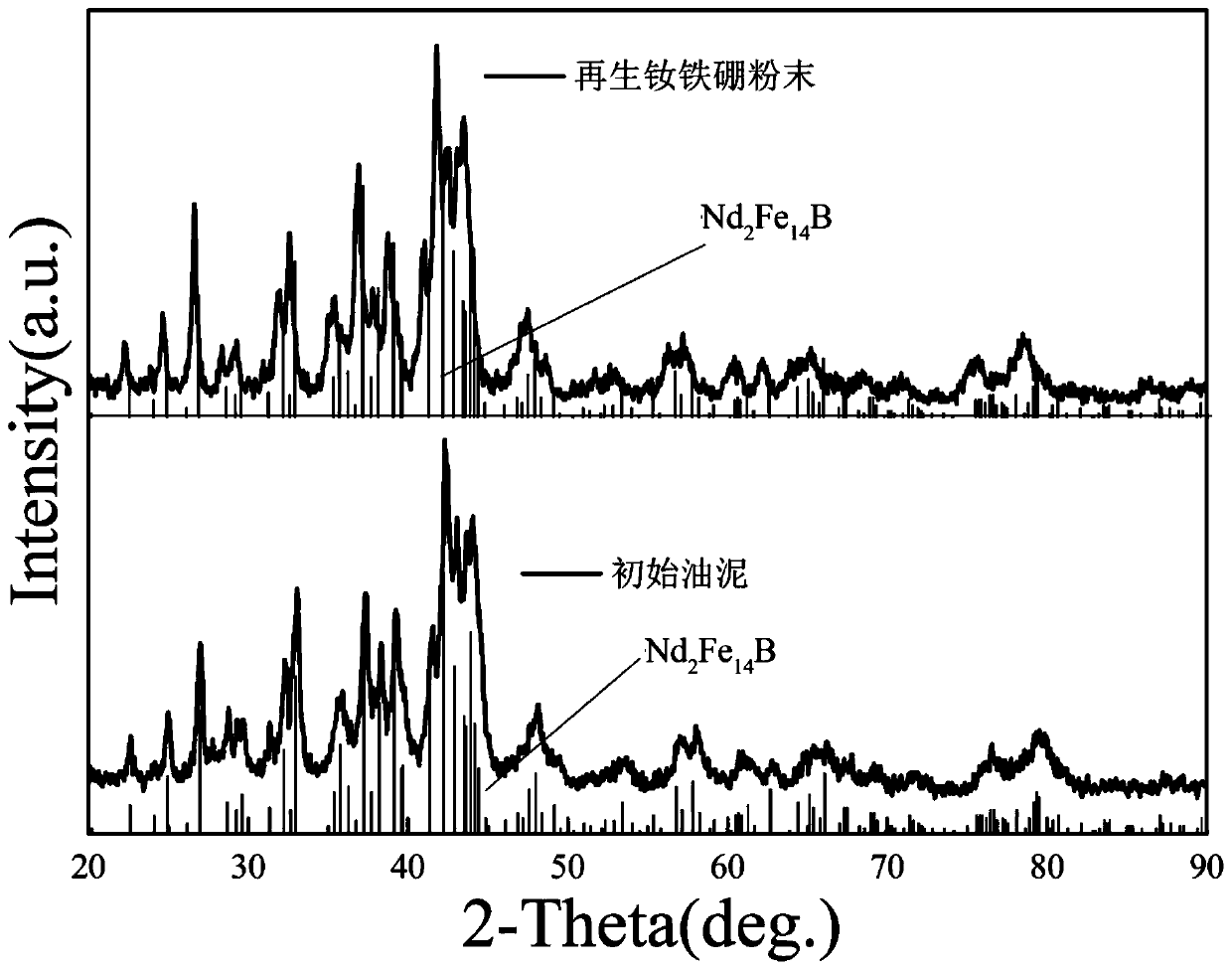

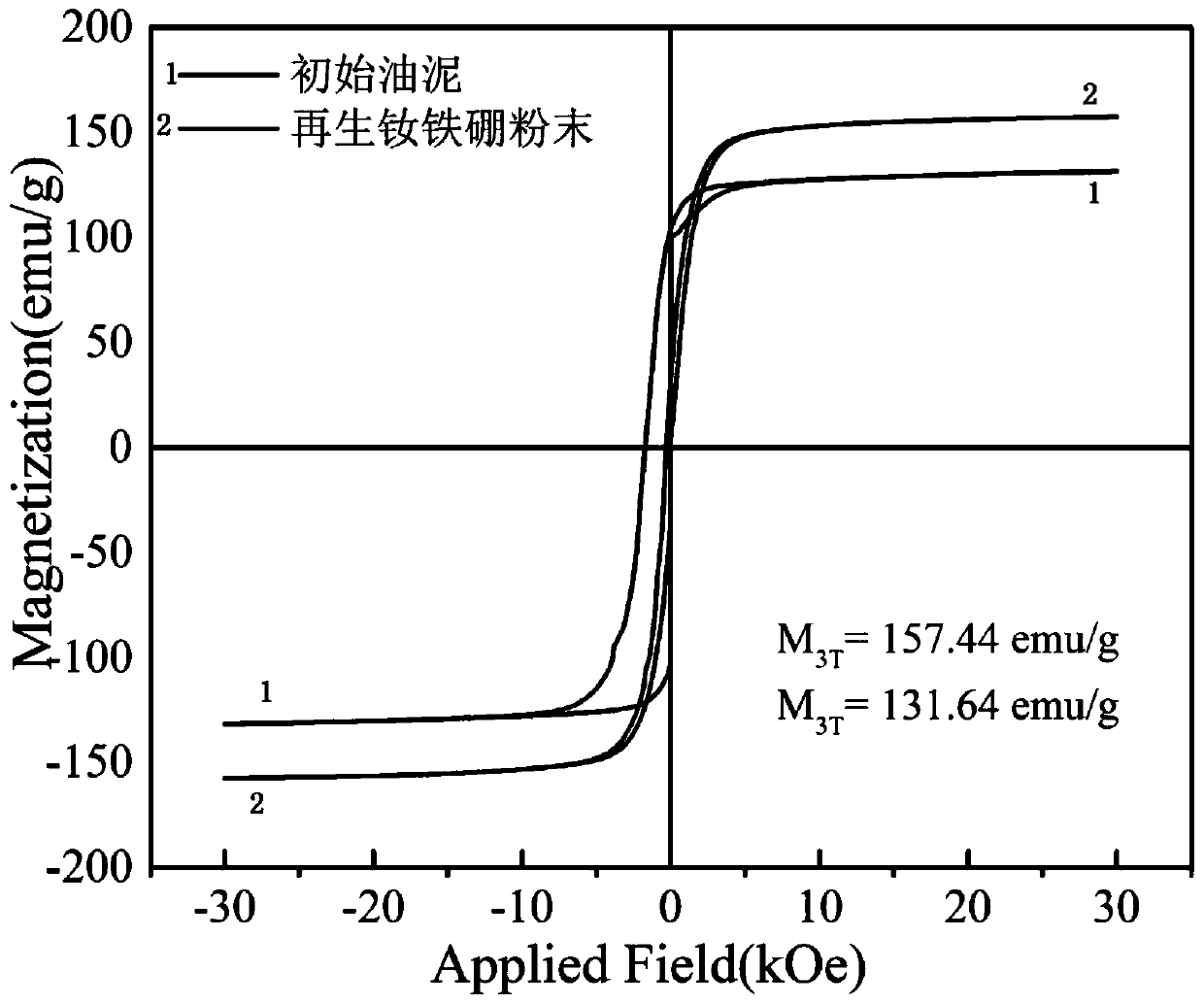

[0028] The main phase of oil-based slicing processing sintered NdFeB sludge waste ① is Nd 2 Fe 14 B. After sedimentation and centrifugation, organic impurities and NdFeB powder are separated to a certain extent, but they are still muddy. Take 10g of oil-based slice sludge and put it in a beaker, add 100ml of absolute ethanol, and perform ultrasonic cleaning at room temperature for 15min, with mechanical stirring during the process. The obtained mixed solution is magnetically separated to remove liquid, non-magnetic powder and solid impurities to obtain solid powder. At this time, the carbon content of the powder is 2.00%, the oxygen content is 5.95%, the hydrogen content is 1.76%, and the saturation magnetization at 3T is 136.59emu / g. Prepare 100ml of solution, including 1% hydrochloric acid, 5% OP-10 emulsifier, and water as the balance. After stirring evenly, use it to ultrasonically clean the obtained solid powder at room temperature for 2 minutes. After magnetic separat...

Embodiment 2

[0030] Oil-based slice processing sintered NdFeB oil sludge waste No. ② The main phase is Nd 2 Fe 14B, After precipitation, organic impurities and NdFeB powder are separated to a certain extent, but they are still muddy. Take 10g of oil-based slice sludge and put it in a beaker, add 100ml of absolute ethanol, and perform ultrasonic cleaning at room temperature for 15min, with mechanical stirring during the process. The obtained mixed solution is magnetically separated to remove liquid, non-magnetic powder and solid impurities to obtain solid powder. Among them, the carbon content is 2.00%, the oxygen content is 5.95%, the hydrogen content is 1.76%, and the saturation magnetization at 3T is 136.59emu / g. Prepare 100ml of solution, including 2% hydrochloric acid, 1% OP-10 emulsifier, and water as the balance. After stirring evenly, use it to ultrasonically clean the obtained solid powder at room temperature for 2 minutes. After magnetic separation, repeat the above process. Th...

Embodiment 3

[0032] The main phase in the oil-based slice processing sintered NdFeB oil sludge waste ③ is Nd 2 Fe 14 B, After precipitation, organic impurities and NdFeB powder are separated to a certain extent, but they are still muddy. Take 10g of oil-based slice sludge and put it in a beaker, add 100ml of absolute ethanol, and perform ultrasonic cleaning at room temperature for 15min, with mechanical stirring during the process. The obtained mixed solution is magnetically separated to remove liquid, non-magnetic powder and solid impurities to obtain solid powder. Among them, the carbon content is 2.00%, the oxygen content is 5.95%, the hydrogen content is 1.76%, and the saturation magnetization at 3T is 136.59emu / g. Prepare 100ml of solution, including 1% hydrochloric acid, 1% OP-10 emulsifier, and water as the balance. After stirring evenly, use it to ultrasonically clean the obtained solid powder at room temperature for 2 minutes. After magnetic separation, repeat the above process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com