Preparation method of wear-resistant ultrahydrophobic flame-retarding leather

A super-hydrophobic and leather-based technology, applied in special leather manufacturing, leather impregnation, leather surface treatment, etc., can solve the problems of low surface microstructure strength, super-hydrophobic performance failure, structural damage, etc., to achieve large-scale industrial production and facilitate Effect of large-scale promotion and reduction of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The leather with a diameter of 9 cm was rinsed and dried with deionized water and absolute ethanol in sequence, and then the absolute ethanol dispersion containing 5 mg of single-walled carbon nanotubes, 500 mL of wattle bark tannin solution of 2 g / L and 1 g / L 500mL of ferric chloride hexahydrate solution of L was sequentially sucked onto the leather and dried to obtain leather (SWCNTs-CF) loaded with single-walled carbon nanotubes; soak the gained SWCNTs-CF in 1.0g / L Polydimethylsiloxane (PDMS) in dodecane solution for 20min, taken out and dried to prepare wear-resistant superhydrophobic flame-retardant leather (PDMS-SWCNTs-CF).

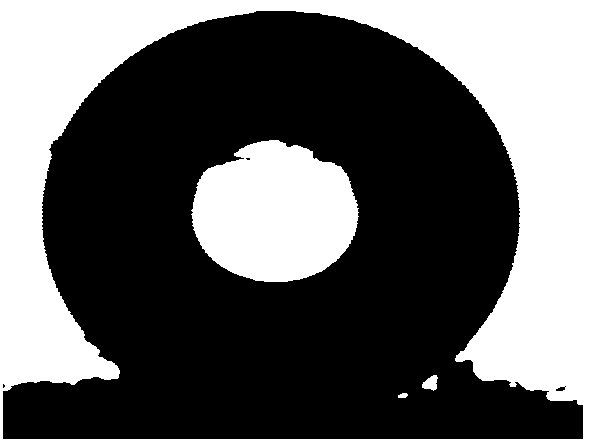

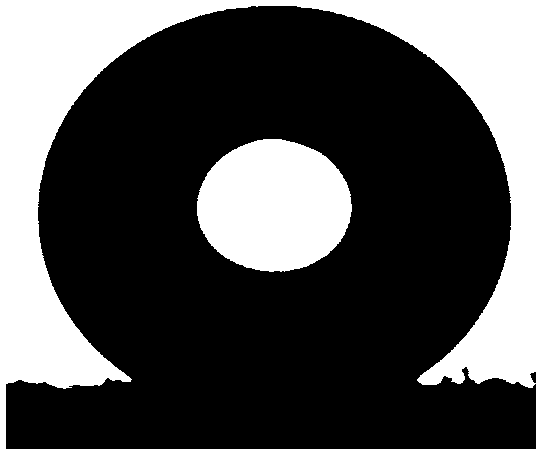

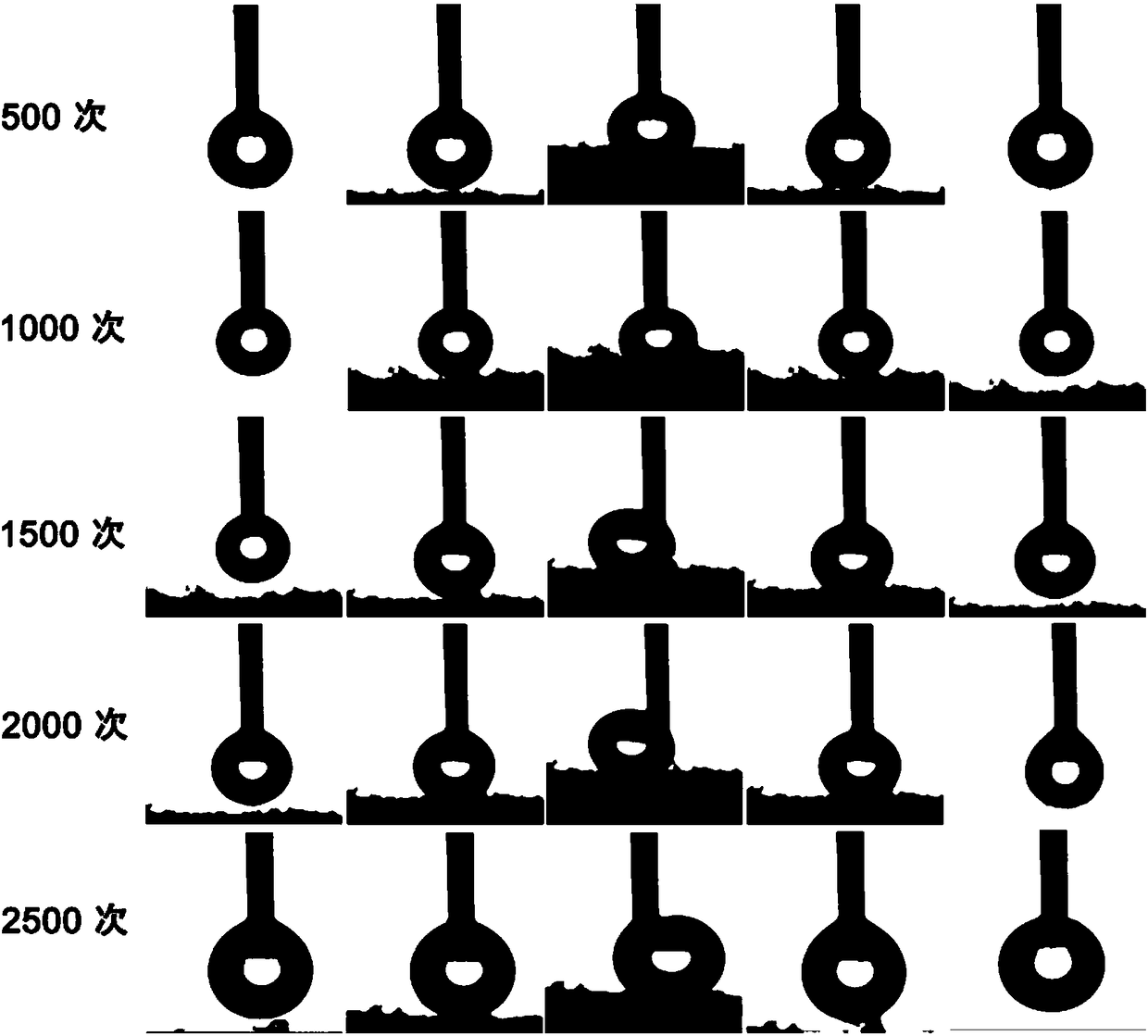

[0028] The obtained PDMS-SWCNTs-CF has a contact angle of 152.3° and a limiting oxygen index of 36.9%. After sanding for 500-2500 times, the dynamic wetting performance was tested with 5.0 μL deionized water, and it was found that water droplets could not wet the surface of the material, indicating that PDMS-SWCNTs-CF still maintained its sup...

Embodiment 2

[0030] The leather with a diameter of 9 cm was rinsed with deionized water and absolute ethanol in sequence and dried. Then the dehydrated ethanol dispersion containing 7mg of graphene, 500mL of wattle bark tannin solution of 20g / L and 500mL of ferric chloride tetrahydrate solution of 10g / L are sequentially sucked onto the leather and dried. The graphene-loaded leather (Gr-CF) was obtained; the Gr-CF was soaked in a toluene solution of 0.05mol / L vinyltriethoxysilane (VTEO) for 24h, taken out and dried, and the wear-resistant super Hydrophobic flame retardant leather (VTEO-Gr-CF).

[0031] The contact angle of the obtained VTEO-Gr-CF is 154.5°, and its limiting oxygen index value is 37.2. After sanding for 500-2500 times, the dynamic wetting performance was tested with 5.0 μL deionized water. It was found that water droplets could not wet the surface of the material, indicating that VTEO-Gr-CF still maintained its superhydrophobic performance after friction.

Embodiment 3

[0033] The leather with a diameter of 9 cm was rinsed and dried with deionized water and absolute ethanol in sequence, and then the absolute ethanol dispersion containing 11 mg of multi-walled carbon nanotubes, 500 mL of 1 g / L bayberry tannin solution and 0.25 g / L 500mL of the titanium sulfate solution was suction-filtered onto the leather in sequence, and the leather (MWCNTs-CF) loaded with multi-walled carbon nanotubes could be obtained after drying; the MWCNTs-CF was soaked in 2g / L polydimethylsiloxane (PDMS) in n-octane solution for 20min, take it out and dry it, then you can make wear-resistant superhydrophobic flame-retardant leather (PDMS-MWCNTs-CF).

[0034] The obtained PDMS-MWCNTs-CF has a contact angle of 151.2° and a limiting oxygen index of 37.6%. After sanding for 500-2500 times, the dynamic wetting performance was tested with 5.0 μL deionized water, and it was found that water droplets could not wet the surface of the material, indicating that PDMS-SWCNTs-CF sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com