Material for use with a capacitive touch screen

A modified material and electrical conduction technology, applied in the field of conductive gloves, can solve the problem of failing to allow the touch screen ten-finger gesture function and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

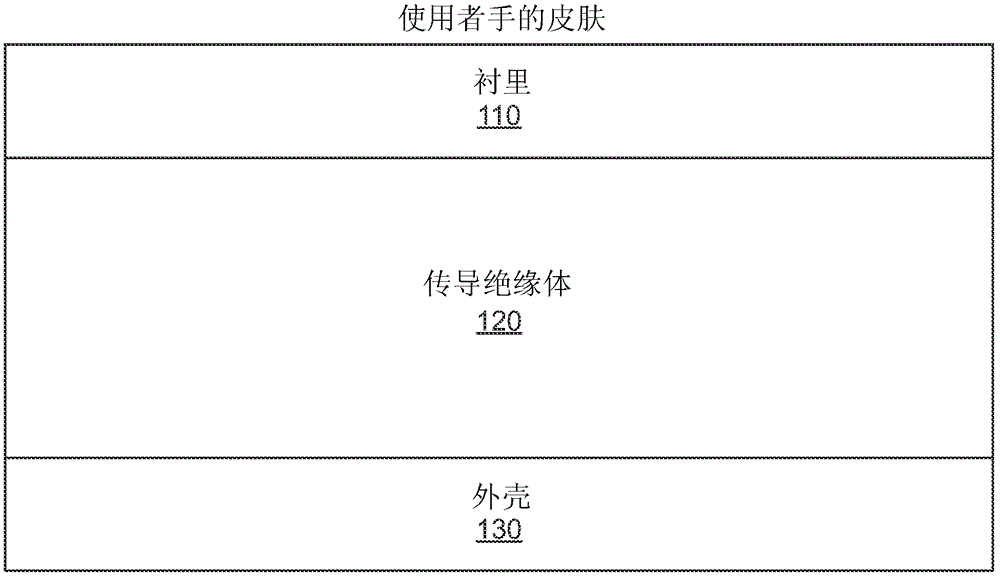

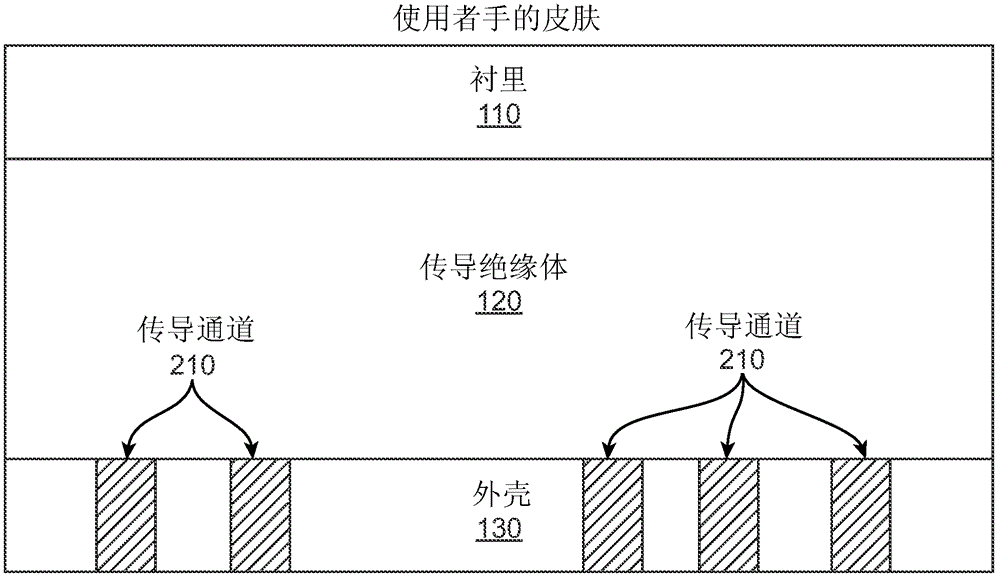

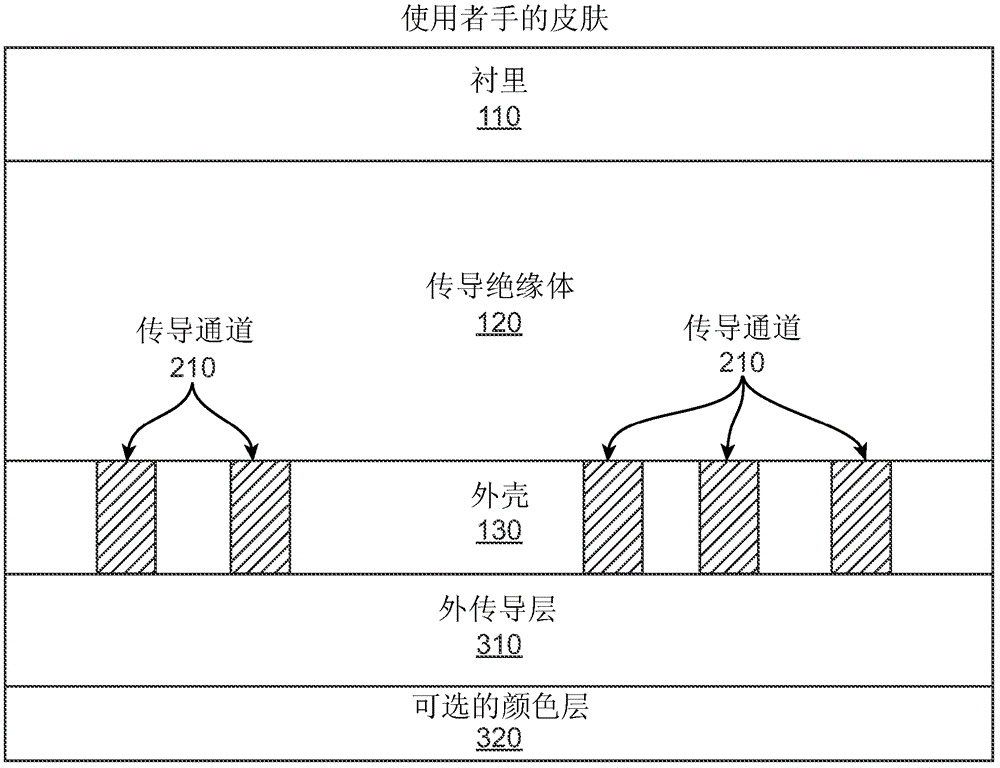

[0106] The modified material of the present invention can be used with a variety of properties as described above that allow a user to operate a capacitive touch screen. Briefly, provided are modified materials that include electrically conductive materials and / or chemical treatments to enable capacitive coupling with capacitive and projected capacitive touch screen devices, as well as any other type of touch screen device, Regardless of the technology used by the touch screen. The modified material either provides the projected capacitance of the human body to the interface through the material, or provides capacitive coupling directly to the fabric itself, thereby requiring no human contact to operate the touchscreen or touchpad. Modified materials can be fabricated into functional articles of clothing, such as gloves, or other articles made from woven or knitted fabrics to increase the functionality of the article of clothing or the articles made of it. The conductive mate...

Embodiment 1

[0166] Tanning Example 1: Tanning and Leather Preparation

[0167] Leather tanning is an ancient process that began somewhere in South Asia between 7000-3300 BC. Leather tanning has been practiced on a wide variety of materials. The process described herein can be applied to many raw materials, including, but not limited to, the hides of sheep, goats, cattle, deer, horses, reptiles, birds, pigs, and kangaroos, for example. The raw material depends on the application required for the final leather product.

[0168] All animal hides are composed of a fibrous matrix consisting of water, proteins, fatty materials and mineral salts. These materials include elastin, collagen, keratin, albumin, globulin, mucin, and mucinoid. Proteins can be made up of many types, but one important class is collagen, which gives leather when tanned.

[0169] In a first embodiment of the method of the invention, the raw material is brought to a fully chrome-tanned state, which imparts durability to...

Embodiment 1

[0186] Formulation Example 1: Leather

[0187] The leather (full grain sheepskin) is spray coated with two undercoats, first at from 6.5 to 7.0G / FT 2 (wet) thickness, then 6.0G / FT 2 (wet) thickness and then pressed (Sand, 90°C, 50Kg). Spray top coat from 1.5 to 2.0G / FT 2 (wet) thickness and subject the leather to spinning (low pressure) at 250°C. Finally, the leather can be dry rolled to achieve the desired visual and fabric effects.

[0188] Bottom coat:

[0189] materials used

number of copies

water

35

20

Unithane IC-1600

25

Unithane IC-1500

15

paint

2.5

2.5

[0190] Note: Base coat is not filtered before use.

[0191] Topcoat:

[0192] materials used

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com